Positive Impact Vest

Basic information

Project Title

Full project title

Category

Project Description

We want to challenge the status quo of the industry and show case that we can achieve better physical properties with 3d Printed Structures than fossil fuels based foams. The impact protection vest we want to develop is suitable for water sports athletes and enthusiasts which need protection while practising the different water sports. The industry at this moment did not innovate too much in this area and we want to show that innovation is still possible and sustainability can be achieved as &am

Geographical Scope

Project Region

Urban or rural issues

Physical or other transformations

EU Programme or fund

Which funds

Description of the project

Summary

My start Up was born due to the passion for sustainability and enthusiam for water sports. Being an engineer by background, 30 years old, I thought that more can be done within this space and not enough efforts is spent when applying circular and sustainable design.

I am aiming to design a Positive Impact Vest having circularity, sustainability, aesthetics, inclusion and safety as first priorities. Value added is coming from the sustainability and technical know-how which is relevant for the task which we have in front.

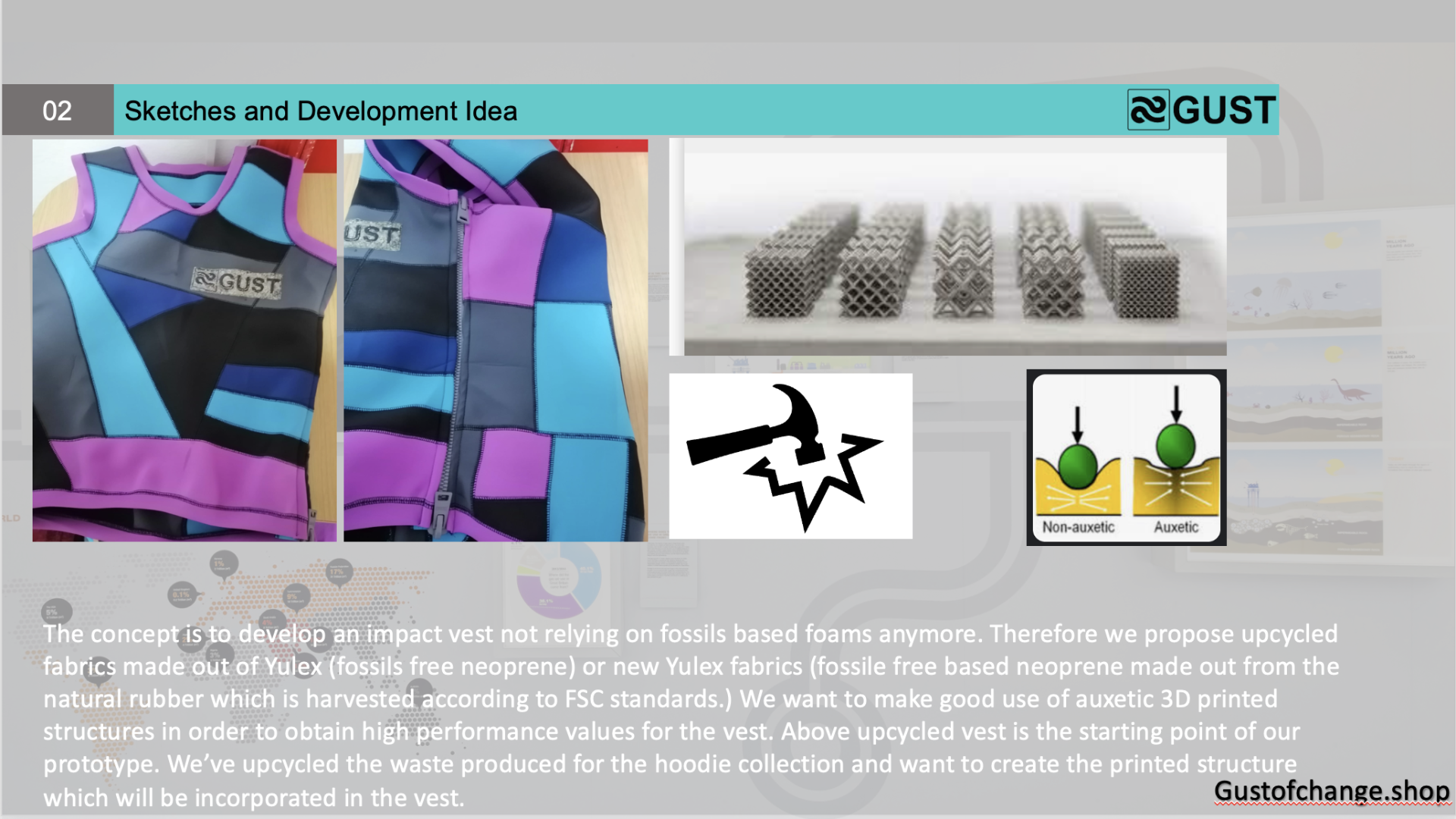

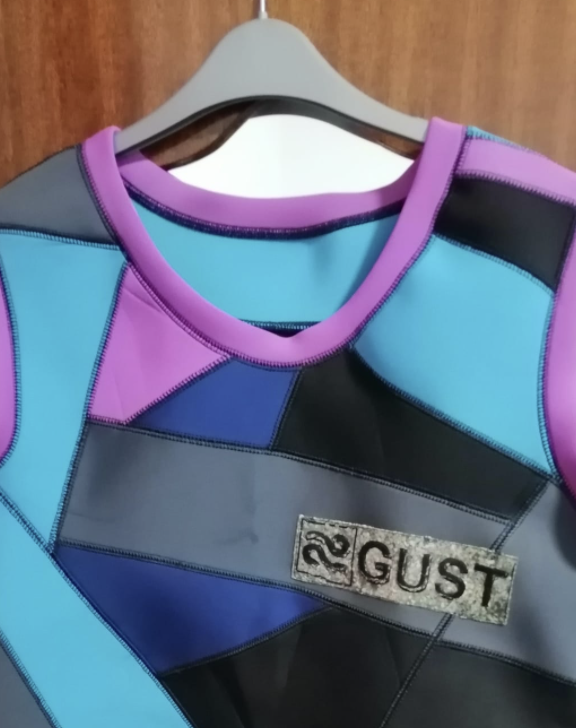

Current market is not focused on using sustainable or recycled materials for the main fabrics (mostly fossil fuel neoprene is used) and more over the protective characteristic is provided by the foam inside (which is also fossil fuel based). Our project will be using from the start a main fabric which will consist of an alternative neoprene called Yulex (made out of natural rubber and being harvested in a fair and sustainable way for the forest out there, being Forest Stewardship Council). Main innovation and research for the ‘Positive Impact Vest’ is referring to the protective padding, which instead of using fossil based foams, we will be prototyping different structures of 3D printed auxetic structures. The structures will be used as an exoskeleton for the Impact vest improving the weight of the product and increasing safety due to the enhanced impact strength.

Increased impact protection will increase the safety of our users while practising water sports. The concept can be also useful for other markets such as helmets used also within the water sports industry. The idea is to build on top of the upcycled prototype prepared by us from the waste of our natural rubber hoodie project. We want to keep a low carbon footprint of our product and innovate as much as possible while keeping at a minimum our planet limited resources.

Key objectives for sustainability

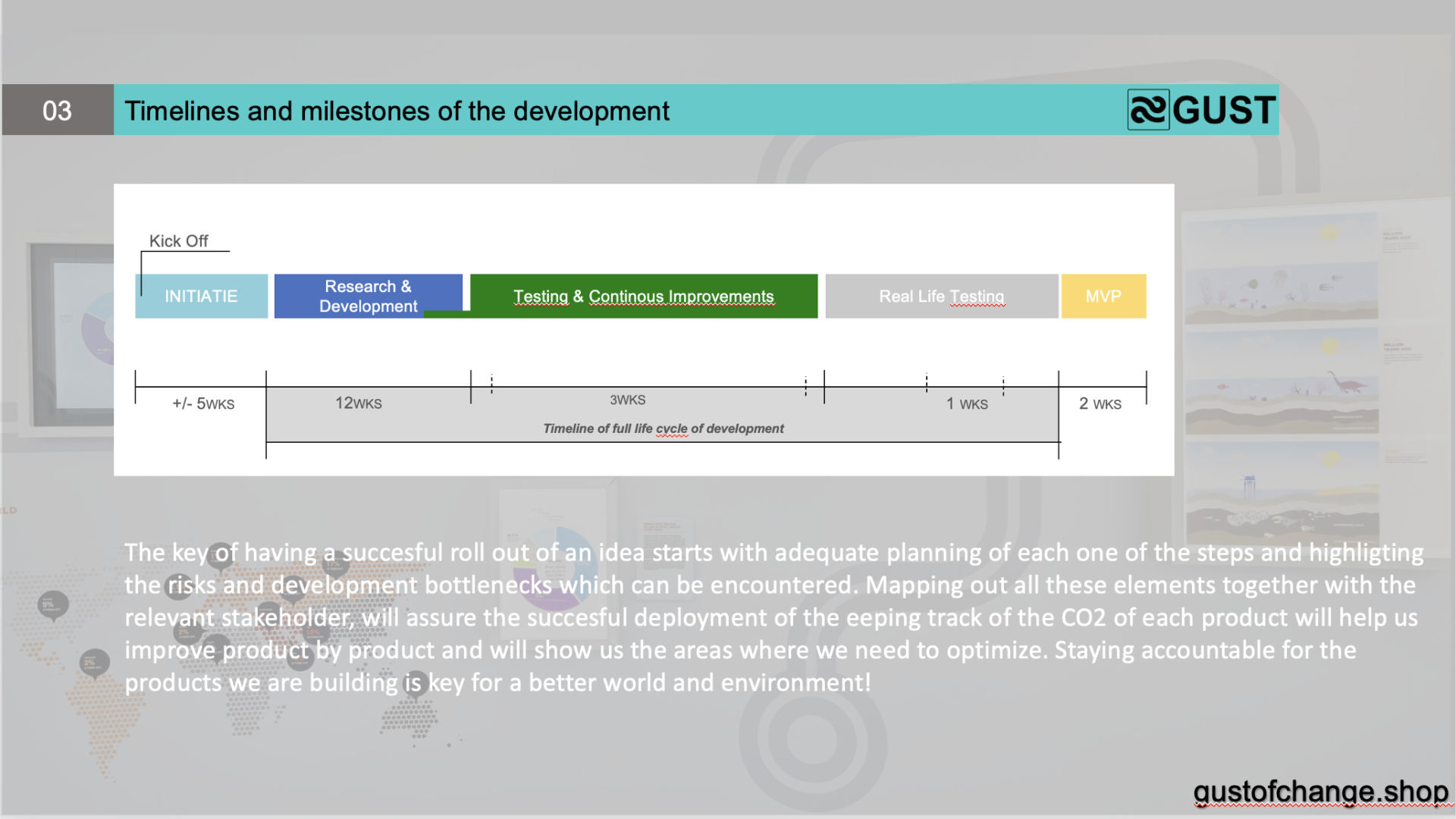

Current TRL of the solution is 2 since 3D knitted fabric technology concept is something which is used by other industries already for some years. The grant will support us to roll out a Proof of Concept which we can test in real environment and assure that is providing the right quality in terms of protection of our water sports athletes. Once prototyping is completed and we achieve the minimum viable product, we will plan the collection launch and raise awareness in the market about the innovation and circularity of our solution.

The final outcome will be a viable impact vest using 3D printing technologies, instead of fossil based foams. It will be one of the disruptors within the industry mainly because there is a high dependencies on foams which are mainly coming from Asia. Being able to produce the 3d printed structure locally will significant amounts of CO2 being emitted in the air and will stimulate the use of recycled or bio-based 3d filaments / products.

The sustainability elements comes from the fact that we will be experimenting also with bio-based sources and recycled filaments for the 3D printer. The circularity is achieved via the traceable 3D printer filament which comes from certified recycled / bio based content. The concept might replace the shipment of fossil fuel based foams which are used by the industry at this moment. Having them 3d printed will stimulate the inclusion of more local suppliers for these kind of services. The use of auxetic structures and materials will stimulate innovation within other sectors as well where reliance on foams exists.

Significant CO2 emissions can be saved related to the actual shipment of the foams (which are mainly coming from Asia). Instead of making these shipments the local 3D printing vendors can support locally with the development engaging and being inclusive with the rest of the market players. Sustainability is a team s effort!

Key objectives for aesthetics and quality

Sustainability and safety are the most important criteria, but in order to achieve higher adoption by the general public we are focusing as well on aesthetics and quality of the experience while using our product. The aesthetics will be assured by the 3D printed structure which will need to allow for the adequate impact protection as well as a good look and feel. Within the 3 D structures we will aim to imitate some structures seen in the nature (hexagon structures from the bee house, branches of trees etc). The quality of the experience will be achieved by the high quality of the 3D print as well as the decreased weight and dimensions compared to traditional foams. The user will be able to be protected in a more efficient way from external factors. The structure would have higher impact protection characteristics compared with the foams.

The idea can be exemplary in this context due to the fact that there is a lack of innovation within the industry. Competition always stimulates great innovations. At this moment in time, competition and brands are following the same approach, mainly due to the time and cost for Research and Development.

The base material of the impact vest will be made from upcycled materials which is generated by our water sports collection Anorak series. The series is available in multiple colors and all waste is collected in order to produce further value added products. We intend to build a long-term, life-cycle thinking in the industrial ecosystem for similar products setting out an example for the industry of what can be achieved when our planet limited resources are kept into our minds and goals. Having into consideration the price would support circular economy and would be using the waste streams of other industries, there are much more broader positive impacts. The price of the final product would also contribute to NGO's sharing the same values and principles as ours (healthy seas, fair sewing practices, neutral transport etc)

Key objectives for inclusion

The concept and idea has been drafted and will be implemented by Adelin Oles, start up founder and experienced program, project and design manager within energy transition projects. These blend of skills will assure the success of the prototype.

At the early stages of the concept, the market has been extensively researched for similar products. Engagement has been done with the industry sports professionals. Feedback has been incorporated within the concept. Main outcome was that the industry is not innovating enough within this area. The intention is to keep an open ended feedback loop with the customers in order to improve the process by each iteration.

With the planned marketing campaign we intend to pursue citizen engagement and raise awareness from the general public audience. We want to engage with the industry standards in terms of showing the replicability to other sectors which might benefit from these ways of working.

The production atelier at this moment is located in Turnu Magurele, Romania and the lead pattern making is a very skilful female tailor. We do have a gender equality plan which we follow with the aim to have a 50/50 ratio btw. male and females. The region where the production atelier is located has been a textile hub for many companies. For the past years many companies decided to relocate their production units to other geographies and the local market remained without their loved jobs which is tailoring. The water sports market is something new for them but creates interest and comes with enthusiasm. The aim would be to grow the production atelier to more employees. Current working stations at the moment counts 3, but expansion foresees more working stations being purchased. We want to bring along the local labour market and raise the awareness about the importance of being a sustainable business following industry best practices in terms of CSR and ESG initiatives.

Physical or other transformations

Innovative character

The approach can be exemplary because of the novelty and the different angle towards impact protection. Circularity and sustainability are assured by the fact that on one hand the waste from some industries are being build up in the 3D filament which we will be using for the auxetic structures, and on the other hand the upcycled own materials which will be used in the base fabric of the impact vest. During further prototyping efforts we will also try to experiment with bio-based filaments and see which solution is easier and more sustainable to adapt.

Aesthetics will be achieved via the actual 3D structure which will be designed to resemble some elements from the nature, since nature is one of our biggest teacher in a lot of areas. Indicative sketch design shows that the honeycomb might be a good structure or brenches of trees can also be explored.

The inclusion element consists on the fact that different suppliers will be included in the development supply chain and new areas / business for them will open due to this collaboration. The 3D printing industry advantages can be seen in multiple sectors already (construction, bio-medical and so on). The advantages of 3D printing and the reduction of the CO2 footprint (sustainability), as well as the high quality of the 3D printing methods (aesthetics) would assure a successful deployment and show case.

Inclusion element will be also noticeable within the cross collaboration within the industries. We intend to create as many connection as possible within the industry when the product campaign will be launched. One of the market which we want to facilitate and transfer our lessons learned would be the protective equipment meant for head (helmets) and arm protections (knee, elbow, wrist guards and so on). Cross sector collaboration is key to stimulate innovation.