Renewable concrete & building techniques

Basic information

Project Title

Full project title

Category

Project Description

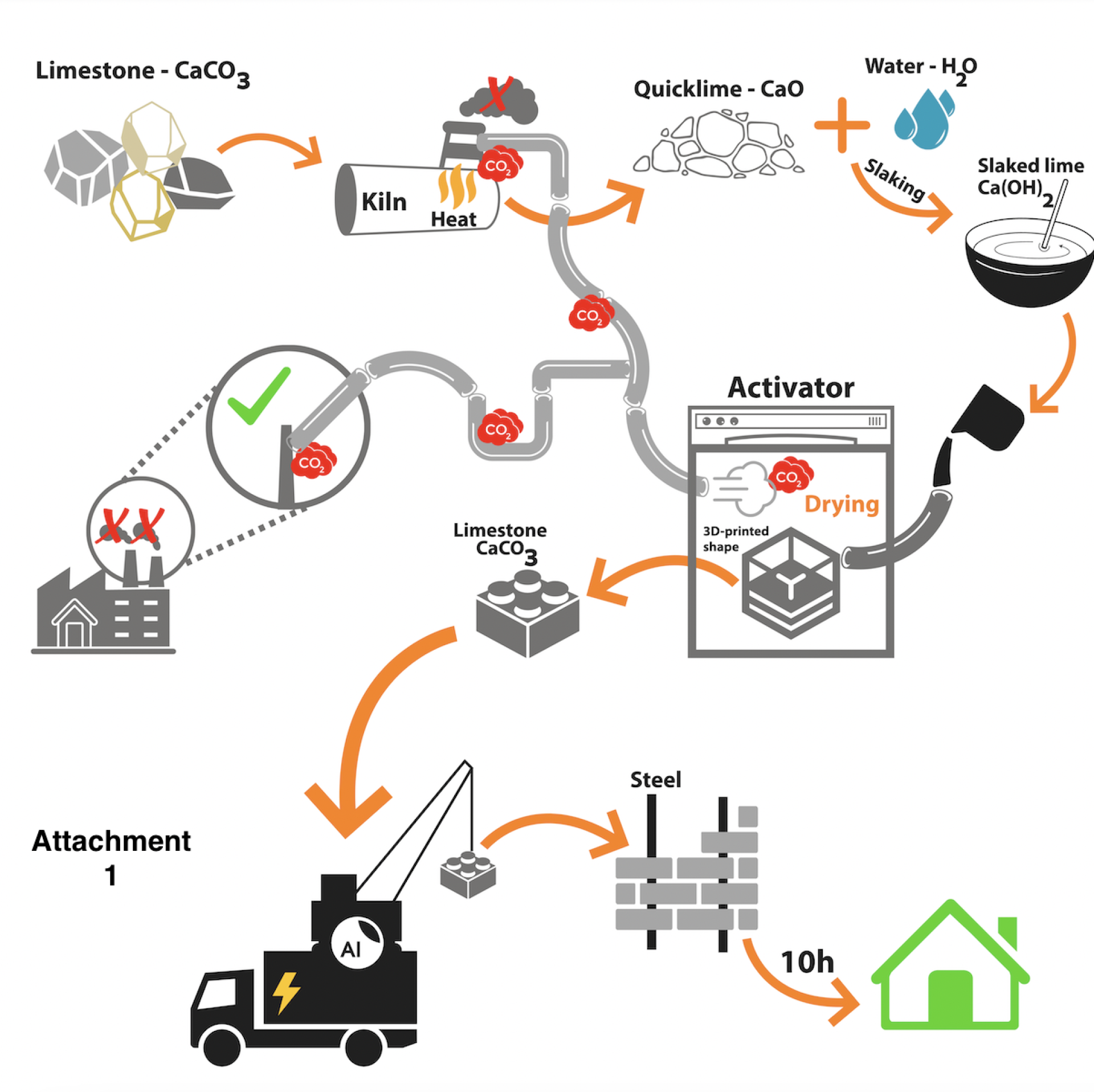

By directly capturing CO2 from gas & coal fired power plants, steel factories and breweries from their emitting pipes, solid concrete building blocks can be created by mixing quicklime with water and the captured carbon is added in straight from the emitting source's pipe.

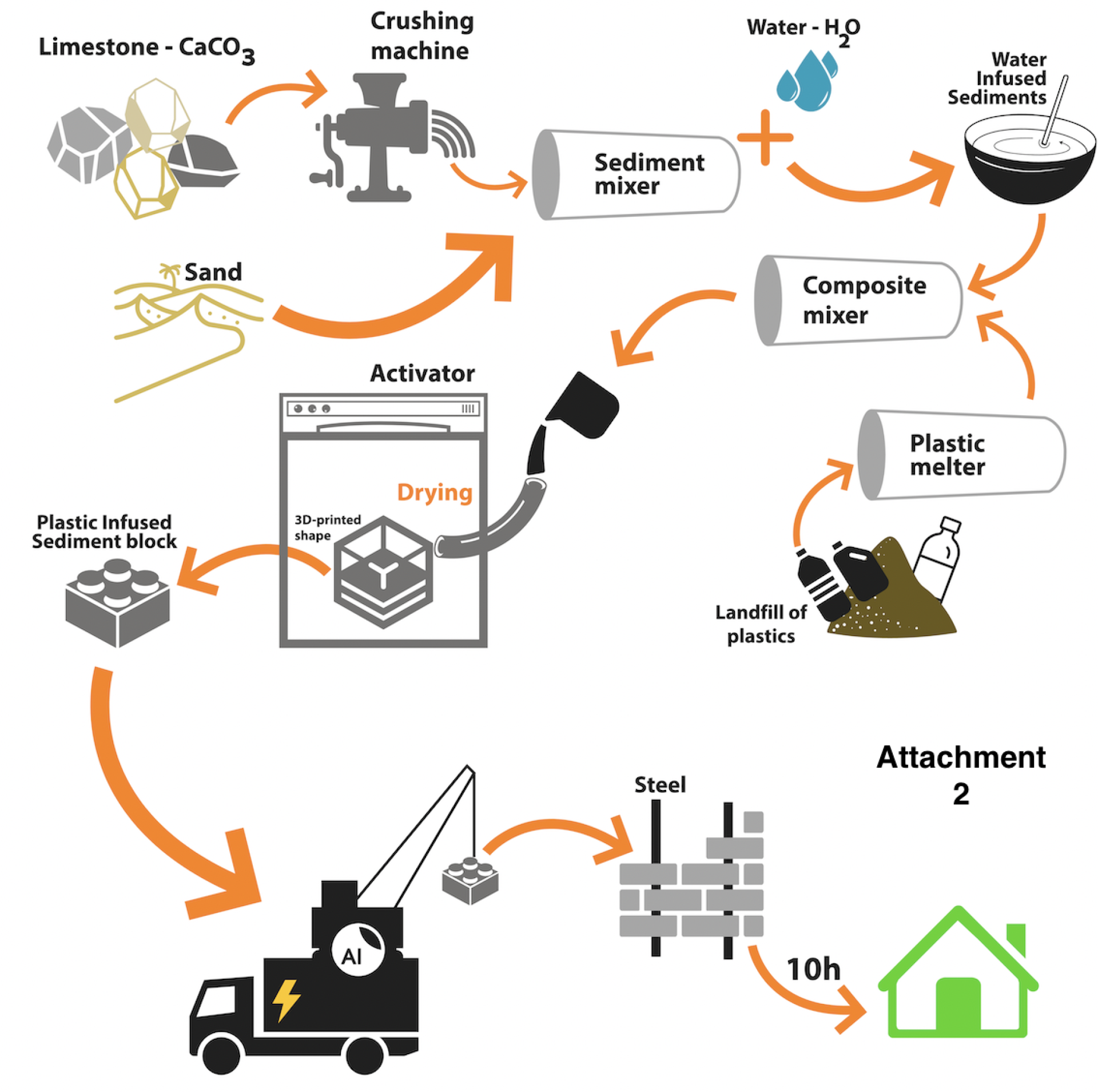

Another sustainable concrete could be created by mixing limestone with recycled PET plastics. Both techniques drastically reduce material manufacturing and transportation emissions.

Project Region

EU Programme or fund

Description of the project

Summary

The projects firstly aims to reduce overall CO2 emissions from fossil fuel power plants and other industrial polluters by extracting the CO2 produced, right from the source of the flue gas stream before it enters the atmosphere (hereon referred to as recycled direct decarbonisation of polluters or RDDP) and to create building materials from the extracted carbon by mixing it with widely available and cheap elements like limestone (that's locally available in northeastern Spain and most EU countries) and calcium hydroxide by disrupting conventional building material processes that will further curb their emissions by reducing the reliance on them in the first place.

Secondly, the goal also entails eliminating the amount of different plastics in our oceans and landfills (with the majority of landfills and incinerator plants in Catalonia) by using them as a glueing agent for the creation of a different type of concrete material made of sedimentary rocks like limestone or sand (hereon referred to as plastic infused sediments or PIS), bypassing the conventional cement creating processes.

Key objectives for sustainability

Building materials and construction account for 11%, while building operation for 28% of global CO2 emissions, which I aim to mitigate by adequate carbon-neutral building materials and techniques:

- The recycled direct decarbonisation of polluters (RDDP) will not only prevent greenhouse gases escaping from the industrial factories, but it will also support a "greener" and more sustainable form of building material creation for smaller buildings and even allow capitalisation on the process rather than burying the extracted carbon underground. The ingredients for this concrete are CO2 and limestone (calcium carbonate) decarbonated into calcium oxide which is then mixed with water in a reactor, creating calcium hydroxide. The semi-final downgraded and mixed limestone product could be so durable that when it's mixed with the carbon dioxide extracted from the polluters' pipes, it solidifies into a new type of concrete.

The RDDP supports the sustainable continuous use of fossil fuel-fired power plants, so it is important that this potential breakthrough is implemented to prevent additional CO2 from entering the atmosphere.

- With plastic infused sediments (PIS), I can dramatically reduce the time, cost and emissions of the transportation, manufacturing and assembly processes of materials as well as the construction of buildings. The production of PIS in the case of sand or other fine sediments would not require several machinery to crush rocks, heat them up and cool them down as this is an energy-heavy process. It would only need recycled plastics like drink bottles (PET), takeaway (HDPE) & homeware containers (PC), bags (LDPE) and ketchup bottles (PP) that we can already find in landfills, floating in the ocean and sunken at the bottom, to be melted with sediments to achieve the stable concrete.

Both techniques would need further durability research so that they can be used as safe materials.

Key objectives for aesthetics and quality

RDDP will undoubtedly increase living standards of people living in marginalised communities where industrial sites are set up in the first place, since the industrial pollutants' emissions would be extracted before they enter into the atmosphere and cause severe respiratory diseases linked to early death. It will also pave the way for new building material methods and further support the deindustrialisation of the construction sector and seemingly provide a better sight around cities and towns that have been overcome by industrial complexes like cement manufacturing sites and refineries, as taking CO2 right from the source could be applied at any polluting pipeline that emits CO2.

While PIS would aesthetically free up oceans, beaches and landfills from toxic plastics and prevent fish from ingesting them, reducing the risk of marine life getting poisoned or suffocated by plastics (in the case of sea turtles or dolphins with plastic straws and six-pack holder rings)

The two separately prepared and newly formed polymer cements as a result of the chemical reaction between the calcium hydroxide and the CO2 (in the case of RDDP) as well as the various plastic infused sedimentary rocks merger (in the case of PIS), would stabilise the materials into solid form by using different techniques and machinery (produced in the same physical location for savings and environmental purposes) which would then be poured into custom 3D-printed "lego" shaped containers. Once dried into concrete blocks, they would be used by an automated crane run similarly to a 3D printer by a computer program (to be developed), to assemble the walls significantly faster and cheaper than a human, making the work a lot more enjoyable for those operating the concrete merging process and the assembly machinery.

The resulting blocks coming from two different techniques would be used for different building purposes depending on durability.

Key objectives for inclusion

Besides the clear benefits for the environment, the goals of this project also entails inclusiveness of society and these can be observed below by the two main building material techniques:

The Recycled Direct Decarbonisation of Pollutants

- Installing the carbon extractor and quicklime reactor part of the RDDP near fossil fuel power plants and other industrial buildings will create new jobs for people in the usually low-income neighbourhoods where these plants were built in the first place.

- In relation with global decarbonisation efforts, an additional aim is the indirect effect it would have on consistently reducing yearly wholesale electricity prices for consumers (or more like preventing it from increasing drastically) associated with carbon capture in general, as otherwise in alternate scenarios more energy would have to be used over the years to decarbonise industries, therefore spiking up the price and demand of electricity.

The Plastic Infused Sediments

- The collection, importing and processing of the different plastics from landfills and abroad will create new jobs, especially in developing countries where waste is exported to from developed countries and dumbed into waters.

- Reduce the further spread of plastic particles from the oceans and the risk of marine livestock ingesting them.

- Soft sediments like widely available desert sand could be used as free building material in regions of the EU where desertification increases due to climate change.

Innovative character

Disrupting the status quo is important for human development as most of our processes haven't changed since the first industrial revolution.

Science has allowed us to experiment across various disciplines like geography, chemistry, biology, etc., which has led to my hypothetical research into alternate ways to create solid materials for any purpose. I knew right after getting my BSc in Geography that I would have to use my knowledge of global issues for bigger purposes, so I started looking into what materials can hypothetically solidify byproducts of different polluting industries while also reducing their carbon footprint.

In case of the RDDP, solving the problem of industrial polluters was the starting phase for me, which led to reading scientific papers on materials used in construction. I have learned that most of the machinery used in the process of cement produces loads of carbon as energy is used up from power plants and realised that most of the cement manufacturing processes can be cut out without compromising material safety and stability, if the correct materials are used as alternatives, removing the need for extra processes.

While for the PIS technique, the starting point was reducing plastic waste. So I thought that if melted plastic eventually dries, it creates some sort of holding agent that could solidify soft sediments that will hold under heavy pressure.

Using semi-automated cranes, the solid blocks would be placed on top of one another through steel bars to secure them in place, rather than using manpower to put bricks in one by one. A house's walls could be built within hours, as opposed to days with conventional techniques.

As seen on attachment 1, the RDDP process follows the full cycle of limestone, in which it is decarbonised and then recarbonised following a sustainable process, forming blocks. While attachment 2 details the PIS process in which wet sediments are mixed with melted plastic to form the solid building block.