JetClay

Basic information

Project Title

Full project title

Category

Project Description

JetClay is an open source Platform that explores the world of 3d printing and ceramics, relating the digital and the analog, tradition and technology, makers and ceramists.

We develop our own tools to make unique pieces of ceramics at the crossroads among industrial design, architecture, interior design and sculpture; tools and knowledge that we give back to the community on social networks and open knowledge platforms such as Wikifactory.

Geographical Scope

Project Region

Urban or rural issues

Physical or other transformations

EU Programme or fund

Which funds

Description of the project

Summary

Jetclay started in the year 2017 as a private r+d project associating designers, engineers and chemists to develop an open source and low-cost solution for large volume 3d printing with fluid dense materials such as ceramics and biomaterials. It is halfway between digital fabrication and craftsmanship, being essential the traditional techniques of ceramic work for its work, although the modeling process has been automated with computer modeled and 3D printed pieces.

JetClay performs multiple activities related to the world of ceramic 3D printing, ranging from the provision of immersive workshops to the printing service, the latter being their main source of income. They operate, design and build their own machinery. Based on the maker philosophy and being aware that their project would not have been possible without the knowledge distributed by this community, they continue to share all the details of the progress they make on their printers on social networks and open knowledge platforms such as Wikifactory under CC BY-SA 4.0 license that allows for all types of use, including commercial, for all types of organizations and individual inventors.

Although in 2017 when they started their activity there were already several Open Source printer projects, there were no large format printers. Instead of resorting to commercial options that were quite expensive, they started developing machines, always with a focus on large-scale printing. The printing service focuses on clay and porcelain mainly, working with any type available in the market. This is always accompanied by an advisory service since, due to the characteristics of the technique and its novelty, most of the proposals that are presented are not suitable for printing.

Key objectives for sustainability

We pursue sustainability in 3 key areas:

MATERIAL SUSTAINABILITY

Our technology is suited for fluid dense materials, printing with clays and biomaterials. These natural materials offer a more environmentally friendly life cycle, as they don’t release harmful chemicals to the environment. Moreover, these materials do not generate additional waste derived from the manufacturing process, since prototypes, leftover parts, failed parts and other remains resulting from printing can be converted back into paste and reprinted infinitely without losing mechanical properties.

TECHNOLOGICAL SUSTAINABILITY

We open our projects with the aim of democratising technology, demystifying it and making it accessible to society. By sharing this knowledge with the community providing step by step guides for the operation of this technology, we facilitate the repair, customization, and improvement by anyone; extending its life cycle and reducing the environmental impact and waste.

Secondly, reducing the gap between concept and manufacture represents a significant paradigm shift in design. By bringing the production processes closer to society, people become aware of what objects require, giving them more value, and consuming only what is necessary, avoiding overproduction and manufacturing according to the specific needs of every community.

By sharing and co-creating 0 kilometre supply chains, we want to create awareness, to shine a light on a new way of manufacturing. We learn from the community, develop projects and share successes and failures, innovating and evolving rapidly.

CULTURAL SUSTAINABILITY

3D printing follows the steps of traditional ceramic processes. It is an alternative to the existing ones, such as hand modelling and potter's wheel. The rest of the work related to ceramics such as selection and modification of clays, decoration and firing are the same.

The ceramic tradition is preserved, adding another chapter to its extensive history

Key objectives for aesthetics and quality

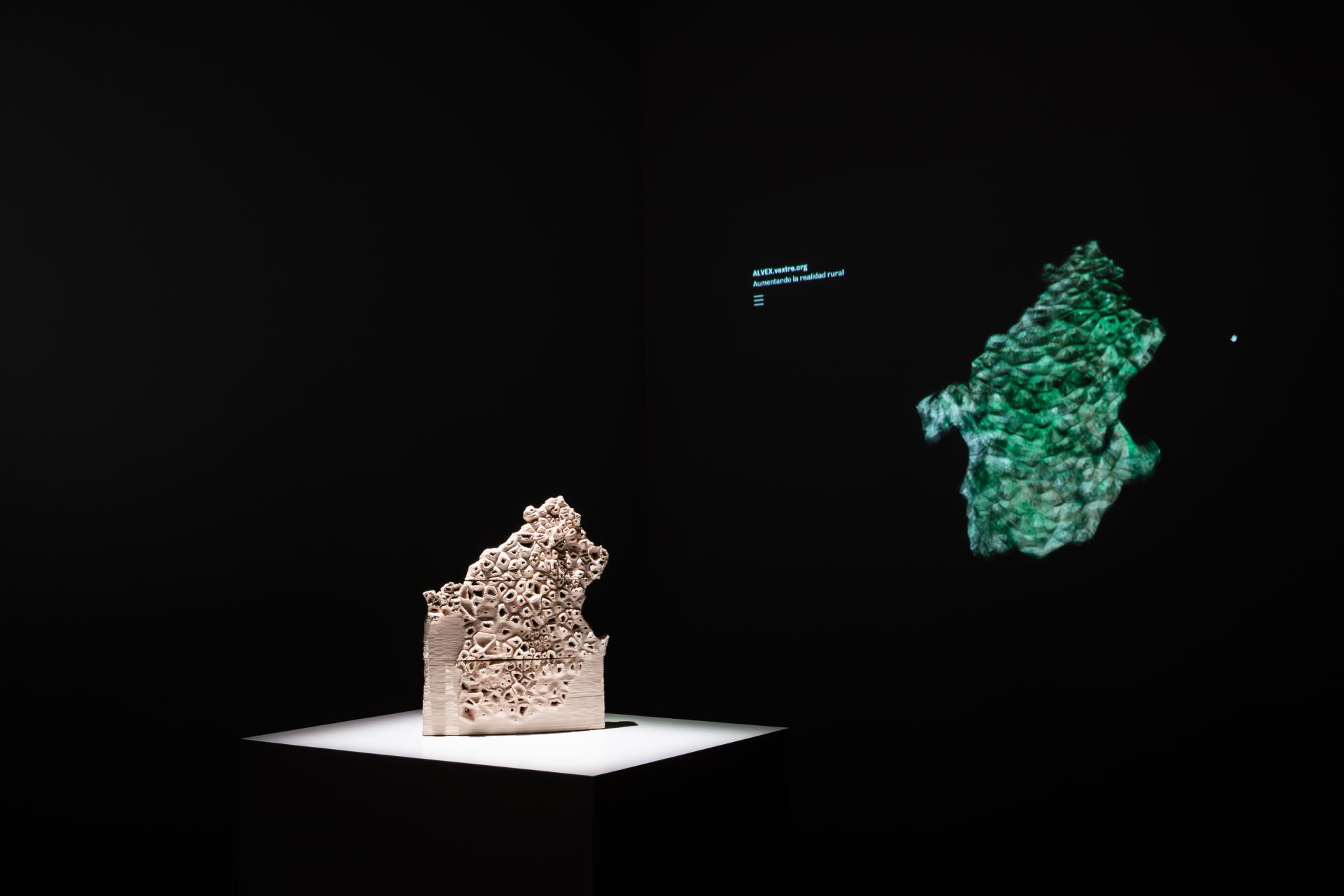

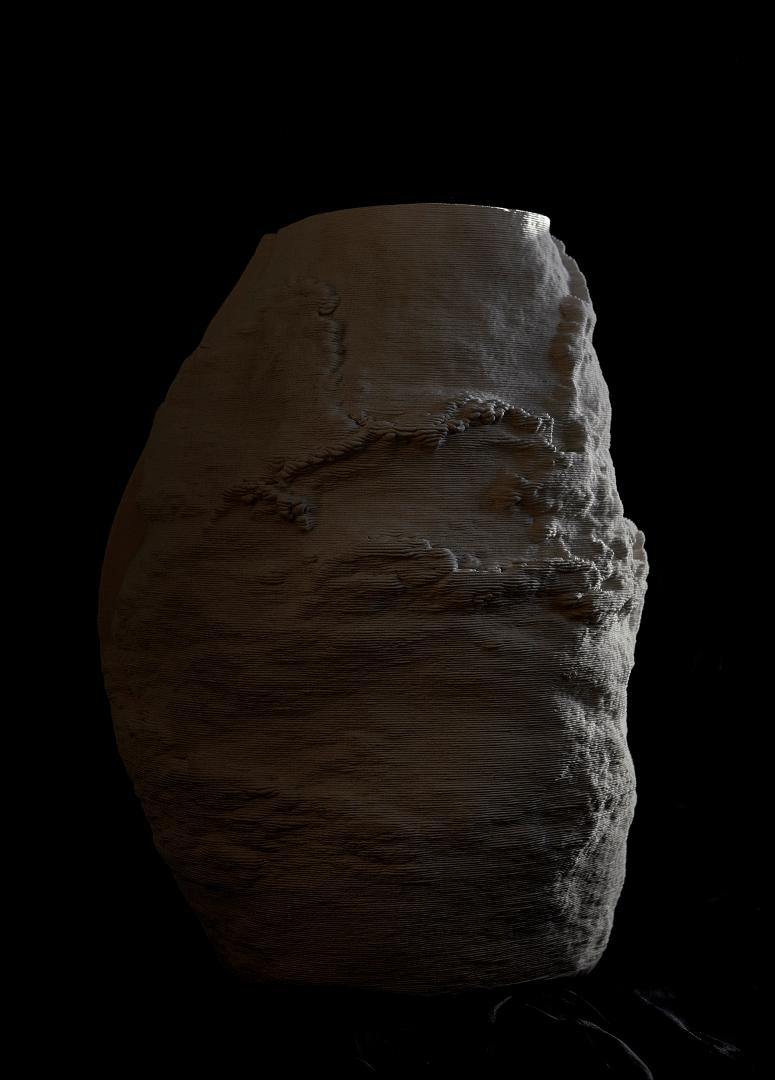

Ceramic 3D printing mixes craft and digital technology, creating a specific aesthetic look.

The pieces portray the mixture of these techniques. On the one hand the mark of the machine (layers, blotches and protrusions), and on the other hand the manual work thanks to the behaviour and memory of the material, always present. If the industrial revolution removed the hand, the digital revolution reintroduces the uniqueness of the single process. We like the singularities that appear in the process; the response of the material to gravity and the friction in the transfer of information between the 3D model and the machine.

We understand all these characteristics unique to the manufacturing process as inherent to the making of the medium and its aesthetic. Far from trying to correct them, we embrace them. Every manufactured piece has its own idiosyncratic presence, born out of the conditions during its making and visually present in every object. A digital 3D model file is able to replicate itself ad infinitum, but its digital transformation into a ceramic piece is only possible through a unique process. The ceramic object regains the soul that was taken away by industrial manufacturing.

Key objectives for inclusion

We learned from the maker community, from open knowledge, where we felt included. Now we are active members, creating documentation and giving back to society an evolution of an old way of making ceramics. By developing our own tools, both 3D printers and extrusion systems. We know that the more you give the more you receive and therefore we operate in an open source spirit.

One of our main objectives is the transmission of knowledge. For this we publish in repositories like WikiFactory where a community of product designers, engineers and entrepreneurs come together to design, prototype and manufacture hardware products. Our workshops are focused on the manufacture and use of these tools to create collaborative networks. We help students who want to introduce this technology in their projects (IED, NEBRIJA, ESNE...); and we participate in numerous maker fairs and craft fairs.

We believe in art and design as tools for change with their ability to solve problems. Creating communities around 3d printing ceramics, talking, learning, imagining and making, questioning and investigating all the dimensions that play a part.

Results in relation to category

Regarding the Open Source technological development, these are our contributions, all of them published in https://wikifactory.com/@jetclay :

- XL Delta Printer - The aim of this project is building a large delta printer, with a printer volume of 1 metre high and 70 cm wide.

It is specifically designed to be used with clay, but any sort of extrusion system can be added to it.

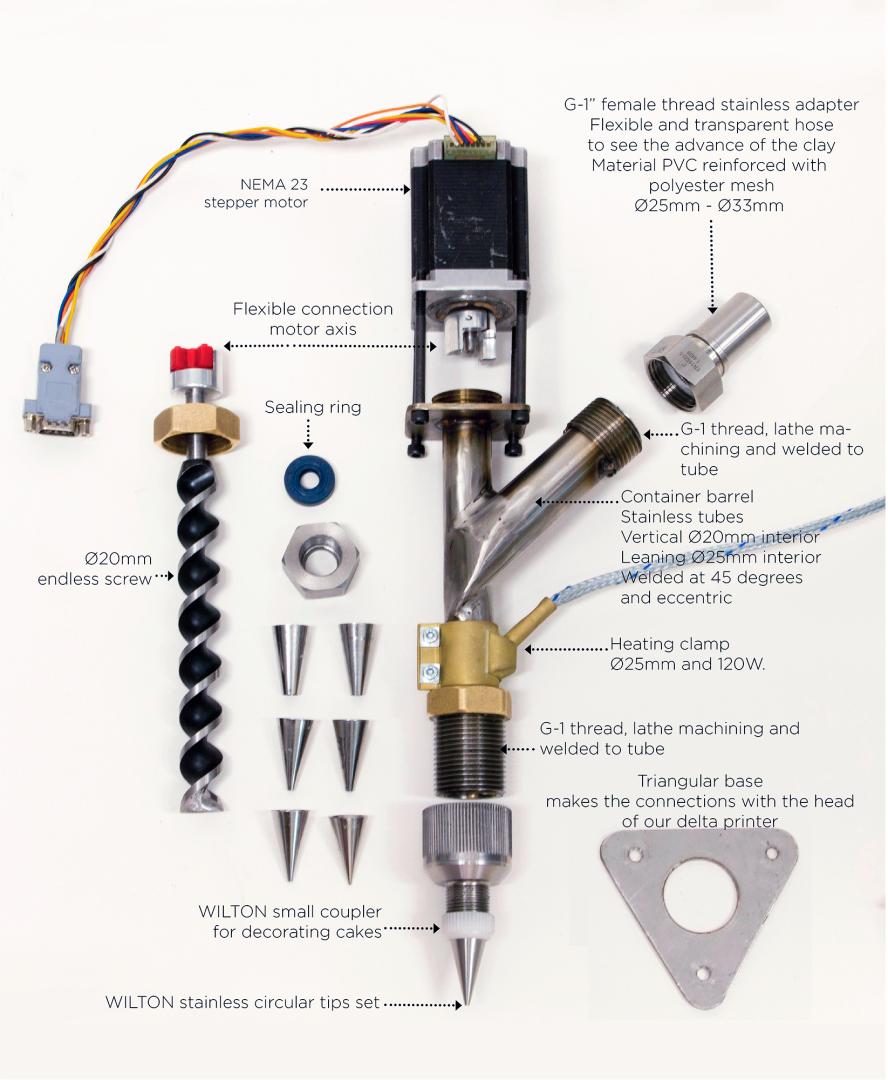

- Clay extruder - Dry clay extruder to 3D print large pieces of ceramics (up to 1 metre) using less than 20% of humidity.

These technologies have been implemented in Madrid, Leon and Bilbao (Spain), San Luis de Potosí (Mexico) and Santiago de Chile (Chile), and are maintained and updated by our collaborators and Jetclay.

JetClay has participated in several Maker Faires around Spain (Maker Faire Madrid, León, BIlbao and Barcelona), also in Maker Faire Rome.

JetClay has imparted several workshops about the fabrication and use of its technology and the creation of a collaborative ecosystem that fosters collective innovations.

Recently in MakerFaireBilbao 2021, the following link is the presentation of the participants results:

https://www.youtube.com/watch?v=Zy68zaO9zq0

Building on the paradigm of Open Manufacturing, the project has achieved this goal by bringing together traditional manufacturers and digital-savvy makers and engaging in the process also universities, local authorities, civil society organizations and policy-makers.

JetClay has participated in the Distributed Design Documentary introducing the emerging field of distributed design, covering key aspects such as its origins, the social and environmental impact, noteworthy practitioners, and future directions:

https://www.youtube.com/watch?v=lUJJtdFGyrc&t=1s

How Citizens benefit

This open process of creating and sharing technology and knowledge is itself a participatory process. We are not engineers but designers, we didn't come from a technological background, or any previous knowledge in engineering, programming or electronics.

We learnt from the maker community, using shared knowledge under open licences. From open sources we developed our own technology, tested it ourselves and with others; creating community around the process of learning and making.

This produces a feedback loop that feeds innovation. Finally, we share it back with people, spinning the loop again and improving together.

The success of this project should be measured by the degree it has contributed to create a 3D printing community with dense fuild materials.

Physical or other transformations

Innovative character

The success of open innovation, open source, and hardware movement is being driven by democratising access to formerly incredibly expensive tools. These tools are not only cheaper but also easier to use. The biggest transformation is not only the way things are done, but who is doing them.

JetClay, as makers, have innovated in three different aspects:

- Open Source technological development - Tools for 3D printing in fluid dense materials such as clay and biomaterials in large format.

- Contribution to the Community - Publication of JetClay’s developments in WikiFactory under Creative Commons Licences.

- Spreading the word - Participating in the different channels that the Maker Movement provides such as MakerFaires, Workshops, etc.

- Ceramics memory - 3D printing follows the steps of traditional ceramic processes, preserving its tradition, adding another chapter to its extensive history.

Learning transferred to other parties

Sharing and building together is at the core of what we do. Both things are complementary and need each other. We have learnt from what others have shared and we have built together with students and practitioners in workshops, lecture halls and fairs. Sharing and building is what makes us grow.

In the documentation we provide for using the technology we have developed anyone can become a user, and start building and sharing.

Making the technology accessible and viable for a wide potential user base, enables its use in different contexts, providing solutions for the local and specific problem. Making a difference starts by “making”. We want to give people the ability to bring down technical and conceptual barriers.