From Trash To Treasure

Basic information

Project Title

Full project title

Category

Project Description

In 2019 in EU OECD countries recycled only 14% of plastic material [1]. This situation is not sustainable and through this project I want to improve it. Plastic material is a valuable resource that should be recycled in bigger scale with affordable technology. By providing open source content and knowledge transfer, people can see real example how to process domestic waste into beautifull parametric bench with positive environmental impact.

[1] www.oecd.org

Geographical Scope

Project Region

Urban or rural issues

Physical or other transformations

EU Programme or fund

Which funds

Description of the project

Summary

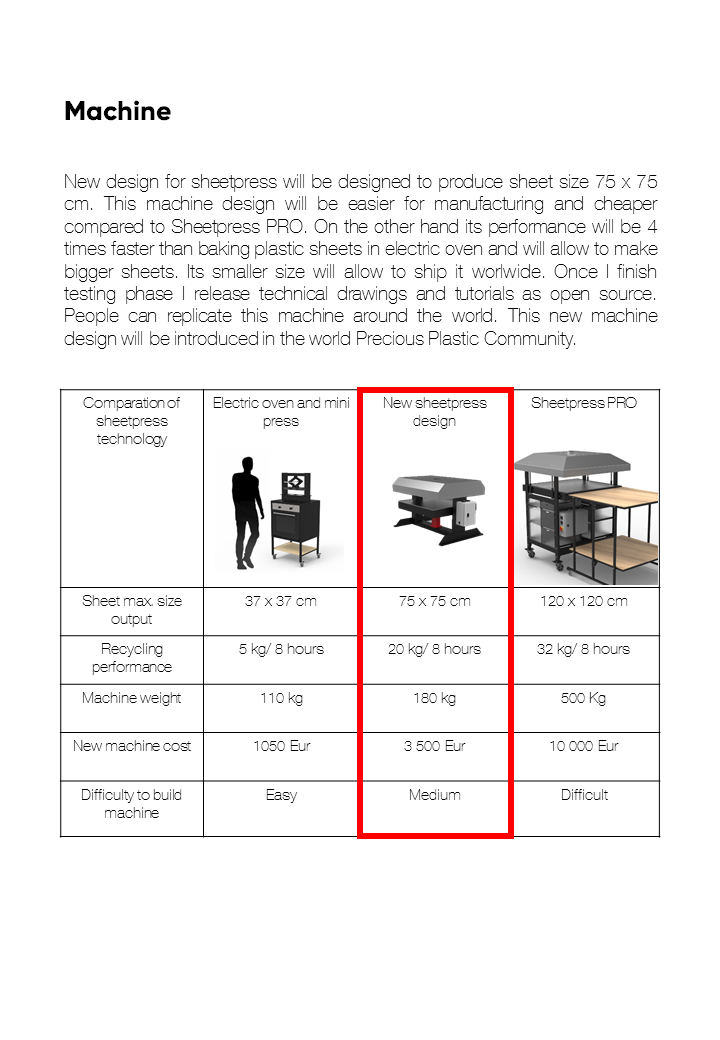

1) machine development and building

I decided to develop a version sheetpress that can produce a board from shredded plastic into dimensions of 75x75 cm and process 20 kg of plastic in 8 hours. This type of machine will be easy to manufacture, easy to use and will have small dimensions for its shipping, and its purchase price will be 1/3 of the Sheetpress PRO (designed by Precious Plastic). After design phase I build machine in my region, test it and release technical drawings with tutorials as part of free open source content to allow more people involve into plastic recycling world.

2) material collection

In Liberec (Czech Republic) I already have a small collection point for domestic plastic waste. Now I collect and process on average 11 kg of plastic material per month. In cooperation with NGOs and schools I can increase amount of colected plastic. Clean and sorted bottle caps, buckets, food trays, old sport equipment, scrap from 3d printing. With my experience I focus mainly on HDPE, PP, PLA or PETG. Within this project is a goal to process in total 1000 kg of plastic waste per year.

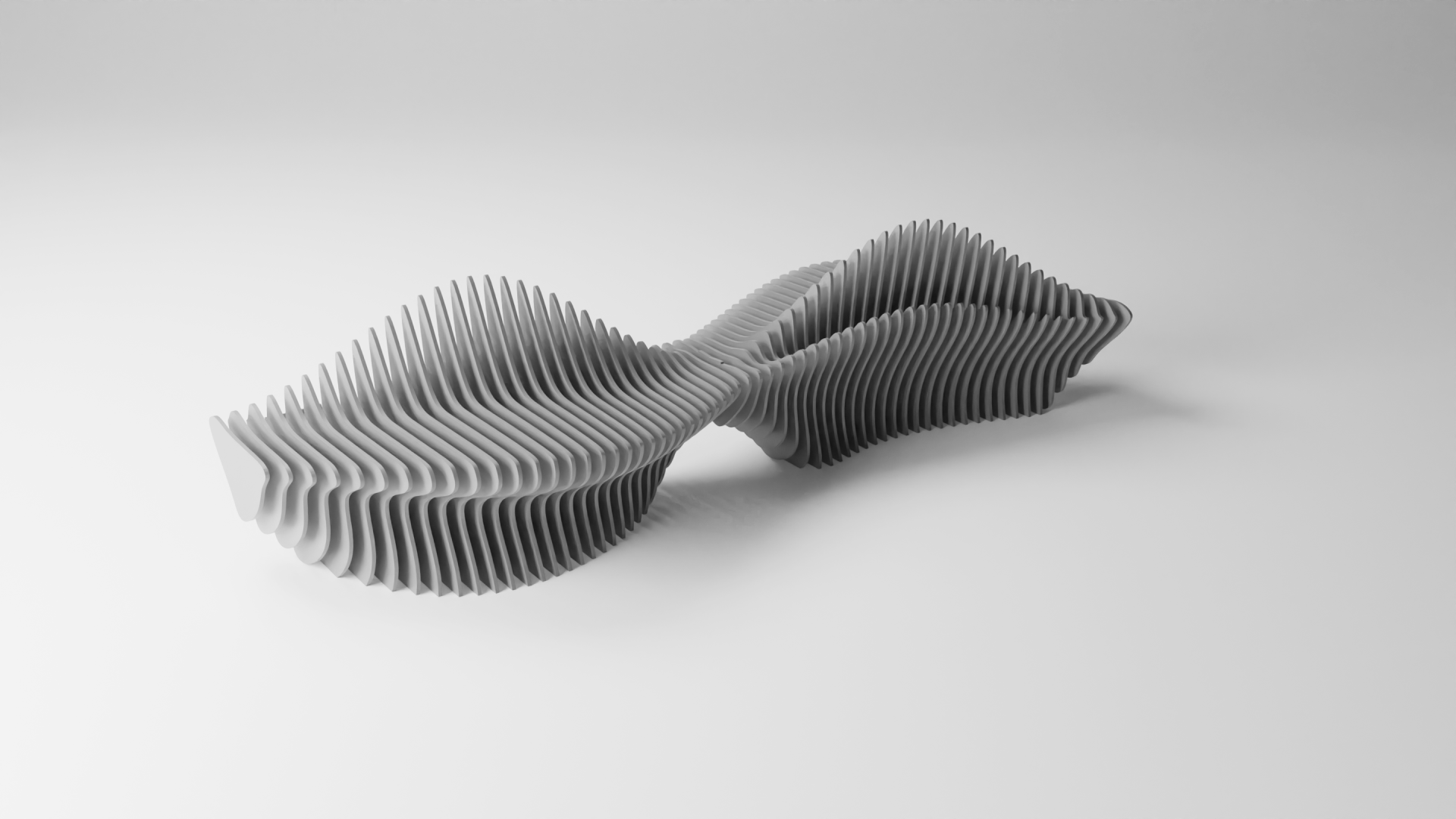

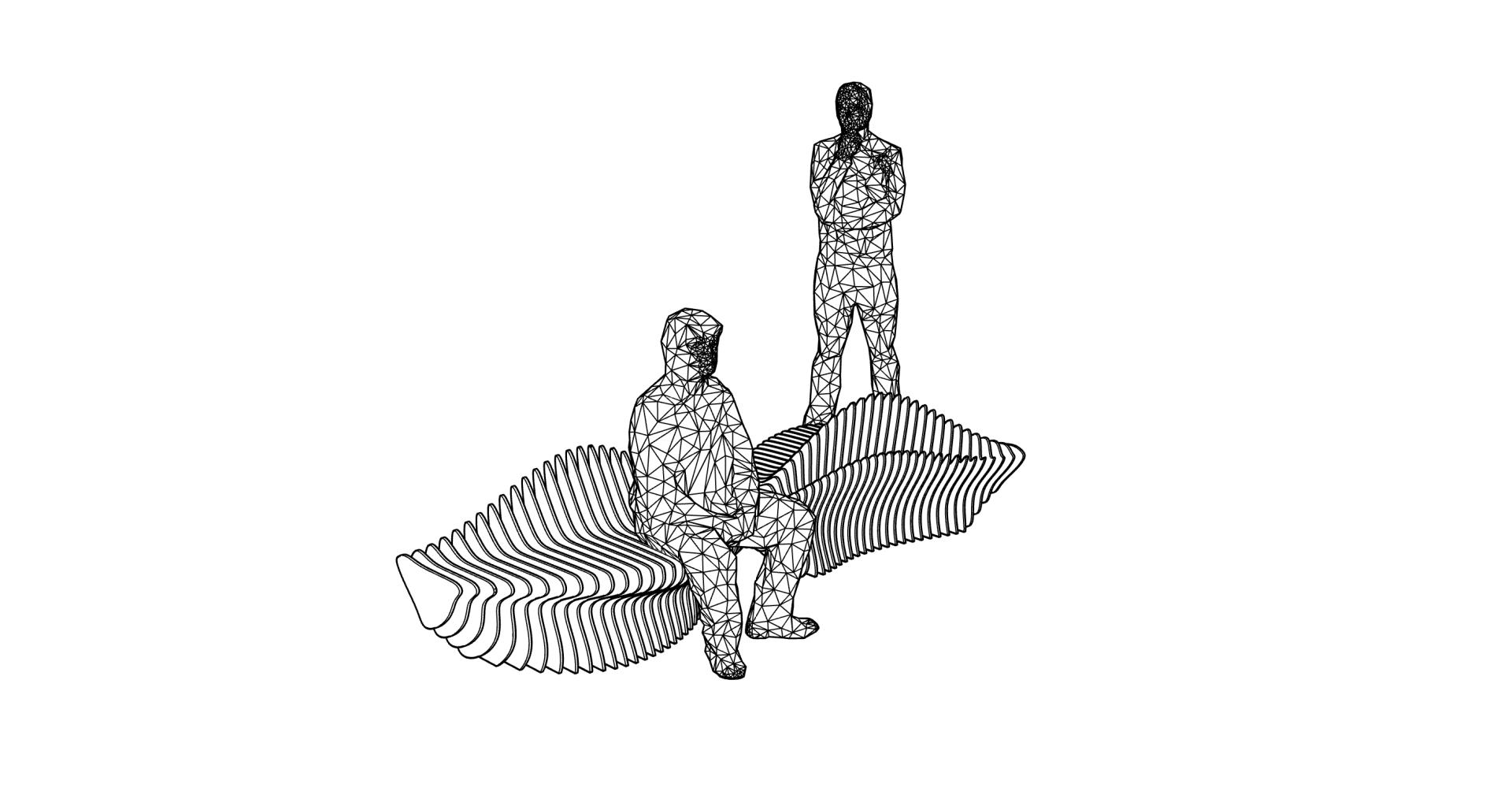

3) make beautiful product from waste

Parametric bench was custom designed for output from sheetpress machine. All sheets will be shaped into elements of bench and connect with rods. This shape will attract people´s attention. The first prototype we can locate at public place in Technical museum Liberec (approx. 10 000 visitors per year) as promotion for plastic recycling. Made design will be also released for free with tutorial and digital data for its reproduction around the world.

4) involve public and education events

To increase awarness about plastic recycling I focus on 25 education events at elementary schools. Each educational event at the school will have a reach of 50 - 75 children. Next to schools we can involve adults via 2 public presentations in cooperation with organization Technopark Liberec and organize 10 practical workshops.

Key objectives for sustainability

Objective is to collect and recycle 1 000 kg of plastic waste in 1 year into beautiful looking and usefull products.

A single parametric bench I want make can offset 150 kg of plastic material. As an example, for making this bench I need approx. 100 000 bottle caps. Based on my experience with other machines I estimate consumption of electric energy for recycling activities (1 bench) 120 kWh that will lead in 28 kg CO2 [rentsmart.com]. If this amount of plastic will be burned, it produces 435 kg CO2 [no-burn.org]. That means every produced bench will can save a difference 435-28 = 407 kg of CO2 Its an equivalent to amount of CO2 produced by car Toyota Yaris in distance 2 408km.

After reaching recycling target 1000 kg I estimate to save 2713 kg of CO2 emissions.

During education events I will pay attention to describe methods how to reduce consumption mainly of single use plastic. 25 events at schools can reach approx. 1500 pupils. I believe it can help reduce consumption of plastic material but it will be hard to measure.

This is only 1 workspace with 1 machine. :)

Key objectives for aesthetics and quality

Key objectives are:

1. Design, build and test a new open source machine for processing plastic material into plastic sheets. This machine will be easy to make, material cost under 2200 Eur, machine can process around 20 kg of shredded plastic per day. Powered by electric energy 380V.

2. Create 6 collection points in region where people can bring their clean and sorted domestic plastic waste. Total goal for collection is 1000 kg

3. Make 1 prototype of parametric bench. Product weight 150 kg, designed for 4 sitting people. Locate it in public space and make more copies.

4. Organize 2 public presentations, 10 workshops and 25 events at schools to spread information about plastic recycling technology, advantages of circular economy and lowering consumption of single use plastic.

Key objectives for inclusion

All project sites follow free open source access to information, knowledge and development.

Outcome from machine development will be : virtual assembly of sheetpress in CAD, technical drawings for machine component, electric wiring diagram with respect EU norms, bill of material with used materials and components for building sheetpress, video "HOW TO" build and use machine. Estimated material cost for building machine is 2 200 Eur.

Outcome from product development will be: Virtual assembly of parametric bench in CAD, HOW TO video make parametric bench. Manufacturing process should be possible in1 person only with electric power hand tools.

This project is good opportunity how to involve public and schools into recycling activities. Children and adults can collect plastic material that will be later used for parametric bench or other usefull product design. From education perspective I can organize 25 events in cooperations with schools, 2 presentations about advantages of circular economy and organize practical workshops to teach about plastic processing.

The goal is to enable people from all over the world to copy and develop the machine and the product - bench.

Physical or other transformations

Innovative character

This project deals with a global plastic waste problem. It can be used in rural and urban areas. First side of project focuses on physical transformations (material recycling into new product), second side of project focuses o change of awarness. People who will participate in local recycling system will realize how can be plastic material recycled, they will better understand advantages and disadvantages of plastic and hopefully will start behave more environmental friendly.