Fundermax Worktop Collection

Basic information

Project Title

Full project title

Category

Project Description

As a central element of every kitchen, worktops shape the character of the entire room. Beside that, the worktop has to fulfill high standards in terms of functionality. Fundermax worktops stand out as they are highly resilient, easy to clean, extremely durable and the core is made of 100% recycled core paper. Thanks to their surface quality, they prevent the spread of bacteria. The high pressure laminates (HPL) can be processed with millimeter precision, s

Project Region

EU Programme or fund

Description of the project

Summary

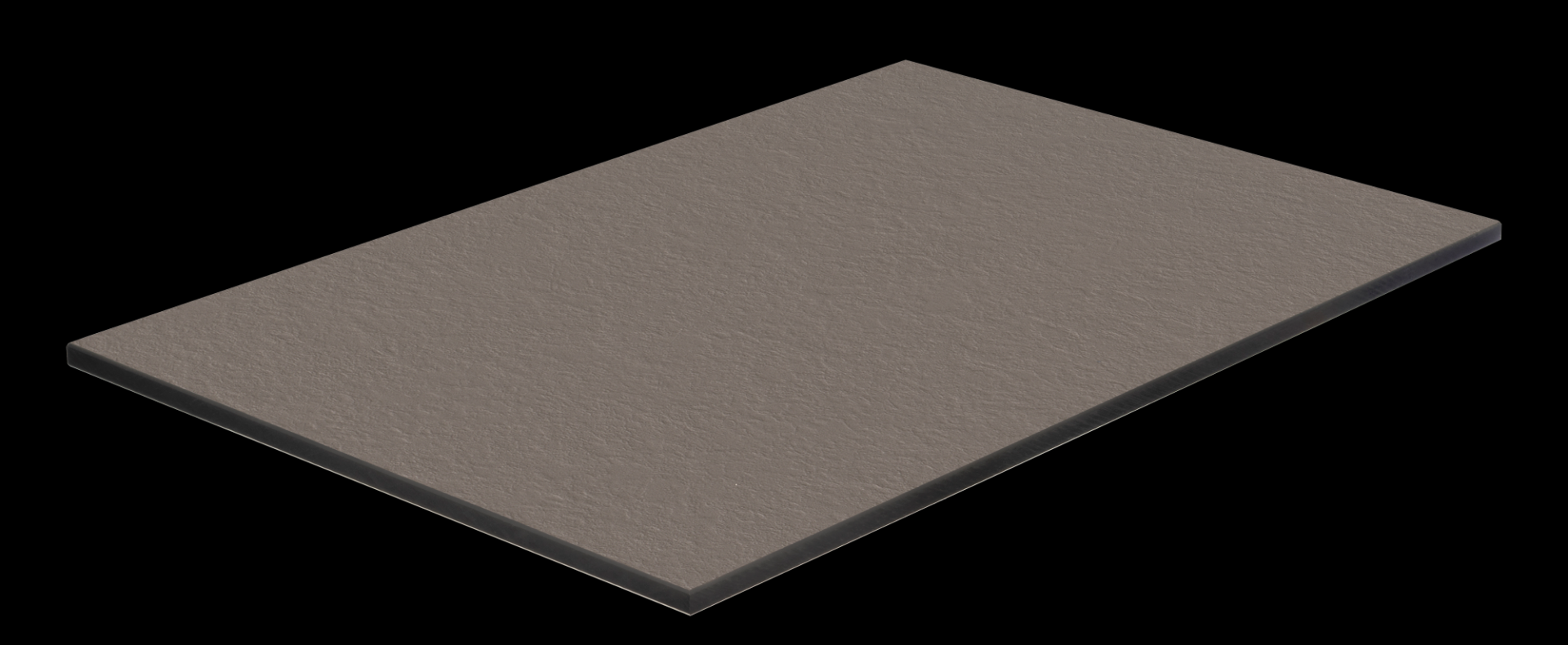

The perfect combination of design and functionality in the kitchen: As a central element of every kitchen, the worktop shapes the character of the entire room and has to do more than just impress with its looks. Fundermax worktops stand out as they are highly resilient, easy to clean and extremely durable. Thanks to their surface quality, they prevent the spread of bacteria. The high pressure laminates (HPL) can be processed with millimeter precision, so you can plan the kitchen you want. The worktop collection offers 29 first class decors, as well as 6 outstanding surface strucutres. For our high pressure laminates, a certain amount of core paper layers and a decor paper layer are pressed under the addition of resin. The result is one of the most durable materials in the building industry.

Key objectives for sustainability

At Fundermax, we attach great importance to ecological care. Our subsidiary Ranheim Paper & Board in Norway is our source for the necessary core paper and relies entirely on recycled paper in production, which is made from regional waste paper. Additionally, by shifting the transport of goods at Ranheim Paper & Board to sea and rail transport, up to 600 tons of CO2 can be saved per year. That's another step toward sustainability that we're very proud of. In comparison, around 50,000 trees would have to grow for a year to sequester this amount of CO2. Further, with various adjustments to the logistics and transport process and after numerous tests, it was also possible to completely dispense with this protective packaging made of plastic film. This made it possible to avoid around 10 tons of plastic waste, which corresponds to around half a million disposable plastic carrier bags per year.

Key objectives for aesthetics and quality

The Key Objectives of the worktop collection in terms of aesthetics, quality of experience and functionality: When you look at the common shifts in design streams the focus turns more and more to a minimalist aesthetic. Taking this into consideration, we focused and reinforced the haptical experience and apperience. This resulted in structures which convey a warm feeling and a natural touch while applying these characteristics into the functionality of the product. The feature of the colored core embodies its personality and reaches it’s peak of Design in the application. This enables you to use the product as a Design Element. The numerouse qualities which are highly resilient, easy to clean and extremely durable and translates into the functionality of the product, while preventing the spread of bacteria.

Key objectives for inclusion

The historical perspective and traditions is important also for the future. Our subsidary, Ranheim Cellulosefabrikk was established back in 1884. The Papermill created jobs in a remote place in the country side, in an area were there populations was limited. With the Mill, jobs came, the workers' housing, and the local community could grow with infrastructure connected to the church, sports, teams and other associations. Since then, we have stood firm through pandemics, world wars and financial crises, and built a strong and proud local community, with safe jobs for generations in our region. Today we are in full operation in exactly the same place as in 1884. The old factory has taken ownership of the future and is today on its way to become a billion-dollar company, with recycling and green technology as its business model. We are an important part of the cycle in Norway, and already recycle 50% of all source-sorted cardboard.

Long story short: Fundermax and its subsidary Ranheim both are important local partners within their surroundings, not only in terms of generating jobs, but also when it comes to investing in a sustainable future. Helping where needed has always characterized everyday life in our companies. Without much fuss, people, projects and also associations were supported, where often even a small contribution can make a big difference. It is not the limelight or public applause that counts, but a smile, a sigh of relief, a quiet "thank you" from people for whom our commitment has made a decisive difference.

Results in relation to category

Offering the new Fundermax worktop collection, we were able to offer a interior design prodcut range that meets the latest design standards. The six surfaces we offer impress with fine structures and sandy, rough touches. They offer dynamic stability, anti-fingerprint effects and ultra matt finishes, while, at the same time, deep strucutures that resemble natural stone or wood. In combination with 29 high fashion interior decors that range from chilled, elegant uni colours to majestic and raw natural and materials, the new Fundermax worktops are ready to shape the future trends of interior design. Speaking of trend: To us sustainability and respect for natural ressources are not just empty phrases. As described above, we always aim to take a step further towards creating a better tomorrow. We spare packaging, we shift to land and sea transport where ever possible. We produce local, but think global and we proof that design and sustainability do not stand as opposites.

How Citizens benefit

Environmental foot-print: Every time a wooden fiber is recycled, it will increase the environmental impact from a LCA perspective. A new corrugated carton made from recycled fibers has a limited life-time When our 100 % recycled fiber based Ecosat is used in the laminate, with life expectancy of more than 30 years, it will work as a tool for long-term binding of CO2 and can be therefore be considered as recycling 2.0. The importance of sustainable recycling requires us to utilize the recycled fiber better – Ecosat is a perfect example of how to “upgrade” the recycling process to next level – which is aligned with the IED targets. At our subsidary Ranheim we also visit local schools to inform the young local community about the necessity, the chances and the opportunities of cicular economy for a sustainable future.

Innovative character

The use of recycled paper in the HPL industry is still very limited. An essential prerequestite to enable this development is the location of the production plant in Norway, where high standards in the collection of "waste paper" are given. Only due to the purity of the base material, which is called OCC (old corrugated containers), the successful joint development of the high quality Kraft paper made of 100% recycled materials was possible. The strong transnational collaboration between the the paper production plant in Norway and the HPL production site in Austria, relying on direct and fast paced feedback allowed the development of a Kraft paper of exceptional quality in less than one year. The continuous improvement of quality allows us now to offer a sustainable and high quality product on the market as well.