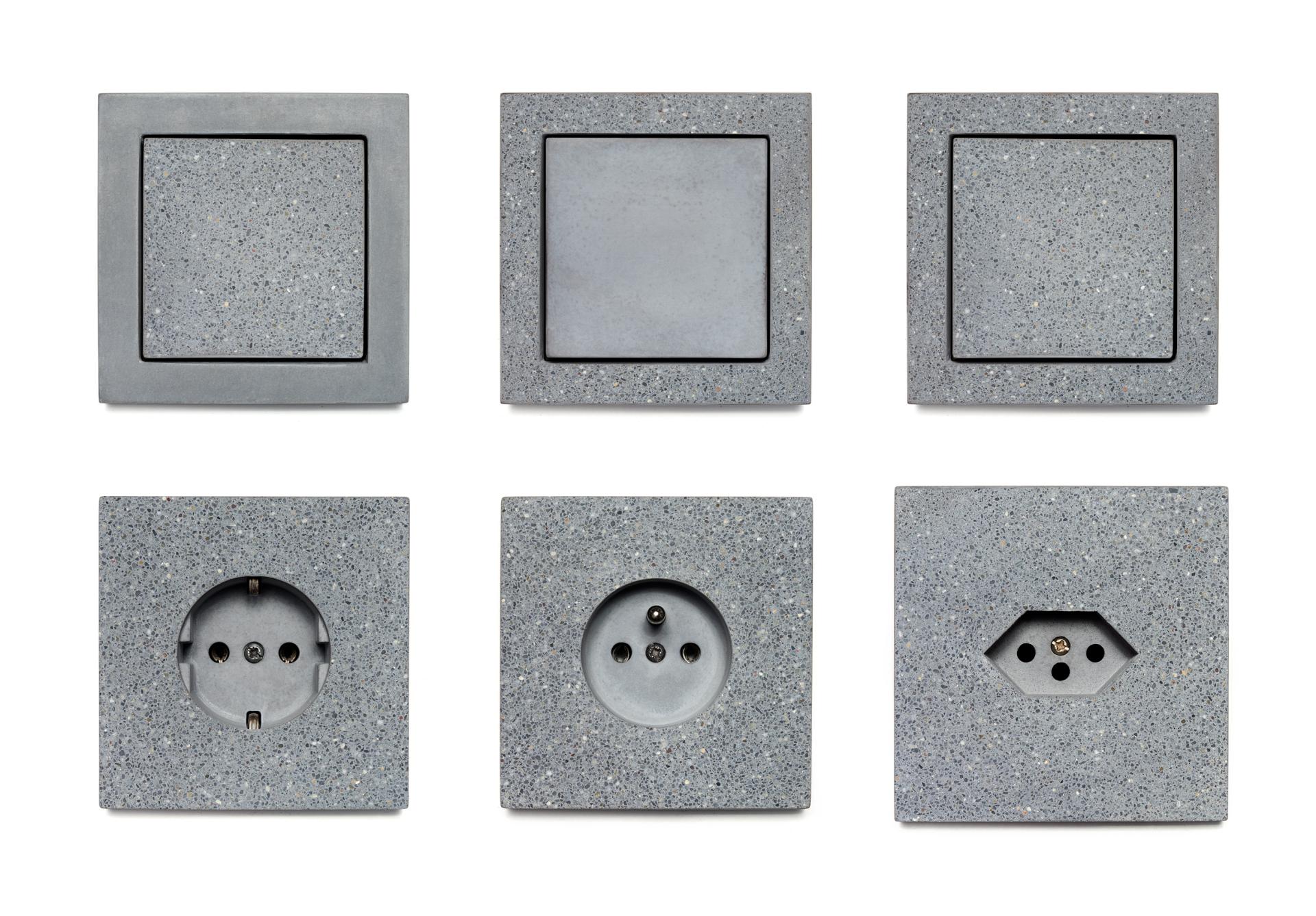

Silicate switches and sockets

Basic information

Project Title

Full project title

Category

Project Description

These products combine the benefits of modern minimalist design with the humanity and purity of the handcrafted process.

- Perfect fit, in harmony with all wall surfaces,

- Fine to the touch

- Unique, individual, arty

- Handcrafted and diverse

- More sustainable than plastic

Project Region

EU Programme or fund

Description of the project

Summary

Concrete switches and sockets had to exist already, so we thought initially. It seemed such an obvious idea. But we couldn’t find them anywhere. We thought they would look and feel fantastic, so we created them. You can now find the very first completely concrete cover of switches & sockets. Made from only silicates, more sustainable, more beautiful.

Why concrete?

Concrete is an electrically insulating and fireproof material. It is easy to shape.

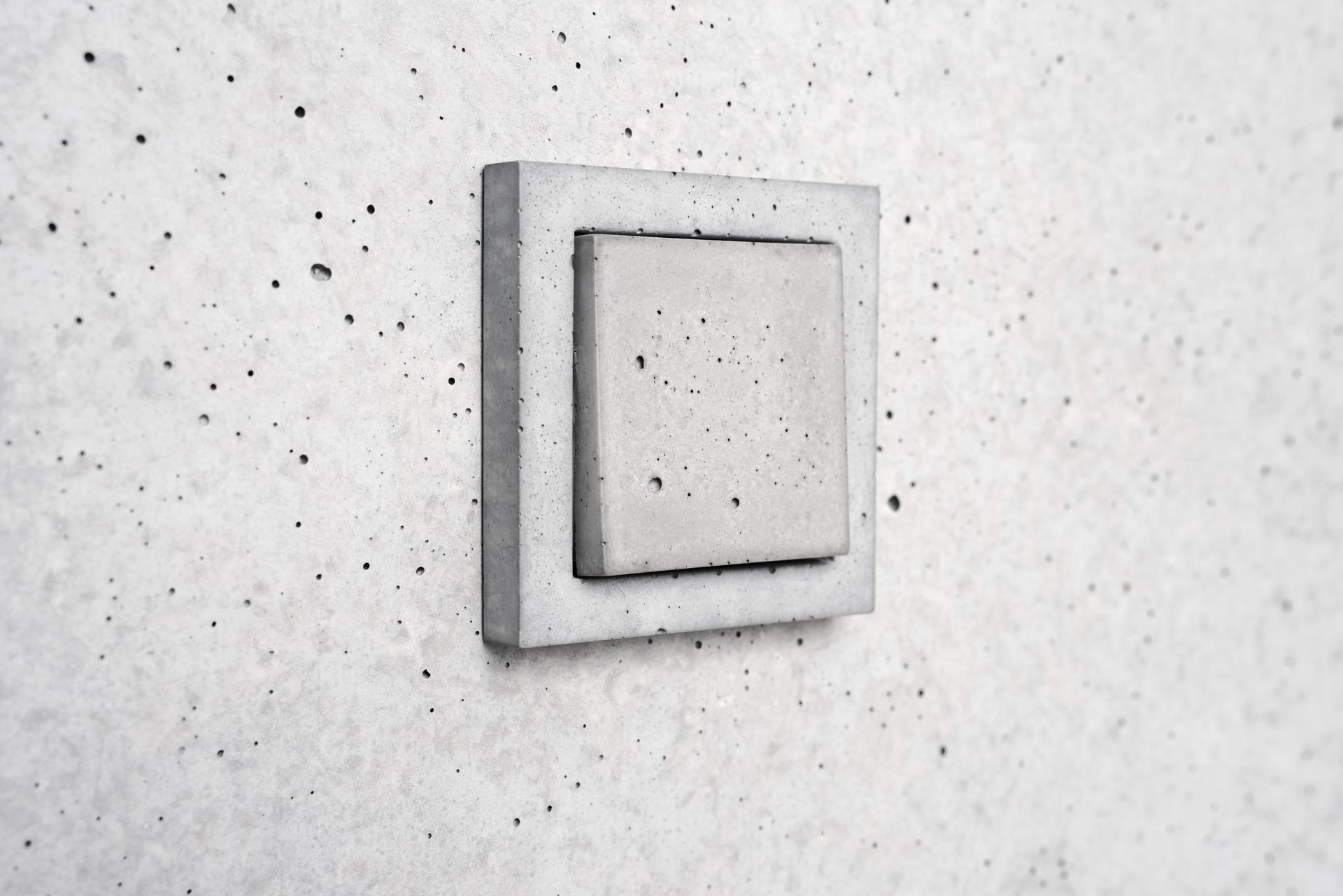

Perfect fit, in harmony with all wall surfaces

A piece of plastic on the wall can be bizarre, sometimes quite terrible. Interior designers very often try to hide switches and sockets as they blunt the general aesthetics of their work. But, they‘re functional, useful objects. If we have to search for a long time to find them and posture freaky poses to use them - that’s not too comfortable. The answer is concrete.

Unique, individual, arty

The surface bubbles and blots make up a distinct, unique object with an individual character and personality. If you look closely at our polished Mini Terrazzo surfaces, a lively, colourful, and abstract world opens up. We hate monotony. There is not one piece the same as another.

Durable, well-built and easy to clean

We work with the finest, purest materials to use high-performance concrete. We infuse all items with an eco-friendly water-repellent agent that is invisible on the surface. Stains and grease of any kind are easy to clean from the switch or socket.

We make just the concrete covers and fit them over safe, well-known, industry-standard electrical mechanisms made by trusted name-brand manufacturers. These products are certified and follow the rules.

Key objectives for sustainability

More sustainable than plastic – We say no to carbon dioxide!

We know that the plastic materials of switches and sockets make up a very low percentage of global plastic pollution, but we think that all of the tiny steps to create a more sustainable future are remarkable. We are very proud that we can offer a better alternative although we know that concrete can harm the environment as well. We do not use artificial resin nor pollutant additives. We just call it a "stone to stone" product.

Our products contain only 25% of cement at most, and we use a specially developed concrete recipe that is free of synthetic resins and contaminants, reducing the use of toxic substances significantly. Compared to plastic, our products truly represent a more sustainable choice.

“To completely neutralize our carbon footprint, we will be planting trees in cooperation with an environmental organization and get advice from environment-protection specialists before starting mass production to ensure that our impact on the environment can be completely neutralized. Our R&D team will be experimenting with other sustainable materials as well to expand the diversity of our product portfolio," says Gabor Kasza, CEO of Sekhina design company.

When we enter the market, we will be operating in accordance with the Triple Bottom Line model. Ethical and environmentally friendly operation is the most important for us.

Key objectives for aesthetics and quality

Handcrafted and diverse

The handmade manufacturing way is not an anachronic technology. It has many advantages. Easy to create almost anything that the customer wishes for, even in small batches. We can make many varieties, use many colours. This process allows us to tailor the perfect fit combination to any interiors.

The product development model is similar to the model used in the automotive industry in that we use parts developed and manufactured by other manufacturers and draw our own design ideas on it. This makes it more spectacular, faster to grow, more diverse, and faster and cheaper to respond to market expectations.

Key objectives for inclusion

Fine to the touch

How many times a day do you touch light switches? Physical contact with objects has a physical effect on our body, and consequently, on our soul. If you feel it is better to wear a natural silk scarf than a nylon one, prefer to use glass in contrast to a plastic cup and you can feel the difference between the perfume of flowers compared to a cheap toilet fragrance, then surely you will appreciate our products.

Results in relation to category

We have made a market research campaign when stepping out our invention to the highlight for the first time. It was very successful we get many positive feedbacks and found many potential distributors and partners and we get many inquiries and request until now as well.

We got very strong media publicity.

Some samples:

https://www.designboom.com/design/sekhina-concrete-switches-sockets-06-25-2020/

https://www.dezeen.com/2020/07/07/sekhina-concrete-light-switches-plug-sockets-design/

https://www.baunetzwissen.de/beton/tipps/news-produkte/design-bis-ins-detail-7379427

https://www.stylepark.com/en/news/sekhina-concrete-switch-sockets

https://www.whitemad.pl/betonowe-kontakty/

How Citizens benefit

Some people helped us to develop the product as early adopters.

Innovative character

These products combine the benefits of modern minimalist design with the humanity and purity of the handcrafted process. As a natural substance, concrete is a more sustainable alternative compared to plastic, more beautiful, more diverse.

This is the first project that starts to use a new type of material in this industry and use completely concrete!