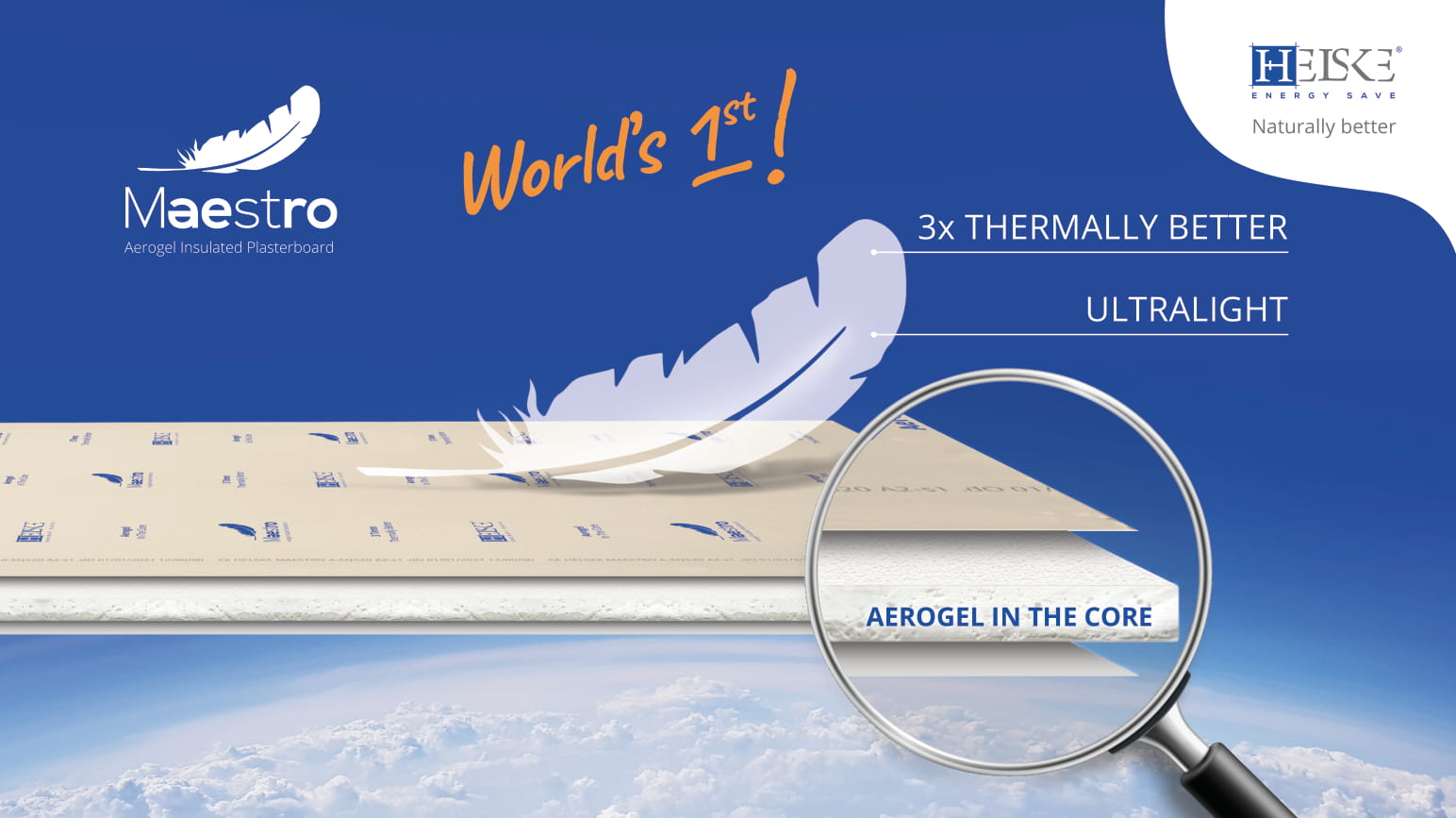

Maestro aerogel gypsum board

Basic information

Project Title

Full project title

Category

Project Description

The building industry is considered to be a major polluter. Plasterboards are a widely-used multi-billion-euro business. By infusing aerogel, the number one thermal insulator in the space industry into gypsum plaster, we developed a new generation of "Maestro plasterboards" with special properties such as: low thermal conductivity and lightweight. These features facilitate thermal comfort, energy and space savings, as well as lower transport emissions. With a sector this large, every bit helps!

Project Region

EU Programme or fund

Description of the project

Summary

Tasked with finding a competitive edge for plasterboard to compete with the industrial goliaths, we researched aerogels and their applications and discovered its potential in the building material industry. Aerogel is an expensive additive, but even very small amounts dramatically altered the conductivity of everyday building materials. The major challenge was getting it inside the board. Due to its nano-pores it has a very high specific surface which in turn increases it surface tension so much that it becomes super-hydrophobic.

For the production of plasterboard, it was indeed difficult to convince the aerogel to stay inside the board and fuse with the gypsum around it. Similarly, since the aerogel is very powdery it was equally difficult getting the paper to stick to the board. Our tiny, yet determined team of researchers had no prior experience with plasterboard or aerogel and so the adventure to achieve our results relied on networking, cross-border collaboration, determination and yes, also a bit of luck. Our marketing team have also worked to create a user-friendly experience for DIY customers so that they can transport, handle and install the boards easily and of course safely.

Key objectives for sustainability

Our key objective is efficiency, not only energy efficiency, but overall efficiency.

By augmenting gypsum with aerogel, not only does the overall structure become lighter, reducing the thicknesses of structural systems, which tend to consume more fossil fuels during their production process than non-structural elements, but it also improves the efficiency of the worker/installer as the installation is safer and less laborsome.

Additionally, for the transport of building materials, weight restrictions are usually the limiting factor. By reducing the density of the material we can increase the volume of material transported reducing the number of trips which translates to further savings in carbon emissions. Finally, improving the thermal resistance of the board would either translate to a slightly larger interior footprint as the walls can be built thinner or alternatively better thermal performance could be achieved for the same thickness.

According to studies within the building industry, for example Roland Berger's 2019 research report of mega trends in the building industry, "Maestro Board" could offer occupants greater useable space within a given floor layout, by reducing the thickness of the partitions and building envelope.

Key objectives for aesthetics and quality

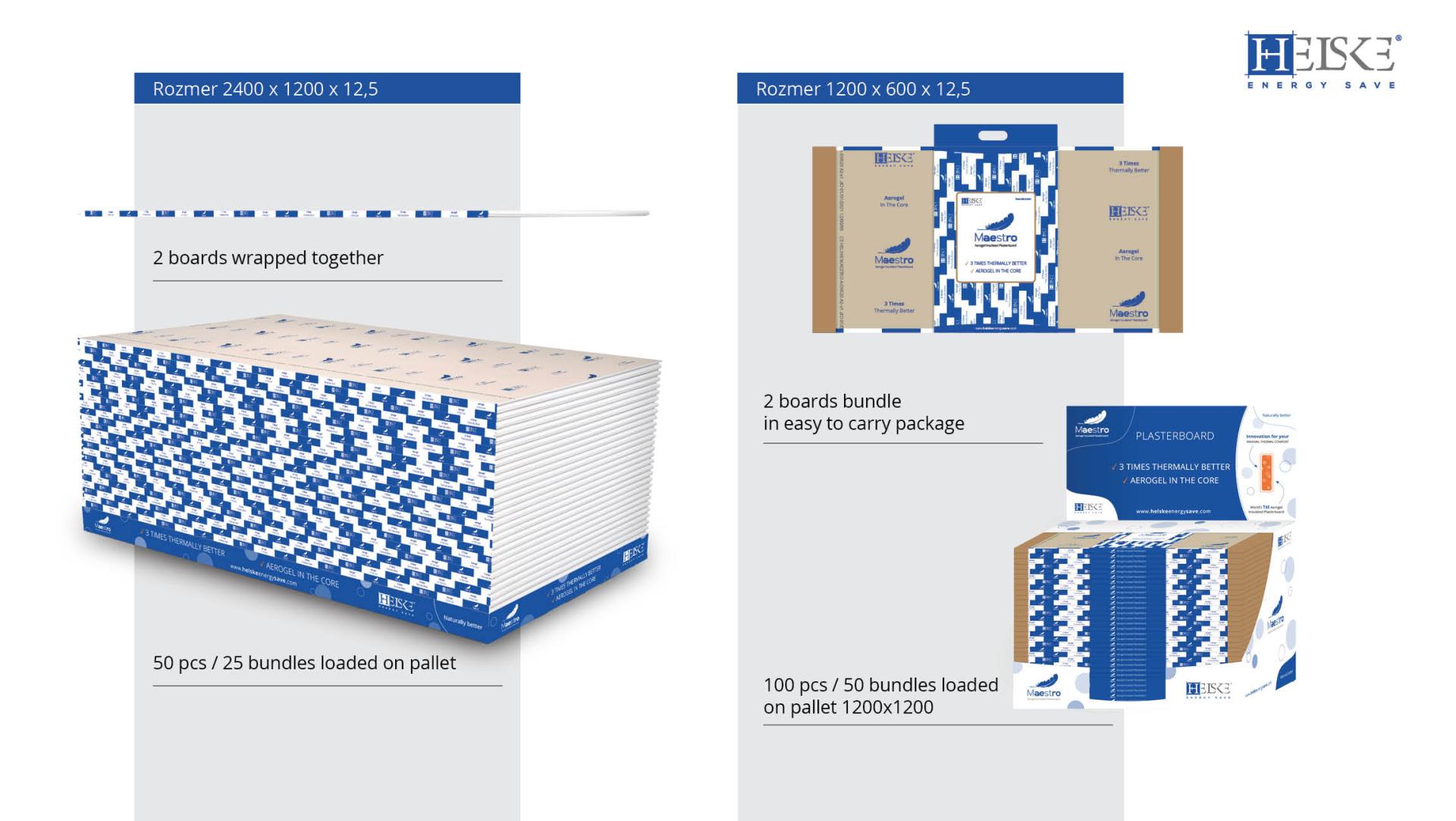

Quality of experience is a tangible construct for both by the user, the forwarder and the applicator. For the DIY market we have packaged the board in an easy to carry format that can fit into car. The boards are clearly identifiable due to their unique self-explanatory design and are lighter and easier to carry and manipulate. The boards are also formatted in such a way to minimize waste and a DIY application has been developed by us to calculate how many boards you need to minimize waste and help with your material planning.

Multivalent properties make the board quite versatile which allows it to be used in many standard applications. The user or occupant will also experience benefits in terms of a slightly larger floor area as the need for thermal insulation is reduced, the boards will also be more responsive to low potential heating which are often powered to some extent by renewable energy sources.

When designing "Maestro" we looked holistically at the impact we had on the environment. Our state of the art factory with its A1 energy rating implements integrated recuperation systems where waste heat is used to heat water, condition air and is filtered before being exhausted. We also use high efficiency LED lighting augmented by natural light to save the equivalent of 120 days per annum of lighting.

Key objectives for inclusion

We chose Levoca in Central Europe to boost employment and development in a beautiful, but economically poorly performing region in Europe. The region includes minorities that are socially excluded and heavily dependent on the country's social system. We are an equal opportunity employer and support the local community both directly and indirectly.

Gypsum board in general is considered to be both a cost effective and versatile building material which is readily available in all markets. Almost all homeowners and businesses will use gypsum plasterboard to some extent during their construction or renovation stage.

By pioneering improvements in the industry we are hoping to make our board accessible to the general public at an affordable rate while setting a new standard for the gypsum board industry. The long term outlook is to drive a trend where within 10-15 years all standard gypsum boards will be elevated to include improved thermal performance to bring them closer in line with high performance composite elements.

By improving the properties of the new standard board, we reduce the need for double layering, further saving space, natural resources and ultimately the environment.

Results in relation to category

The achievement of a board 25% lighter than most standard boards,

A 300% improvement on the coefficient of thermal conductivity compared to our market benchmark of plasterboards,

One of a very few boards available on the market with an A2 s1 d0 fire rating combined with thermal insulation properties,

An added 140m2 capacity for transport within the same weight limit,

In line with construction mega trends in terms of space-saving and thermal performance,

No negative impact on the construction or installation process. Compatible with existing techniques,

Easy to cut and form,

Waste reduction as result of variable size formats.

How Citizens benefit

We conducted a research study which involved hundreds of installators in six EU countries and asked them what they liked about gypsum board, what they disliked and how they could imagine it to be better. A large percentage of respondents repeatedly mentioned weight and format as a factor that they would like to have improved. It was through this method of exploration that we discovered a niche in which it was very difficult to find a board with an A2 fire rating whilst having increased thermal performance. This is because most insulations are organic in nature and decompose at lower temperatures releasing volatile organic compounds making them unsuitable for use in areas where fire resistance is an important factor.

Our company treats your home as an extension of your body where every indoor space, every surface you touch should be in harmony with you. Bringing nature back into your home. This is especially important as we spend more than three quarters of our lives indoors. Since 2013, we have dedicated our research and development on the nano-scale to improve building materials to provide solutions to everyday problems.

Innovative character

The first commercial implementation of aerogel fused directly interstitially to the gypsum core is unique to our company and indeed the world. By dispersing the aerogel within the hemi-hydrate, we dramatically reduce the cost needed to achieve improved thermal performance making the board many times cheaper than that of a heterogeneously applied aerogel composite layer such as a blanket or other medium.

Due to the high surface tension produced by the nano-pores of the aerogel particles, it was an achievement for us to transfer the proof of concept from a laboratory environment to a full-scale production line with an annual capacity of 4 000 000 m2 per annum.

We also remove additional steps that would otherwise be needed to make composite elements. The quantity of aerogel required is also highly variable allowing for the implementation of different concentrations of aerogel within the same thickness. Ultimately it provides the platform for further improvement as we can continually develop the board to yield better performance with the same or marginal increases of aerogel concentration without affecting the overall thickness.