Natascha von Hirschhausen

Basic information

Project Title

Full project title

Category

Project Description

Our zero-waste fashion label Natascha von Hirschhausen stands for easy, elegant designer fashion produced locally on demand in Berlin in a radically sustainable and innovative manner - always aiming to set the benchmark for sustainable fashion.

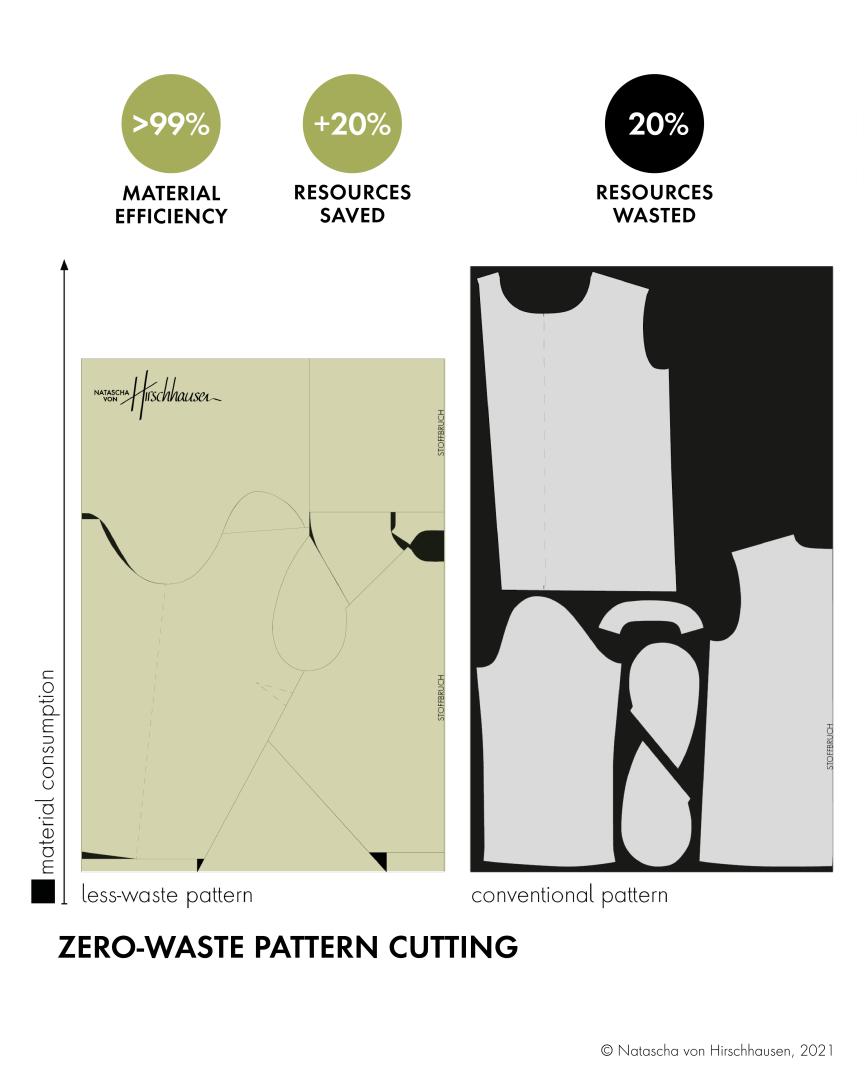

Our zero-waste innovation saves around 20% of resources and the cutting process of each garment with more than 99% of material efficiency. All garments are made of natural, organic and fair materials in every component - for a wasteless future.

Project Region

EU Programme or fund

Description of the project

Summary

Our company Natascha von Hirschhausen stands for radically sustainable fashion.

Thanks to our zero-waste pattern-cutting design, the entire fashion collection is produced with less than 1% waste. With this design innovation, about 20% of resources can be saved in cutting alone compared to all conventionally produced garments.

In addition, all components of our garments are made of purely natural materials, which are audited annually along the entire value chain for ecological and social sustainability - from the main material to the care-tag and the packaging.

We also focus on waste-free solutions in fashion retail through innovative made-on-demand and pre-order systems.

Design is the key to sustainability. Only garments that are worn with pleasure for a long time can be truly sustainable. That is why we create sophisticated, minimalistic garments with size-fluent tailoring and a unique design.

Key objectives for sustainability

With our zero-waste fashion brand we aim to raise the bar and set the benchmark for sustainable design.Every decision is based on the idea of finding the most sustainable solution, resulting in a truly holistic concept. Since not every detail of our complex sustainability agenda can be discussed here, let us introduce the most important and unique ones:

HOW WE AUDIT THE SUPPLY CHAIN FOR ALL COMPONENTS: MATERIALS

In the textile industry, over 60% of the materials used are oil-based. Less than 1% of cotton is organically grown. We use 100% organically grown and fair materials for our entire collection. All components are sustainable, fair, plastic-free and biodegradable. Strictest certificates, such as GOTS and IVN Best, as well as additional Fairtrade agreements ensure the environmental and social sustainability of our materials along the entire value chain - from the main fabric to the care-tag.

HOW WE SAVE 20% OF RESOURCES: ZERO-WASTE DESIGN

The entire fashion industry causes about 20% material loss per garment due to offcuts in the cutting of clothing alone. These scraps are usually burned or thrown away, which means that a fifth of all resources are wasted in this process alone - even with sustainably produced materials. To avoid this immense waste from the outset, we developed our innovative zero-waste cutting technology with less than 1% waste. Thanks to this innovation, the production of our items saves around 20% of resources per cut and causes less than 1% of waste.

Beyond production, the key to sustainability lies in design, as only garments that are worn long, often and with pleasure can be truly sustainable. That's why we pay special attention to a perfect fit, which we guarantee by working with curves in the pattern in a complex way - for a wasteless future.

Key objectives for aesthetics and quality

DESIGN IS THE KEY TO A SUSTAINABLE FUTURE

Beyond production, the key to sustainability lies within the design, as only garments that are worn long, often and with pleasure can be truly sustainable. Therefor our collection stands for minimalist, versatile design with a unique and long-lasting form. The whole collection ist handmade locally without causing waste in the production or the retail, which adds additional value to our sophisticated design.

In true tradition of the Bauhaus we search for the "Gute Form“ meaning for well-designed items, that are true to their use. Our fashion is created to be used for a long time and to empower the people and their active lifestyles.

Our new rationalism combines high-end sustainable materials, with a local zero-waste handcraft production and timeless minimalist design. Our garments come to life on the body and are created in a size-fluent way, meaning it will fit even if the body changes - for a wasteless future.

Our fashion embraces the people, who wear them, not the other way around.

Key objectives for inclusion

HOW WE EMBRACE EVERY BODY

We stand for body positivity and size-inclusiveness. Our size-fluent design embraces every body. No one has to fit in a number or has to worry about not having the „right“ size anymore. In the buying process this stigmatization is taken away and even more our garments are created to grow with you, no matter how your body changes:

One dress, for example, will fit all body types from size 34-48.

Some people feel stigmatized by having to buy a bigger size. Some worry, if their carefully chosen clothes might not fit anymore if they gain or loose weight. This focus on weight is not healthy. Feeling good in your own body is the key to feel welcomed within society. This focus on weight has to end. For us it means the focus on the numbers and sizes has to end. Size-fluent design is our answer to well-being and inclusive fashion design.

We go beyond offering every size. We lift the emotional weight off by neglecting sizes wherever possible. To embrace all different body types and for a wasteless future.

Results in relation to category

FOUR HOLISTIC APPROACH TO RETHINK AND REINVENT THE BUSINESS OF FASHION

Everything we do at Natascha von Hirschhausen is under the premiss of raising the benchmark for sustainable fashion.

Sustainable fashion design starts with the choice of fabric. Two thirds of all garments in the conventional fashion industry are made from petroleum. This leads to a massive pollution of our oceans with micro plastic. 35% of micro plastic originates from the textile industry. We on the other hand love the distinctive quality of natural materials and only use plastic-materials like e.g. cotton and wool. All components of our garments are organic and audited annually along the entire supply chain for high social and ecological standards.

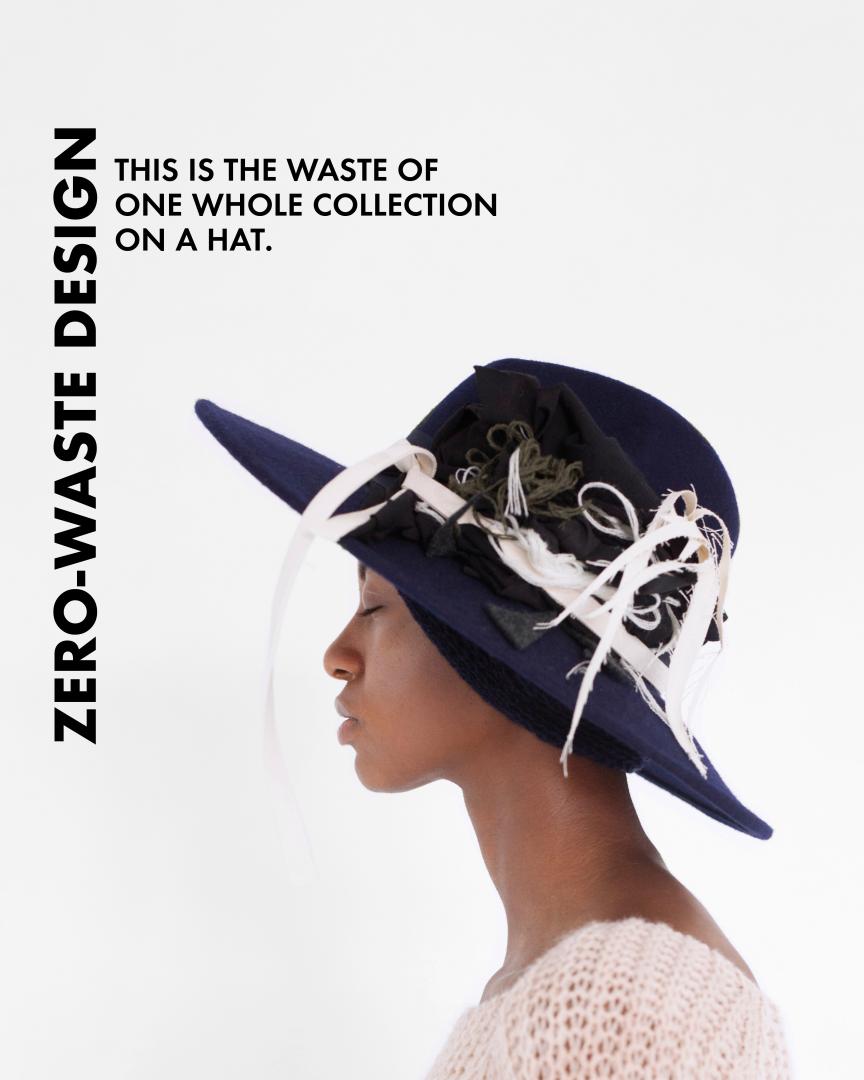

OUR ZERO-WASTE DESIGN

Usually the process of cutting a garment causes an average material loss of 20%. Thanks to our innovative zero-waste pattern-cutting technique, we reduce these clippings to less than 1%.

Using our pantsuit as an example, we illustrate the clear advantages of our innovation: We need 3.80 m2 of cotton for a pantsuit. A conventional suit, on the other hand, uses about 5.18 m2 of material. In comparison, we thus save about 26% of the material for our suit, which means that 1.29 m2 of material are saved for each cut of the zero-waste suit. The waste from conventional cutting corresponds to about 0.31 kg of cotton material per cut. Therefore, at least 0.31 kg less cotton must be grown for our pantsuit. Zero-waste cutting thus saves 2.3 m2 of cultivation area per suit. In addition, 3410 litres less water are used per suit.

To illustrate the strong leverage of our zero-waste cutting technology: let's assume that a large fashion company would switch the production of its cotton products to zero-waste cutting. With a production volume of about 1.6 billion garments and a cotton content of 35%, this means a saving of 180,000 tons of cotton, 130,000 ha of arable land and 2 Billion m3 of water.

How Citizens benefit

WASTE AND RESOURCES HAVE AN IMPACT ON ALL OF US

In the last two decades the textile industry has doubled the production and global annual consumption of textiles has doubled from 7 to 13 kg per person and reached to the threshold of 100 million t of textiles consumed per year leading to a massive waste problem.

All garments produce about 20% of offcuts during the production process. Therefore about 20 million t of waste originate from the cutting of the garments alone. With our innovative zero-waste cutting technique we reduce this waste to less than 1% saving up to one fifth of resources per cut. Unlike minimising the symptoms like many recycling projects do, we tackle the core of the waste problem with our zero-waste designs.

Even before the Corona pandemic, at least 230 million unsold textiles per year were burned, shredded or shipped abroad as cheap goods in Germany alone. This is a huge waste of resources and labor and therefore also capital of the companies. Our garments are made-on-demand, so no piece gets wasted. We produce our collection locally and on demand, this way we can shape the retail of clothes in a future proof manner and add on to our zero-waste concept.

Since the disposal of waste as well as a lot of recycling yards are funded by the public, every citizens benefits by avoiding waste in the first place. Furthermore we can not ignore the challenges we will face in the 21st century any longer. We know, that every citizen will benefit, if we reduce waste and the consumption of resources (1-earth!).

Wasteless future means, we are fighting to have one for our children. That concerns everyone!

Innovative character

With our zero-waste fashion brand we aim to raise the bar and set the benchmark for sustainable design. For us this means to make every decision based on the idea of finding the most sustainable solution, resulting in a truly holistic concept. The most important and innovative topics are:

TRANSPARENCY & MATERIALS

Transparently on the website you will find all information about every component of our garments. All fabrics and trims we use are audited along the entire value chain of social and ecological sustainability and we let our costumers know.

ZERO-WASTE DESIGN SAVES ABOUT 20% OF VALUABLE RESOURCES

Our production innovation in zero-waste cutting technology proves potential for immense savings in resource consumption and waste avoidance. With less than 1% waste in the cutting of the garments, we can produce our entire collection with virtually no waste. Using our pantsuit as an example, we illustrate the clear advantages of our innovation: We need 3.80 m2 of cotton for a pantsuit. A conventional suit, on the other hand, uses about 5.18 m2 of material. In comparison, we thus save about 26% of the material for our suit, which means that 1.29 m2 of material are saved for each cut of the zero-waste suit. The waste from conventional cutting corresponds to about 0.31 kg of cotton material per cut.

At least 0.31 kg less cotton must be grown for our pantsuit. Zero-waste cutting thus saves 2.3 m2 of cultivation area per suit. In addition, 3410 litres less water are used per suit. In line with these figures, we also save significant amounts of energy, pesticides, herbicides, dyes and other factors in the further processing of resources per item, which are used to a considerable extent in conventional textile production. We therefore contribute to saving CO2 and avoiding environmental damage - for a wasteless future.

A holistic sustainability concept plus the innovative zero-waste pattern cutting make our company unique on the market.