THE ARTICHAIR PROJECT

Basic information

Project Title

Full project title

Category

Project Description

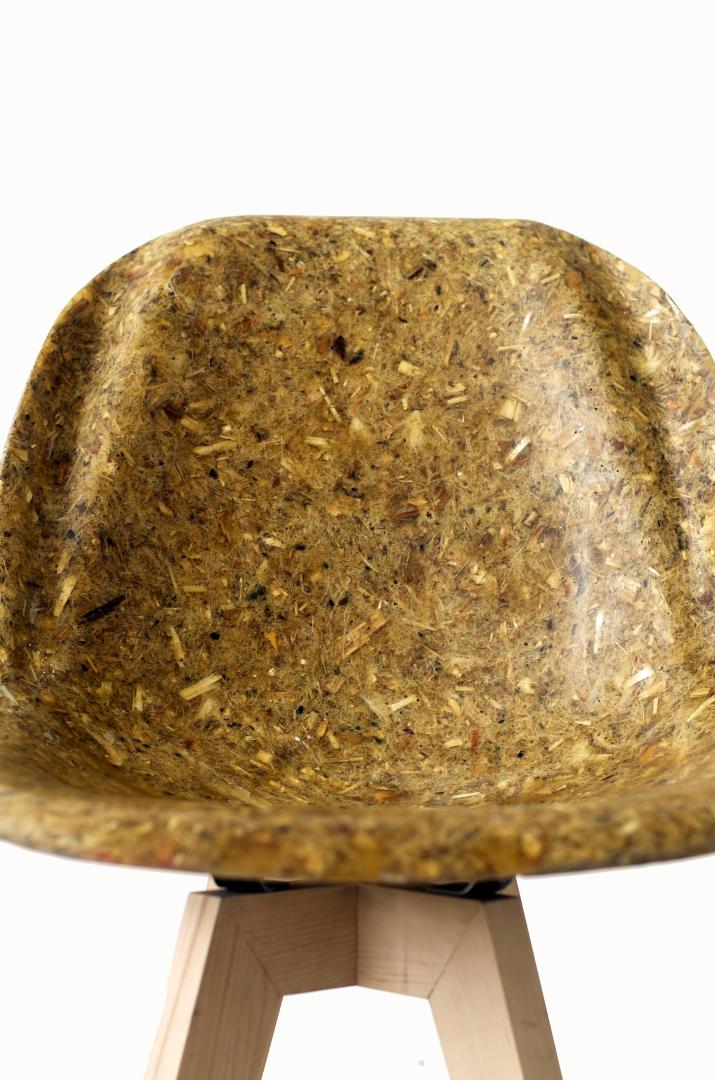

Meet The Artichair. An innovative chair made by wild artichoke thistle fibres and a genuine expression of ‘tangible nature’ in a small badge production of furnishing made in Greece by design brand LOCUL

Project Region

EU Programme or fund

Description of the project

Summary

The “Artichair Project” is a project focused on sustainability, agriculture economy and design.

The main idea is to alternatively use artichoke thistles in order to produce high quality furniture and decorative objects. Our flagship product is “Artichair”, a chair made from wild artichoke fibres and bio resin. Artichair was originally created during my studies in Edinburgh College of Art in 2013, as an artistic statement through materials exploration, that was about questioning not only the contemporary industrial materials and processes, but also the stage of material extraction, fabrication and disposal.

Since then, I have been trying to find a way to transform this student project into a sustainable, ethically produced and manufactured product. After 8 years of experimentation and research it is with great pleasure to say that finally six months ago me and my colleagues at LOCUL design brand, found the way to mass produce the Artichair.

But why this specific material? The cardoon, also called the artichoke thistle, is a plant native to the western and central Mediterranean region, where it was domesticated in ancient times. It is adapted to dry climates and is among the most abundant natural resources to be found in Greece. Recent studies have shown that cardoon crops are able to enhance the Greek economy through the biofuel industry. Taking advantage of unseen potential within this developing industry, this project has involved the development of a new eco-material, and explored possible applications for it within product design.

Starting with a dining chair, we are now in the process of designing and producing several objects from light shades to coffee tables being in tight collaboration with local farmers and composite material experts that are undertaking the production.

Key objectives for sustainability

“The aim is to reduce the negative environmental influence, to keep the technical requirements at the same time and to design aesthetic products.”

(Anne Farken, BMW Group, Designworks USA) Having this in mind, I started investigating sustainable natural resources that could potentially replace hazardous raw materials used in design industry. My interest was focused on composite materials such as fibreglass and epoxy. This is because on the one hand large amounts of energy are required for its construction, on the other because these products can hardly be recycled, and when they can, the process is economically unviable. It is estimated that 25% of our land fields are covered by plastics which means that there is a need to vanish plastic waste. On the other hand, according to the most recent World Energy Outlook report (IEA) oil plastic process is not only a pollutant process, but an expensive one as well. The need for a new material being able to replace plastic in a sustainable way, is not new, though the case of wild artichokes is rather special. Using Artichoke plants instead of other plant based extracts and fibres has multiple financial and ecological benefits. In a nutshell, there is no water required for its growth cultivation can be done just once in ten years, it is not comestible and no pesticides are required.The Artichoke Thistle is considered today as one of the most efficient plant at the field of bio - energy, used as a bio - fuel, replacing petrol for heating and electricity. Since there is already agricultural interest in that, we have developed a tight collaboration with local farmers, as they can supply our project with the waste of their production. The Artichoke Thistle reinforced plastic, could potentially fit into the “cradle to cradle” process depending on the binder used as if burned it could be a great opportunity for our products the end of their life circle by becoming biofuel.

Key objectives for aesthetics and quality

'Getting the most of the best to the greatest number of people for the least'

These are the words of Charles and Ray Eames describing their goals as designers.

None of their other designs come as close to achieving this ideal as the plastic dining Chair they designed in 1948. Mouldability, rigidity, pleasant tactile qualities, suitability for industrial manufacturing methods. Those were the design values that had to be met combined with high aesthetics and fine taste that reached the holy grail of design in the late forties. Glass-fibre reinforced polyester resin was the way to get there, without being able to imagine at the time the negative impact this method could have to the environment.

Eighty years later, we are still trying to meet the same design values, though sustainability is key in every aspect of design expression. At the same time, it has been stated that we spend more time indoors than ever before and people in big cities have been detached from nature in a unprecedented way.

Using this iconic design item as a reference, Artichair combines the values of modernism with social responsibility and sustainability, bringing nature indoors. Its particular complexion and crafty way of production make every chair special as the artichoke fibres when mixed with the bio resin create a unique texture that cannot be repeated.

Ethically grown and FSC certified oak is used for the legs, which combined with the fibre textured shell gives an elegant result that brings in a piece of furniture all of our hopes and dreams for a greener way of living.

Key objectives for inclusion

Inclusion in design should be tightly related with ethical production and respect to everyone involved in the production chain, from designers to the workers and obviously the buyers. This is why we are very proud to say that Artichair project meets these objectives in so many ways.

A very diverse part of society is mixed in order to bring this product to life. A group of farmers, agriculture engineers, industrial designers, mechanical engineers, composite materials experts and marketing consultants have worked together in order to bring the product to life.

Providing furniture for all is not only important for us as individuals or as designers but also for a spectrum of our customers, like the hospitality field, office spaces, food and beverages services, that want to give access to people facing physical challenges and disabilities.

The fact that we work in small batches, custom made products with different dimensions (height, width a.o.) that adjust to the user’s needs is part of our philosophy. This is great proof of inclusivity and diversity.

Results in relation to category

From the very beginning of this project in 2013 until its recent successful launch, our aim was to contribute to a sustainable, attractive and inclusive lifestyle.

Artichair was awarded by Green Design Awards as a greener approach to everyday furniture, stating that this is indeed a project that pushes people towards that direction.

In 2017 we were approached by Selfridges - London and Blue Hill Farm restaurants - New York in order to be part of their sustainable project “Wasted”. The idea was to create a restaurant where everything (from the menu to the furniture) would be made out of waste. Artichair was key to that project, and since at the time Artichair was not yet in production, we found an alternative way of working with the Artichoke fibres, by transforming them into veneer. A combination of these veneer pieces and wood led to a great collection of furniture that inspired people that visited the event to adapt a relevant lifestyle.

This was a great kick starter for us, and helped us to create a multidisciplinary team that worked really hard in order to make this project feasible. After almost 8 years of research and development, we have now two innovative ways of converting wild artichokes into a material suitable for moulded veneer and resin transform moulding techniques.

How Citizens benefit

What is quite interesting about the Artichair project, is that it brings together people from different occupations and places. Besides the end user that benefits by using a sustainable piece of furniture, there are multiple people that get affected by this project.

The Artichoke thistle fibre reinforced plastic resulted from combining natural resources, such as Greek artichoke thistle fibres and a biological resin. It was developed through an approach that researches current environmental and social issues and could potentially serve as a response to the long economic crisis in Europe, through the development of ecological agriculture.

Velestino is a town in the Magnesia regional unit, Thessaly Greece. It is a modern town and the hub of considerable farming and livestock-raising activities due to the fertile lands surrounding it. This is why we chose this place as our main supplier of wild artichoke fibres. Local farmers are benefiting by this project by developing a more efficient way of harvesting, by chopping away the top part of the artichoke plants which makes the pelletization harder. This is the part of the plant we use for our furniture.

Once we receive the raw material in Athens, another group of people are stepping into the Artichair journey. These are the composite material experts that used to work with glass fibre and epoxy resin. We are giving work to these people and replacing the hazardous materials they used to work with (epoxy, polyester resin, fibre glass) by natural ones. This is a great impact for their health and a great potential impact for local economy.

Last but not least, the local wood workers that are shutting down their workshops not being able to compete with the rising furniture industry, have now potential to be part of a creative team, working on a small batch production enhancing the slow design philosophy underlining that faster and cheaper is not always better.

Innovative character

The innovative character of this project lies between its raw material and the process we invented for the Artichair production.

As it mentioned before, the Artichoke thistle grows in huge quantities in the mediterranean, fact that makes it a very sustainable source. Trying to find possible ways to take advantage of this plant into product design and construction, we focused on the parts that would not affect negatively the pellet production of bio fuel industries. Artichoke thistle is full of natural fibres on its stalk. Our innovation is that we use these fibres that are slowing down the pelletising process in order to make sheets that resemble the old school fibre glass sheets. When these natural fibres are mixed, the create a nest that when is infused with bioresin makes an eco friendly new material. So basically we are imitating and old school crafty technique which is proven to be unhealthy and dangerous with as much natural substitutes as possible.

The technique we use is a mix of resin transform moulding and hand fibre layering. We are trying to use new technologies as CNC milling machines and rapid prototyping for our design and tools, and keep the production line under the philosophy of Arts and Crafts.