Mineral Accretion Factory

Basic information

Project Title

Full project title

Category

Project Description

Mineral Accretion Factory is an alternative production system of objects and furniture based on an artificial reef production process developed to restore coral reefs and seabed (fauna, flora).

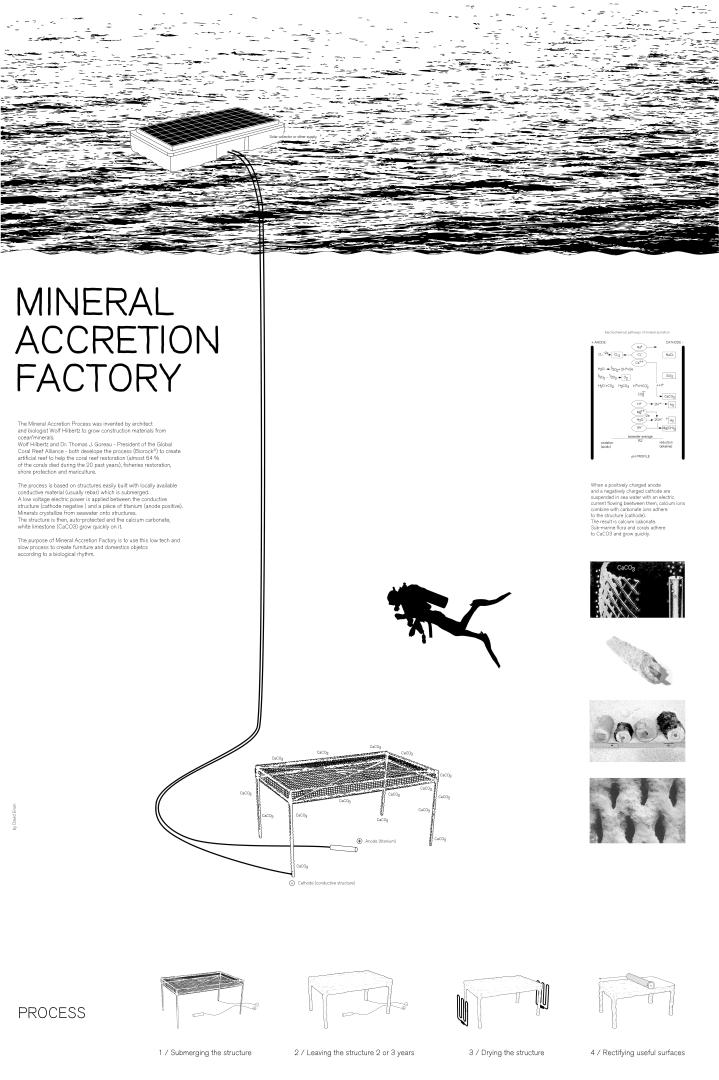

It consists of the immersion of a steel structure (the object’s skeleton) connected to a low-voltage supply (solar panel or windmill). A redox reaction starts, the object is self-generated, made of a material created from the ocean’s minerals in collaboration with non-humans.

Project Region

EU Programme or fund

Description of the project

Summary

Mineral Accretion Factory is an alternative production system for objects, furniture and constructive parts with a positive impact on the environment.

This principle diverts and augments the construction method of “Biorock” artificial reefs which enables the reconstruction of coral reefs which have been decimated by man (global warming and ocean acidification) and the preservation of the coastline (flora, fauna).

This production method consists of immersing a steel structure (skeleton of the object) connected to a low voltage supply (buoy equipped with solar panels or wind turbines). An electrochemical reaction is triggered. The ocean minerals cluster around the structure. The object creates itself with a material stemming from ocean minerals. At the end of two to three years the result achieved is more resistant that reinforced concrete.

The hypotheses of the project were put forward for the Analog exposition at the Ecole supérieure d’art et de design TALM in 2010.

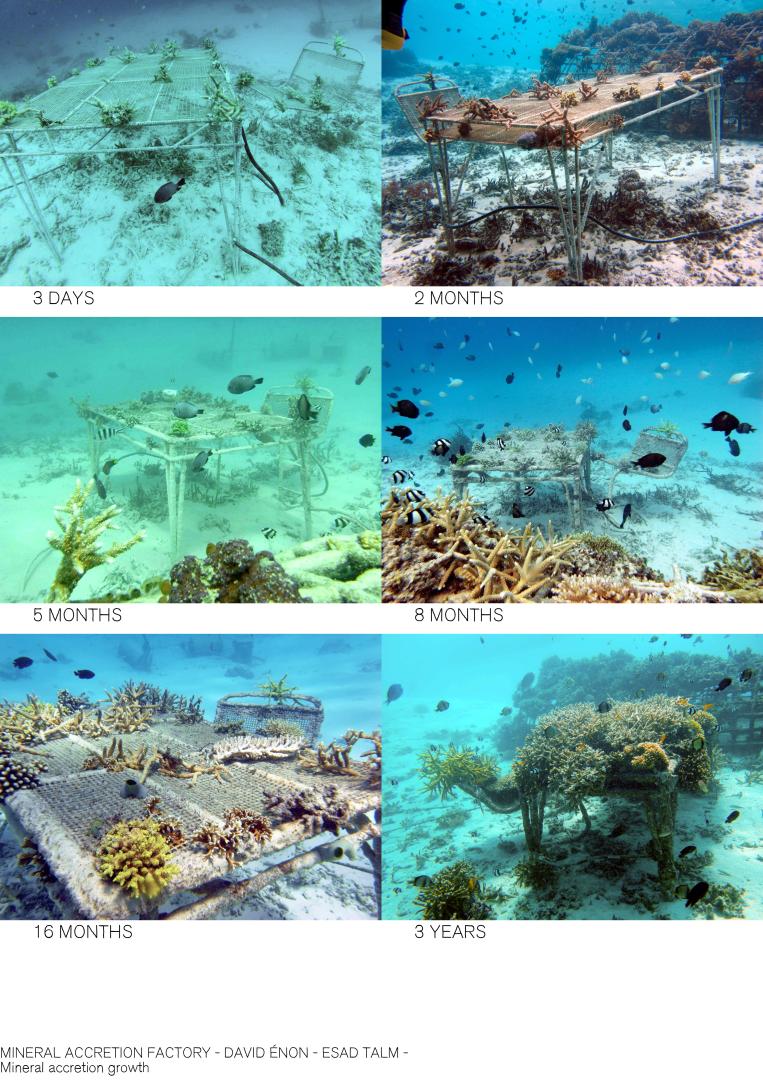

The first try took place in November 2012 during the 8th Biorock International Workshop in Gili Trawangan (Indonesia) This first experiment enabled us to understand the principle of mineral accretion; address the main biological and ecological challenges; design, manufacture and submerge the object prototypes. The project took another turn on the island of La Réunion in 2016. Two workshop sessions with the students of the École supérieure d’art de La Réunion (ESAR) took place and enabled the implementation of a partnership with Kélonia, a marine turtle research centre and museum. A first series of test objects, made with the ESAR students, were submerged into Kélonia’s basins. A series of “obvious” objects which question the relationship between production, design and nature is currently being produced. The first series of objects, eight public benches for the outside areas of Kélonia, is in the final stage of production. They’re planned to be taken out of the water in 2022.

Key objectives for sustainability

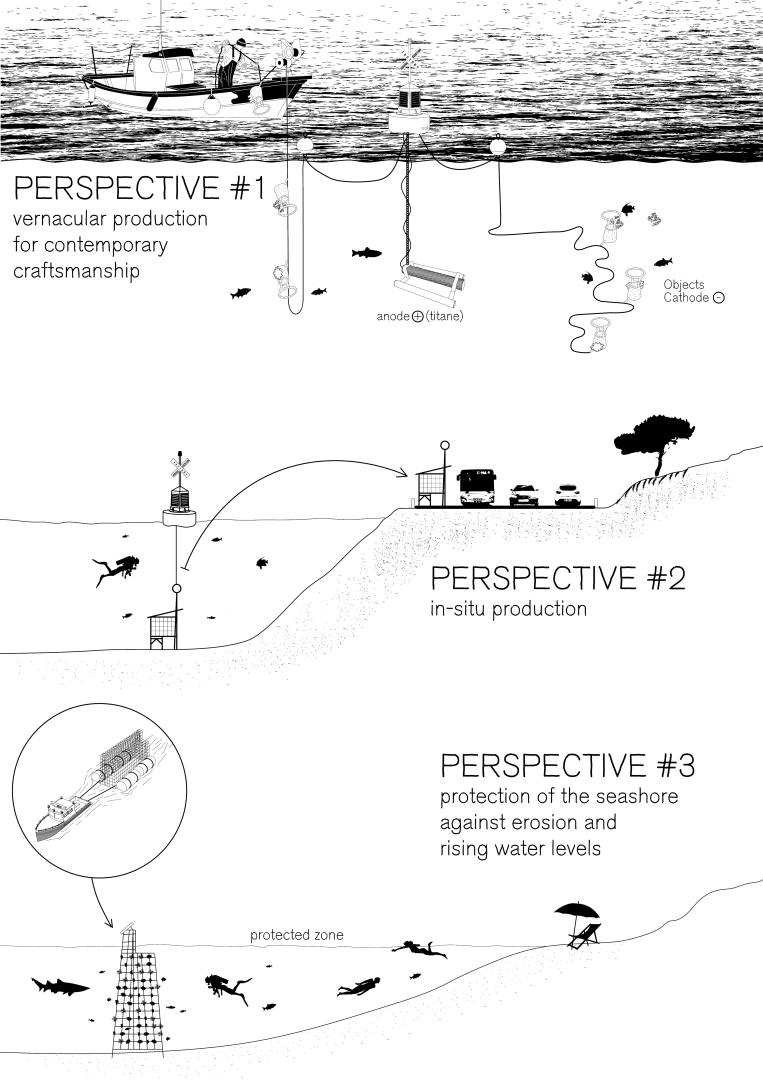

The Mineral Accretion Factory project notably raises the question of an in situ production and multiplies the positive ecological impacts.

The production means through mineral accretion is in itself sustainable. It’s a low-tech and slow-tech system which respects the earth’s biological rhythms and production capacities.

- The factory being the sea, there’s no local impact to lament (building to construct, access roads, parking, bins, heating, air conditioning, etc.). The footprint is advantageous as it participates in the reconstruction of the coral reef, supports the development of marine flora and fauna and protects the coastline.

- The objects being produced participate in the preservation of the environment, enabling the coral to grow three to six times faster and therefore contribute to repairing the damage caused by man.

- Mineral accretion is a long-term test (considered as negligible) of the ocean’s minerals, local materials, from the natural environment. The test of these minerals leaves no trace of deterioration (contrary to quarry rock extraction for example).

- The objects produced by mineral accretion are inert, sustainable and degradable while not damaging the environment.

The production of objects which will be submerged is also advantageous. The objects are produced in temporary construction workshops, with no lasting footprint; no trace is left after the production. They’re manufactured with an economy of motions and means. The object skeletons are made of concrete reinforcing bars, a basic resource in building construction which is easily found around the world and is completely recyclable and biodegradable.

Finally, the production is carried out in situ. The series of eight white benches is being produced less than 50 metres away from where it will be used. So their carbon footprint is reduced.

Key objectives for aesthetics and quality

In terms of material aesthetics, the achieved result combines the project’s main objectives:

- the challenge of sustainability: high resistance of the structures achieved – more solid than reinforced concrete;

- a “laissez-faire” style of production suitable for organic: the objects are subject to a random component due to the exterior influences of natural constraints which cannot be controlled.

In terms of the relational aesthetic – within Nicolas Bourriaud’s Relational Aesthetics (2002) – the objects have been designed in association with the students and the technicians of the art school in La Réunion. The production launch in temporary seaside workshops and the submersion of the products into the ocean or basin, creating a technical and pedagogical event on our material environment and their production means.

The assembly means is unique (arc welding), the production of the structures/skeletons of the objects requires “amateur” technical knowledge which is easily learned and doesn't require any particular training. Simple supervision from a professional is enough. The production method is spectacular and can be collaborative with the local population. It can be an event.

The production means through mineral accretion shows that it’s possible to produce artificial objects in a symbiotic way: meaning that it’s made with living things in close collaboration with these things (humans and non-humans) within an accepted complex system – in the meaning of Staying with the Trouble by Donna Harraway: Making kin in the Chthulucene (2016).

Key objectives for inclusion

The Mineral Accretion Factory project has had an impact on several audiences: it enabled people from an art and design school (students, professors, external public) and people from the Kélonia marine turtle research centre (research staff, visitors) to connect. The public at the observatory - which is also a museum - is therefore made aware about preserving living things, the existence of alternative production means for objects, over a long period, in connection with biological rhythms, breaking with production practices generally used in the industry which predominantly produces the objects which make up our material environment.

The major inclusion aspect of the project resides in its capacity to include non-human life in the long term of production. This long term view enables the creation of an environment and a symbiosis. The coral is grown from a cutting on the submerged structures. It grows, welcomes fish, shellfish and other living things. The object becomes an artificial reef over the course of its production. When it’s ready, it’s replaced by a clean structure on which coral cuttings are placed in order to limit the disturbance of the environment as much as possible.

At the end of the first bench test, submerged in a basin with no apparent life, we observed the development of an environment in which green and brown algae, calcareous algae coral reef (porites), branching coral develops and we saw the presence of brittle star, mollusc eggs, sea snails, small crabs, hermit crabs and around them prawns, a cardinal fish, a gobies fish, two damselfish and a surgeonfish.

Results in relation to category

The Mineral Accretion Factory productions are made of ecological and sustainable materials from ocean minerals: calcium carbonate which coral uses to make its exoskeleton. If this material serves well in the long term, time generally being considered as a problem in the industry, here it’s time devoted to supporting the development of flora and fauna through the role of the artificial reef which the object plays during its production. The means of production constitutes a dialogue with living organisms and non-human creatures.

The production can be deployed from the object to the landscape through architecture. Made to the scale of the object to date, it’s possible to develop the project to make urban seaside furniture, structural planning for the coastline: avoid concrete and only keep the structure, generate porosity in seafront structures (dykes), break the wave while welcoming flora and fauna. The production can also be launched from a single object to substantial series.

This in situ production method is particularly suited to tropical coastal areas and to island territories – even if it can be implemented in any marine environment. Indeed, in these specific areas, the quantity and diversity of locally available materials is restricted and, when they’re imported, their carbon footprint is often catastrophic. Production through mineral accretion fits in perfectly, in all of these aspects, in the question of sustainable development, the protection of local resources, preservation of the environment and the development of the local economy.

How Citizens benefit

This project has enabled collaborations between students, teachers at the art school, staff at the Kélonia museum/marine turtle research centre and observatory on problems which were new for everyone.

Communication on the project was constant throughout its development, both within the art school, at Kélonia, and at the university and with potential partner institutions: The Réunion Marine Reserve, the urban community, Ville du Port, FRAC (art centre), BRGM (Geological and mining research bureau). These communications were open to the public.

Exchanges and debates were often raised regarding the potential launch of this production method on the island of La Réunion: perspectives in terms of coastal development were tackled, notably in connection with the issue of protection against shark attacks which are more and more frequent.

Innovative character

Mineral Accretion Factory shows that it’s possible to produce our artificial material environment differently:

- within a natural device (without a factory);

- in direct relation to the context (social, political, environmental);

- with a positive impact on the environment (restoration of coral reefs, contribution to the development of marine biodiversity);

- with a simple technical device which relies on high-level scientific knowledge (low tech + high tech = wild tech);

- in keeping with the biological production rhythm (slow tech);

- in an economy of motions and means.

The major innovation consists of creating a means of producing artificial forms in connection with non-human organisms (flora and fauna) in keeping with biological rhythms. It contributes to the reconstruction of damages caused by man and the reconstruction of marine biodiversity. It enables, like any artificial reef, to preserve the coastline and counter the consequences of climate change, notably its direct consequences in the ocean and the disappearance of coral – an essential element for maintaining marine biodiversity.