Timber Earth Slab

Basic information

Project Title

Full project title

Category

Project Description

Timber Earth Slab is the first timber construction system that can challenge concrete on a global level by providing mass-producibility, high fire resistance and – crucial in hot and warm climates - thermal mass. Harvesting the strengths of timber and earth by robotic fabrication and material science, we have prototyped a cheap and ecological high-performance system with which we can build our ecological cities and high-rises of the future.

Project Region

EU Programme or fund

Description of the project

Summary

Developed in an interdisciplinary master's thesis, Timber Earth Slab is a high-performative, sustainable and economical construction system based on natural materials. By utilizing recent advances in digital fabrication and material sciences, it provides a solution for the complete lack of global alternatives to concrete construction.

While concrete pollutes our planet - cement production alone accounts for 8% of global CO2 emissions - there hasn't been a serious alternative: Timber construction is not only vulnerable to fire and sound transmission but offers too little thermal mass, being therefore unable to store enough cool energy at night to prevent the building from overheating during the day. This is why people in Southern Europe (and many other parts of the world) build their houses out of stone. While we actually have enough wood to make the switch towards timber construction, it doesn't make sense on a global level because the initial CO2 savings would in most parts of the world be over-compensated by an increased cooling energy demand. We have to do much better than that.

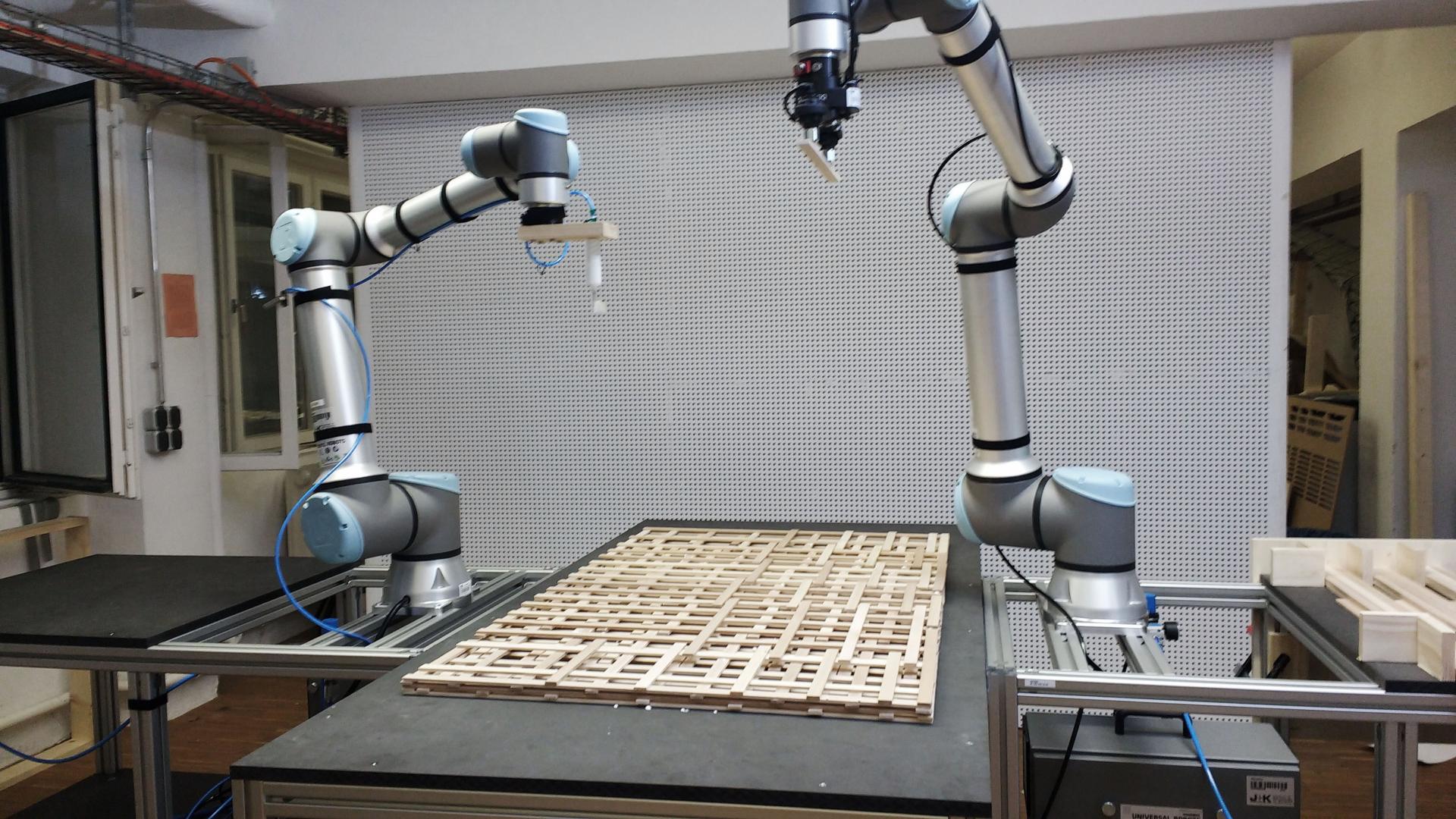

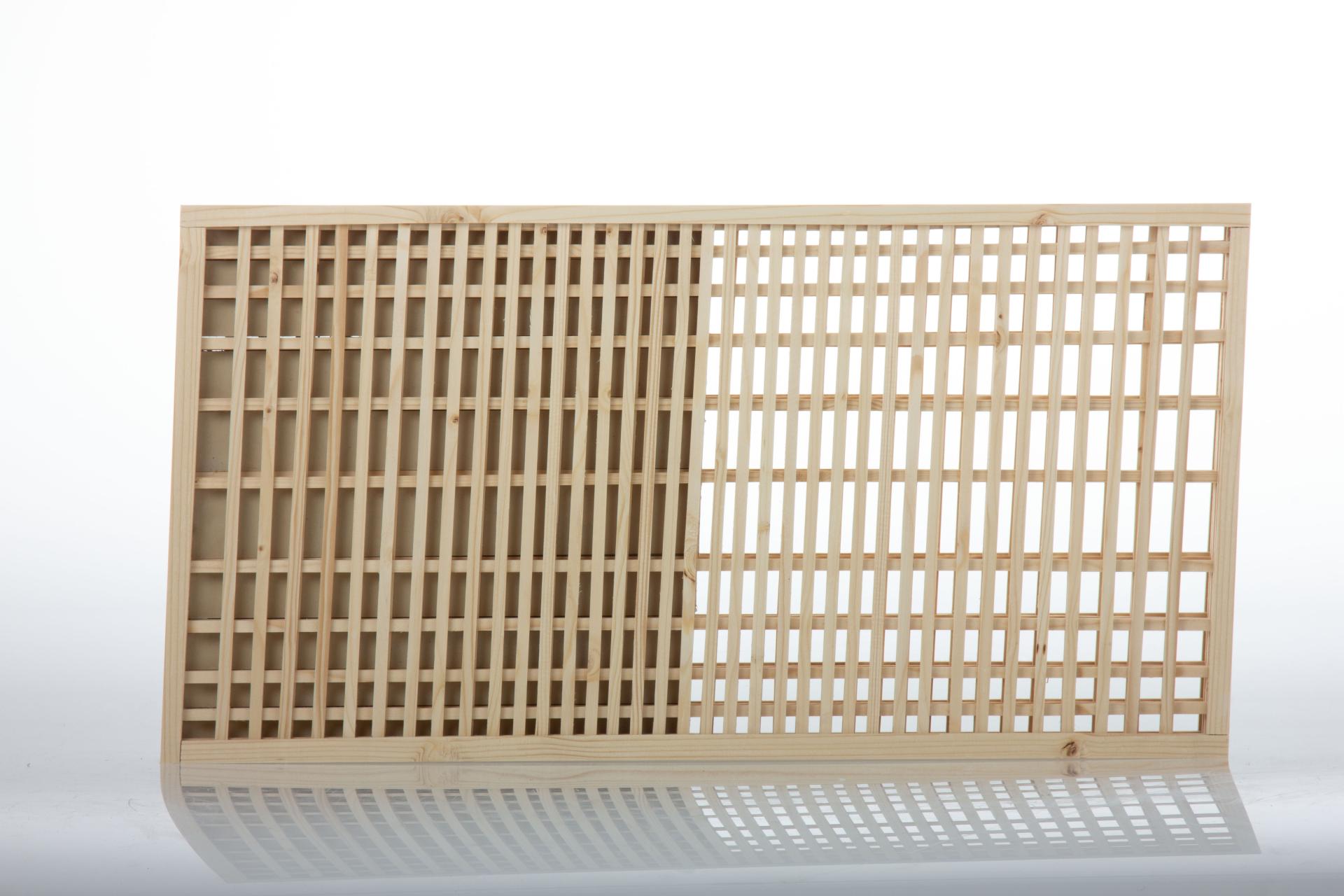

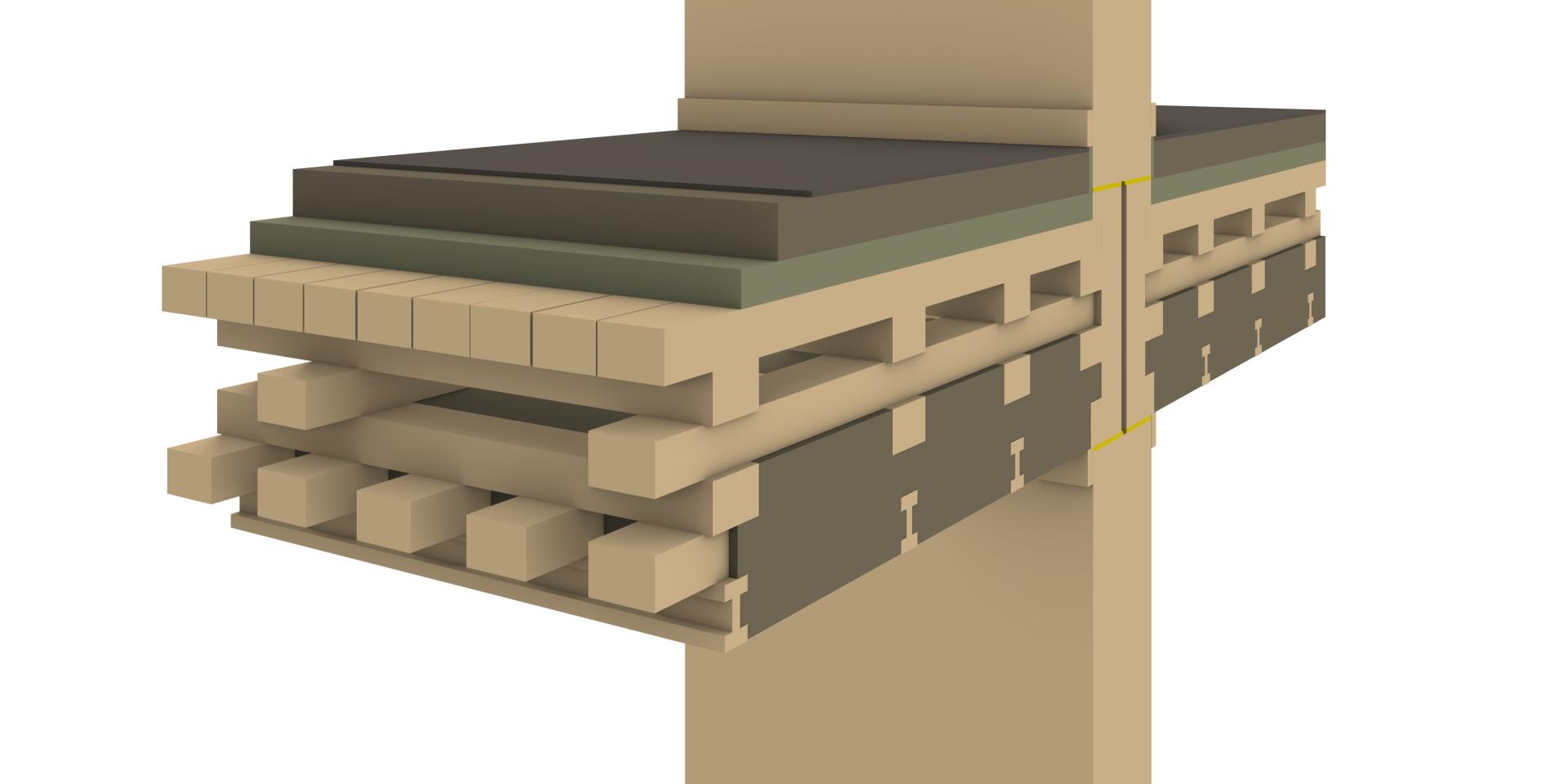

To provide a solution for this dilemma, we have developed a simple component that can serve as a floor slab or wall: A timber structure covers all structural requirements while an earth infill provides fire protection, sound insulation, and, crucially, thermal mass. Robotic fabrication allows for the economic prefabrication of a fine-grained, structurally optimized, cross-laminated timber structure that provides mechanical interlock for the infill which, thanks to the material technology by ETH-spinoff Oxara, can simply be cast like concrete. After a drying phase of approximately two weeks, the slab can be transported and installed on site.

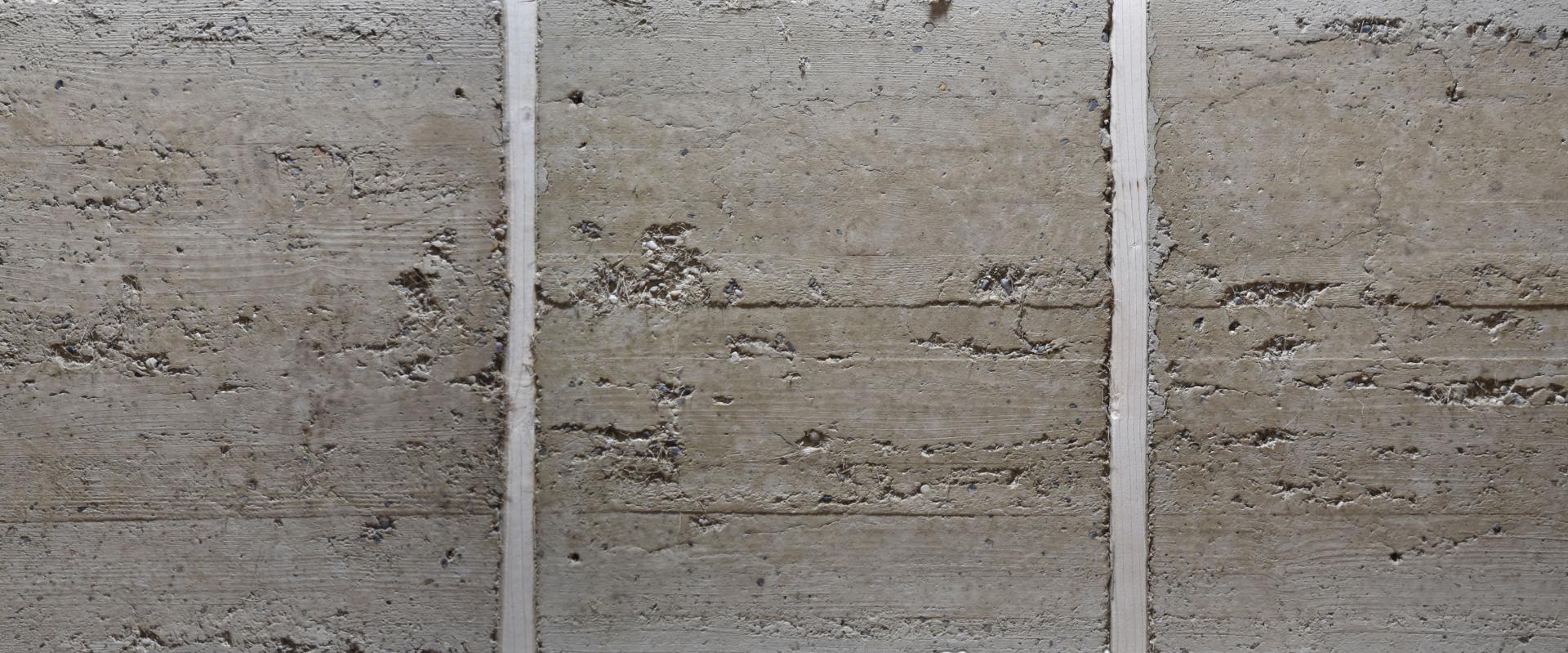

Prototyping the system in 1:1 and under bending, we were surprised to find out that it actually works. The earth infill was solid and did not feature any tension cracks or particles falling down even as jumped around on the slab.

Key objectives for sustainability

The overall mission of Timber Earth Slab is to fight global climate change. The strength of TES is its ability to deliver high sustainability throughout the lifecycle:

- Low CO2 emissions in the construction phase: thanks to the use of timber - which is CO2 negative - and earth, which is available in abundance and requires very little energy in its production

- Resource-efficiency: Due to structural optimization and the approach of applying earth for all non-structural tasks, the timber consumption of TES is very low, ensuring that it can be applied globally without leading to mass deforestation. Earth on the other hand is anyways available in abundance; in our prototyping, we simply got it from a gravel plant where it is a waste product. To complete the mix, one only needs a very small number of fibres - 1kg/m2 of flax in our case but whatever is available in the specific region will do -, a little amount of mineral admixture, water and, if it shouldn't be found in the earth material, sand and gravel.

- Less energy consumption throughout the lifetime: The thermal mass of the earth infill keeps the building warm in winter and cool in summer. Like concrete, it can be thermally activated, allowing for the use of low-temperature energy sources such as waste heat from server centres and the use of excess energy.

- Recyclability: The earth infill can be re-liquified and therefore easily separated from the timber structure and reused infinitely. The timber structure can on the other hand be downcycled to wood products or decomposed. Being protected by the earth infill, the timber does not require any protective treatment that could compromise its recyclability.

Key objectives for aesthetics and quality

A central part of TES is the desire to make the natural aura of timber and earth actually perceptible to the user.

Interiors with natural surfaces are often seen as a little luxury in modern construction, usually reserved for projects with decent budgets while low-budget projects such as social housing have to do with plasterboards and PVC floors. Moreover, most components in multi-storey timber buildings have to be encapsulated with gypsum boards to meet fire safety requirements. Particularly in most modern timber high-rises, the natural character of the building is not accessible to the user who instead only gets to experience the usual artificial interior finishes one can find in any other building.

With earth being non-inflammable, Timber Earth Slab does not need any encapsulation but the natural character of the building can be seen, touched, and smelled by the inhabitants. While in the initial design phase there were many people who were skeptical about exposed earth in the interior, all doubts faded away once they could see, feel and smell the physical prototypes with their warm and soft surfaces. If desired, however, plaster or paint can always be applied.

Very thin timber boards in the ceiling have turned out to lead to a surface that, as we have found out, is visually appealing to many. Originally developed as a counter-measure against tension forces, they have turned out to be not strictly necessary from a technical perspective, but considering that they hardly compromise thermal mass and fire safety, they have been kept as part of the concept.

Key objectives for inclusion

Fighting climate change with TES can only work out if it is a system for everybody, rich and poor, and can be implemented in any kind of building - be it an office tower in Dubai, be it a school in Cameroon.

It is for this reason that TES was designed with the objective of material efficiency and mass production from the first day on. We believe that healthy and sustainable building components do not need to be expensive. Digital Fabrication for us does not serve for spectacular shapes in high-end projects but for creating safe and efficient construction processes to produce ecological high-quality components for everyone.

Beyond digital fabrication, we are also developing alternative designs and processes to make sure that the system can also be built efficiently when there is no robotic equipment at hand. The development of TES is open-source. Everyone can assess the software tools and details on the design and construction process and is welcome to implement the system on their own and share their experiences.

Innovative character

There are no floor slabs out there that can deliver good values sustainability, economic efficiency, and performance in regards to fire resistance, sound protection, and thermal mass at the same time. Considering that floor slabs often constitute more than 70% of the total load-bearing volume, TES steps into a very painful vacuum by seizing digital fabrication and material technology to channel the forever existing strengths of timber and earth into a revolutionary building kit that finally satisfies all requirements.

After all, these two elementary building materials complement perfectly: Timber has very good load-bearing capacities, but its characteristics are in many ways disadvantageous if one wants to achieve high fire resistance, thermal mass, and sound protection. Earth on the other hand can offer all of that but has very poor structural parameters and is usually hard to work with since it has to be rammed.

By eliminating the need for ramming earth by adding a very little amount of minerals developed by Oxara while using digital fabrication to create a timber structure that can offer sufficient interlock for an earth infill, a high-performance construction kit is born.

We have already programmed an A.I. configuration tool in Python with which planners can automatically generate a structurally optimized geometry in a fast and simple way and send the data directly to the robot and verified it by robotically assembling a slab in scale 1:4.