NEXT STEPS

Basic information

Project Title

Full project title

Category

Project Description

NEXT STEPS is an initiative that stimulates designers, makers, and patients (as user innovators) to co-design and prototype a collection of open-source walking aids that can be distributed through digital platforms and materialized in Fab Labs. Next Steps is based on the principles of openness and customization of products, inclusiveness of citizens and implementation of local networks to create walking aids with real market potential, respecting regulations and certification.

Project Region

EU Programme or fund

Which funds

Other Funds

Creative Europe - Culture Sub-programme (2014-2020) – 'Support to European Platforms' – Call for proposals EACEA 06/2017

Description of the project

Summary

NEXT STEPS is an experimental initiative conceived and developed by Polifactory, Fab Lab of Politecnico di Milano, within Distributed Design (DD), a "Platform" project funded by the Creative Europe Programme, to implement the global Fab Lab network, promote and improve the connection between makers and designers with the European market. NEXT STEPS was conceived to stimulate designers, makers, and patients to collaborate in the co-design of open-source walking aids that can be produced on-site through digital fabrication processes and distributed production models with particular attention to Fab Labs.

Based on the principles of openness and customization of products, inclusiveness of citizens and implementation of local production networks, already present in DD, the challenge of NEXT STEPS was to demonstrate how designers, makers and users/patients can concretely co-design, produce and distribute new models of open source walking aids with real market potential, respecting regulations and certification systems.

The initiative took shape thanks to the collaboration with the Italian Glycogenosis Association (AIG), which represents people affected by a rare and degenerative metabolic disease that progressively forces people into infirmity. Sanofi Genzyme, a division of the pharmaceutical company Sanofi dedicated to rare diseases, has provided its support to the communication and promotion of the results.

NEXT STEPS has been developed in 3 phases. An initial "challenge" addressed to designers and patient-innovators, culminating in a co-creation workshop to identify the most promising ideas. In the second phase, a group of designers and makers developed 4 design solutions working in residence in the Fab Lab Polifactory. In the third and final phase, the solutions were prototyped and the open-source projects - accompanied by documentation (code, digital files, instructions, indication of materials) - were released on the platform distributeddesign.eu

Key objectives for sustainability

Already today, some types of products such as aids, orthotics, and prostheses can be designed using knowledge, software, and open-source hardware, and then be partially or totally manufactured in Fab Labs by combining the skills of makers with digital fabrication technologies.

Three levels of environmental sustainability characterize the whole set of NEXT STEPS solutions:

- Sustainability of Solutions. Some walking aids, such as sticks, can be designed with mono-material or disassemblable components. For other walking aids, it is possible to "hack" already existing products such as crutches or walkers by adding or replacing parts and/or components operating both in a logic of refurbishing and technical or technological upgrade but also reasoning in a service dimension.

- Sustainability of manufacturing processes. Open source walking aids can be made using on-site and on-demand digital fabrication technologies such as 3D printing that reduce material waste and use non-petroleum plastics.

- Sustainability of distribution. The use of digital manufacturing technologies for the production or integration of walking aids allows the transferability of the production to any place/laboratory equipped with such technologies, thus creating zero km production chains able to reduce the environmental impact of transport and distribution.

In addition to these elements, there is also an aspect of social sustainability since the project focuses on weak users directly involved in the co-creation and testing phase.

Key objectives for aesthetics and quality

At the basis of the whole process of conception, design, and development, Design-driven innovation has made a decisive contribution, enhancing aesthetics, quality of experience, and functionality of the outcomes. The following aspects are the characterizing elements of the design outputs.

IDENTITY. In the preliminary phase of needs analysis, carried out together with the patients of the association AIG, it emerged that the aids are tools that accompany a person's life in different contexts, occasions, and activities. They consider the aesthetic dimension of walking aids as crucial as their functional aspects. In support of this, generative and/or parametric design related to digital fabrication contributes to redefining the aesthetics of products such as prostheses, making them technical objects that can be worn visibly and not necessarily hidden or camouflaged.

PERSONALIZATION. When used daily, walking aids progressively tend to become physical extensions of people. Therefore, the personalization of walking aids is an important aspect because it also characterizes the identity of these products from an aesthetic and performance point of view, "tuning" it with the identity, characteristics, or needs of the users, going beyond the purely ergonomic and functional dimensions.

ADAPTABILITY. The design and development of accessories and components realized by NEXT STEPS is also conceived to adapt to walking aids of different cost ranges already available on the market. This makes it possible to create technological upgrades or functional add-ons to make objects such as crutches and walkers smart, interactive, and digitally controllable devices. The adaptability of walking aids is also important from the point of view of manufacturing processes and embedded technologies. These open-source devices must be made by self-producers or artisans and makers in places like makerspaces and Fab labs.

Key objectives for inclusion

NEXT STEPS was designed focusing on different levels of inclusion:

- inclusion of patients and caregivers who are confronted daily with personal walking problems or those of their loved ones (for which the AIG association was involved), and who finally had the opportunity to voice their needs and desires;

- inclusion of communities of makers and designers (orbiting in the sphere of Politecnico di Milano, the city of Milan and the surrounding area), who were able to offer their skills and knowledge to devise solutions to meet the needs of niche or weak communities;

- inclusion of local production networks scalable at European and global level (such as Fab Labs and makerspaces), which have been considered central in the product development phase of the designed solutions, considering the technologies and tools they already have, for production gaps;

- inclusion of a wider audience, which can access the results thanks to the production of dissemination material (flyers, photos, videos) published on the web, and which can also choose to reproduce the products using the documentation distributed online (code, digital files, instructions, indication of materials).

Results in relation to category

The NEXT STEPS collection demonstrates how it is possible to develop collaborative processes among designers, makers, and users to develop products that can improve the quality of daily life of people with diseases/disabilities. The approach of NEXT STEPS is to use design and technology to make walking aids more attractive and intelligent, improving the possibilities of usability for users by increasing their chances of autonomy and social inclusion. The 4 projects of NEXT STEPS can answer the change of lifestyles through products designed ad hoc.

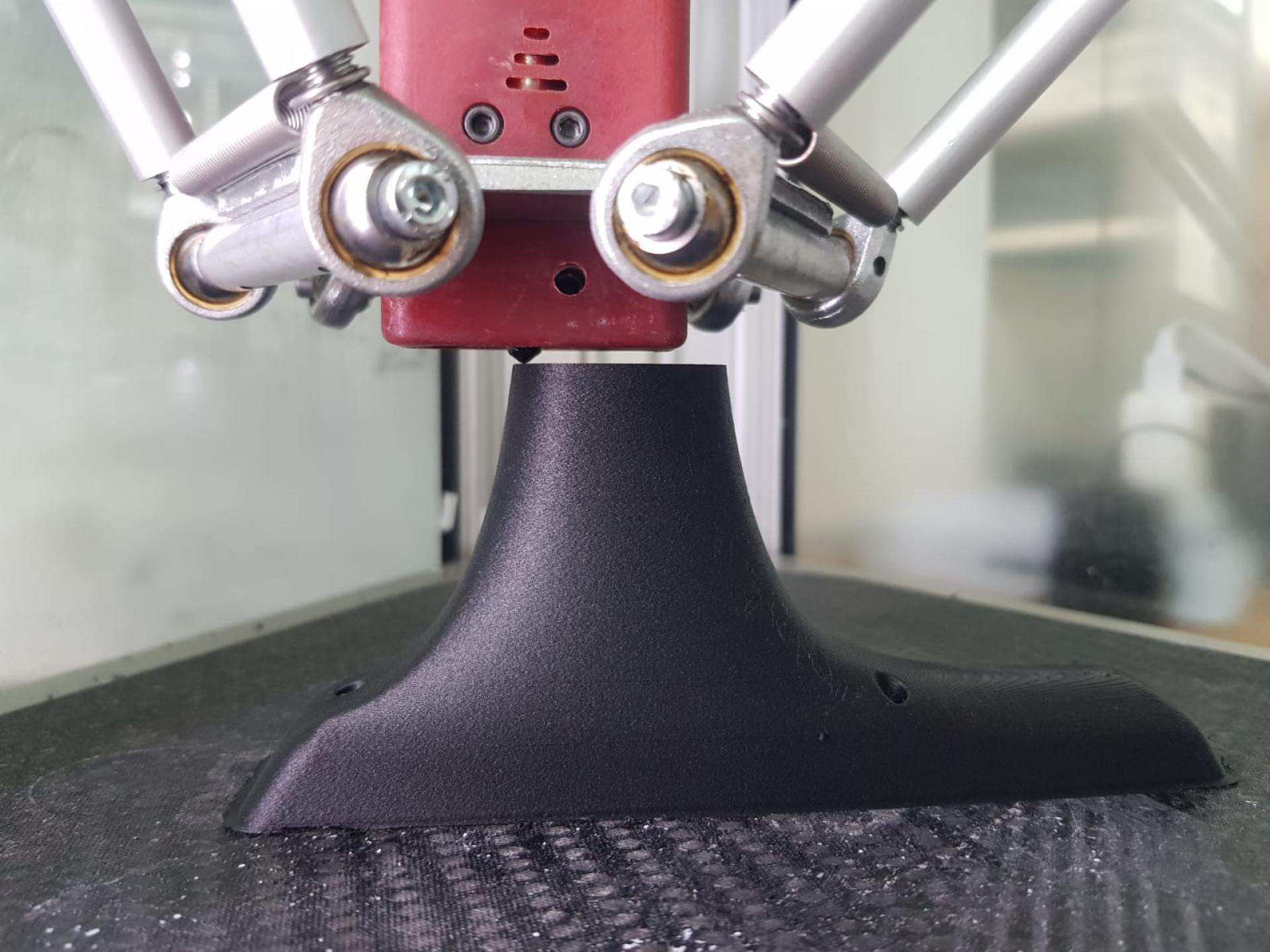

Twistr is a parametric stick made by Polifactory and designed with A. De Iesi, A. Ascani, E. Westerduin, A.M. Glaser. A digital design and fabrication method has been developed to produce personal parametric sticks - with Kinect and grasshopper - that possess a 3D printed structure. The stick is printed with a polymer loaded with carbon powder.

Taylor is a generative cane created by Polifactory and designed in collaboration with A. Ceriani and M. Ceruti. It is based on a generative design process that allows users to create customized canes that can configure themselves according to users’ weight, height, and gender.

Wander3d is a walker transformed into an IoT tool. Thanks to this hacking it is possible to transform a typical entry-level walker into a motorized and sensorized object that the user can activate and control according to their needs to make small movements or overcome obstacles or roughness of the ground. Polifactory designed and made Wander3d in collaboration with L. Lucchetti and S. Meregalli.

Finally, Clip Clap is a project that concerns the co-design of removable decorative clips, made with additive manufacturing processes, to be easily applied and removed from the rod of the crutch customizing in various ways the aesthetics of the aid. The clips are made by Polifactory and designed in collaboration with L. Cereda, N. Colombo, G. Cortellessa, and A. Stefanelli.

How Citizens benefit

Thanks to the role played by the AIG association, a significant number of patients affected by Glycogenosis - considering that it is a niche of 200 people in Italy and less than 10,000 worldwide - has been involved within NEXT STEPS. Users' habits, needs, and desires related to the use of walking aids were investigated. The co-creation activity of the solution ideas was based on the results of the survey with patients. It was validated by participating in the events of the AIG association, talking with some patients and their families.

The further phase of co-design, development, prototyping, and production of the solutions has been entirely carried out within the Fab Lab, making appropriate use of technological resources and professional skills within the place. From the NEXT STEPS project it emerges, in fact, that Fab Labs are suitable places to develop collaborative project activities with small groups of users who have specific needs and that their productive capacity can be finalized. In addition to this, Fab Labs make it possible to give life to products that use the materials of industrial production and do not have the numbers to give life to batches made in traditional production chains.

The impact of the entire initiative, in addition to the data relating to the number of downloads of digital files of open source products released (through the distributeddesign.eu platform but also through the site polifacotry.polimi.it), can be measured in the involvement of users and the audience reached:

- 60 Creative Talents involved

- 49 User-Patients, 2 patient innovators and a Patient association involved

- Local and social media audience (110 + 5703 people)

Innovative character

At a general level, NEXT STEPS has been working on creating innovation ecosystems dedicated to patient innovation that connect creative communities of designers and makers with healthcare specialists and the world of patients with their caregivers and associations.

Today, there is a growing demand for personalized products in the healthcare sector: some could be already designed and materialized using open source knowledge, open software, and hardware, digital fabrication, and skills present in Fab Labs and makerspaces.

All projects developed within NEXT STEPS are available in open-source mode under the Creative Commons license (cc-by and cc-by-sa) and published on the Distributed Design platform (distributeddesign.eu) with the related documentation.

The project's innovative character is expressed in three aspects: design-driven, technological, and social.

For design-driven innovation means the inference between open and distributed design in the development of care solutions. This has encouraged user participation in co-creation and co-design processes to create open-source aids with comprehensive technical documentation for their replicability.

Technological innovation is recorded when parametric and generative design solutions have been implemented to generate files to produce tailor-made products through additive manufacturing.

Finally, social innovation is detectable when niche users (weak) are given the opportunity to increase their autonomy and, consequently, the level of social inclusion, leading to an improvement in lifestyles.