Velaskello: Let’s make recyclable recycl

Basic information

Project Title

Full project title

Category

Project Description

Velaskello: a new world is possible. Rethinking the common good through the innovative practice of recycling PLA, deriving from waste produced by additive manufacturing, inserted in a circular economy system. Superforma has taken up the reflection «think global, act local» as it combines the global dimension with local considerations and actions. Velaskello represents change through a new metaphor of rebirth for an artisanal production rooted in the territory, community and eco-sustainable.

Project Region

EU Programme or fund

Description of the project

Summary

The project conceived by Superforma has a double objective: to recycle polylactic acid (PLA) and encourage the use of recycled PLA through a circular, inclusive and sustainable economic system. To make this possible Superforma has connected different realities of digital manufacturing in Milan: the territorial network is made up of institutional and private entities, who have stored PLA waste in special containers designed and supplied by Superforma. The wastes were taken to the Superforma laboratory where the team divided them into color families, then the PLA was processed through a granulator. It was then dehumidified to increase the printability properties, finally the recycled PLA was used thanks to an extruder. At the end of the process, Superforma returned an agreed quantity of recycled PLA to the local partners, thus making it possible to convert it into an eco-sustainable key. The network focuses on the ecological sensitivity of those who make it up, it’s based on the exchange of knowledge and on the community management of recycled PLA, factors that make it possible to combine innovative openness and local roots.

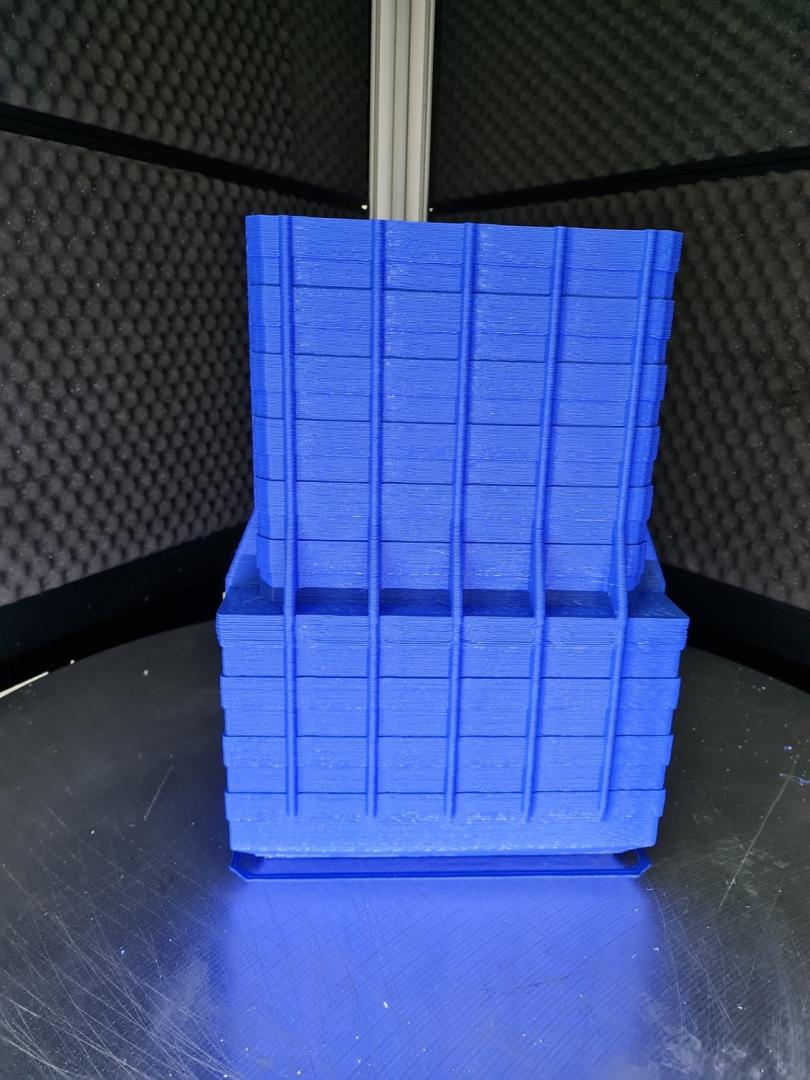

Velaskello is part of the circular sustainability process as it was created to shine a light regarding a still little known topic: the life cycle of PLA, widely used in additive manufacturing. Indeed, in addition to being a stool made entirely of recycled PLA, it has been designed so that it doesn't need supports and doesn’t produce waste, thus it can be defined as a zero waste interior design product. Velaskello also offers its contribution on the imaginative level by forcing reflection on a new possible world, so much so that already starting from the conception of this project Superforma has not set the limit to play only a sensitizing function, but he intended to experiment with a proactive function, which generates transformative imaginaries.

Key objectives for sustainability

The idea was born after a careful cross-research on PLA and additive manufacturing, which shows that the PLA used in digital manufacturing, a segment in which it is extremely widespread, doesn’t find a place within the recycling systems. Consequently, in Milan, as in other cities and states, the PLA must be thrown into the unsorted waste container without the possibility of recycling. Superforma has set itself the goal of creating a system within the world of digital craftsmanship that recycles and encourages the use of recycled PLA by focusing on the exchange of knowledge, inclusiveness and replicability.

In order to achieve the set objectives, Superforma has created containers that it has supplied to the realities of the territorial network in which the rejects deriving from printing errors, supports or other are thrown. After that Superforma took care of creating an eco-compatible logistic system for the collection of waste and equipped the laboratory with technological tools that make it possible to process PLA to bring the material back to life. The processing includes a first step dedicated to sorting and grouping the waste by color family; the second step is dedicated to the reduction to flakes of the PLA to be recycled; the third step involves the elimination of hydrolysis through a dehumidifier, the machinery used is a dryer capable of effectively removing any traces of moisture from the polymers, preventing the filaments from showing any differences that could compromise the final quality of the product; finally, we reuse the recycled polymer through the Delta Wasp 3MT pellet extruder. These tools have made it possible to recycle PLA and, integrated with additive manufacturing technologies, have made a positive contribution to the circular production system, creating an opportunity for cooperation between institutions and individuals in an eco-sustainable key.

Key objectives for aesthetics and quality

The subject is a comfortable stool that moves from Torre Velasca, emblem of the city of Milan, a building full of symbolism that influenced the society and culture of reference after World War II, as well as glue between innovation and tradition. Velaskello was burdened with multiple symbolic functions that bring the experience to the level of reflection given the need to act in the "here and now". The main symbolic functions are inherent on the one hand the communicative sphere and on the other the sphere dedicated to the implementation of actions that turn towards a tangible change. The first aims to raise awareness of the use of PLA, the practice of recycling and the design of forms that transform production into zero waste.

The second sphere concerns circular economy practices, in fact, we believe that acting to create and maintain a territorial network, by encouraging the use of recycled PLA within the circuit, penetrates change significantly.

From an aesthetic point of view, it aims to enhance the manufacturing process typical of digital craftsmanship through evident layers, this processing method favours an animist vision of the material, as it is alive in the creation phase, it forms details and imperfections that make each Velaskello unique. Furthermore, each Velaskello carries with it the traces of the previous one, triggering a common thread that makes up the historical heritage which can be traced back through the tracing of the colours used.

It becomes possible to rethink product and process design with a view to efficiency as well as the choice of raw materials, favouring simple designs with less use of components and the reuse of recycled raw materials. In fact, by replacing virgin raw materials with recycled material, through local recycling initiatives, upcycling processes are created that promote a more sustainable production system and consumption.

Key objectives for inclusion

The project aims to form in Milan a recycling system of PLA, a biodegradable but not compostable material in the manufacturing world; the foundations of this system rest on a circular, replicable and inclusive economy. Velaskello is part of the realization of the project as an emblem that certifies the possibility of creating quality design objects with recycled material without producing waste. Furthermore, Velaskello had the burden of supporting the birth of the territorial network so that it could feed itself. The territorial network is made up of institutional bodies such as: the Politecnico di Milano which offers its students, but not only, a digital manufacturing laboratory complete with 3D printers; Scuola Cova, Foundation that deals with professional training dedicated to manufacturing 4.0; Naba, academy of fine arts; Domus Academy; and private entities such as start-ups, digital manufacturing laboratories and research centers. Through the practice of recycling Superforma reinserts the recycled PLA into the circuit, instead, through the practice of exchange it is committed to supporting partners in the ecological transition towards a circular model. In fact, for each amount of waste material that is collected, Superforma returns an agreed amount of recycled PLA, encouraging its use within the territorial network, in which Superforma acts as a guarantor for the achievement of objectives while respecting the environment.

The model based on the circular economy presents itself as the only solution to the generation of waste and the intensive consumption of raw materials, in which the establishment of closed production systems, the reuse of resources and the extension of the life cycle of products can lead to a transition to a sustainable economy

Results in relation to category

On average monthly, a digital manufacturing laboratory discards 5% to 10% of PLA relative to the amount of what it produces through print. The territorial network was born in the spring of 2021, from that moment it has collected about 40 kg of PLA waste to which we have added 150 kg of PLA waste produced by Superforma in the previous three years, from which we have been able to give life to 26 Velaskello stools.

The practical impact of the project translates into about 190 kg of reused material rather than being thrown in the unsorted, as was the case before the birth of the circular economy circuit.

Furthermore, Velaskello is a transformative project, aimed at opening new perspectives, inspiring behaviors, attracting and influencing public opinion to create new possible ways of living in the world. In fact, through Velaskello, Superforma deconstructs the way of designing, without losing the traces of the pre-war artisan tradition in which, by necessity, the impossibility of producing waste material raged; thus was born the need to rethink design in a zero waste key. If every storm begins with a single drop, Velaskello tries to be that drop by combining style, utility and ecology. While the circular economic system offers an opportunity for organization that makes the positive impact that derives from it tangible on the community of Milan.

How Citizens benefit

The territorial network, open and inclusive, is made up of institutional bodies such as: the Politecnico di Milano which offers its students, but not only, a digital manufacturing laboratory complete with 3D printers; Scuola Cova, Foundation that deals with professional training dedicated to manufacturing 4.0; Naba, academy of fine arts; Domus Academy; and private entities such as start-ups, digital manufacturing laboratories and research centers. The members of the circuit take an active part in the project since they have transformed their laboratories by virtue of becoming in an ecological key, supported by the sustainable craftsmanship practices implemented by Superforma. In addition, Superforma involved local partners by encouraging and supporting initiatives open to citizens with the aim of informing and stimulating innovative recycling practices with a community, inclusive and replicable entity. In addition, Superforma has provided the digital manufacturing laboratories involved in the project with related infographic material from a qrcode, which refers to a video, which comprehensively articulates the project, activities implemented to inform and involve citizens. Finally, from the birth of the project to the present day, Superforma has been committed to maintaining a level of high transparency and involvement aimed at citizens by regularly updating its social profiles.

Innovative character

The innovative character of the project lies in its community and inclusive structure as well as the technologies used to make it possible. Velaskello was made with PLA deriving from the waste produced by the companies that have joined the territorial network, recycled by Superforma through the processing steps described above.

PLA has become the protagonist of the project after careful research, in fact, from the analyzed data and surveys it is clear that PLA is the most used material in 3D printing laboratories or by those who own one as a hobby.

Furthermore, it has been found that, in digital fabrication, the main sources of PLA waste come from unsuccessful prints, supports to make a structure print possible, print tests and prototyping; but the PLA used in additive manufacturing is not compostable even if biodegradable, therefore, the waste resulting from unsuccessful supports or projects must be thrown into the unsorted bin. Interrupting the life cycle of the product contributes to the increase of waste, with consequences that are still little known but certainly harmful to the ecological footprint. Although additive manufacturing significantly reduces the waste resulting from the processing stages, it is not, however, completely immune from environmental risks deriving from the use or disposal of materials used in 3D printing processes. In this context of large-scale use of the 3D printer, it must be taken into account that the recycling of plastic materials in the use of this technology continues to be a new and developing theme today. Despite the implementation of 'green' practices in the use of 3D printing, which is by nature more sustainable than others, recycling is an unconsolidated practice by the companies that use it.