MTWO 6D Sustainability Platform

Basic information

Project Title

Full project title

Category

Project Description

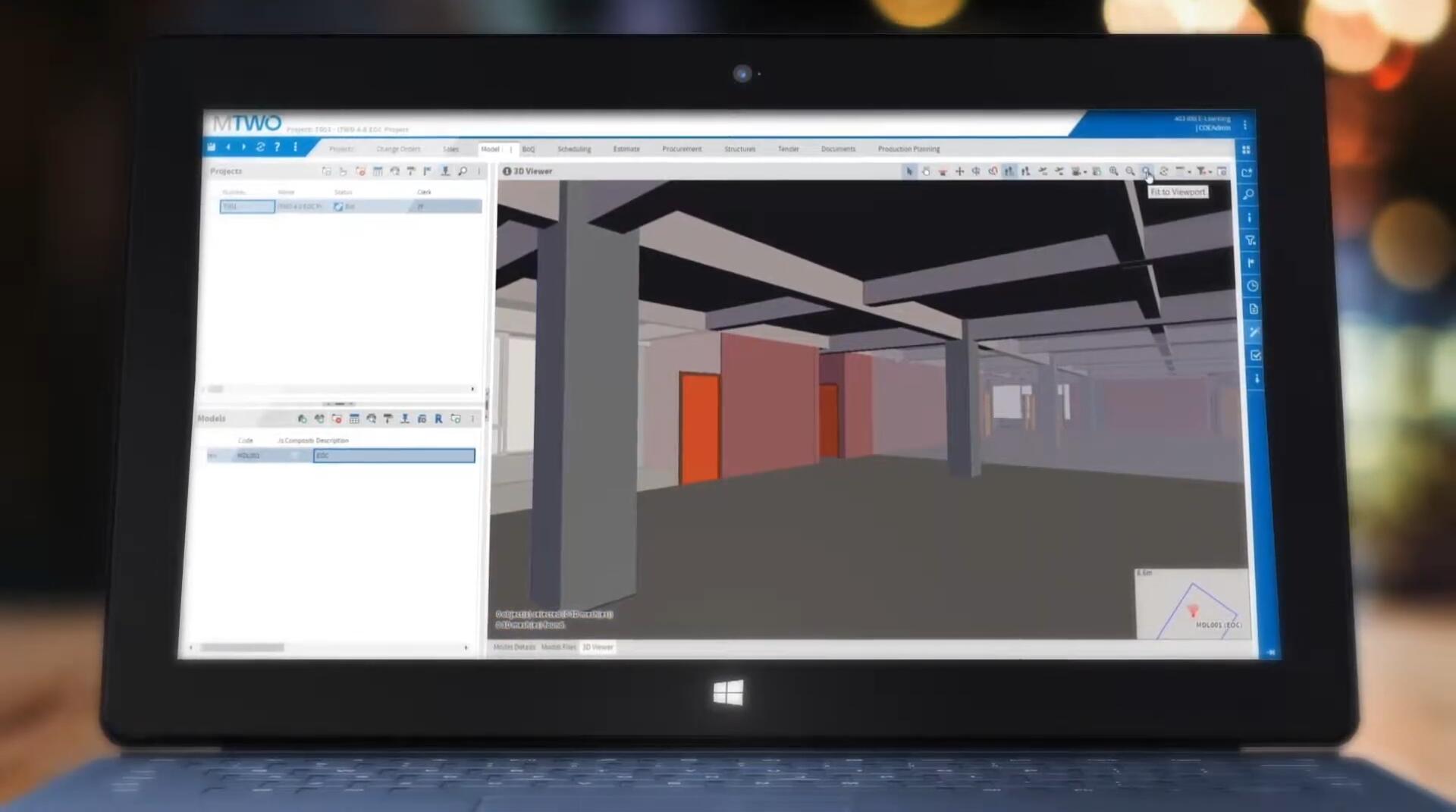

MTWO is a 6D digital platform for the sustainability of the Architecture, Engineering, and Construction (AEC) industry. It is the world’s first digital construction platform equipped with AI integration that connects 3D design model with 4D project time, 5D cost, and 6D sustainability. Teams can first build the entire project lifecycle virtually, the physical construction then follows the virtual building process, improving sustainability and productivity while reducing waste.

Project Region

EU Programme or fund

Description of the project

Summary

MTWO is a 6D digital platform for the sustainability of the Architecture, Engineering, and Construction (AEC) industry. It is one centralized platform for all building stakeholders to collaborate at every phase of the building process, calculating and monitoring all carbon data from all stakeholders. The lifecycle of a building project can be virtually simulated in 6D BIM (3D design model + time + cost + carbon), and the finished model serves as the basis for efficient physical construction and facility management. All teams and processes work from one single source of data.

MTWO is developed by RIB Software, a German company headquartered in Stuttgart with 60 years of history. The solution has been supporting general contractors, project owners, real estate developers, and specialty contractors to build efficiently and sustainably.

In the age of digitization, the Bauhaus movement is gaining new importance. To this end, RIB Software launched the Bauhaus 4.0 initiative under the direction of its CEO Tom Wolf, aiming to turn digitalization into art to solve the pressing challenges of the 21st century, climate change in particular, in harmony with technology, art and craft. In 2019, on the occasion of the 100th Bauhaus anniversary, RIB awarded the Walter Gropius Prize for the first time to thought leaders and visionaries who have had a formative influence on life in the 21st century.

Key objectives for sustainability

The Engineering and Construction (E&C) industry account for 39% of energy-related carbon dioxide emissions annually. For the industry to achieve an eco-friendly future, digital transformation must be at the heart of the industry to transform how buildings are planned, built, and operated.

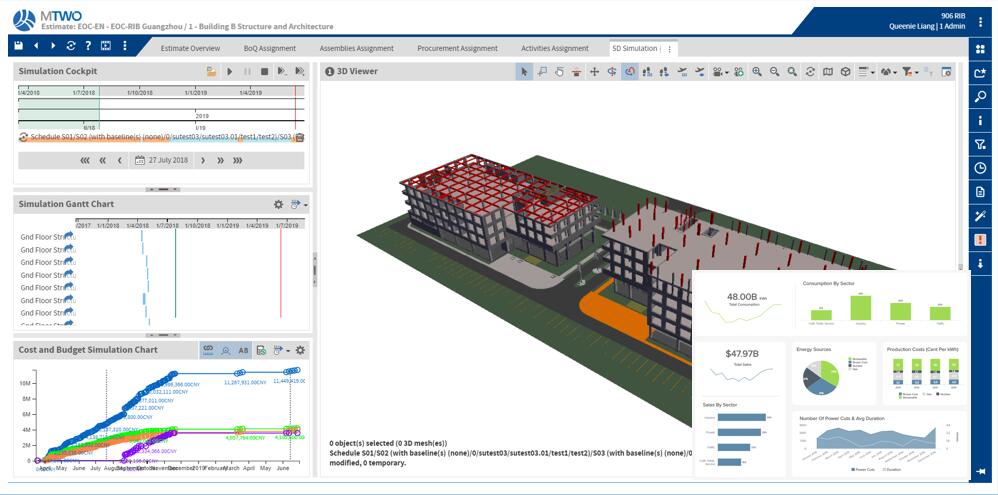

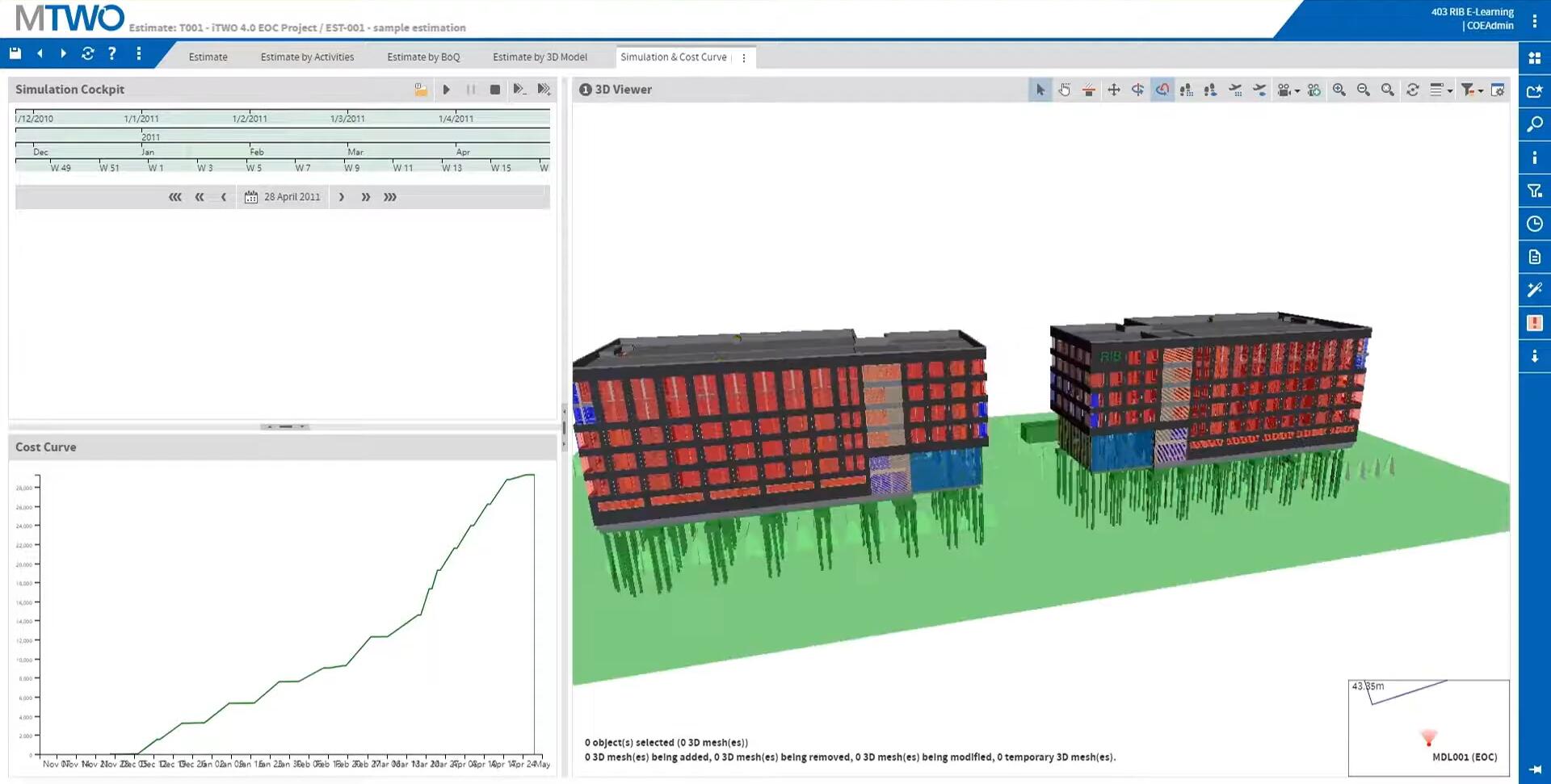

- Physical-Follows-Virtual: For 60 years, RIB Software has been the pioneer for innovations in the E&C industry with the mission of transforming construction into the most advanced and sustainable industry. RIB’s MTWO platform virtually simulates the entire life cycle of building projects in 6D BIM - connecting the 3D design model of a building project with the time factor (4D), cost (5D), and carbon factor (6D). This makes it easy for teams to know the building design, timeline, materials, workforce, and carbon emission calculations before a shovel touches the ground.

- Digital Twin: The virtual simulation creates a digital twin for sustainable construction and facility management. In the physical construction phase, the carbon performance is tracked by comparing it with the planed numbers in the digital twin. The master data from the planning and construction phase is transferred to the operational phase to continue tracking the carbon emission performance, enabling projects to significantly cut waste.

- Intelligence Supply Chain: Every aspect of the supply chain is planned in MTWO from the very beginning. Green building materials are selected in the planning phase, empowering projects to achieve the most optimized time, resource, and carbon footprint outcome.

- One single source of data: All project phases are interconnected with one single source of data, allowing the platform to automatically analyze all aspects of the project data, generating key metrics, including the carbon aspect, for informed decision-making.

Key objectives for aesthetics and quality

“The ultimate goal of all art is the building!” The Bauhaus school attempted to unify the principles of mass production with individual artistic vision and strove to combine aesthetics with everyday function. The basic rule of the Bauhaus Manifesto is that Form follows Function. It is about products being functional and unique.

- Physical Follows Virtual: For the Europe-born MTWO platform, it is about Physical Follows Virtual – first build virtually to create a digital twin, then build physically following the digital twin. As a key step in the preconstruction phase, MTWO creates a lifelike virtual building process for everyone involved in planning, execution, and operation phase, enabling teams to explore design alternatives, promptly compare, test complex scenarios, and predict the consequences of selecting a plan across factors such as aesthetics, time, cost, and carbon emission. This ‘Physical-Follows-Virtual’ process triggers creativity, optimizes design and maximizes resources.

- Improve the image of industry professionals: The construction industry is still considered the so-called “brick and mortar” industry. Adopting digital technology not only accelerates the speed of transformation of the industry, but also elevates the image of the industry professionals, from quantity surveyors, estimators, bidding and tendering teams, procurement managers, to site members.

- The only existing software for enterprise digital transformation: MTWO is the only existing solution Europe-wide that can help E&C companies to digitally transform their business and projects with one single platform.

Key objectives for inclusion

Conventional point solutions are not able to cover the full construction lifecycle. They only operate one or a few domains of the whole building project lifecycle. Organizations utilizing these point solutions do not have the data connectivity to include all teams in one place.

MTWO connects all stakeholders, processes, and data in one place. The construction lifecycle is all connected by the data flow in the cloud. One team’s data can support other teams in the platform, bringing enhanced collaboration early on.

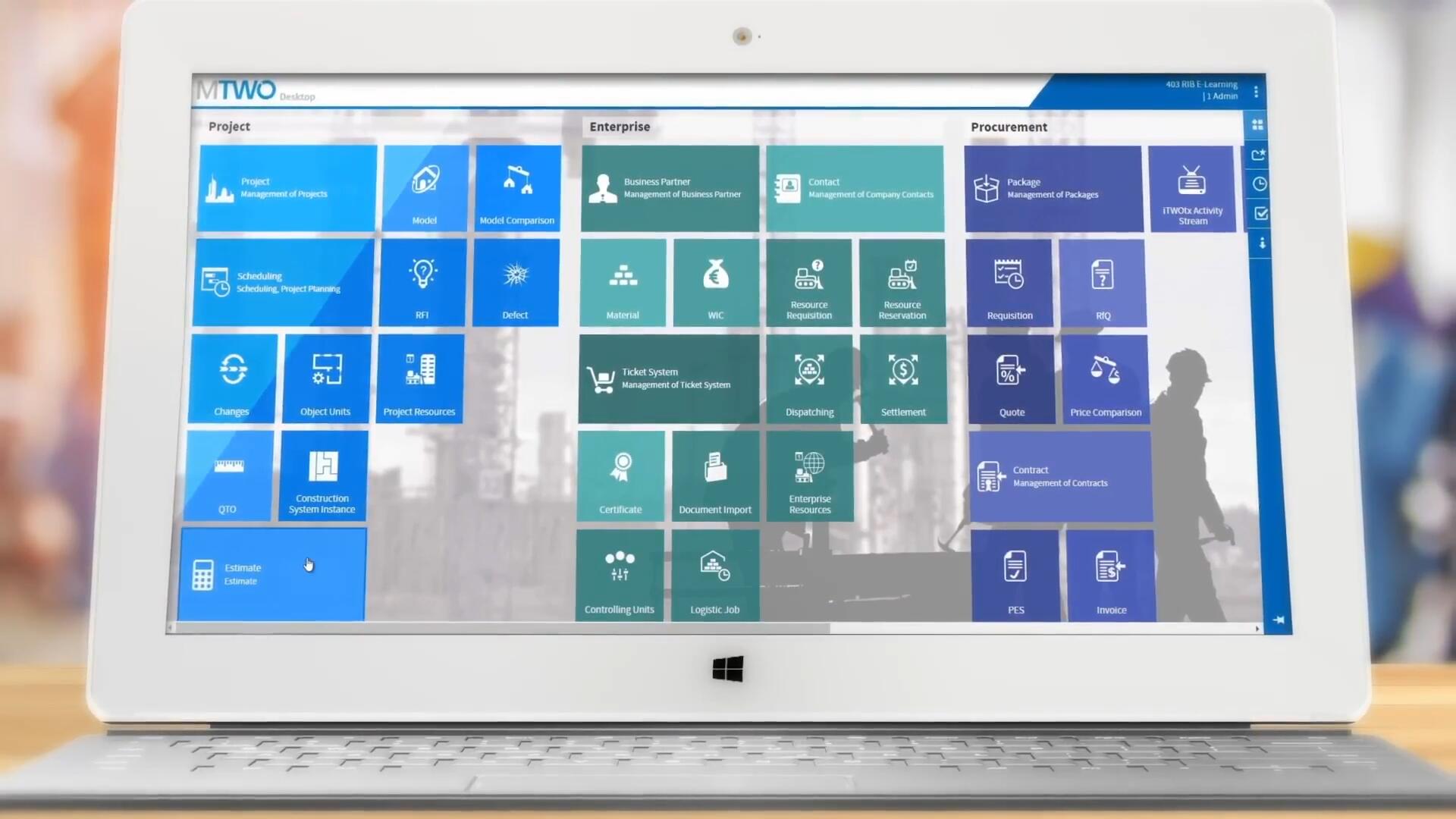

All teams collaborate on one complete construction cloud using one set of data, for example:

- The predefined quantity take-off logic of MTWO helps Quantity Surveyors to calculate the carbon emission with model visualization.

- Using MTWO’s enterprise master data, estimators can easily calculate the carbon credit with the results from quantity takeoff.

- Procurement managers can valuate material suppliers with the pre-set rules in the system to work with the most ESG compliant suppliers.

- With data from the estimation team, schedulers can create reliable schedules to reduce material waste and carbon emission.

- With the one single reliable source of data, project managers can systematically track project progress and carbon emission.

- MTWO’s mobile applications support field teams to collect and report information through mobile phones, which reduce transportation between jobsite and office.

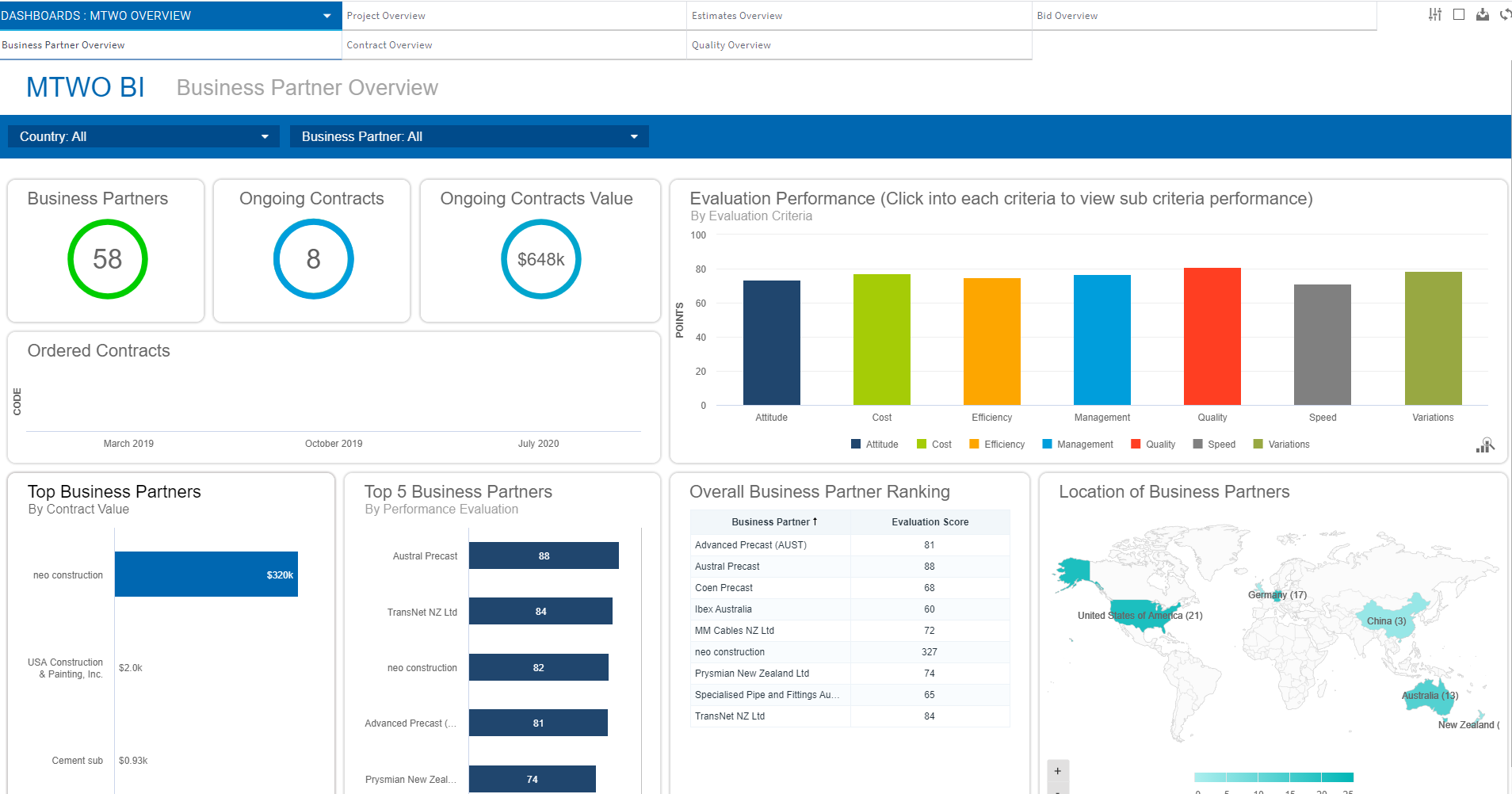

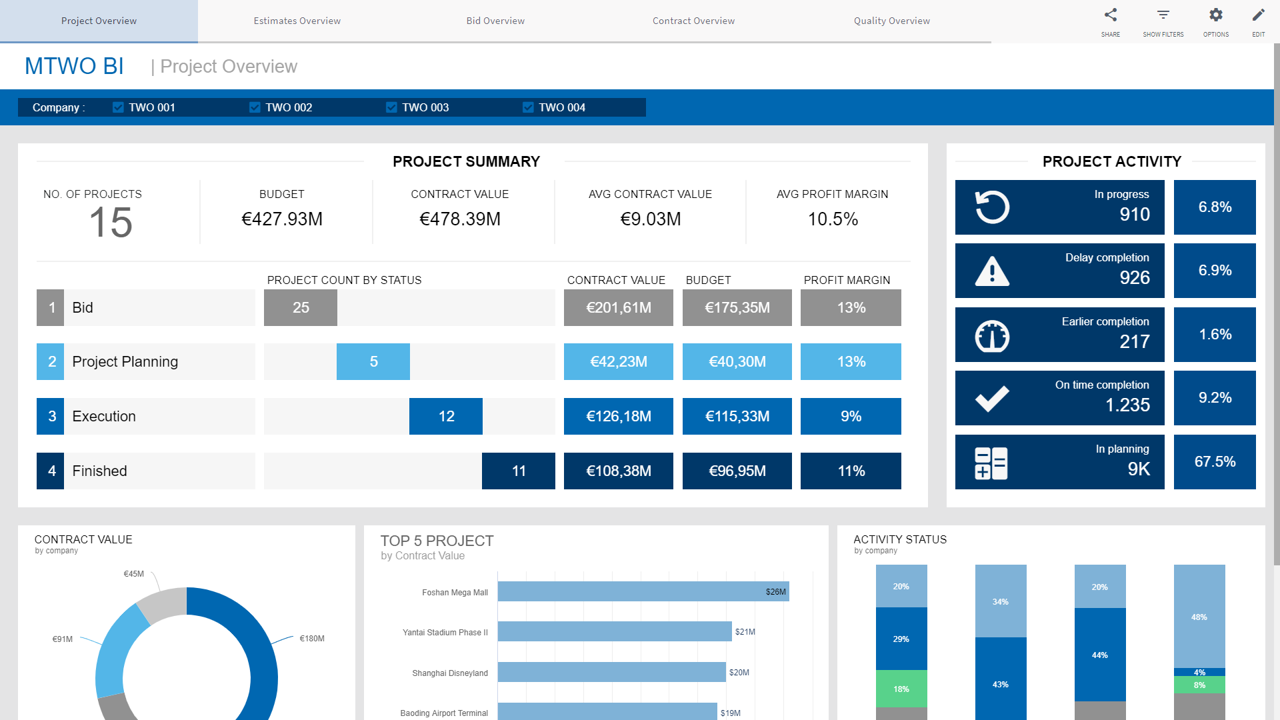

- Executives can make more informed decisions by using real-time dashboards and reports on project performance and sustainability indicators.

Results in relation to category

- Elevates sustainability: MTWO virtually simulates the entire life cycle of building projects in 6D BIM (3D design + 4D time + 5D cost + 6D carbon) before the physical construction. The result of the virtual simulation serves as a strong foundation for efficient and low-carbon physical construction and facility management.

- Increased productivity and decreased delivery time: all teams, processes, and data are connected in one place, significantly improving collaboration among different teams based on one single source of truth throughout the project lifecycle, which also means less wasted time and materials.

- New technology, new thinking, and new working methods: Transforming the E&C industry is not just about adopting New Technology, but also adopting New thinking and New working methods, to succeed in the digital world and to transform the industry into the most advanced and sustainable industry.

How Citizens benefit

- Sustainability benefits: 6D BIM simulation (3D design + 4D time + 5D cost + 6D carbon) makes it easy for project teams to understand the building design, timeline, materials, cost, and the carbon emission calculations right from the planning phase, so that carbon factor is easily tracked early on.

- Time and cost benefits: digital twin combined with full transparency into the entire project lifecycle in in one place helps to reduce waste and project delivery time.

- Affordability benefits: With the integrated MTWO platform, it might take longer to build the first project, but as lessons learned from each project are captured and the knowledge get transferred to new projects, teams can speed up project execution. This translates into a reduction in the overall cost of construction projects and shorter project delivery time, resulting in affordability.

Innovative character

- Physical-Follows-Virtual: MTWO platform virtually simulates the entire life cycle of building projects in 6D BIM simulation - integrating the 3D BIM model of a building project with the time factor (4D), cost information (5D), and carbon factor (6D). This makes it easy for project stakeholders to understand the building design, timeline, materials, equipment, workforce, and the carbon emission calculations before a shovel touches the ground. The virtual simulation creates a digital twin, serving as a strong foundation for efficient physical construction and facility management.

- One single souece of truth: For many E&C companies, most data is scattered in different systems and hard drives, as a majority of them still use different systems specializing in different jobs simultaneously across the organization. MTWO offers a common data environment, allowing different teams in a company to access and share the latest project data in real time, mitigate project risks, and prevent safety issues, all of which, cumulatively, will maximize productivity.

- Business Intelligence-powered dashboards: Construction projects contain thousands of elements, so it is important to have comprehensive visibility in all aspects of the project and immediate and accurate information. MTWO Control Tower combines all aspects of the project data analysis in an intuitive interface, allowing teams to monitor all metrics in one place in real time to gain more insights and upscale their performance.

- Artificial Intelligence-powered deep data analysis and automation: Powered by Machine Learning, Deep Learning, and automation, MTWO AI assistant McTWO supports E&C companies to establish a real-time decision-making system by automating workflows, generating predictions, forecasts, and recommendations through analyzing historical data and extracting value from it.