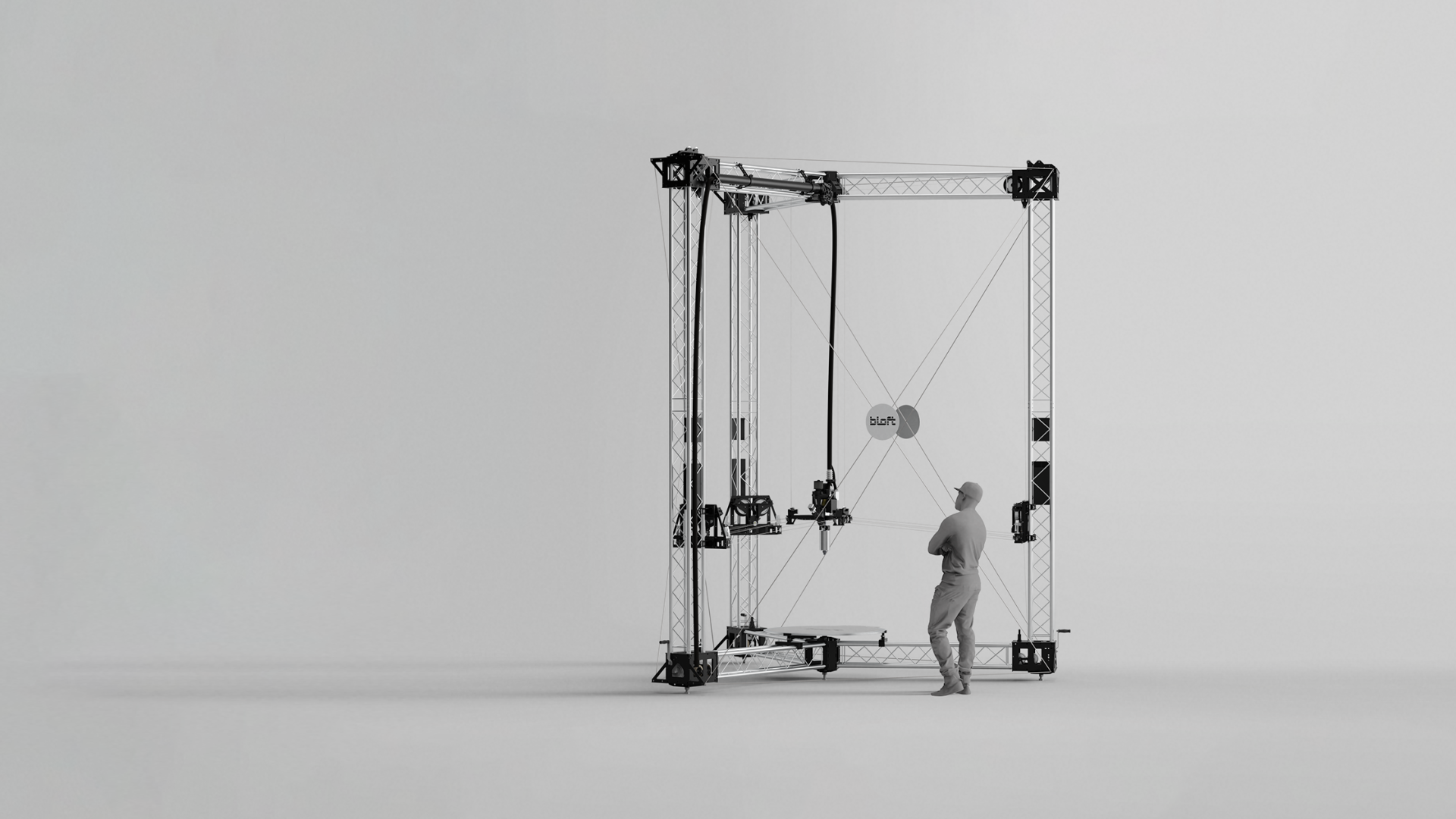

Bloft Mk2 plastic waste 3D-printer

Basic information

Project Title

Full project title

Category

Project Description

We want to offer a new perspective on how we can take on the fight against plastic waste pollution. With one of Europe's largest 3D printers, the Bloft Mk2, we are making distributed plastic recycling by additive manufacturing coming true. The huge scale of the printer, combined with speed and the possibility to process shredded plastic waste enable a whole new window of opportunities for designers and architects to come up with new, beautiful and sustainable solutions.

Project Region

EU Programme or fund

Description of the project

Summary

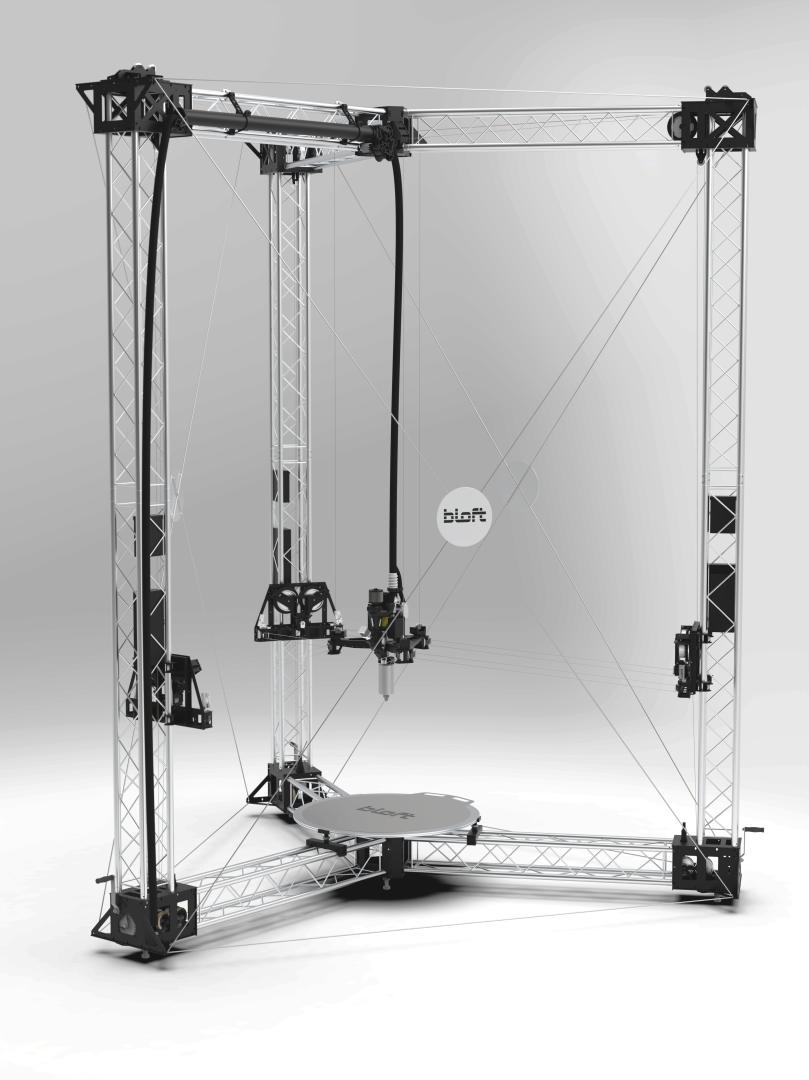

Bloft Design Lab set begin of 2020 a goal of developing a solution which utilizes plastic waste as feedstock for additive manufacturing. We took our experience and insights from our first large-scale 3D-printer and used them to come up with a 3D-printer design the world has not seen yet - the Bloft Mk2. It is based on a worldwide unique motion system best known for its scalability, extreme speed and versatility. A close relative is the SkyCam motion camera system that covers the scene above football stadiums.

Our first printer prototype made use of the widespread plastic filament extrusion technology, which we identified to be poorly suited for 3D-prints beyond the desktop size. For life-sized objects the use of filament wasn't viable in terms of cost and process duration, but foremost from ecological point of view. Most of the FDM-filaments are made from virgin fossil raw materials.

That's why we opted for FGF-extrusion, which allows us to process plastic pellets and especially shredded plastic waste directly in the print-head. This gives us the possibility to completely bypass the filament production, saving one melt cycle of the plastic and the energy put into the production. We wanted to turn additive manufacturing from a problem to a solution. FGF-extruders are usually operated as a tool-head of an industrial robot arm. A rather costly solution, with a rather small action radius. Our printer is designed to be modular and easily extendable, with only minor cost increase. The technological concept is scalable from desktop size up to construction or shipyard size.

Even though we focus at the moment on plastic waste extrusion, the ground-laying technology adapts to other materials as well. In future we are going to plan new tool-heads for bio-based materials, construction materials, etc.

Key objectives for sustainability

In 2020 we participated in the agile experiments of the Baltic Sea Challenge by the City of Helsinki to validate the use of marine plastic litter as feedstock for additive manufacturing. For the experiment we partnered up with local environmental organizations to collect plastic waste from the Helsinki shoreline. Samples of that plastic waste were examined alongside with virgin plastic pellets and reference ocean plastic samples in the material testing lab of Metropolia UAS. The results revealed only approximately 10% weaker tensile strength, which we considered a very good value for partly degraded plastic waste that had been exposed to the elements.

This fact and the literature on the recurring recyclability of plastic gave us the incentive to press forward with the printer development. We set the goal to eliminate the use of virgin plastic as feed-stock for additive manufacturing. By using plastic waste we can cut the carbon footprint by at least half compared to virgin plastic - a benefit which accumulates by every new cycle. Plastic is recyclable up to 10 times with little to no difference compared to virgin plastic, but research shows that at least certain plastics can retain up to 80% of their mechanical properties even after the 100th melt cycle.

Based on this we want to explore a deposit-based return system on the products we will manufacture with our technology. Deposit would be paid out to our customers on return of the product, or they could have discounts on the next print when they return the old product. Eventually we want to keep plastic in circulation and thus preventing it from ending up in energy production where the carbon bound in the material gets released.

Key objectives for aesthetics and quality

Large-scale additive manufacturing plays out its advantage with big and fat extrusions, which aim to accelerate the process cycle and keep the duration at a minimum. This is achieved with large extruder nozzle diameters and high throughput of material. Obviously this happens on cost of fine details, but those thick layer lines also represent a distinctive feature of this manufacturing method. It's like the known saying, if you can't hide it, decorate it. For us, those thick layers are the new style of modern plastics. Combined with the lively tone of shredded plastic waste of the same color, but different source, and the possibility to create color gradients by mixing different colors, this manufacturing method offers an absolute unique way of creating something beautifully organic out of the embodiment of synthetic - plastic.

But it isn't only about the aesthetics. By now it is a known fact that our world is drowning in plastic. Between 1950-2018 the global production output of plastic, synthetic fibers and additives has reached a level of staggering 8 300 000 000 tonnes which equals a share of more that one tonne per each living person on the planet. Just imagine a cube of plastic in a size of a small car bound to the leg of each European citizen! That is our unfortunate heritage to the coming generations. Plastic will be around us for thousands of years, whether we like it or not. It is in our best interest to learn to live with that and especially with the nearly 5 billion tonnes of plastic currently dumped in landfills and discarded in nature. This is the reason why we do, what we do. Essentially we want to offer people hope. Hope that there will be a way to make use of the plastic currently regarded waste. And that it can be used to make again something functional and beautiful for the future.

Key objectives for inclusion

Our technology originates in open source hardware and software development. It is an ideology that information should be free, as in free speech. Open source is deeply democratizing by putting knowledge into the hands of many instead of a few chosen one. We as a company acknowledge the contributions of countless people around the globe, that have enabled the ground-laying technology of our printer. Therefore, we will contribute our knowledge back to the community with the open source release of our Bloft Mk2 once we have concluded the initial development. By releasing the technology we also want to provide local entities around the globe tools for profitable upcycling and encourage people to collect and reuse discarded plastic waste.

This will enable local plastic recycling not only in wealthier countries, but also in developing countries that often lack functional plastic recycling systems. Countries with the burden of imported plastic waste from the western world including the European Union.

We expect to be ready with the initial development of the printer in early 2022.

Results in relation to category

As we are still in the development stage, we don't have yet results on our impact that would rest on long term observation.

From the first results we can tell, that our printer will be capable of recycling plastic at a rate of approximately 6-20 tonnes per year. Which equals the plastic waste amount produces by 170-570 Europeans on average. Market research analysts expect global 3D printer shipments to grow from 2.1 million units in 2020 to 15.8 million units in 2028. A hypothetical global market share of 0.1% (15 800 units) in the 3D printer business would already mean an annual growth in global plastic recycling capacity of approximately 94 800 to 316 000 tonnes. The Czech open source 3D printer manufacturer Prusa Research has delivered in ten years existence over 100 000 3D printers. A figure that serves us as a benchmark.

Apart from these estimations we are already gaining attention across the domestic and international designer and maker community. Several Finnish corporations active in recycling and raw material production have expressed interest in our work and our technology.

How Citizens benefit

Our technology and recycling process isn't like the traditional plastic recycling concept where the responsibility of the disposal ends by putting the trash in correct bin. The reality behind the trash bin lid is unfortunately not as sustainable as it should be. It is not uncommon, that a large amount of the plastic meant for recycling ends up in energy production, or even worse in landfills or in illegal dump sites.

This fact makes people question the conceptual point of plastic recycling. It is a worrisome development that should be prevented as quickly as possible. We want to offer a transparent way of showing people how their plastic waste is turned into new goods and even encourage them to bring the waste for recycling to a local print shop where they literally see the whole process.

Innovative character

From technical point of view there are two major innovations which we utilize in our 3D printer.

- The Badass FGF-extruder

With a granulate extruder we entirely skip the need for costly filament. Instead we are using as our print-head the same technology needed in filament production. This means we bypass the unneeded melt cycle and save energy at the same time. Only with the help of a granulate extruder, it is possible to process plastic waste in semi-industrial scale and speed. The FGF-extruder is also the key for processing plastic waste with small impurities.

- The Cable Driven Parallel Robot kinematics of the Bloft Mk2

Our unique kinematics concept enables us to extend future printer models with only minor cost increase. The inexpensive lines supporting and moving the print-head are one of the few things that restrict the printer dimensions. The concept is suitable for small desktop sized printers, but it could also be a printer of a massive scale. For instance on construction or shipyards.

It is our firm belief, that the challenges of this century are not soluble by concepts and solutions that have led to them in the first place. Our business model and the distribution strategy rest on open source, which represent a radically different approach to the usual business.