Ignorance is Bliss Ceramic Tiles

Basic information

Project Title

Full project title

Category

Project Description

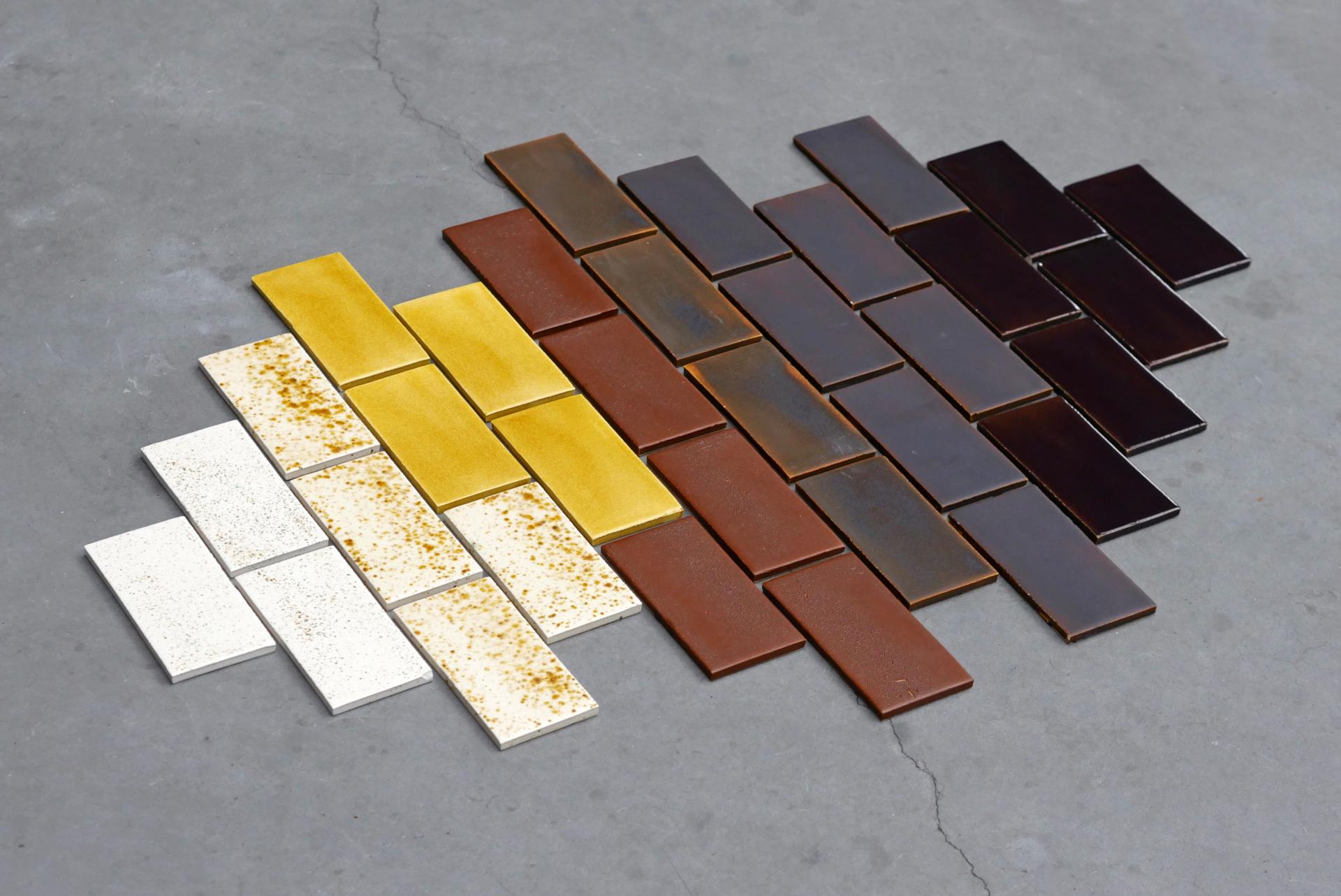

Ignorance is Bliss ceramic tiles are glazed using pigments solely derived from industrial metal waste and by-products. Usually, these metals would be mined and undergo excessive processing. Drinking water supply and soil remediation industries, which produce thousands of tons of residue per year and are the main suppliers of metal waste for Ignorance is Bliss ceramic tiles. The collection of 20 selected colours is the result of years of extensive research and experimentation.

Project Region

EU Programme or fund

Description of the project

Summary

Ignorance is Bliss ceramic tiles are glazed using pigments solely derived from industrial metal waste and by-products. Usually, these metals would be mined and undergo excessive processing. The amount of waste in the glaze is up to 40%, as ceramic glazes are a combination of base transparent glaze and pigments. Drinking water supply and soil remediation industries, which produce thousands of tons of residue per year and are the main suppliers of metal waste for Ignorance is Bliss ceramic tiles. The collection of 20 selected colours is the result of years of extensive research and experimentation. During the production process, each tile is touched by human hands around 9 times, leading to slight irregularities and subtle variations in shades. The collection has a distinctive look and feel and is intentionally formulated without poisonous lead and barium, which typically are common choices for bright colours. Designed with a responsibility to human and environmental health, Ignorance is Bliss ceramic tiles are on the way to becoming fully circular.

Key objectives for sustainability

I collaborate with Aquaminerals (secondary raw materials originating in the water cycle), which have access to drinking water plants across the Netherlands. Each plant generates around 10 tons of iron sludge a month. My other partner Theo Pouw is located in Weert and remediates the soil by extracting metals in different ways, such as using magnets or hydrocyclone separation machine. Soil remediation company generates around 30200 tons of metal waste per year. Part of it is used in the concrete industry to build the roads. Other part goes to metal dumpsters, but more and more dumpsters refuse to take the waste. The amount of waste material accelerates if depicted from a global perspective. Hereby, those companies are facing difficulties with the disposal. My research and development show that those metals can be adapted and used in the ceramics industry.

Reusing waste, such as in this project, decreases the need for natural resources, reduces environmental pollution, and allows materials to be used to their fullest extent. The industrial metal waste from the diverse locations is sent to the factory, where the preparation of pigments, production, and packaging to the client is done within the facility. The 'Albarello' tile factory has similar values as mine and produces adopting zero waste principles. All their waste of defective tiles is collected and stored. We are setting up plans to integrate this waste into the clay as a further step to make my product even more circular. In order to save energy, we are focusing on the low-temperature firing of 1060 C versus 1260 C.

Key objectives for aesthetics and quality

Ignorance is Bliss ceramic tiles project focuses on sustainable glazing techniques while enabling further focus on craftsmanship, which requires professional skills. Starting with my education, continuing with highly research-based work, a rigorous selection of partnerships, and aesthetics, I made sure that this project can be considered of the highest quality. The collection of 20 selected colours is the result of years of extensive research and experimentation. Being limited with metal waste sources, I managed to create a diverse colour palette for tiles. The collection has a distinctive look and feel and is intentionally formulated without poisonous lead and barium, which typically are common choices for bright colours. My customers are interior designers and architects who design projects with awareness and understand the value of this exceptional product. In this project, surprisingly, the more contaminated the raw material, the more vibrant the designed objects are. Factory-made tiles, coloured 100% using industrial metal waste were already successfully integrated into the restaurant interior De Republiek in Bloemendaal by Anne Claus Interiors, and other projects.

Each decision regarding size and shape is made to be most energy- and cost-efficient. The various tile sizes are adapted to the current factory production setting, so the tiles can be cut using existing knives and dried before firing, which allows an unlimited stock. In addition, the current sizes lead to tiles being placed in cassettes saving a lot of space during firing. Classic square and rectangular shapes save the most space, limit the occurrence of defects, and are best for handling and efficient logistics. Within the production, each tile is touched by human hands around 9 times, thus leading to little irregularities and subtle variations in shades.

Key objectives for inclusion

Ceramic tiles are part of Ignorance is Bliss brand, where theoretical and material research is conducted, waste and secondary raw materials are upcycled, and which encourages collaboration between industries, designers, environmentalists, scientists, architects, and manufacturers. Drinking water supply and soil remediation industries are the main waste suppliers for ceramic collection. Tile manufacturing facility aims to produce implementing zero waste principles. With the type of projects like mine, closer collaboration is required. Ceramic production is very sensitive and the results differ from small ceramic workshop to factory production. In order to deliver good, balanced results hundreds of tests are repeatedly required.

Results in relation to category

The abundance and prevalence of waste and by-products allow exploration and experimentation. As a result of thorough research, such salvaged materials are repurposed into interior and exterior products of high quality and value. Ignorance is Bliss ceramic tiles are glazed solely using pigments derived from industrial metal waste and by-products whereas usually these would be mined and undergo excessive processing. Upscaling is significant to the project, while not solely relying on industry standards and maintaining a balance with crafts. Generational architectural products adopt responsible production methods and give a new identity to space. My intention is to create products that are functional, aesthetically pleasing, and designed for greater longevity.

How Citizens benefit

The sustainable approach of the project is seeking an active involvement of manufacturers and craftsmen, and hereby maintaining, evolving, and applying their skills in a cross-industrial context. Moreover, this project is oriented towards the circular economy, which creates social responsibility and targets consumers who want to make a positive difference with their purchase decisions. The project's broad visibility and ongoing education of the customer incorporate and underline further benefits of my approach.

Innovative character

Metal waste could be categorised as toxic and non-toxic. Toxic waste is difficult to recycle and most of it is stored at special depots. It is not common knowledge that ceramics is glazed with toxic materials. Once fired at high temperatures the glaze becomes glass, the chemical structure changes and there is no way for toxicity to leak if the glaze is balanced. The only way to change the toxicity is to “lock” it in the material. My project confirms that we can replace industrially made ceramic pigments with the ones from metal waste, avoiding mining in this industry. The composition of metal waste I use is almost the same as industrially produced colour pigments. At the moment I am working with iron, manganese, and metal mix waste from diverse industries and processes. Surprisingly, the irregularities present in residue lead to more vibrant design objects.