Infinite Athletic

Basic information

Project Title

Full project title

Category

Project Description

Infinite Athletic has born from the need of circularity in the textile sector, being the 2nd polluter in the world.

It relies on our mission, based on our 3 C:

Circularity where all of our products are both 100% recycled and 100% recyclable

Chain which is totally local where we only spend 200 kilometers from the raw material collection to the final garments

Community which involve engaged users and structure for the sales and recollection of raw material and final used garments

Project Region

EU Programme or fund

Description of the project

Summary

Infinite Athletic vision is to be the leading sustainable sport apparel brand based on 100% circularity.

Our mission is based on our 3 C:

• Circularity

o Use of raw material that went to landfills

o Eco-conception of the garment so that it is 100% recyclable

o No use of chemicals

o Colored pigments within the thread itself

• Chain

o Totally local production chain. Less than 100kms between raw material / recycled / thread / garment

o Sales chain for “pre-orders”, limiting the over-stock as much as possible

o Respect the prices of the chain to have a win-win in this

o Social impact with% of sales for NGOs

o Use of ecological means for transport

• Community

o Use of the community (tennis, mountain, sea, etc ...) for the "engagement" of its members

o Participation in the eco-conception of the product through collection within the clubs

o We solve the logistics of collecting the garment, once used. Well, the player leaves it in his own club, eliminating the friction of logistics.

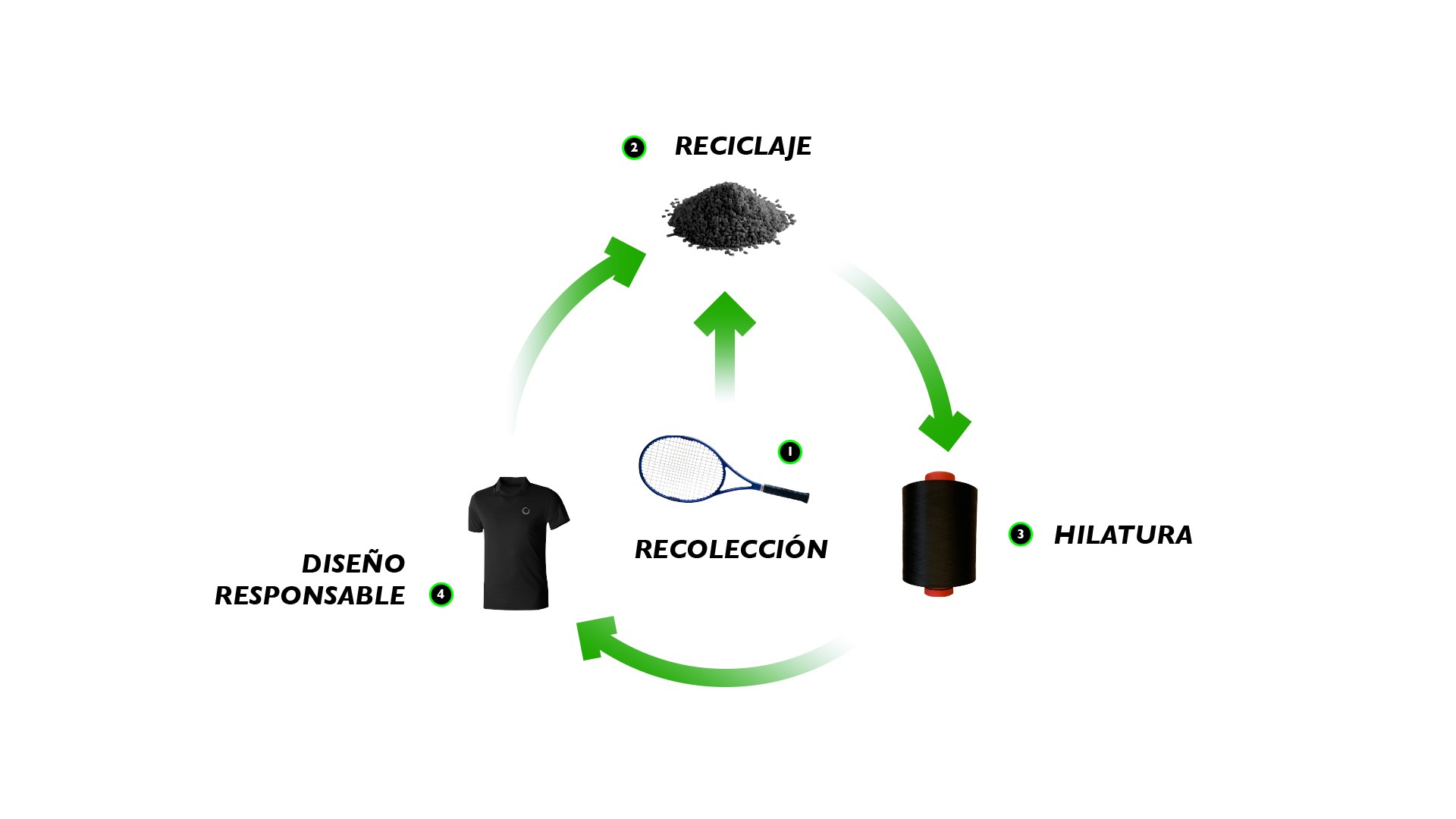

We are starting with concentrating on tennis where we collect the used racket strings and, through some recycling steps, are able to transform them into new garments.

Through eco-conception, we do create garments that are 100% recyclable, 100% circular.

And through the help of the community and the involvment of the tennis club, we have secured three important items to be sucessful:

- The securization of the raw material, collected by the clubs

- The access to their members, who will be engaged customers and ambassadors

- The place to drop their used garments for us to recycle (I play tenis and play for the planet at the same place)

Key objectives for sustainability

In terms of sustainability, we had several targets:

- Reduce water consumption

- Reduce CO2 emission

- Reduce energy consumption

- Cope with the classical linear model and do a 100% circular business model

- Create a fully local supply chain

The classical linear business model in textile is not sustainable anymore.

- It extracts: 87% of the raw material used in the textile industry comes from natural resources

- It produces: 20% of the world's pollution is caused by the textile industry

- It uses: 30% of the clothes bought is used only once

- It throws: 87% of the garments end up in landfills and incineration plants in less than 1 year

Our circular business model:

- Is 100% circular thus solves the "Throw" issue as well as the "Extract" problem

- Reduces the consumption of water by 75% as all of our yarns are dope dye. No need to do huge water consumption's dying baths afterwards

- Reduces the CO2 emission and energy consumption by more than 60% as it uses recycled material

- Will be essentially proposing recurring collections with small choice of colors to avoid the fast fashion issues

- Our supply chain will be not more than 200 kilometers from the recollection of raw material to the final garments (compared to the 20.000/30.000 kilometers of most of the brands, going through China/Vietnam)

Key objectives for aesthetics and quality

In fashion, the experts in the sector have lost the savoir-faire and mainly focus on the faire-savoir.

We have come back to the solutions of the 70s where we knew in Europe how to do quality-wise garments.

We are developping a product that is elegant and with extreme quality. The 2 are totally interdependent in our mind.

Elegant for sport players with designed anchor collections, based on our experience in fashion we will bring to the sport sector

Due to the technology used (dope dye, antimicrobial within the yarn) and the selection of yarn (number of filaments, cross-sections), we have managed to create a signature collection with elegant garments and extremely soft touch and naturally technical features necessary for sports (sweat moisture management through natural physical capilarity funnels).

In the end, we are creating elegancy and sustainability by design

Key objectives for inclusion

We are going into the direction of inclusion through 3 main items:

- We do produce everything with very local partners, thus following the European and Spanish labor law that push the inclusion through the employment of minorities/disabled citizens, with the equality of genre

- We are working in several other sector were we will embrace collaboration with local association to clean and triage the raw material.

- We will dedicate a certain % of our sales to our foundation, Play for the Planet, that will support start-ups, ONG, association working for the good of the planet

Results in relation to category

The KPI achieved compared with a standard process using virgin polymer are the following:

- 100% circularity: this production process is not jeopardizing anymore the resources on the planet

- Minus 75% water consumption: thanks to the use of technological innovations in colors, we save more than 75% of water compared to a classic process.

- Minus 70% CO2 emission: the reuse of recycled material and its collection process minimize the carbon footprint.

- Minus 60% energy consumption: using our innovation in recycled materials, we managed to simplify the processes necessary to manufacture our yarns by half, saving a lot of energy at each step.

Also, the fact that we use a local chain (200 kms instead of more than 10.000 kms normally) use a lot of CO2 footprint. That, combined with our customer sustainable logistic transportation mean is a clear driver for sustainability.

How Citizens benefit

Citizen will see from the product itself, the communication tied to it that the idea of circularity and sustainability is not necessarily what they think. And that everything is possible to do with a pragmatic and logic way.

We just need to come back to a certain quality standard and involve communities to be part of the equation to solve this unsustainable story.

The community we are starting with, the tennis club, did answer very positively.

They will help use transmit the message about real sustainability, they will push on our behalf this circularity implementation by promoting it within their clubs, implement logistic route for us to recollect both tennis racket string and our end-of-life garments eventually.

Innovative character

Innovation comes from the addition of several items and is highly replicable to other countries, to other sector.

- Selection of untapped source of raw material within the landfill

- Mechanical process that is more sustainable than chemical one and more scalable

- Various use of yarn technologies (cross-sections, microfilaments, etc…)

- Use of dope dye technology to reduce water consumption

- Use of Seamless technology to reduce the manufacturing timing and machine usage

- Use of local and sustainable supply chain