The Re-Built Project - Building Circular

Basic information

Project Title

Full project title

Category

Project Description

Polycare has been innovating in material science, manufacturing and architecture since 2010.

First the target was to create an efficient and superior building material that can substitute cement concrete by using other filler materials such as industrial waste streams or desert sand and more efficient binder technologies. Out of that, a Lego-like building block system was developed. To proof its circularity abilities, a 5-year old building was dismantled to re-build a complete new office space.

Geographical Scope

Project Region

Urban or rural issues

Physical or other transformations

EU Programme or fund

Which funds

Description of the project

Summary

After the first Corona lockdown in 2020 we came back into our lab and office to really make the next step on our circularity roadmap. For our growing team of scientists, engineers and designers we needed more space for our own workshops but also client workshops.

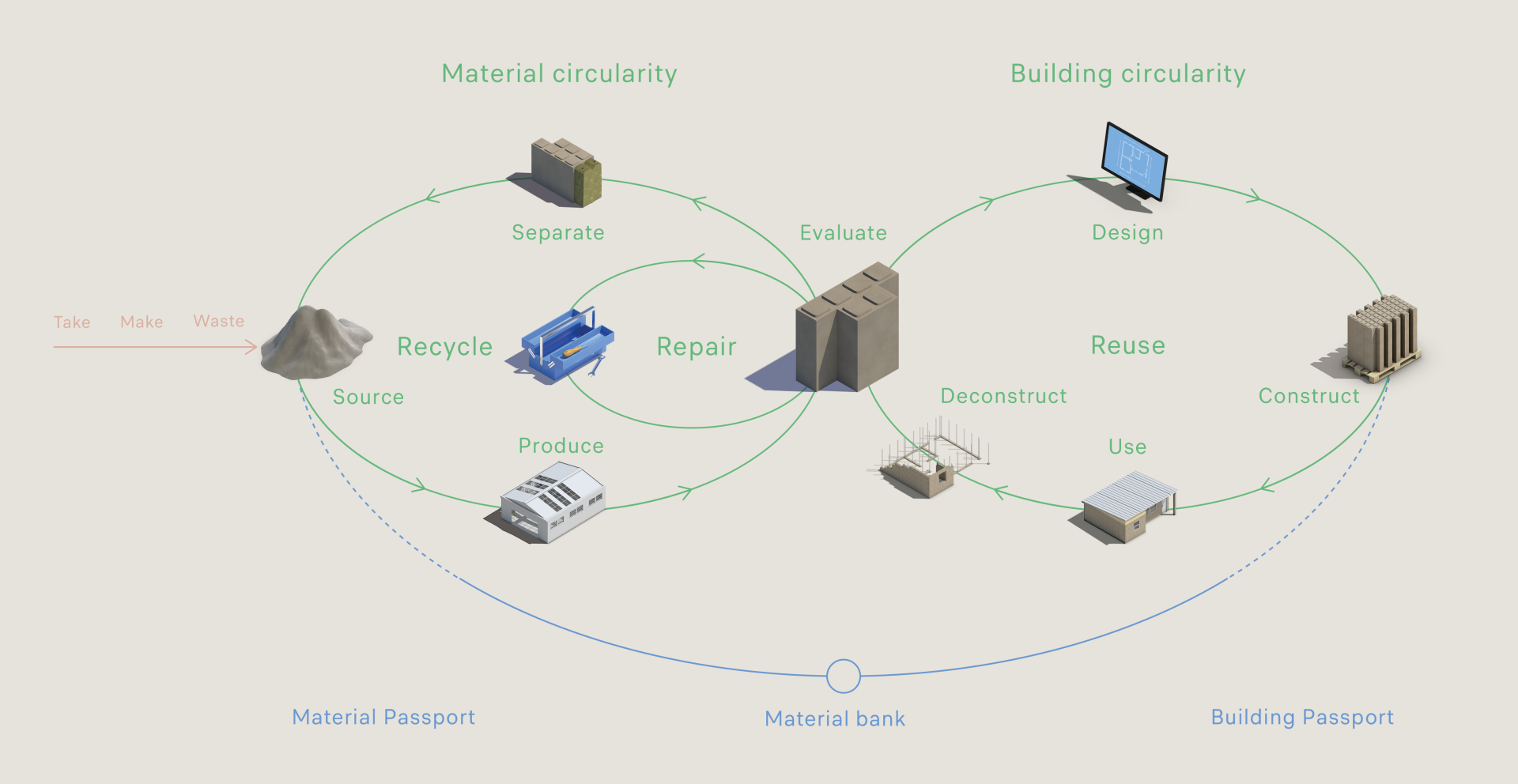

So far, the team of Polycare concentrated mostly on the efficiency and circularity of the so-called Polyblocks. We call that part Material Circularity: manufacturing a component like a building block from secondary raw materials (addressing the recycling industry as well as the producers of building materials). Producers take over consistent responsibility for their own product (component). The product development follows the premises: It must be designed for reuse and repair. Finally, it needs to meet certain criteria in order to enable resource efficient recycling like simple separation of the used materials.

The next step was to really proof the Building Circularity: building a house that is designed for disassembly (deconstruction) and reuse and thus, to decouple the lifecycle of the components from the lifecycle of a building (addressing the building, architecture and construction industry). As we had build a 2-storey show house in 2014 for our first North African partners on our little campus, we had the opportunity to proof the reuse of each element right in front of us. The simple but yet smart building system made of these Polyblocks enables everybody to be part of the construction process, and that's why we integrated all our co-workers to build it.

The target was to design and build a new 100 sqm office space where people feel comfortable, where they enjoy to come together, become creative, work and live. We were inspired by the DGNB Circular Economy as well as by the Urban Mining Design Guidelines. That is why we decided to use screw piles as foundation system to not seal the ground and to even make the foundation ready for disassembly and reuse.

Key objectives for sustainability

In summary the project followed clear major paradigm shifts:

- Take Waste to Make: Integrating waste streams into the product development and manufacturing

- Design follows Availability: Designing new buildings based on a stock of components that have been part of another building before

- Design for Disassembly: Making Deconstruction possible instead of Destruction, Reuse First

- Business Models for Circularity: Promoting repair to extend the lifecycle of the components to the maximum, de-coupling lifecycles of components from the building lifecycle

In terms of key performance indicators, we basically look at two categories:

1. Circularity:

a) % use of secondary raw materials (e.g. recycled materials) --> 55-60% for the manufacturing of our Polyblocks

b) % direct reuse of parts after disassembly --> >97% of all pre-used Polyblocks

2. CO2 and GHG emissions

a) CO2 emission caused by the material production and supply chains --> 60% emissions saved compared to cement concrete

b) CO2 emissions caused along the life cycle of the building --> in this project, no change to baseline as we did not integrate off-grid energy systems like e.g. solar power.

Our research roadmap shows from here, how we can raise the circularity of our product to almost 100% and with the integration of carbon sinks like bio char we are working hard on a carbon neutral or even carbon negative building block.

Our building system can be applied to any kind of rectangular designed building in a 10cm grid. Therefore we are able to replicate this approach of building to almost any kind of building typology which we are planning throughout the next few years by scaling our research and manufacturing capabilities.

Key objectives for aesthetics and quality

As a deep tech company we integrated design and architecture students to explore the possibilities of new aesthetics.

So far we have been optimising towards speed, clean construction site (no waste, only needed material on site with minimum requirements on the needed tooling, no heavy machines), high quality procedure to bullet-proof the intuitiveness and simplicity of the building system and low maintenance (easy to repair things, high accessibility of screw and other technical connections.

Therefore thinking the whole building as a circular product inevitably leads to a new aesthetics. For example our building is elevated and is "floating on big screw piles" so that we don't seal the ground and assure full potential disassembly as well. All these aspects have been incorporated in the design process with the student group until we found a holistic, simple but yet smart way of creating an office space where people feel comfortable, where they enjoy to come together, become creative, work and live. As mentioned above the DGNB Circular Economy as well as Urban Mining Design Guidelines were an inspiring input for that assignment.

Key objectives for inclusion

At this stage we planned this project as a team building and unique experience for ourselves. After the first Corona lockdown it was nearly impossible to integrate a lot of people on the ground and to workshop the background idea to create awareness among students, architects and other interested parties.

But this project opened up many new involvements, like the very inclusive and international workshop series we did with the Domaine de Boisbuchet in late 2021, see attachments (the project is in its finalisation phase).

Today the inclusion and co-design methodology is an integral part of our approach when we undertake construction projects.

The universal design of our building system and philosophy as well as the easy accessibility to this intuitive way of building is helping us to explore the future potential and power of thinking circular and sustainable from any perspective.

Results in relation to category

We truly shape a circular industrial ecosystem and support life-cycle thinking in every customer project. As a deep tech company we apply material efficiency and circularity to finally drive the saving of carbon emissions in this very material and emission intensive industry.

In this project we managed to

* reuse more then 97% of the dismantled building blocks and other elements (ground bars and ring beam)

* create a fully emission free (CO2, noise, dust) construction site that is accessible and safe

* build a building typology that can be dismantled again with more than 80% assured reuse ratio on all materials / components used in this project (compared to about 2-3% reuse today as a benchmark of the current industry)

The building blocks itself save around 75% of raw materials by design through our lightweight Polyblocks and about 60% CO2 emissions. (learn more about them here: https://polycare.de/en/products/polyblocks).

How Citizens benefit

As mentioned above, for this specific project we included external design and architecture students for the design stage.

After finishing the project we invited the municipality and building experts from the Thuringian building institutions to show off our result and possible impact to the industry. Since then we experience a lot of support to ramp up further projects in this area but also in other German counties.

Physical or other transformations

Innovative character

The traditional construction and building industry is organised as a linear value chain: Natural resources are taken to produce components (building blocks, windows, roofing, etc.) and then to make buildings out of that. Once the end of life of the building is reached (very often just after a few years or decades) the building is demolished or destructed which leads to those massive waste streams that ultimately are put on landfill or used for down-cycling. Ultimately, the lifecycle of the component is coupled to the lifecycle of the building.

Therefore the construction and building industry is one of the most resource-intensive businesses. At present, construction and demolition waste (C&DW) is with 850 million (metric) tons per /year the largest waste stream in the EU, representing 30-35% of all waste generated in the region.

Thus, reshaping the European construction sector into a resource-efficient and sustainability-oriented circular approach is imperative to achieve the EU major climate and circular economy objectives. Waste generation and related (greenhouse gas) GHG emissions are key areas to be assessed to reach Europe´s climate targets. At present, most of the recycled material from construction is used only as backfill material in a down cycling process.

We are searching and developing ways how to integrate the waste streams of the linear economy into our circular value chain to drive the evolution towards a circular economy, as depicted in the attached illustration. The new paradigms to develop components or products ready for reuse, repair and recycle and that are inclusive and empowering people on the other side are in the center of our DNA and long-term strategy.

Learning transferred to other parties

The Re-Built project got a lot of attention from architects and designers. The Domaine de Boisbuchet (Boisbuchet.org) - a place for experimental and inclusive architecture - asked to make a public workshop on their grounds together with the architects from dmvA (Belgium based) which happened in October 2021. The feedback was amazing and is now leading to new opportunities.

We are now heading the development in Germany together with our partners from UrbanBeta to Carbonauten to Concular to develop holistic end-to-end solutions for the future circular built environment. The joint offering to the market will be public soon under the name of "Polyspaces".