TAREC²

Basic information

Project Title

Full project title

Category

Project Description

TAREC2 aims to transform waste wood biomass ash into resilient construction composites. By superimposing an interdisciplinary approach to identify ash as a valuable raw material for the 21st century construction industry, the problem of industrial waste is solved while conserving natural resources. The use of WBAs in the construction industry is a decision motivated by environmental protection but also triggered by the application of WBAs in creating sustainable and affordable products.

Project Region

EU Programme or fund

Description of the project

Summary

The project was carried out from 2017 to 2021 with the ambition to develop new construction composites with wood biomass ash. Bioenergy has more than doubled since 2000 and accounts for 56.6% of total renewable energy in the EU. The development of wood biomass power plants already leads to significant amounts of WBA, as the combustion of 1t of wood biomass generates about 3% WBA. It is foreseen that the use of energy from wood biomass power plants will lead to the production of around 600,000t of biomass ash in the EU in the future. These figures are a strong indicator of the need for strategic and sustainable management of waste ash. In addition to highlighting WBA as a valuable resource in building materials used as a partial replacement of cement or fine aggregate, the aim of this research was to ensure added value through the inclusion of other waste types, such as recycled polymer tyre fibres. To enable the transition from low-value applications where WBA are currently used, such as soil amendment or fertiliser, usually without any form of control, to high-value applications, both the mechanical and durability behaviour of the designed composites were monitored for the first time. This is of great interest to all concerned, as many supplementary cementitious materials have a negative impact on the long-term behaviour of the finished products. Moreover, promoting eco-innovative solutions to prevent waste generation and boost the reuse of waste as a novel material can improve the natural and living environment in urban and rural areas. TAREC2 applied an interdisciplinary approach with unique and synergistic expertise that considers a circular relationship between urban metabolism, waste and infrastructure. Providing a detailed insight into the impact of WBA on the mechanical and durability properties of cement composites is recognised as the first step in defining the missing guidelines for the acceptance of WBA as a new raw material in the construction sector.

Key objectives for sustainability

Sustainable waste management and promotion of waste reuse, as part of global sustainable development, have been highlighted throughout the project as key pillars of raw materials supply. The complexity of the TAREC2 'waste to construction' framework required multidisciplinary expertise in complementary fields, which was brought together by the consortium, consisting of scientists from civil engineering and chemistry, but also representatives from the concrete and energy industries. The overall approach was to create a multidisciplinary and cross-scale process for WBA quality control, optimization, and utilization of novel construction material. Also, by addressing the lack of standards and guidelines for WBA application, the impact of the project would be maximized, leading towards sustainable use of WBA. Through the adoption of the "Circular Economy Package", including the Waste Amendment Directive 2018/851 and the Landfill Directive 2018/850, the EU strongly supports minimization of waste landfilling. Renewables are certain to become mainstream, shedding the 'alternative' label as they meet the rising global energy demand. This backs up Europe's plan to achieve climate neutrality by 2050, the backbone of the European Green Deal, underpinned by a legally binding target of net-zero greenhouse gas emissions. While wood biomass is seen as a sustainable alternative to coal, WBA appears to be a serious environmental and economic problem. For that reason, novel concrete containing waste materials is a viable solution that simultaneously solves the problem of industrial waste disposal and reduces the use of energy-intensive Portland cement clinker. The above objectives address the following specific impacts in terms of sustainability: development of breakthrough innovative technologies & products with high potential to achieve a green circular economy, improved resource efficiency, reduced environmental impact, and more sustainable consumption of natural resources.

Key objectives for aesthetics and quality

The response to solving WBA management must be holistic and comprehensive, involving all stakeholders, from global policymakers to the public sector and private companies to academia and civil society. Customer experience has been identified as a strategy to boost a positive approach to the acceptance of novel materials in the construction sector and make them competitive with conventional materials. The drive to fuse different domains into a functional, seamless, and harmonious whole in terms of quality of experience included recognition, involvement, education, and community engagement. Involvement and community engagement are fundamental to educating society to a new collective and moral consciousness formed on a shared sense of responsibility. Although the Covid 19 pandemic led to the largest drop in global emissions ever, the rate of increase in CO2 emissions from fossil fuels in 2018 was the highest in the last 7 years. Thus, stopping all greenhouse gas emissions would still not prevent the climate impacts that are already occurring. Therefore, it was necessary to recognize WBA as a serious environmental and economic issue, as well as a sustainable substitute for primary raw materials that would help reduce energy consumption and greenhouse gas emissions, in addition to intensifying the use of alternative materials. In order to be competitive with unsustainable conventional building materials, it is essential to outline the guidelines and standards required for a wider application of WBA in the construction sector. From this perspective, the development of a new value chain based on the valorization of WBA is the basis for promoting employment in the construction industry. Furthermore, education in terms of improved and continuous communication and knowledge transfer with stakeholders, decision-makers, and potential end-users is crucial to find a suitable application for each WBA.

Key objectives for inclusion

Inclusion as a value that our project promotes implies a process of developing an affordable and novel material that focuses on waste recycling, improving waste management systems, and their future implementation in the construction industry. The ultimate goal is the welfare of the whole society, involving not only experts and scientists but also the entire local community. In order not to exceed the benefits of using this waste material as a partial cement substitute, WBA should be utilized nearby the energy plant where it originates from, taking into account CO2 emissions due to transportation. Local production of wood biomass offers green skills and renewable jobs to the local community. Incentives for education and training are necessary to meet future skills needed for a successful and imminent energy transition. These incentives should take into account social and gender equity. It is important to note that ensuring gender equity within the project and positively influencing gender equality in the construction and energy sectors was a major concern. With the aim of achieving a balanced participation, ten women and six men were immediately involved in the research. There was also a focus on introducing, enabling, and integrating measures that would attract the full range of investors, from individuals and communities to larger companies, to participate and invest in innovative technologies and materials, not necessarily just capital, but also their time, involvement and effort.

Results in relation to category

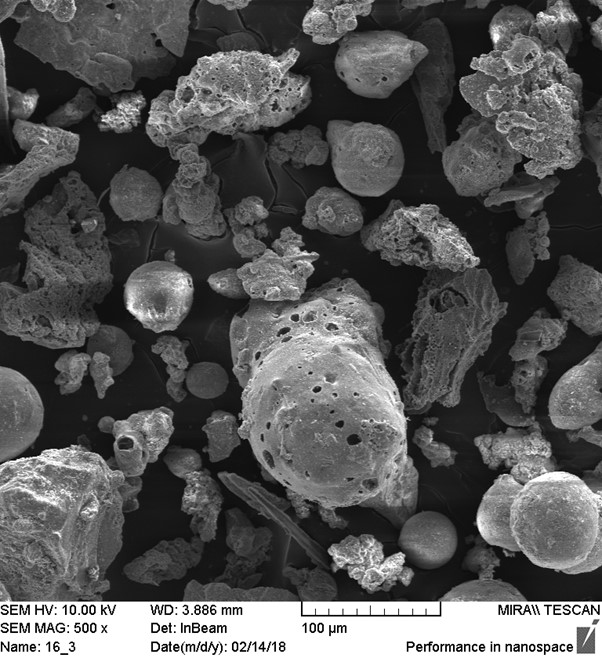

With the adoption of the European Green Deal in 2019, the EU has committed to becoming a carbon-neutral global leader by 2050. Energy-intensive industries, including the cement industry, which is one of the largest CO2 emitters in the world, are crucial to the European economy; therefore, decarbonization of this sector is essential. The cement industry should increase energy efficiency by using alternative materials as fuel and/or raw material. Addressing these challenges has brought supplementary cementitious materials into focus. To ensure a thorough transformation of Europe's energy system, ambitious targets have been set for all EU member states, including the implementation of at least 32% renewable energy by 2030. To achieve this, Europe aims to phase out coal combustion by 2030, relying largely on renewable energy capacity to fill the gap left by the decline in coal combustion. Bioenergy and biomass in particular could make a valuable contribution to building a low-carbon energy system. Due to the already existing scarcity of landfill sites, strict EU landfill regulations, and air pollution from wind-borne particulate matter causing respiratory health problems for residents living near landfills, the disposal of WBA in landfills should be managed appropriately restrictive. Leaching of heavy metals from WBA, which can lead to contamination of groundwater resources, is also a major concern. Therefore, efforts to reuse waste translate directly into cost savings and protection of the environment and human health. TAREC2 has developed innovative solutions to mitigate the impact on the environment, including a detailed characterization of the available WBA. Considering combustion technology, kiln and tree types, and hydrodynamics, the development of novel mineral admixtures and construction composites has been carried out as a tangible experience through the implementation of mini-demonstration projects in collaboration with construction industry representatives.

How Citizens benefit

Since TAREC2 is a project that revolves around people and the environment, it deals with complex relational issues that go beyond that. Reuse and recycling is fundamentally a people-centered environmental solution and must concern a profound cultural change that requires access to people, places, and policies, as well as technologies and techniques. Blueprints must describe new institutions and markets built around networked systems, assemblages, and relationships, not just silos and sectors. Considering that the current practice of WBA management in Europe is based on the disposal of WBA in landfills, mostly without any form of control, resulting in additional costs and endangering the environment, the existence of illegal landfills is also a growing global problem. Therefore, showcasing and promoting the health benefits of reusing WBA instead of merely landfilling was a milestone to increase the success of the project. Replacing fossil fuels with renewable energy technologies is not only a positive force for our climate and health but also for civil society as an integral player for sustainable development. In order to demonstrate to the industry and end-users that advanced solutions and highly acceptable products can be developed in the construction sector with WBA, four workshops were organized during the project. Findings on environmental, technological, and economic competitive benefits of the project were highlighted. Benchmarking of new construction products and products available on the market, as well as the whole production chain, was developed to reach key stakeholders, decision-makers, and potential end-users. Improving the availability of information about the project at all levels of dissemination, scientific, professional, and the general public, was important to encourage the participation of civil society and to create a positive environment for the future use of the project results.

Innovative character

TAREC2 was based on the development of innovative solutions with reduced environmental impact through a detailed characterization of the available WBA. As a first step, it was important to investigate to what extent the market is ready to accept WBA and innovative products such as the "novel" concrete with waste materials. The innovative contribution of the research was to develop resilient construction composites using wood biomass waste and demonstrate applications that maximize economic value and provide comparable or better durability when compared to traditional concrete. To achieve this goal, the proposed project had to overcome scientific and technological challenges in detailed characterization of available WBA considering combustion technology, kiln types, hydrodynamics, and tree species to develop novel supplementary cementitious materials and novel construction composites by combining WBA, cement, or other SCMs and implement performance-based design. By conducting mini-demonstration projects and using the developed materials/applications, two demonstrations of WBA application were conducted in collaboration with the construction industry, where finished products with WBA were tailored to provide a full understanding of the new potential material in the construction industry. Firstly, the demonstration of WBA application was carried out in the production of precast concrete elements, which included the production of gutter and paving concrete elements. Secondly, the production of blended cement containing WBA was carried out in collaboration with a cement factory. It was shown that the use of WBA in industrial production is possible and that WBA is a valuable material, through the application of which satisfactory properties of the final product can be achieved and which contributes to strongly emphasize the problem of industrial waste disposal.