Gamma-valerolactone-based biorefinery

Basic information

Project Title

Full project title

Category

Project Description

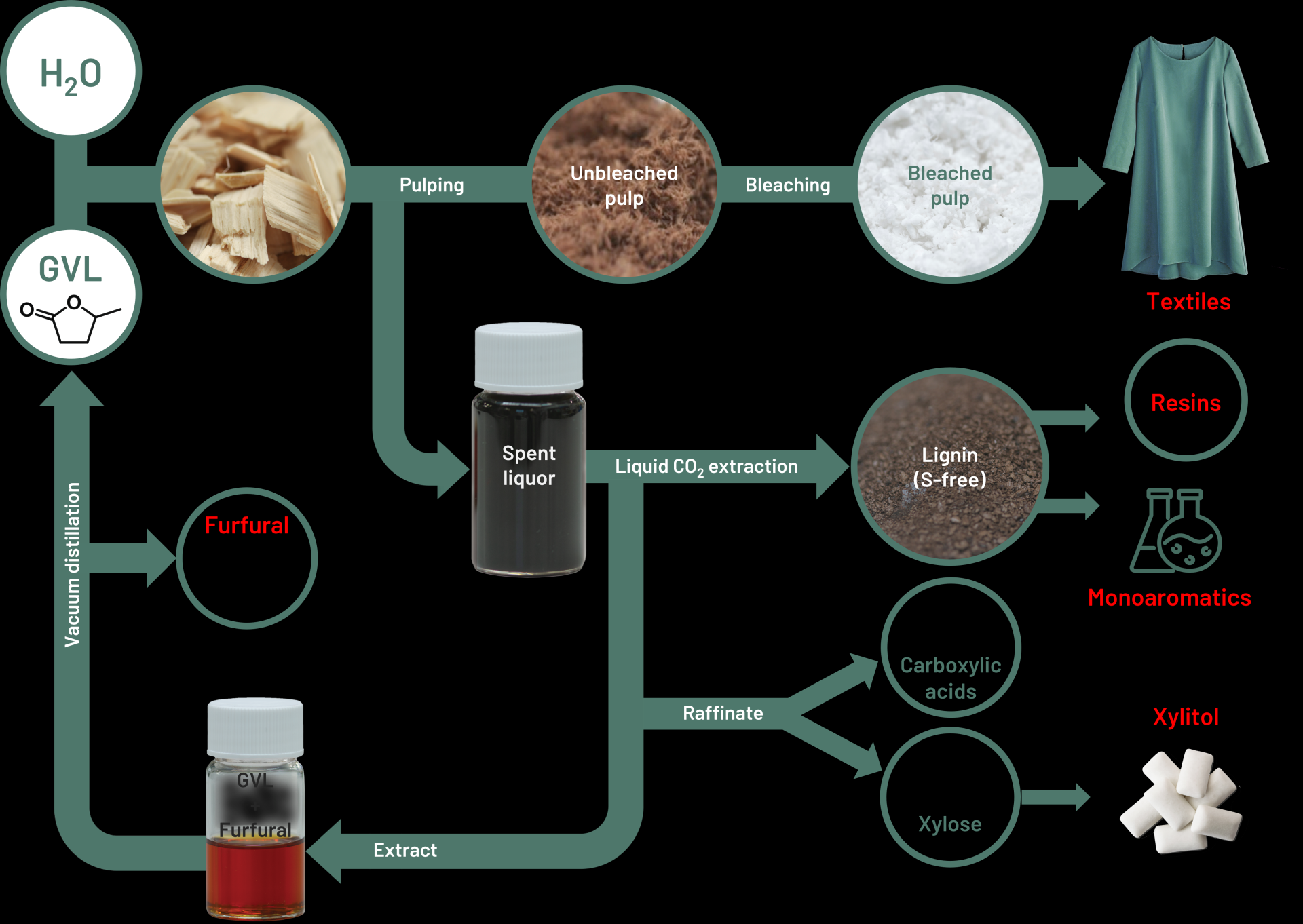

Mitigating climate change, reducing fossil-resource dependence while maintaining the standards of living are driving forces for the transformation to Bioeconomy. Gamma-valerolactone-based biorefinery employs a green organic solvent from nature to fractionate biomass to produce existing commodities such as textiles, platform chemicals, fuels and energy, in a more sustainable manner.

Project Region

EU Programme or fund

Description of the project

Summary

Exponential population growth and improved standard of living are heavily stressing the depleting fossil resources to fulfil the needs for materials, chemicals, fuels, and energy (average daily consumption of ca. 100 million barrels in 2019). Biorefinery is a promising solution to sustainably produce alternative commodities from renewable resources. Beside the usage of environmentally concerning sulfur compounds, traditional biomass fractionation technologies encounter the inherent underutilization of raw materials thus depending on operation with the economy of scales. Gamma-valerolactone (GVL) biorefinery presents a novel pulping technology fully complying with the principle of green chemistry, compatible with existing machinery, and at the same time boosting the product yield from raw material, thus allowing profitable operation without the economy of scale, thus moderating the investment risks and the effect of fluctuation in raw material price.

Key objectives for sustainability

GVL, a biomass-derived chemical with low toxicity, enables an effective, but still safe and environmentally benign biomass fractionation operation. The process is completely sulfur- and chlorine-free, thus widening the valorization spectrum of the isolated biopolymers. Unlike traditional pulping technologies, GVL-based biorefinery offers high raw material utilization rate of the biopolymers to produce sustainable alternatives to existing petroleum commodities, for examples:

- Dissolving pulp for textile applications from cellulose vs polyester fibers;

- Platform chemicals from hemicellulose (sugars, sugar alcohol, furanics, carboxylic acids) vs fossil-based chemicals;

- Polyethylene furanoate from hemicellulose vs fossil-based PET;

- Resins, aromatics building block from lignin vs fossil-based counter parts.

Last but not least, the solvent (GVL) can be recycled by standard unit operations (liquid CO2 extraction and distillation), enabling closed-loop operation.

Besides, initial application of the GVL fractionation technique on agricultural wastes (e.g. wheat straw) and fast-growing plants (e.g. hemp, esparto grass) yielded promising results, offering the opportunity to upgrade the concept to the second generation biorefinery.

Key objectives for aesthetics and quality

This project does not focus on the product aesthetics nor quality of experience beyond functionality. GVL-based biorefinery aims at producing existing products in a better way.

Key objectives for inclusion

GVL-based biorefinery is a new technology to produce dissolving pulp fully complying with the principle of green chemistry. The main pulping chemical (gamma-valerolactone) is non-toxic, non-corrosive, thus making the process compatible with existing machinery. Most importantly, this novel biorefinery concept allow a boost the product yield from raw material, allowing profitable operation without the economy of scale, thus minimizing the investment risk. When the technology is established in the future, every region with a well-managed forest area can have their own neighborhood-friendly GVL biorefinery operating care-free from the traditionally sophisticated raw material supply chain, and producing sustainable commodities replacing (as much as possible) fossil products.

Innovative character

Gamma-valerolactone (GVL) is naturally occurring chemical, widely applied in food an cosmetic products, which low toxicity, low volatility, low corrosiveness, enabling safe storage, transportation and usage. This proposed biorefinery concept employs a solvent from nature to fractionate renewable raw materials, in a closed-loop manner, into products matching currently existing commodities, thus relieving the environmental burden as well as the dependence on fossil resources.