Ohoskin

Basic information

Project Title

Full project title

Category

Project Description

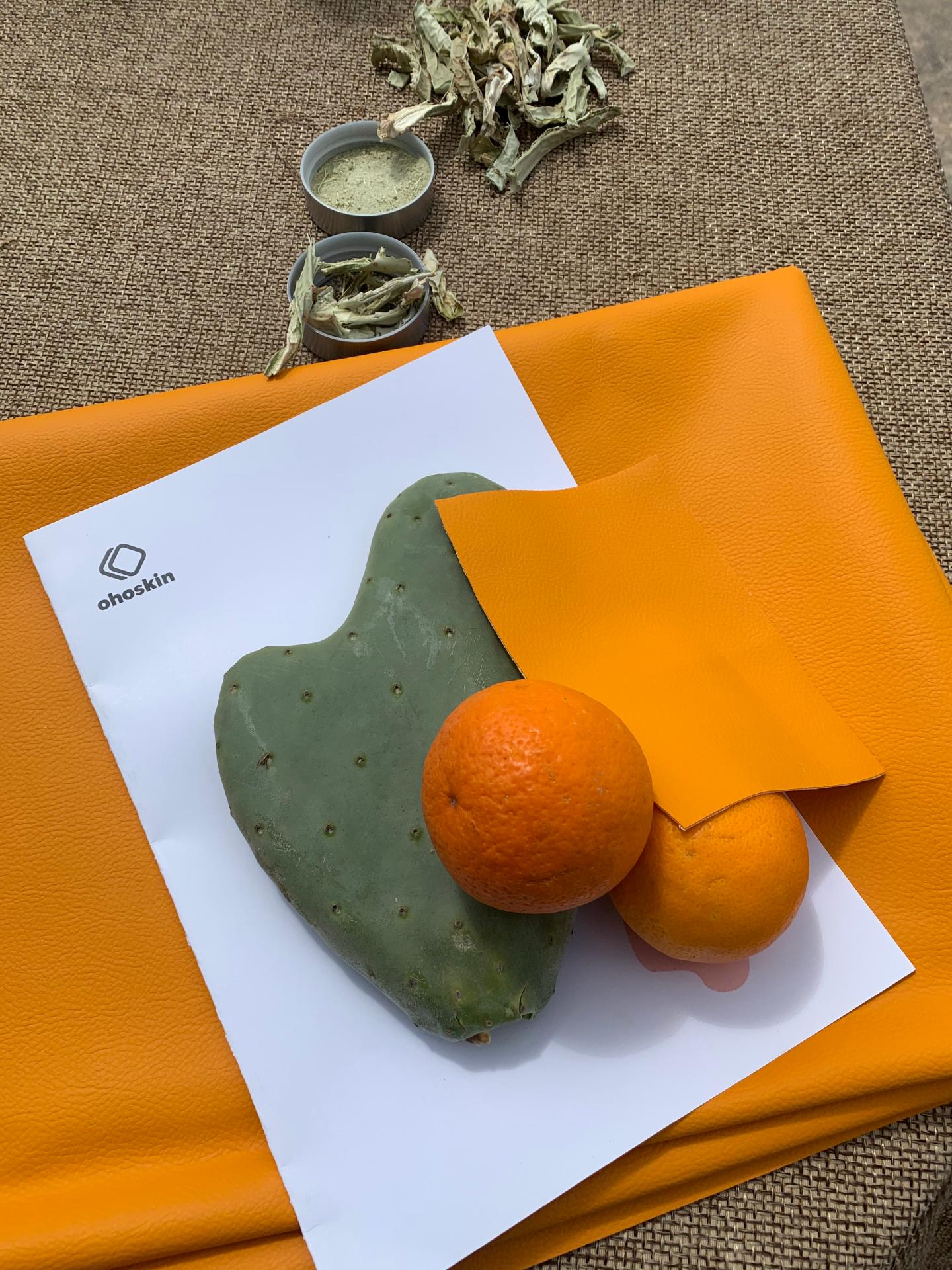

Ohoskin is a vegan, made in Italy luxury leather alternative. Our sustainable process uses the byproducts of oranges and cactuses and triggers a circular economy. The result is a quality skin alternative whose features make it perfect for the luxury fashion, interior design, and automotive industries.

In this way, people can keep enjoying what they love without feeling guilty.

Project Region

EU Programme or fund

Description of the project

Summary

Consumers of luxury goods feel torn between enjoying what they love and living a more sustainable and conscious lifestyle. It is especially true for what concerns leather: the chemicals used in its production impact workers’ health and the environment. Also, it consumes nonrenewable energy sources and water, has a huge carbon footprint, and kills animals.

Consumers are aware of this and are putting pressure on brands to switch to vegan leather, so they won’t have to choose between what is right and what feels good.

With our partner, the plastic-production giant Novartiplast, we patented a bio-based material that we can process and tan as leather without the tanning industry’s environmental and social costs. It’s phthalates-free and complies with REACH and PROP65 guidelines. It also has the VVV+ Animal-Free Fashion label.

Its look and feel make it a valid substitute for luxury animal leather suitable for automotive, fashion, and interior design applications.

Our model focuses on B2B and targets luxury brands. We plan to sell on our website, and we’ll use our social channels that will act as a showcase and as a first touchpoint for brands interested in buying our samples. Our goal is to seal deals and build a commercial network to manage the orders best.

We aim to make Ohoskin known worldwide as quality, innovative, sustainable, vegan leather.

As far as the b2b is concerned, we are positioning ourselves as an innovative yet dependable and reliable company backed by well-established production partners.

Key objectives for sustainability

Around 80% of leather worldwide is tanned using chrome, a highly toxic process that impacts workers’ health and the environment, consumes nonrenewable energy sources and water, has a huge carbon footprint, and kills animals.

We patented a bio-based material that we can process and tan as leather with no environmental or social costs.

Our production cycle does not involve animals at any moment and, in addition, closes a circular economy. It means that we collect the byproducts from the food and cosmetic industries, and we turn them into raw materials for a new product. Thanks to our partners, this process does not produce any waste.

In addition, our phthalates-free PVC complies with EU's REACH and the USA's PROP65 guidelines, giving Ohoskin a longer life cycle when compared to synthetic leather.

Further information about our sustainability will be available when a currently undergoing Life Cycle Analysis is available in a few months.

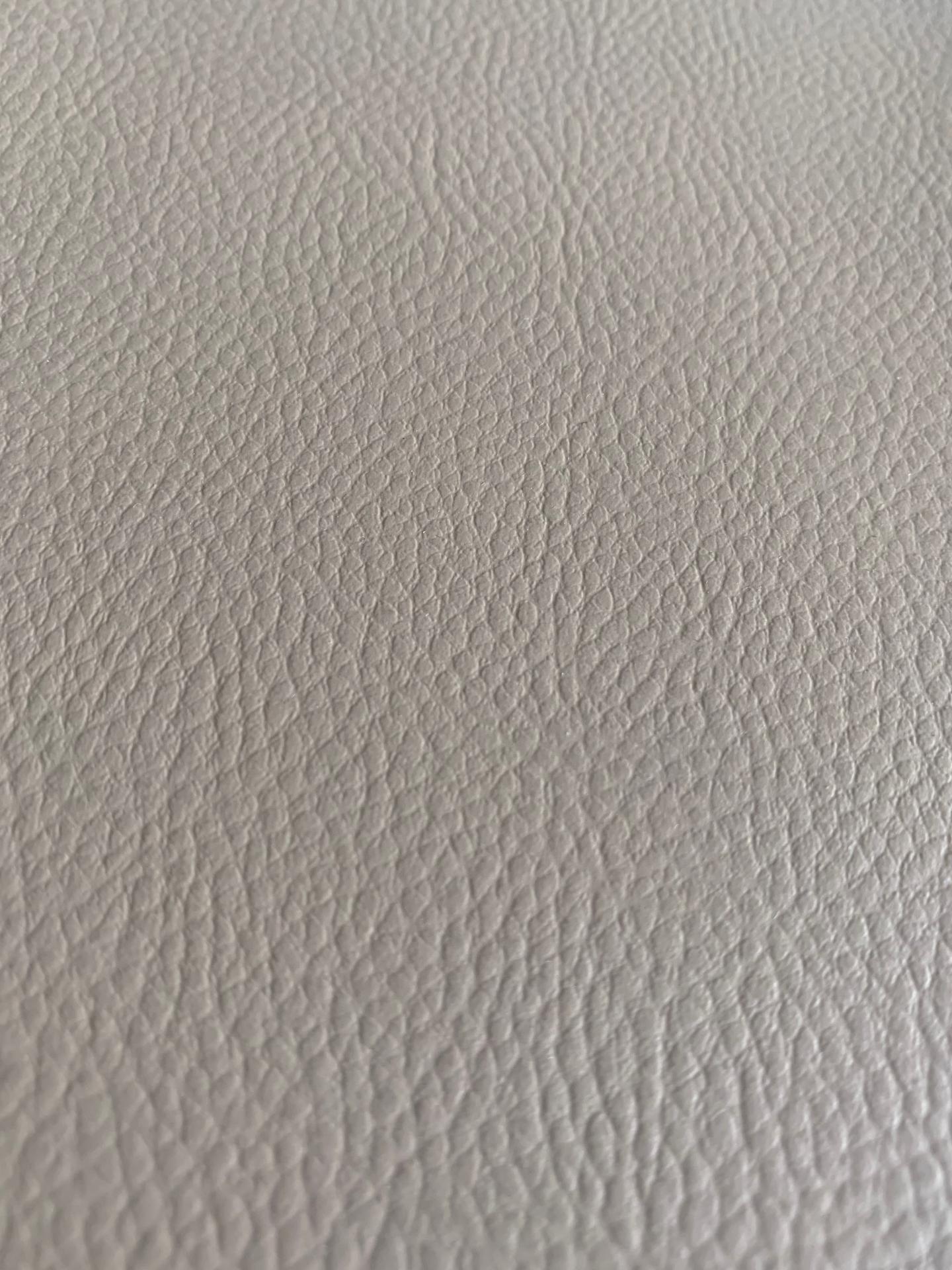

Key objectives for aesthetics and quality

Ohoskin is a quality alternative to leather and replicates its visual, tactile, and performance features, making it perfect for fashion, interior design, and automotive for a guilt-free luxury lifestyle.

In this way, luxury brands can position themselves as sustainable, addressing their rising need for sustainability in the products they buy, without any compromise on quality and aesthetics.

Key objectives for inclusion

First of all, the leather tanning industry damages its workers' health and all those who live in its surroundings, devastating the ecosystems.

Secondly, thanks to our circular economy process, we waste another life and value so that farmers can profit from them. Also, our production process takes place in a former economically depressed area, in an ex petrochemical plant restructured as an innovative green industry plant, creating new jobs.

Finally, as far as cultural challenges are concerned, our women-led company is redefining the very concept of luxury, from something for the few to enjoy to a socially responsible industry that benefits everyone.

Results in relation to category

There's an LCA underway; we'll be able to present it in a few months.

However, we can already say that our circular economy process uses byproducts from other industries that otherwise would have needed to be disposed of, with enormous costs, both economic and environmental.

Also, our phthalates-free PVC has increased durability when compared to PU-base synthetic leather. This means that Ohoskin has an extended life cycle and, thus, a lesser impact.

Besides, we don't use any animal component, so we don't add to mass farming's carbon footprint. Also, don't employ any of the toxic substances used by the leather tanning industry.

All these results enable us to operate within the frameworks of EU's REACH and USA's PROP65 rules. In addition, the Anti-vivisection League granted us the Animal Free Fashion Label with the highest score of VVV+.

How Citizens benefit

By giving new life and value to industrial waste, we transform a problem into a resource. Also, the first stage of our production process takes place in a formerly depressed area in Sicily. Today, a former petrochemical plant has become an example of a green industry that creates jobs and keeps talents in Sicily.

Innovative character

Thanks to our PCT-patented process, Ohoskin produce the first bio-based material made with the byproducts of oranges and cacti. We use the waste of another waste, which remains after the industrial processing and extraction of plant matrices from oranges and cacti by cosmetic and food industries, closing a circular economy. Ohoskin looks, feels, and performs like leather, but without any social or environmental cost.