˛BioProfile

Basic information

Project Title

Full project title

Category

Project Description

The project ,,BioProfile" is a research project of the BioMat department (Biobased Materials and Material Cycles in Architecture) at ITKE (Institute of Building Structures and Structural Design), University of Stuttgart, whose aim was the development of extruded and coextruded façade and window profiles as well as other exterior architectural applications, in particular façade panels made of biobased materials.

Project Region

EU Programme or fund

Description of the project

Summary

The project ,,BioProfile" is a research project of the BioMat department (Biobased Materials and Material Cycles in Architecture) at ITKE (Institute of Building Structures and Structural Design), University of Stuttgart, whose aim was the development of extruded and coextruded façade and window profiles as well as other exterior architectural applications, in particular façade panels made of biobased materials. The profiles were manufactured with a high content of recycled straw fibers as well as other natural fibers and using biobased additives.

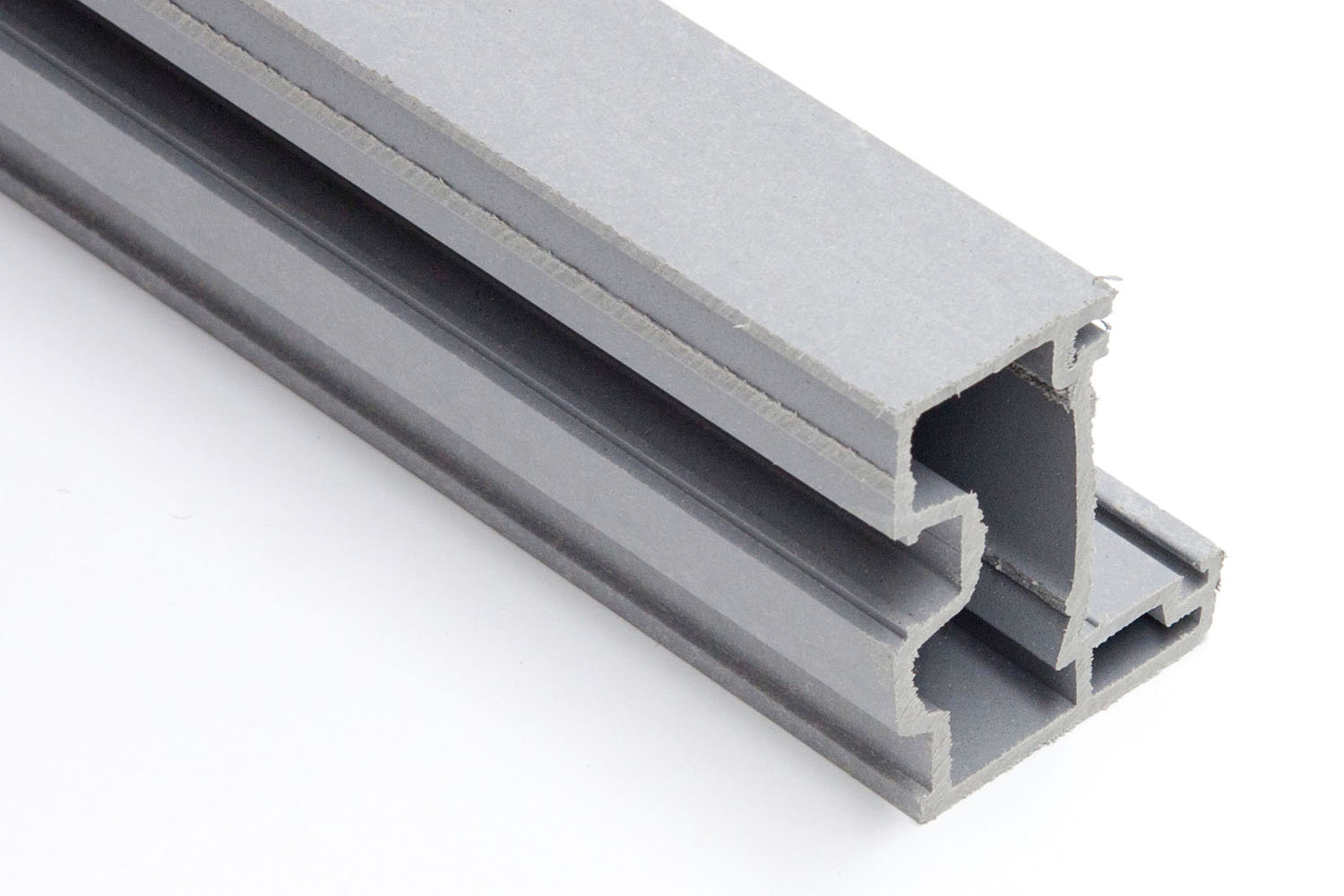

The project specified a range of material formulations and profile geometries that could be used in architecture for both interior and exteriors, and as substitutes for natural fiber-based products available on the market, such as medium-density fiberboard (MDF) or Wood Plastic Composites profiles (WPC),. The profiles developed were produced using extrusion and coextrusion processes and tested for their mechanical properties and durability in a series of experiments and 1:1 architectural prototypes.

In addition to the bioprofiles developed as an alternative material for standard applications, a new type of elastic sheet made of natural fiber-reinforced plastic (NFRP) has been developed that can be used as a core material in sandwich panels laminated with natural veneer. Due to the initial flexibility of the panels, it is possible to obtain double-curved shapes. Laminating changes the nature of the flexible, flat core board into a rigid, curved 3D element that can be used as a structural component. Using this technique, an experimental ,,BioMat Pavilion '' was realized in 2018. The double curved parametrically designed shell consisted of lightweight single curved wood and biocomposite elements supported by three curved and crossed wooden beams.

The project makes an important contribution to resource conservation and sustainable material development and demonstrates the use of biocomposite materials in architecture.

Key objectives for sustainability

The aim of the project is to use recycled wheat straw as well as other natural fibres for the extrusion and co-extrusion of thermoplastic biocomposite window profiles and facades elements. The high proportion of natural additives from agricultural residues should reduce the demand of the construction industry for petroleum-based

plastics.

The project has successfully developed new, more environmentally friendly solutions for common architectural forms. The profiles were manufactured with a high content of recycled straw fibers as well as other natural fibers and using biobased additives. This solution provide a sustainable alternative for petroleum-based plastics. Since the biocomposites can be processed in a similar way to petroleum-based plastics, "BioProfiles" allow complex cross-sectional geometries what offers a wide range of applications in the construction industry.

The focus on architectural semi-finished products should encourage the wider use of biocomposite-based materials in the construction industry. The results of the BioProfile project will make an important contribution, especially for window manufacturers, and can replace/partially replace traditional PVC profiles, aluminium and

wood profiles, which have a much slower renewability than the recycled agricultural fibres used, such as straw.

The extruded profiles can be recycled after their service life, as they can be remelted and processed into further products. This is a major advantage in terms of a bio-based circular economy.

Key objectives for aesthetics and quality

In addition to the bioprofiles developed as an alternative material for standard applications such as window profiles, a new type of elastic sheet made of natural fiber-reinforced plastic (NFRP) has been developed that can be used as a core material in sandwich panels laminated with natural veneer. Due to the initial flexibility of the panels, it is possible to obtain double-curved shapes.

Key objectives for inclusion

The project were created in cooperation between architects, researchers, industry partners and architecture students. This collaboration created a venue for discussion, exchange of ideas and experience, resulting in in new sustainable solutions in architecture.

Results in relation to category

The project goals were achieved in three steps, at which biocomposite material, semi-finished products and final architectural products were developed and tested.

Firstly, the biocomposite materials recipes, with maximum content of chopped wheat straw fibres, were defined and extruded. Samples were subjected to mechanical tests in order to determine and tune their mechanical properties and compare them against other fibre boards such as MDF.

Secondly, the most successful recipes, based on biobased HDPE and powdered HDPE matrix, were used for experimental extrusion of semi-finished products - various profiles geometries ranging from window profiles to large flat sheets. In the course of experiments, the extrusion parameters such as temperature, production

speed etc. were adjusted. Apart from that, necessary modifications in the geometries of the extruded profiles, such as minimum wall thickness, were made.

Extruded semi-finished products were used for assembly of 2 different 1:1 mock-up demonstrating their potential applications. Window profiles were used for building a fully operational 1:1 window mock-up, equipped with hinges, locks etc used in standard windows. Facade panels were applied structurally in the form of curved biocomposite sandwich panels for the realisation of a 1:1 biocomposite shell construction system to represent their wide applications' range.

The project showed that extruded biocomposite profiles, containing even up to 70% of straw fibre in weight, have potential for becoming an alternative to both standard natural fibres based products such as MDF, HDF, OSB boards etc. and PVC window profiles. Their mechanical properties and easy machinability not only do not require significant modification in production chains of architectural products such as window and door frames or façade panels, but also open radically new design possibilities due to their adjustable elastic properties which can be controlled at the stage of material composition.

How Citizens benefit

The BioProfile is a research industrial project of the BioMat department (principle investigator), Fraunhofer-Institut fur Holzforschung (Fraunhofer WKI), and industrial partners Mathias Stange ETS and Profine GmbH. The project carries benefits for the construction sector, where is currently a great demand for bio-based, flame-retardant products, including for facade solutions. The investigations into the flame retardancy and durability of the profiles have met with great interest from companies in the field of compounding, profile extrusion, the construction industry and from the flame retardant manufacturers.

In the design and construction of the BioMat Pavilion 2018 were involved architecture students. The young architects had opportunity to experience research process, physically experimenting newly developed alternative biocomposite materials.

The collaboration between architects, research centers and industrial partners has enabled the exchange of ideas and has brought new sustainable solutions to the industry.

Innovative character

The project has successfully developed new, more environmentally friendly solutions for common architectural forms. It has been demonstrated that extruded biocomposite profiles made from agricultural residues can offer both mechanical properties and processing capabilities as an alternative to commonly available fiberboards such as MDF. At the same time, their increased elasticity, which can be controlled at the level of the material formulation, offers a wide range of design possibilities.