BC materials startup

Basic information

Project Title

Full project title

Category

Project Description

BC materials is a start up & spin off, of bigger brother BC architects. When we noticed that no one in Belgium worked with the big flows of excavated earth, we decided – based on the ecological and health-related qualities of earth building – to produce materials ourselves. We now transform earth streams from construction sites into clay plasters, compressed earth blocks and rammed ear

Project Region

EU Programme or fund

Description of the project

Summary

On the first of October 2018, BC materials as a start up (and spin-out of BC architects) was founded. The company is the first operational enterprise in the European Union that is using excavated earth (officially a 'waste') to transform it into clay plasters, compressed earth blocks & rammed earth. It's a cooperative that has an impact-based mission: to replace as much classic building materials with (circular) earth based materials, that leave zero waste, are 100% reusable and can be produced in a C02 neutral way. Aside from producing and selling, we also offer consultancy and do workshops (>1000 participants) to spread the knowledge, inspiration & fun of clean, circular earth-building.

Key objectives for sustainability

BC architects is a Brussels-based, prize winning architectural bureau that has built several exemplary and raw earth based buildings over the last decade. To nudge the market even more towards healthy & low-carbon materials, the founders (Wes Degreef, Ken De Cooman, Nicolas Coeckelberghs & Laurens Bekemans) decided to start a new company, a spin-out, on 1/10/2018: BC materials, that transforms excavated earth (officially 'waste') into circular building materials. In Brussels alone every year 2 million tons of earth is excavated every year; most of it is transported and dumped in mines or quarries far away. (In France this is 151 million, in Germany close to 130.)

By transforming this 'waste' into building materials, the start up reduces waste, landfilling and the transport (and C02 emissions) that go along with it, but it also inserts healthy and circular building materials into every day construction.

Through years of research & experience in earth building, BC materials developed three earth based products: the brickette (earth blocks), the Brusselier (clay plaster) and the Kastar (rammed earth); all mainly based on excavated earth and 'waste' materials from the construction sector.

The Brickette is a lovely compressed earth block that can be produced with 600 times less the energy than a classic baked brick and who still performs a lot better in regulating humidity and acoustics. Suitable for loadbearing and non-loadbearing walls. The Brusseleir is our best sold product because of his unique texture and colours. In contrast to a classic gypsum plaster it regulates the humidity of an indoor climate, it’s completely vapor permeable, and 4 times better for the acoustics of a room. With its surreally beautiful look, the Kastar can be used for inside and outside walls, and inside floors which are much easier to repair th

Key objectives for aesthetics and quality

BC materials has a positive impact on 8 SDG's (good health, economic growth, industry & innovation, sustainable cities, responsible production, climate action, life on land & partnerships) and inscribes within the EU Green Deal by reducing as much embodied carbon of building materials as possible. It works together with different universities (ULBrussels, UHasselt, Sint-Lukas,..) & research units, it receives students, architects, contractors,.. from all over Europe and teaches in workshops and lectures how to work and build with earth.

Key objectives for inclusion

Inspiring youngsters (designers, architecture students,...) is one of the most important tasks we take pride in. At a rammed earth workshop with Case Design young people get the chance to not just get the theory behind earth building but also work, transform and put their feet in the earth.

Results in relation to category

Our main aim is impact: replacing as much building materials with low carbon, circular earth based materials as possible, inspiring several partners in the building chain (real estate, contractors, architects, students,..) to work with earth and reconnecting locals with the act of (local) building materials & the assets they offer.

At the BC materials production site, an order of compressed earth blocks - based on excavated earth from Brussels is produced by both collaborators of BC materials, volunteers, architects, students & designers in a workshop.

How Citizens benefit

In Brussels alone every year 2 million tons of earth is excavated every year; most of it is transported and dumped in mines or quarries far away. (In France this is 151 million, in Germany close to 130.)

By transforming this 'waste' into building materials, the start up reduces waste, landfilling and the transport (and C02 emissions) that go along with it, but it also inserts healthy and circular building materials into every day construction.

In March 2019 an industrial & circular hub was built to transform on a larger scale these earth streams and to produce, within the city, building materials. From a perspective of urban mining, BC materials is proving that cities not only have to be (large) consumers of materials but can also be producers. Over a number of months 4 clay plasters (Brusseleir), a compressed earth block (Brickette) and 3 rammed earth mixes (Kastar) have been tested, formulated, designed and launched on the market. In every product all 'ingredients' are a 100% reusable (not just 'recyclable') because the elements are not chemically altered (avoiding cement f.e.) , can be produced with purely electrical means, and leave no waste. The water used in the production processes is recovered rain water. Economically, BC materials has increased its production & sales every year, even during the covid year 2020, even finishing a successful cooperative crowdfunding, to strengthen the bonds between company & community, between consumers & producers, between builders, makers & inhabitants.

Innovative character

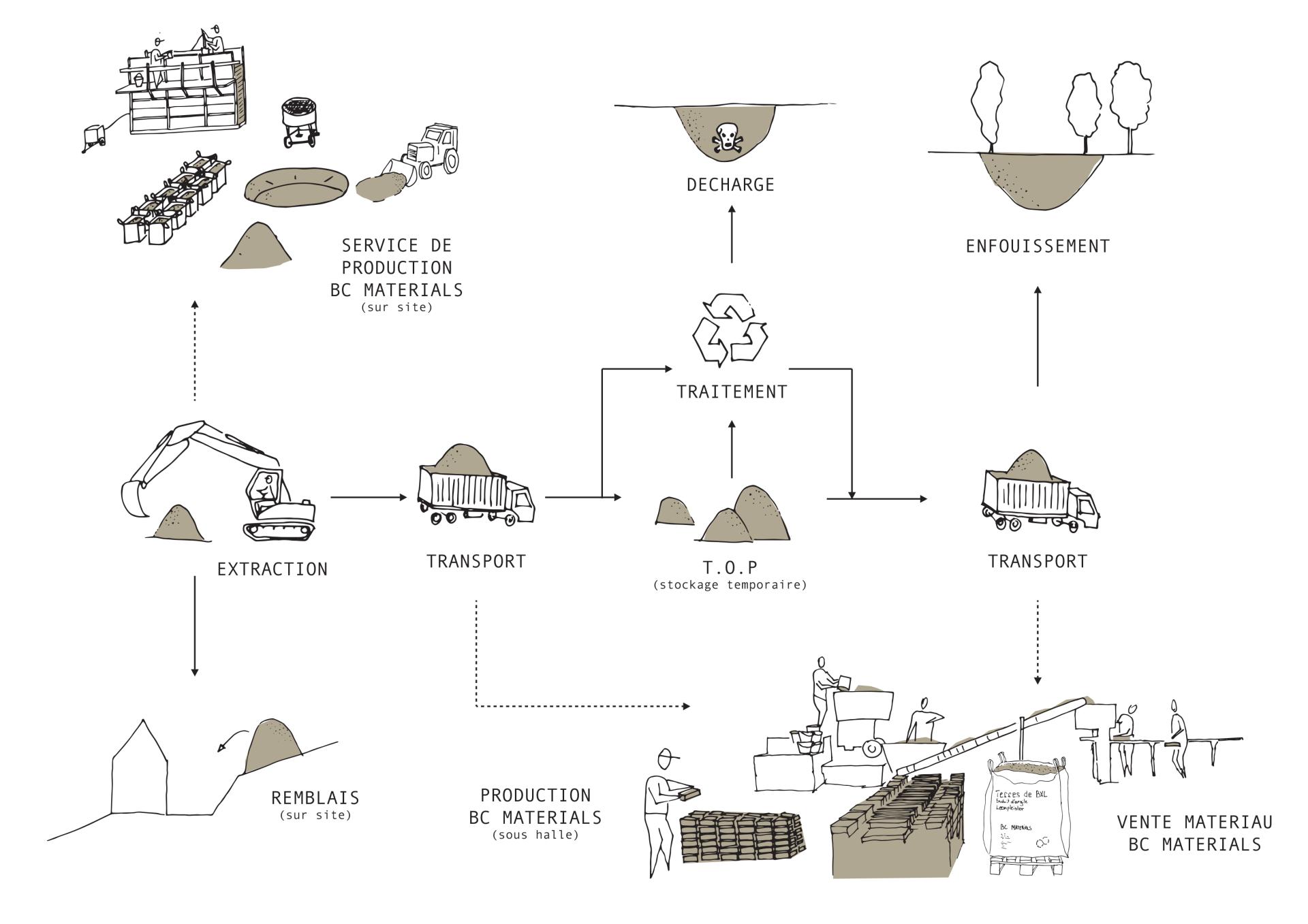

BC materials process: instead of long transports of excavated earth, we can intervene on site to start mixing and producing new building materials, or intervene and stop a longer transport to start the transformation at our production site. Our production hall is built and based on a temporary zone in the harbour of Brussels. It is completely conceived as a demountable and transportable structure, that could technically be transported and mounted elsewhere on a different site in a couple of weeks.