FIVA - Window Prototype with vacuumglass

Basic information

Project Title

Full project title

Category

Project Description

In this project, we developed new window solutions that utilized innovative vacuum glazing products. Thereby, new operation modi were implemented. The rule of the thumb for developement was to develope/construct the window wing based on the necessities of the vacuum glass, while the frame was constructed based on the necessity of the window fittings. In the end, four different, highly-innovative window constructions have been developed.

Project Region

EU Programme or fund

Description of the project

Summary

The present project was a R&D project focussing on the "Window of Tomorrow". Thereby, high-performance glazing products, above all vacuum glass products, have been acquired, tested, and understood as construction starting point for a new generation of windows for Central Europe. Typical windows in Central Europe (in detail the D-A-Ch Region) have experienced a rather linear developement in the past decades: The turn-tilt window that turns to the inside in the opening has been updated with new technologies, such as double and triple glazing, radiation-influencing foils, turn-tilt fittings, and specific "spacers" and seals that seal the glass products and reduce convective heat transfer in the area of the window faceplate. However, this linear developement reached a high-level stagnation and has issues in providing windows of tomorrow.

In the R&D project FIVA, funded by the Austrian Research Promotion Agency, different new, in part disruptive, developements based on the high-performance glazing product have been conducted. Thereby, the window wings were constructed based on the necessities of the vacuum glazing, while the window frame is constructed based on the requirements of new window fittings, enabling other opening and operation directions (such as "garage-door"-movement and offset/sliding without visible rails). Moreover, the integration of automatization via motorization and remote controlling the windows have been studied and implemented.

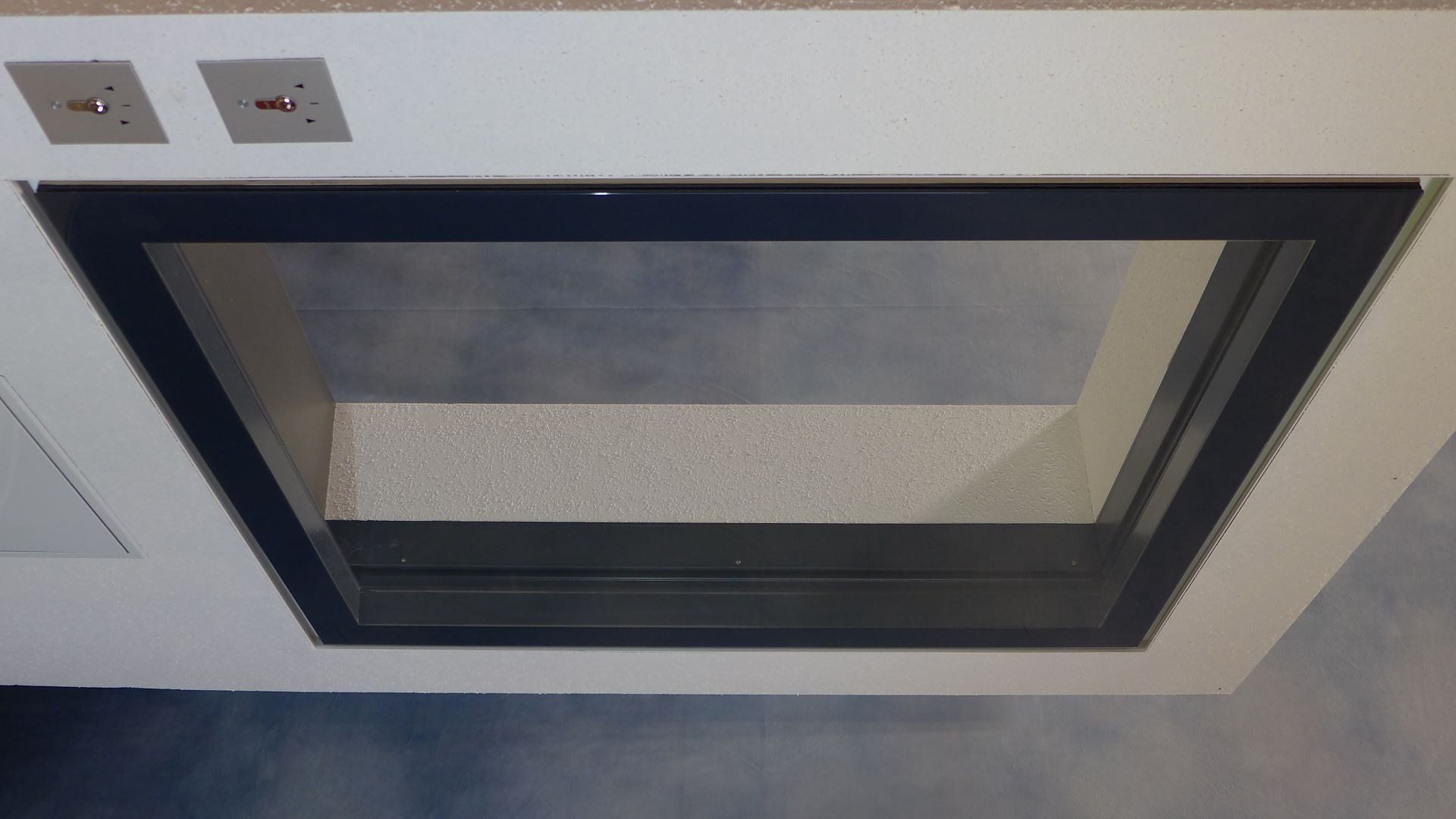

In the end, four different, full-scale- functional mock-ups have been constructed and exhibited to the window-building and supportive industry. These were:

- Turn window opening to inside

- Turn window opening to outside

- Swing window

- Sliding window.

The thermal performance of the windows was examined via simulation and measurements. U-Values of 0,7 W.m-2.K-1 can be reached, featuring significantly less weight and thickness than comparable triple glazing windows.

Key objectives for sustainability

The Key objectives of the project FIVA regarding sustainability can be described as follows:

- developed windows should have an excellent thermal performance regarding heat transfer ("Winter Case")

- developed windows should feature easy possibilities for integration of sun screening / shading devices. Thereby, the integration of shading devices in view of compatability with the opening direction can be considered as highly important. Moreover, if possible, the use of the shading devices while parallely allowing ventilation, shall be forreseen.

- Windows should be easily maintainable, and modularly cosntructed, to allow a long lifecycle and easy repair

- Windows should be constructed in sustainable materials, preferably timber.

- windows should be noise-reducing.

In the four realized constructions, very low U-values have been realized (0.7 W.m-2.K-1 and less, depending on the thermal quality of the vacuum glass), as such meeting the major "Winter"-requirement. The integration of shading devices can be - dependent on the opening direction of the window - considered as "easy to realize" up to "complex". However, in two of the constructions, a "offset"-ventilation possibility is possible even at deployed external shading. The modular construction - including motors in all of the prototypes - has been designed to allow easy maintainance and exchange of components. The durability of the components has been ensured by the industrial partners of the project, including 5 window building companies, 1 vacuum glass producer, and 2 supportive industries (window fittings / motor-drivers and window seals).

All together it can be concluded that the windows that have been constructed have been built on the requirement for new, innovative, and energy saving windows for contemporary architecture.

Instruments to examine the performance, beside extensive testing, included numeric thermal bridge simulation.

Key objectives for aesthetics and quality

Needless to say, in a project that adresses new, contemporary windows, an attractive aesthetic is required for two reasons: (i) Architectural Attractiveness is a key USP (Unique Selling Point) for end users and planners; (ii) A certain attractivity (beside other aspects, such as production feasibility) is required to motivate the industry to take on the developed windows in near future in their product portfolio and to take the investments to finalize developement of the windows to purchasable and produceable windows (Windows need to meet several international and national standards pertaining to product properties, sustainability, performance, ...).

As such, the four final mock-ups were required to not only show new technologies (Glazing, fittings), but also meet the critical taste of both professionals and interested consumers. THis was reached via the following aspects:

- comfortable operation of the windows

- use of high-end surface materials

- Design thinking of aspects of usability, such as "Are users potentially hindered in their space use by the immanend open wing that reduces usable indoor space?"). Furthermore, the "sense of wonder" aspect and additional comfort aspects had been considered: (i) Sense of wonder refers to unusual / non-off-the-shelf operation directions (hidden sliding devices); (ii) Allowing the use of "sitting bench" of the window niche via usage of comfortable timber surfaces and high-level surface temperatures posing a comfortable environment if "sitting" in the window.

- Hiding of "technical components" to the end-user, while still enabling easy access in case of maintance, cleaning, and repair.

The final report of the project, which shows lots of illustrating figures and the performance aspects of the windows, can be found here: https://bit.ly/34DSu5L

Key objectives for inclusion

One major aspect of window operation is the inclusion of all users. This includes children, the elderly, and people with impariments. The aspect of Usabiltiy was a major point in the developement of the windows. Thereby major aspects had to be included: (i) Safety / Operation security: E.g. safety against falling through the window, danger of injury by operation, and safety against environmental influence (windshear/attack); (ii) Usability in terms of easeness of operation, understandability how to operate the window, required forces for operation (comparable to stringent standards for operation, e.g. 50 N closing/opening force); (iii) Informational aspects, such as support for the users in correct operation of the windows.

These aspects were central for the attractiveness of the windows as such. While a manual operation was foreseen for all of the four window prototypes, an automization / integration of motor-driven operation, including remote-control via key-buttons and smart-phone-based steering had been rudimentary integrated. As such the required aspects of usability for all persons had been sufficiently considered in the "hardware". Moreover, safety features, such as avoidance of injury if one gets into the closing operation (fingers, forehand, ...) has been considered also from point of the software lying behind the operation: Comparably to automated doors (e.g. Subway trains), safety routines that avoid closing ´/ opening if (unexpected) resistance is detected in operation.

The integration of ventilation "opening positions" that allow ventilation, but are not a full opening, is another important feature of the windows. This allows property safety at the same time as ventilation during absence times of occupants.

Results in relation to category

The present project is delivered in the category "Techniques, materials and processes for construction and design".

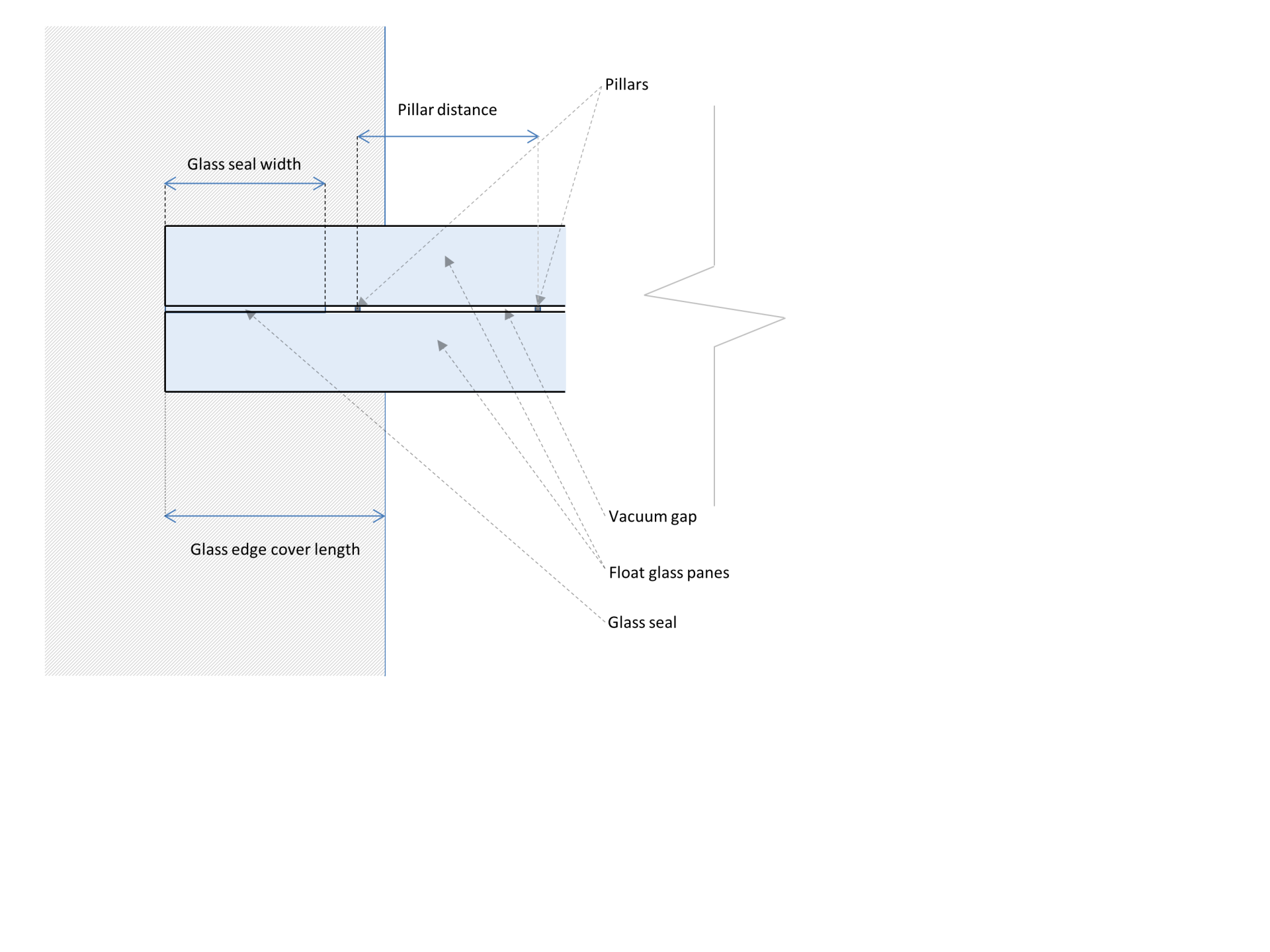

Windows are in general considered as important, but thermally weak sport in building envelopes. The integration of highly-insulating vacuum glass (Ug-value: 0.4 - 0.7 W.m-2.K-1) will become a common feature in close future regarding highly-insulating transparent building components. However, the FIVA project was - to the knowledge of the authors - the first that really tried to include these new and emerging glazing products into tailored-for-these-products windows. The critical point of vacuum glass, the durability of the vacuum layer via spefic seals, was not a developement point of the projects. Rather, extensive testing of vacuum glazing products had been conducted in prior R&D ventures conducted by parts of the consortium starting in 2014 (Project Vig-Sys-Reno, see here: https://bit.ly/3fY0KTs). In these previous efforts, the long durability of vacuum glass was confirmed via a lot of stress testing to the windows (Deforming, breaking, stressing via different force patterns), allowing to assume this property as design basic for the FIVA-windows.

In this context, the partner projects of MOTIVE and VAMOS (can be seen via www.nachhaltigwirtschaften.at) shall be mentioned: While MOTIVE was the less Technology-Readiness-Level approach before FIVA, VAMOS is a monitoring based project that examines historic casement windows upgraded with vacuum glazing.

The consortium tried its best to implement a holistic approach, considering production aspects (vendor parts, feasibilit of products), innovation (opening patterns, automatization, attractiveness) and performance aspects (thermal performance, acoustic performance). As such, we believe to have delivered an important impact on the ongoing discourse of energy-saving transparent building envelopes.

How Citizens benefit

The lowering of heating demand and cooling demand of buildings is crucial to mitigate the impact of climate change and to strick to the 1.5. Degree Celsius Climate goal. The provision of afforable, high-performance windows is of high priority in improving the energy performance of buildings. Building components that have a long lifetime are equally important to decrease the envrionmental footprint of the built environment.

Increasing the design possibilities for high-performance building envelopes as such can be considered as beneficial for society.

People benefit in different contexts and scales:

- building occupants benefit from increased comfort in indoor spaces that can be achieved at a less energy consumption than in less insulated buildings (Buildings with highly conductive transparent components).

- On a larger scale, the reduction of building energy use and increased comfort can have beneficial aspects on population health and environental footprint of a society.

- Innovation in building construction secures jobs and technology leadership within the EU, and offers solutions of a broader scale. As such, innovation in the building construction domain might be beneficial for gross domestic products.

- Blue-Collar construction workers and craftspeople in the construction domain profit from a better ratio of thermal performance and weight of components (vacuum glass is comparable "light") in ease of handling the windows. As such, construction works can be facilitated with all positive side effects (speed of construction, required manpower, cost of construction).

Innovative character

The present project was Europe-wide the first project that considered a different approach onto design and construction of windows employing vacuum glass. Thereby, the specific construction necessities of vacuum glass had been considered.

The designing and construction of windows that specifically utilze the strong parts of vacuum glass products and consider potential weak spots was new for all involved parties and the domain as such.

The construction of disruptively new windows in view of energy performance and operation break the strictly linear dimension of turn/tilt wondows as "established" in central Europe.

The utilisation of numeric thermal simulation for improvement of components per se is nothing new, however, based on these efforts, the necessity of further developement of standards for windows is of critical importance for the next steps.

The stringent automatization of windows brings different benefits, e.g. nighttime ventilation, window operation for people with special needs and impairments, ventilation in non-occupancy times, and similar.