Soft Rigid

Basic information

Project Title

Full project title

Category

Project Description

In France, we produce more than 2.3 million tonnes of plastic packaging per year. 24% are recycled.

I am focusing on LDPE film for professional use. It is used to wrap pallets during transport or for hay bales. I am looking for a waste transformation process that requires few steps in the process and low energy.

My goal in this project is to close the life cycle of waste by reintroducing it directly into the company, in a short circuit logic and also to give another vision of this waste.

Project Region

EU Programme or fund

Description of the project

Summary

I am focusing on LDPE film for professional use. It is used to wrap pallets during transport or for hay bales. This waste is little recycled. When it is processed, it is melted to produce plastic bags in particular.

Better recycling of this waste is possible.

I am looking for a waste transformation process that requires few steps in the process and low energy.

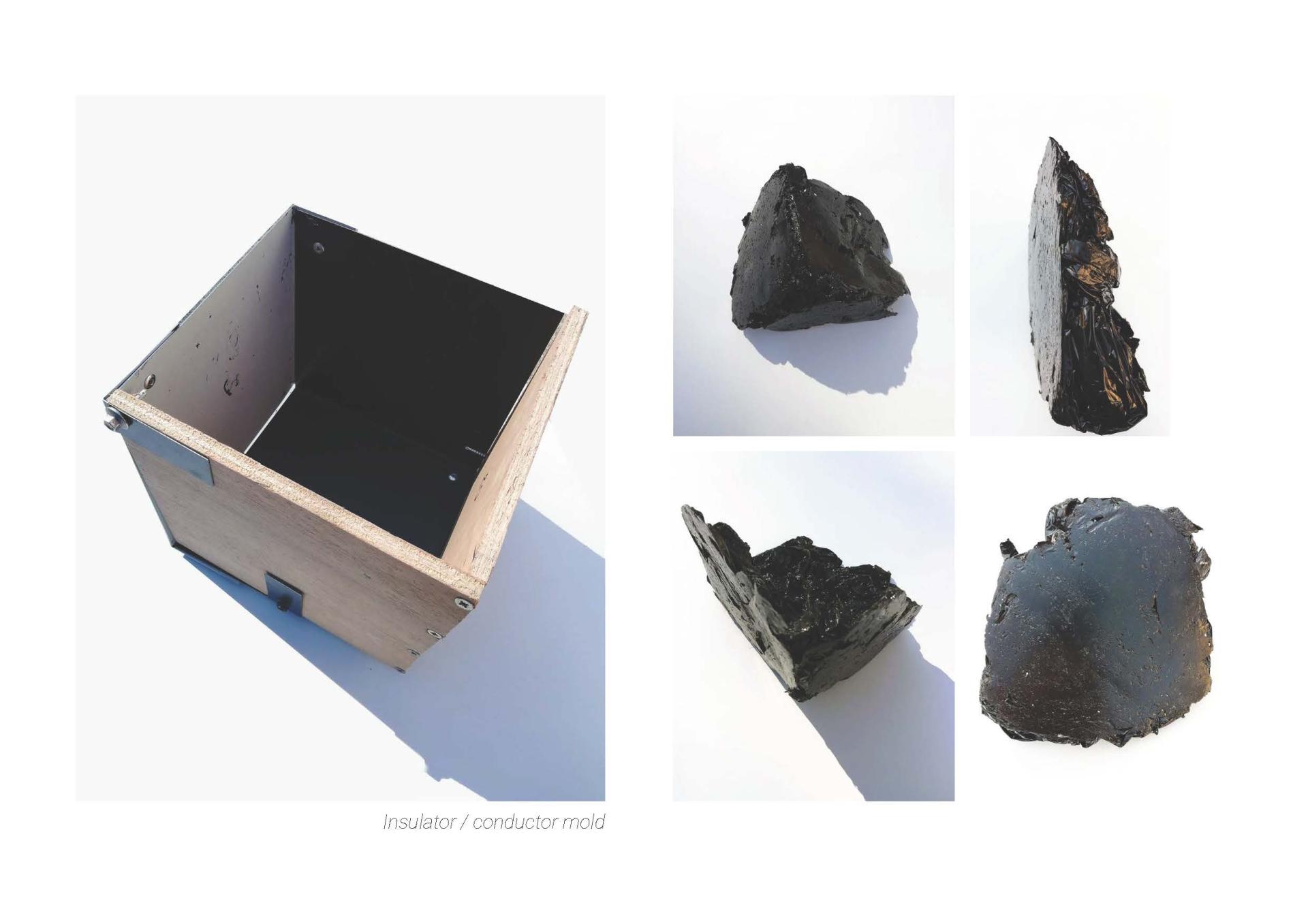

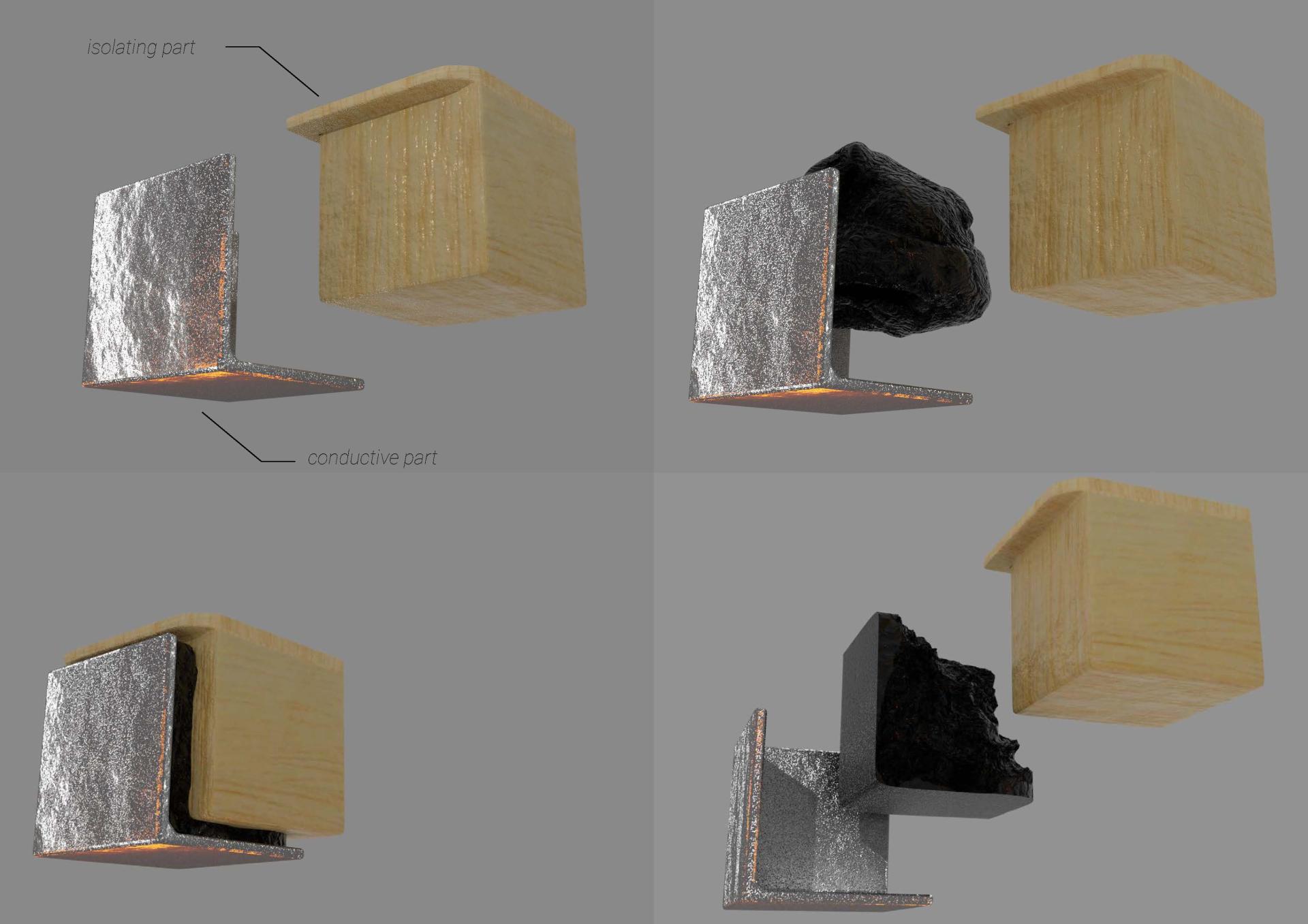

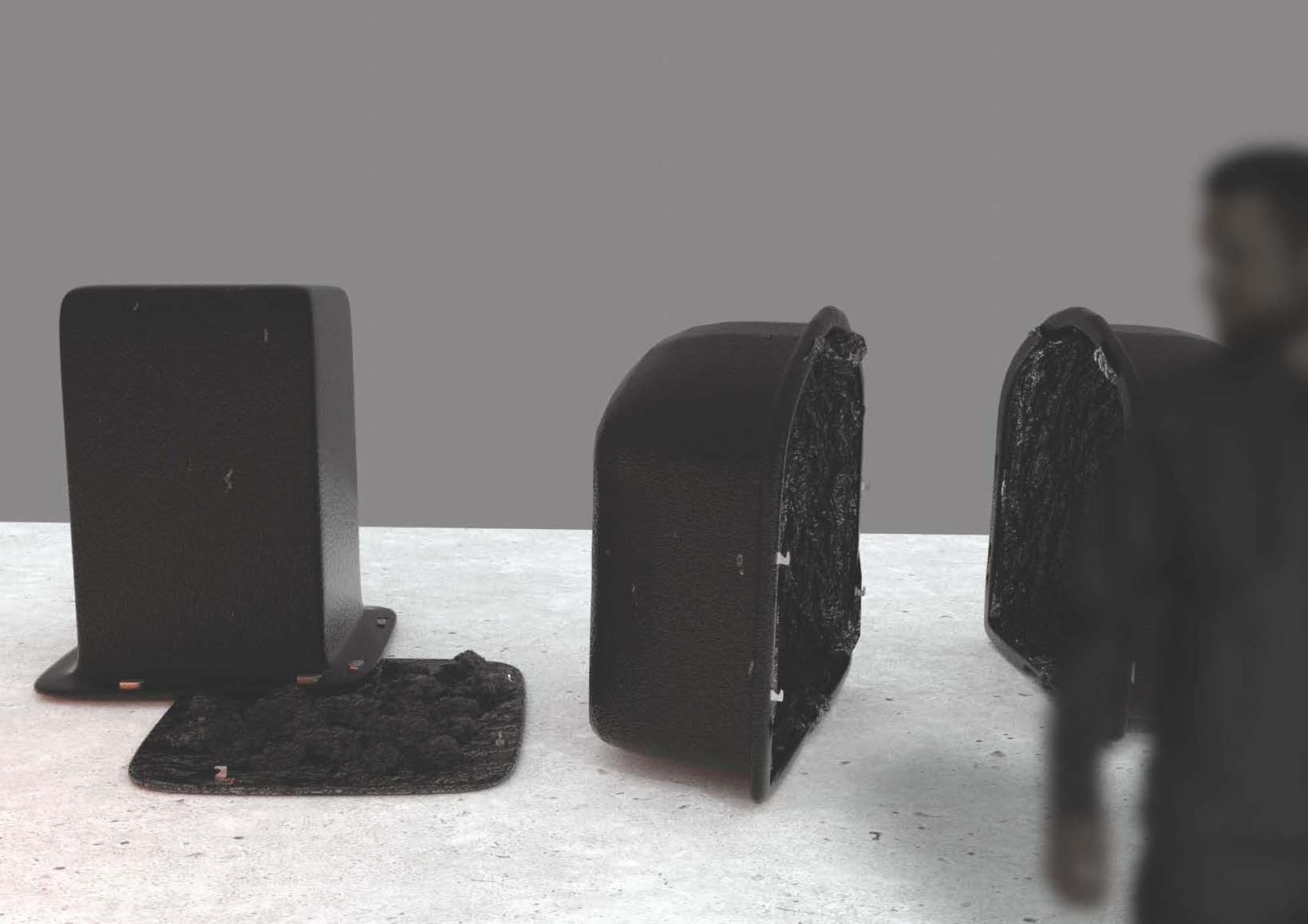

By melting the waste on the surface, I obtain volumes that combine the soft and the rigid. I explore this principle by making molds that combine insulating part and heat-conducting part.

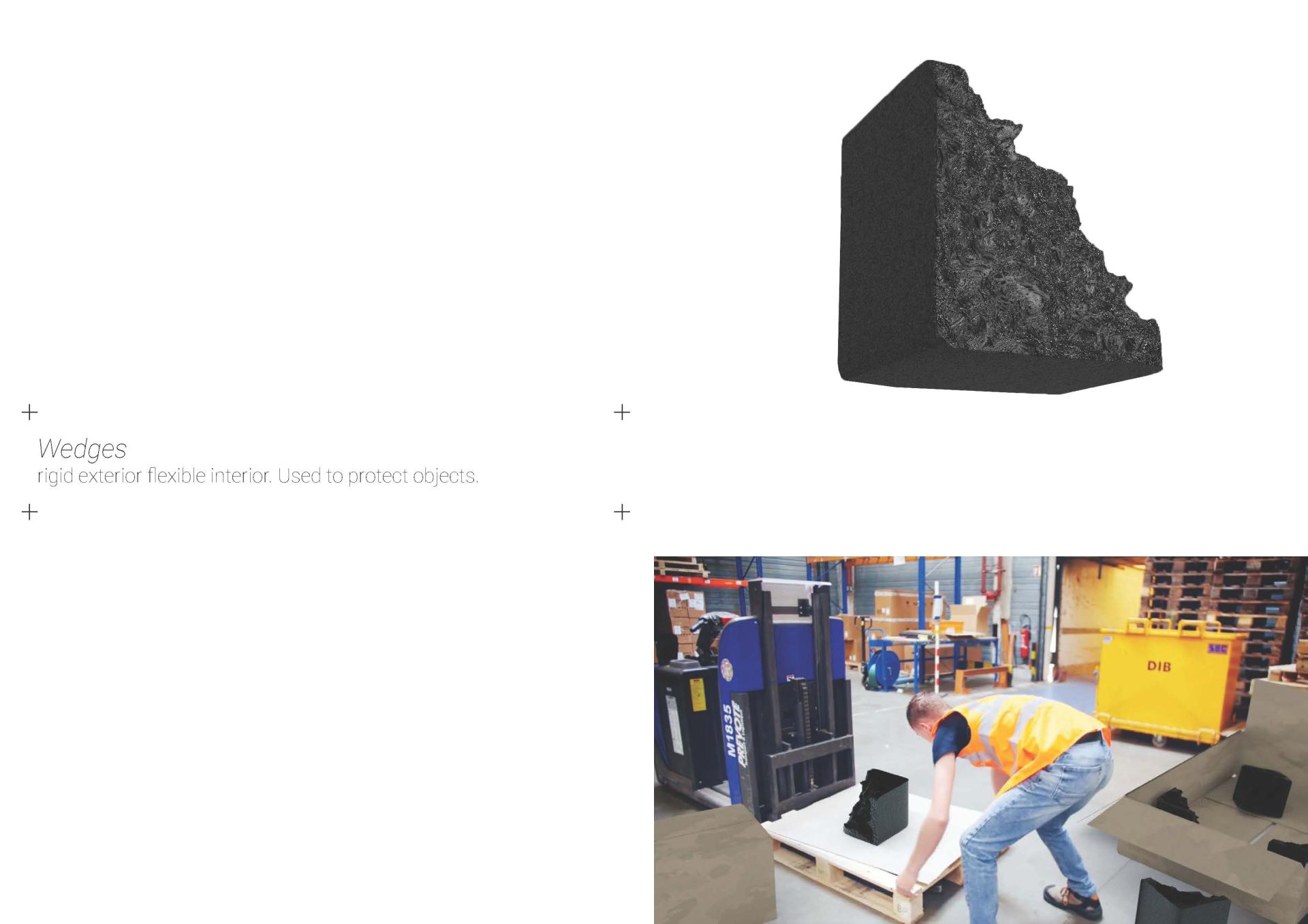

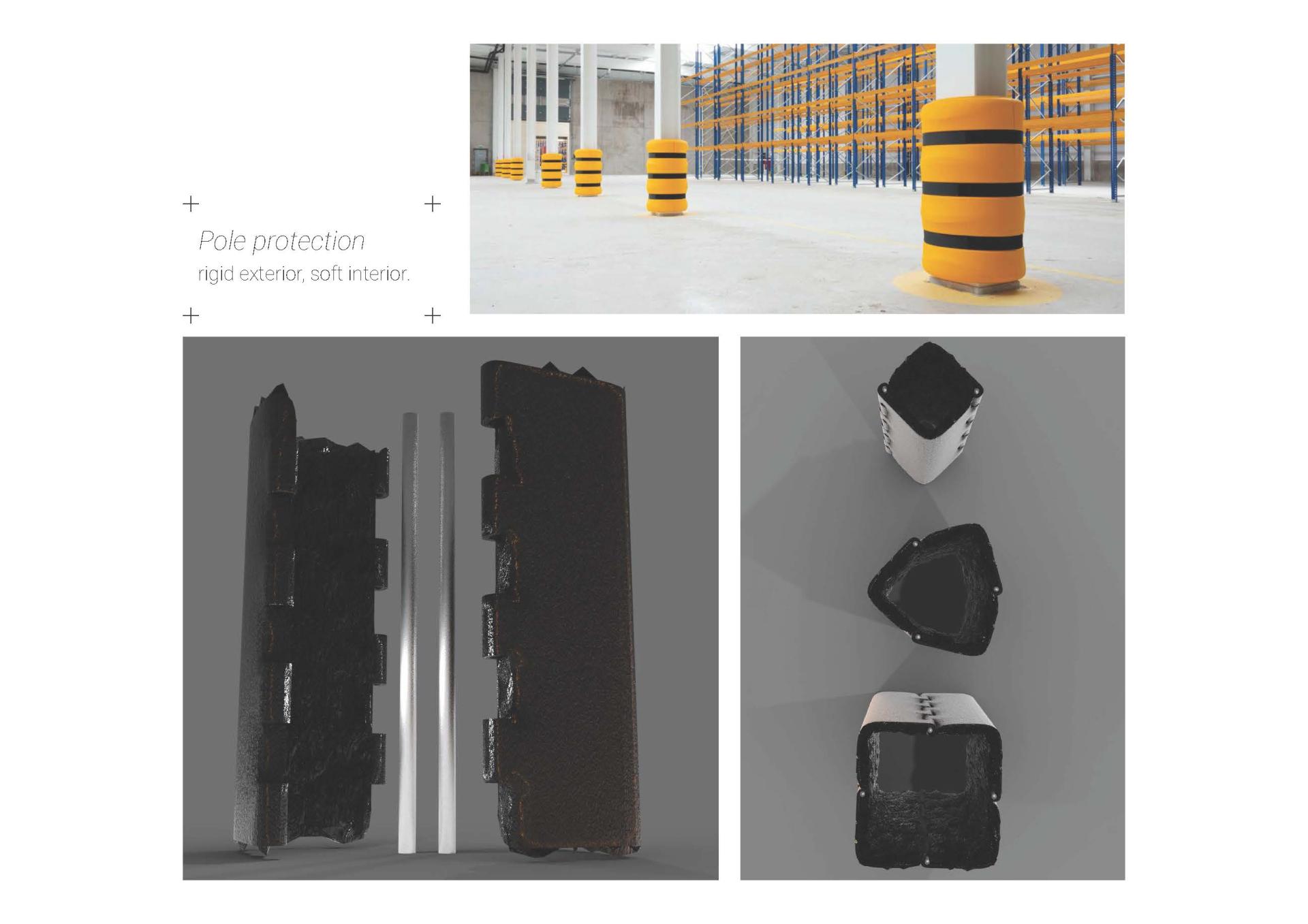

The construction industry is a sector in which this plastic film is present in large quantities. I identify plastic objects used in these trades. LDPE film can be transformed into this type of object. The goal is to close the life cycle of waste by reintroducing it directly into the company, in a short circuit logic.

Key objectives for sustainability

The main objective of the project is to find a way to reuse plastic films that has the least impact on the planet. Thus, the process that I invented requires few steps, materials and heat. Plastic is heated to a temperature below 200 ° C, at this temperature it does not release harmful gases. The transformation can be carried out by the professional who produces the waste. The created object can also be used by the professional in question. There is no transport to take into account in the carbon footprint of this approach.

Key objectives for aesthetics and quality

By experimenting with this material, I discovered its ability to be very rigid and flexible, on the same volume. This particularity makes it possible to create protective objects at different scales which find their place in the construction industry.

Key objectives for inclusion

The process I developed requires little equipment and energy. In fact, the transformation can be carried out directly by the company at the origin of the waste, to create objects for itself or other companies nearby. This short-circuit approach therefore sets up a local ecosystem, united and engaged in actions aimed at making our activities more sustainable.

Innovative character

Today, industrial and agricultural plastic film is not recycled much because this waste is often dirty and therefore impossible to transform. Also, sorting centers are often far from companies, which makes it difficult for the professional to transport plastics. When this plastic is recycled, it is transformed into plastic film or bag, these transformations take time and energy.

The process that I have developed allows the company or the farmer themselves to transform the plastic waste, as is, without having to treat or clean it. The process requires little time and energy.