Green Transmission

Basic information

Project Title

Full project title

Category

Project Description

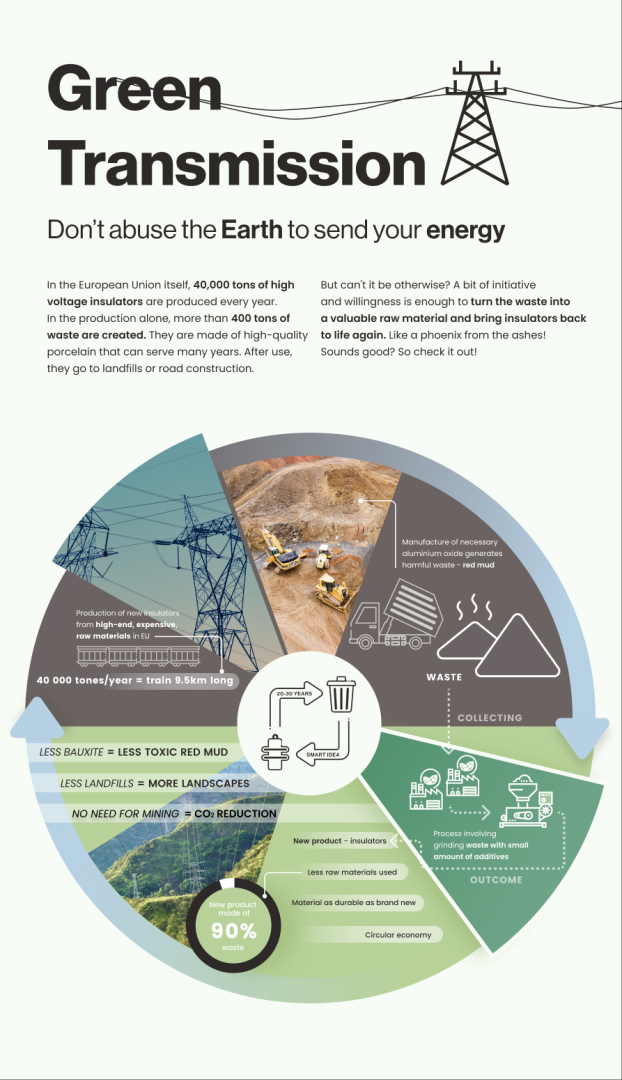

In the European Union, 40,000 tons of high voltage insulators are produced every year. In the production alone, more than 400 tons of waste are created. They are made of high-quality porcelain that can serve many years. After use, they go to landfills or road construction. But can't it be otherwise? A bit of initiative and willingness is enough to turn the waste into a valuable raw material and bring insulators back to life again. Like a phoenix from the ashes! Sounds good? So check it out!

Project Region

EU Programme or fund

Description of the project

Summary

We have been ruthlessly exploiting natural resources for years. Imagine a world where new products are made of waste. Closed circulation of the raw material obtained years earlier. What if such an idea does not have to remain utopian? High voltage insulators are products that none of us have but everyone uses. They build the energy infrastructure of each country. Still not sure what we're talking about? Remember high voltage electricity pylons and electrical substations. This is where you can find these insulators! They are made of expensive, advanced and durable material. Due to the fact that there are few producers in the world and few recipients, collecting them after their lifecycle! This creates the perfect opportunity to make something new out of them instead of being landfilled or sold as aggregate that ends up in soil or concrete. The main idea of the project is to create a closed circuit for electrical porcelain. No need to mine new resources! This is a win-win for the producer and the Earth and thus humanity. This will save around 40,000 tonnes of raw materials per year in the European Union alone (equivalent to a 9,5-kilometre train). Less resources mean less mines, less mines mean less intact environment. In addition, the piles of waste waiting for their chance to come back to life will disappear. You probably thought, "no, it's difficult and expensive"... you couldn't be more wrong! Research shows that it can be achieved very easily and as a result we can get a new product made of over 90% waste. So don't think more about whether it will pay off, but about what more you can do for our home – The Earth.

Key objectives for sustainability

The main goal of the project is to build awareness of the possibilities for effective management of ceramic waste. Glass recycling seems to be in the spotlight while other ceramic waste are neglected because they are harder to collect separately. Therefore, our idea is to focus on materials that are used only by the industry. A niche market, a small number of producers as well as clearly defined recipients and applications mean that those products can be returned to the manufacturer without any problems. Let's take a closer look at electrical porcelain, from which high-voltage insulators are made. Research by Polish scientists indicates the possibility of reusing such waste [1]. In the European Union alone, about 40,000 tonnes of them are produced annually. If we can make new insulators made from > 90% of the old ones, the math is simple >36,000 tons of raw materials remain in the ground. But what is it made of? In short: more than 50% of it is aluminum oxide, also called alumina, which undergo reaction with couple of other minerals to form the final material. The production of alumina is associated with the generation of harmful waste, such as red mud (remember the disaster at the alumina plant in Ajka, Hungary). Is there anything closer to the idea of sustainable development like making something out of spent material?

[1] Michałek J., Partyka J., Pasiut K., Kaczmarczyk K. The Utilisation of High-alumina Porcelain Waste by Calcium-mineralizer Assisted Re-Sintering Process, 8th International Congress on Ceramics, Busan (2021)

Key objectives for aesthetics and quality

One of the assumptions of the project is collecting old electrical porcelain. It is stored in landfills which significantly reduce the aesthetic value of the areas. The implementation of the project will allow gradual reduction of the dump areas and the recovery of green landscapes. We can and we should restore these areas for citizens. If we want a green Europe, we must think not only about producing less garbage, but also about the processing of garbage was already produced. It is one of the easiest ways to start solving this problem. Additionally, thanks to the re-use of old insulators, we can significantly reduce the extraction of raw materials used for their production. They are non-renewable resources, which means they will deplete some day. Furthermore, another waste is generated during the manufacturing - red mud which is very toxic and dangerous for the environment as we saw ourselves in 2010 when one million cubic meters of red mud from an alumina plant in Hungary was accidentally released into the surrounding countryside, killing ten people and contaminating a large area. Within a few days the mud reached the Danube. One of the largest red mud storage sites in EU is located in Germany and covers an area of 150 ha (210 football pitches). Sustainable production of insulators reduces bauxite mining. Less bauxite - less red mud. This will help prevent another ecological disaster. Thanks to our solution, we can use the earth's resources more carefully and wisely.

Key objectives for inclusion

As previously mentioned, the most important thing in recycling is waste collection, which in our case is extremely easy to be realized. The producers of insulators may undertake to take back the broken products and as a result they get free raw material. As manufacturers, they know their material very well, so they can easily process it. But what's next? Further processing of the waste does not differ from the typical treatment of raw materials. They have to be crushed, mixed with other ingredients, shaped and put into a big furnace. Nothing new – except for digging in the ground! In addition to the free raw material, the production plant can pride itself on being a friend of the natural environment. So what has stood in the way of such actions so far? Knowledge and will that we do not lack. Such activities entail the need to educate the society and instil the will to change. The idea of sustainability is very catchy, but we have to spread it all over the world to start the global movement.

Innovative character

What is the innovation of our idea? Mainly looking at waste as a source of raw materials and financial savings. Moreover, until now the main method of managing ceramic waste was adding it to concrete instead of the sand and aggregate. When the lifecycle of this material is finished, the concrete is crushed and used as aggregate. This way, it stays in the soil forever. Our idea is to recycle porcelain waste multiple times, which means that once the raw material is recovered, it can circulate in the industry for many "generations". In this way, we extend the life of the raw material by several generations and finally we can use it as aggregate for concrete. However, we cannot close ourselves to possibilities. If, after a few cycles, the material is no longer suitable for the production of insulators, we can make it a less demanding product - a floor tile, a plate or a mug, which was previously a key element in the transmission of electricity, and now we drink our morning coffee from it.