Expanded Wood

Basic information

Project Title

Full project title

Category

Project Description

Expanded Wood is a novel entirely wooden panel, which has similar firmness to a raw material that it's made of, however it is 25% wider. The panel is lighter and made with less stock.

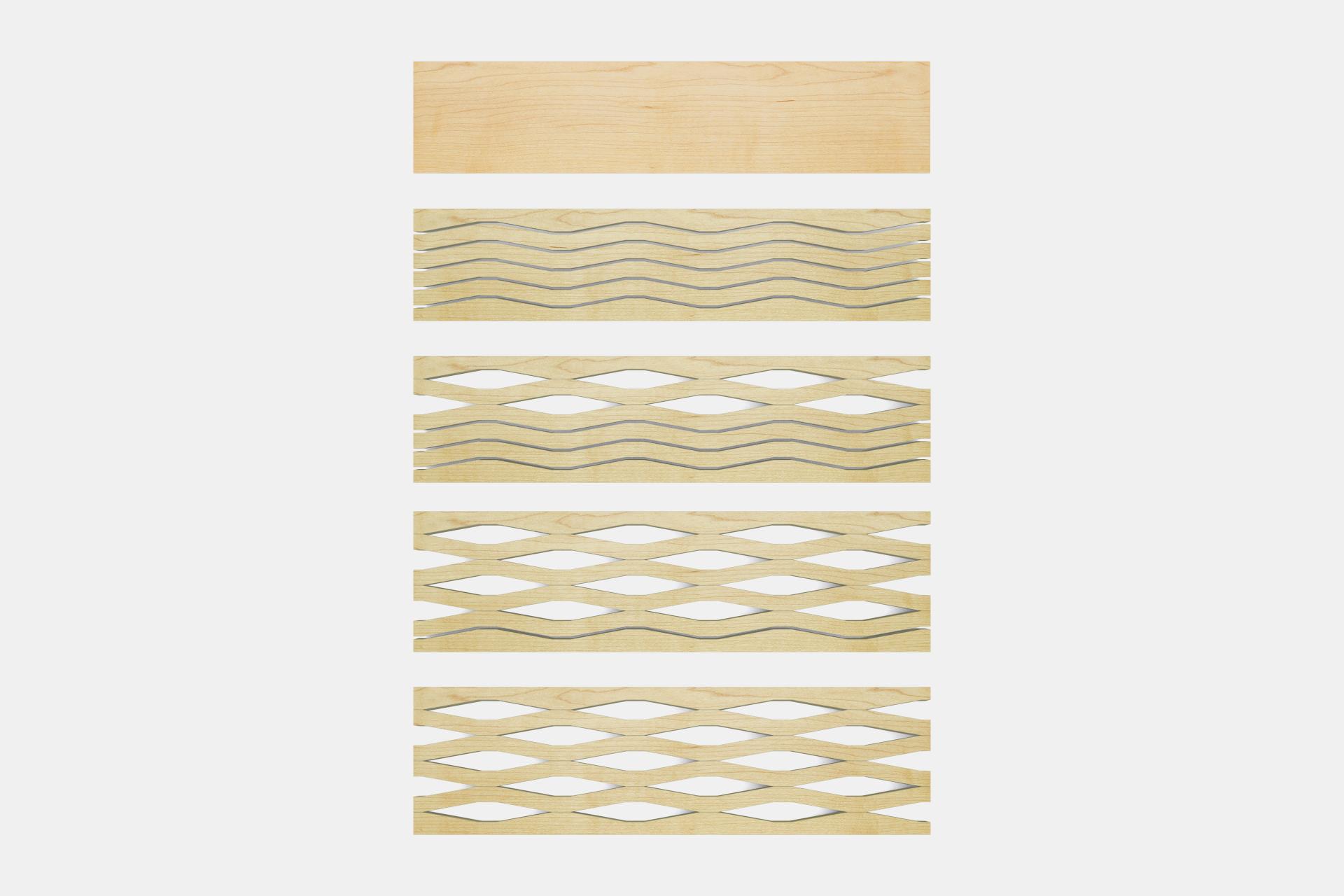

It is made by cutting wood into curvilinear slats, turning every other element and laminating it, forming a hexagonal mesh with oblong gaps in-between elements. The gaps between slats help to reduce the amount of raw wood used for production of the material by more than a quarter.

Project Region

EU Programme or fund

Description of the project

Summary

Expanded Wood is a novel entirely wooden panel, which has similar firmness to a raw material that it's made of, however it is 25% wider. The panel is lighter and made with less stock.

The production of the open work panel consists of the board being cut into longitudinal slats in the shape of a periodic trapezoidal curve, after which, every second element obtained is moved by half the period length or rotated by 180 degrees, and then the adjacent surfaces are glued together. As a result of this process, oblong, hexagonal openings are formed in the glued panel, and the raw material increases in volume, slightly loses weight and gains strength. The board is cut using computer-controlled devices such as a computer table milling machine or a robotic arm equipped with a router bit. This technique ‘allows for the quick, precise and repeatable production of complex shapes’. ‘The second and third phase of production, that is, moving or rotating the elements, applying the glue and fixing the elements while the glue is bonded, can be done automatically or manually’. The trapezoidal curve ‘can have various shapes, proportions and dimensions as well as the radius of rounding the vertices’

Key objectives for sustainability

Due to its new physical features as well as higher material efficiency, Expanded Wood can serve as more sustainable replacement for carbon dioxide-intensive materials like plastic, metal or concrete.

Timber can be, and very often is, more environmentally friendly material than others. Due to its renewability as well as carbon stock fixed in wooden products, timber is far more sustainable than plastic, metal or concrete. Replacing those materials with wood could slowdown or maybe even stop climate change. Naturally, using wood as a replacement for other carbon dioxide-intensive materials would increase wood production, which if sustainable forestry is implemented, could be a positive change. However, for wood to be a viable replacement material in a broad range of contexts, we need to develop new ways of processing wood in order to produce new physical features of the final material. Identifying and exploring these new processes and physical features is the main goal of this project.

Key objectives for aesthetics and quality

Expanded Wood is distinguished by a characteristic, oblong, hexagonal pattern of the mesh, which was shaped by the laws of physics and geometry as well as the hand and eye of the designer.

The material, with its openwork structure, is satisfactory both to use and to look at. Due to its rhythmical complexity it seems to look a bit differently every time we look at it. Depending on an angle, light or background the structure appears very openwork or nearly solid. Sometimes the grid seems oblong and sometimes it looks almost square. The thickness of the panel seems to change too. The unique form of the mesh originates from two revolutionary inventions: expanded sheet metal, invented in 1883 by John F. Golding and honeycomb panels created in 1890 by Julius Steigel. The grids developed by these two inventors were confronted with traditional Slavic and Scandinavian crafts and patterns, which inspired the final shape of Expanded Wood.

Key objectives for inclusion

Expanded Wood has a strong haptic quality, which can be appreciated by eyes as well as hands or other parts of the body. It makes its beauty accessible for people who are blind or visually impaired. Due to its haptic quality it's also more engaging for children.

The mesh is perceived by the body as a rather pleasant texture, with the pattern’s regularity giving the material a special haptic quality. The hexagonal mesh encourages touching. The eyes are not enough to recognize the complex geometric shapes of the openwork. People want to experience it with their hands no matter if they can or can't see and quickly begin to wander over the clearly defined surfaces. The fingertips slide along regular borderlines of the meshes, experiencing planes, edges and vertices.

Results in relation to category

Expanded Wood is an alternative to openwork panels made of plastic, metal or concrete, used in the construction, furniture, exhibition and interior finishing industries. It can also replace structures made of wood and wood-based materials, which are currently produced in a less material effective or more labor intensive ways.

Expanded Wood has a number of physical features with practical applications. The curvilinear edges of the mesh give the surface sharpness, which provides anti-slip properties. The folded planes of the openwork structure refract acoustic waves, increasing the noise absorption capacity of the wood. Due to its mechanical properties, Expanded Wood can serve as both a construction and finishing material. Such a panel would be an alternative to the honeycomb hollow boards used for the large scale production of furniture and doors. The resulting material would have greater mass, mechanical strength and acoustic absorption, which would translate into higher quality products. New possibilities are also offered by partially or completely filling the openings with elements cut from other types of wood or cork. The fillings could also be made of natural hardening masses with various properties. In this way, the openwork structure can be transformed into a solid panel which, thanks to the merge of two different materials, will have a rare or previously unknown combination of properties. The material is now in the process of commercialization.

How Citizens benefit

Expanded Wood, a sustainable and more efficient material, is a solution to the problem of dwindling natural resources like wood on one hand, and the consumers’ demand for natural materials on the other.

According to the Food and Agriculture Organization of the United Nations, global wood consumption is constantly increasing. In 2018, almost 4 billion cubic meters of wood was harvested for production. This is 3% more than in 2017, 14% more than in 2000 and 27% more than in 1980. The FAO does not predict an inhibition or slowdown in growth trends in the near future. On the contrary, production and turnover within the wood industry are to continually increase. These numbers translate into billions of trees and thousands of hectares of forests that are cleared each year. Forests still cover about a third of the globe, but before the industrial revolution, they accounted for nearly 45% of the planet’s surface. This is why we need to make better use of what is left. Expanded Wood, allows to increase width of wooden board by 25% providing a more effective way of using timber.

Innovative character

Expanded Wood is the first structurally sound honeycomb material made entirely out of wood with very little material waste and labor.

Reducing raw material usage and weight of wood-based materials is an emerging need, which is currently satisfied by openwork or sandwich, honeycomb panels. Openwork panels of wood and wood-based materials used in construction, furniture, exhibition and interior finishing industries are made in two ways. The first involves removing material from a solid plate, for example by drilling or milling openings, which involves large losses of the material. The second method consists in crossing the longitudinal elements arranged in parallel in at least two layers, which forms a truss. This method results in low material wastage, but is laborious or requires complex instrumentation. The most popular sandwich, honeycomb panels, when used for example in furniture or door production require a combination of materials, which makes them harder or even impossible to reclame. Expanded Wood addresses all these issues. It is easy to produce, made entirely out of one renewable material and zero waist.