KLIMA-PUR

Basic information

Project Title

Full project title

Category

Project Description

KLIMA-PUR is top-class carpentry improving the energy-efficiency of buildings & houses while reducing the C-Footprint of their thermal envelope. Similar to wooden frames & profiles, KLIMA-PUR are single structural and functional products manufactured with renewable raw materials, providing high thermal and acoustic comfort, extended durability and improved recycling at end-of-life.

Project Region

EU Programme or fund

Which funds

Other Funds

2019 - "Extru-PUR" H2020 SME Instrument Phase 1 (Project Number: 855513) - https://cordis.europa.eu/project/id/855513

2019/2022 - "Doing more with Lignin" H2020 INTERREG-OPZUID (Project Number: 02093-PROJ) - https://www.stimulus.nl/opzuid/avada_portfolio/meer-met-lignine/

2020 - "Safe-PUR" H2020 SME Instrument Phase 1 (Project Number: 889258) - https://cordis.europa.eu/project/id/889258

2021/2025 - "MEZeroE" H2020 Open Innovation Test Bed (Project Number: 953157) - https://cordis.europa.eu/project/id/953157/es

2021 - "GreenThermoWall" H2020 DigiCirc Accelerator (Project Number: 873468) - https://cordis.europa.eu/project/id/873468/es

Description of the project

Summary

In the age of climate change, buildings are currently responsible for 39% of the global CO2 emissions with 28% of them directly related to energy consumption. Despite the use of clean energy has a huge impact, thermal insulation is the other pillar avoiding the CO2 emissions. Indeed, improving the performance and sustainability of the thermal envelope of buildings and houses is the most important strategy to address related to construction materials in the coming years, where windows & doors are the weakest elements in the thermal envelope (thermal performance, maintenance, durability, etc). Related to this, INDRESMAT has developed KLIMA-PUR, a disruptive window & door frame made from polyurethane foam as single structural and functional material with multiple environmental advantages over conventional frames to be used in the next generation of nearly Zero Energy Buildings.

Key objectives for sustainability

KLIMA-PUR has been certified through CE marking, resulting in a top-class energy-efficient frame with the lowest thermal conductivity (Uf = 0.80 W/mK). In addition to its superior thermal performance, KLIMA-PUR frames are manufactured with a low energy consuming technology as no melting process is needed (compared to PVC or Aluminium), reducing by 20-50% the direct CO2 emissions from its efficient and circular manufacturing. Moreover, the incorporation of 40-50% renewable raw materials, coming mainly from natural oils, makes it possible for KLIMA-PUR to offer a window with 164 KgCO2e/m2 of C-Footprint (17% superior to wood, 36% lower than PVC and 66% lower than Aluminium). Finally, KLIMA-PUR frames have been designed for circular use since the wastes coming from production and from end-of-life products can be easily recycled within the manufacturing process (25-30% of recycled content), and together with an extended shelflife (35-45 years), KLIMA-PUR increases the performance, durability and resource-efficiency of windows and doors.

Key objectives for aesthetics and quality

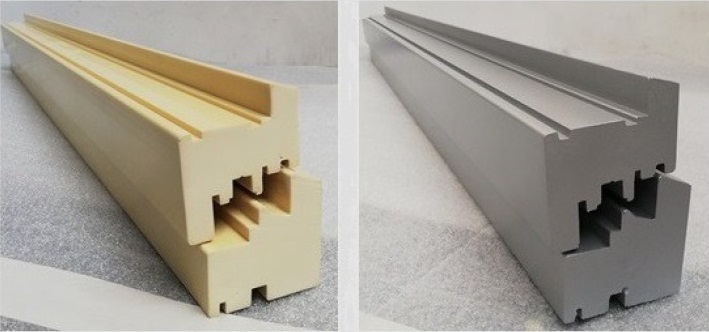

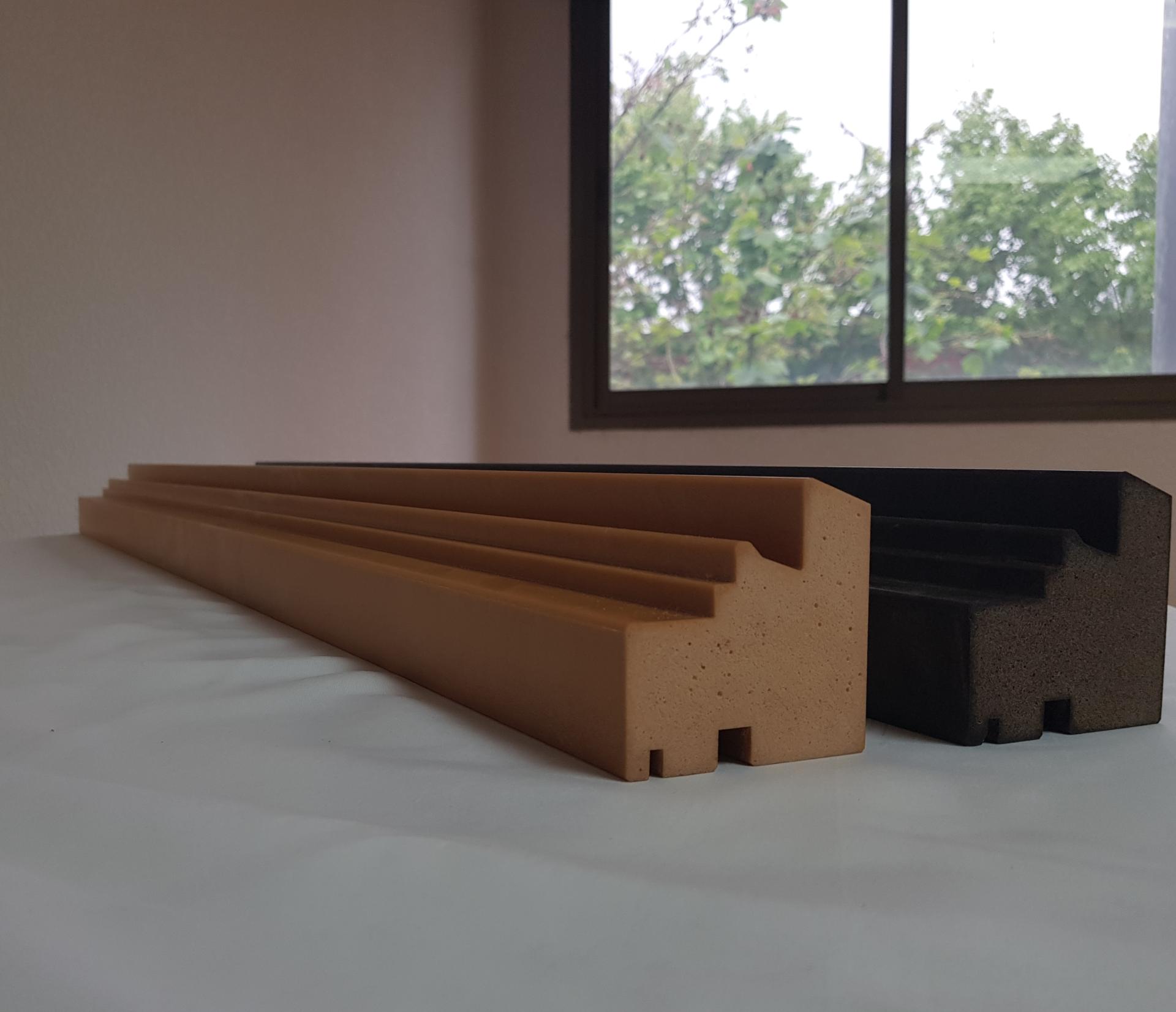

KLIMA-PUR combines functionality, design and lightness with a new own style. They can be painted in any RAL color and finishing (timber, metallic & plastic), leading to a highly customizable product and making possible to target different markets, such as residential, commercial and industrial buildings.Taking advantage of its solid configuration and thermoforming properties, KLIMA-PUR windows can be curved and its simple design with elegant shapes allows the imitation of other materials while integrating both rustic and modern architectural styles.

Key objectives for inclusion

Despite INDRESMAT is composed by a small team (4 men and 2 women), a multidisciplinary team from 3 different countries was integrated. We to achieve in the near future parity gender in our staff and also integrate persons in social excusion risk. In addition, our company will require to our providers to be subscribed to a NGO of their election compromised with People and Planet.

Results in relation to category

Key technical fact 1: KLIMA-PUR frames have a 0.80 W/mK thermal conductivity, being more insulating than wood (x2), PVC (x3) and aluminium (x7)

Key technical fact 2: KLIMA-PUR windows have an estimated lifespan of 35-45 years, 15-20 more than wood, 10-15 more than PVC and Aluminium.

Key environmental benefit 1: KLIMA-PUR windows have 160-170 kgCO2/kgm2 C-Footprint, only 17% higher than wood, 33% lower than PVC and 66% lower than aluminium

Key environmental benefit 2: KLIMA-PUR frames manufacturing process has a Specific Energy Consumption of 0.13kWh/kg, 10 times lower than PVC and 50 times lower than aluminium

Key economic benefit 1: KLIMA-PUR windows will save up to 50% energy consumption for space-heating and cooling compared to conventional frames.

Key economic benefit 2: KLIMA-PUR windows costs 20% lower than wood and 25% higher than aluminium or PVC

How Citizens benefit

N/A

Innovative character

KLIMA-PUR frames have been developed combining 3 main fields of innovation which areas of expertise from INDRESMAT’s team are the differential key values of our company:

1) Product design: Compared to competitor materials, KLIMA-PUR frames are positioned as a product with the highest thermal insulation performance since a very low thermal transmittance (0.8 W/K.m2) has been achieved with a moderate competitive pricing. The price competitiveness of KLIMA-PUR is comprised between PVC and aluminium, which are the most price competitive frames due to the large productivity of plastic and metal extrusion processes).

2) Technology engineering: To ensure price competitiveness of KLIMA-PUR frames, INDRESMAT has developed a Proof of Concept moulding technology that improves the productivity of the conventional Reaction Injection Moulding (RIM) process used by direct competitors.

3) Materials formulation: INDRESMAT has included in KLIMA-PUR frames PUR formulations with a 40% of biobased content to reduce 35% the C-Footprint using renewable raw materials due to the unique know-how of our company in polymer chemistry. These bioPUR formulations include natural oil-derived polyols (Fig. 18) such as glycerol, dimerized fatty acids and epoxydized oils coming from soy, rapeseed and castor oil sources, as well as from lignin