From excavated soil to ceramic tiles

Basic information

Project Title

Full project title

Category

Project Description

Currently, in Paris metro lines are being extended. This results in a huge amount of excavated soil that could be considered as a resource instead of being stored in waste landfills.

My project is about reusing clay soil to create glazed ceramic tiles. The different types of soil, containing various minerals, generate rich and 100% regional colors. These locally sourced tiles will allow to reduce the landfill congestion and the extraction of resources needed for the production of new ceramics.

Geographical Scope

Project Region

Urban or rural issues

Physical or other transformations

EU Programme or fund

Which funds

Description of the project

Summary

In the Parisian region alone, more than 20 millions tons of excavated soil are extracted each year. Only 20% to 30% of inert excavated soil is recycled. This soil is considered as waste while it is a resource. The current project to extend metro lines in Paris and the suburb, called The Grand Paris Express, will generate in total 43 millions tons of excavated materials. This leads to a risk of landfills sites being saturated.

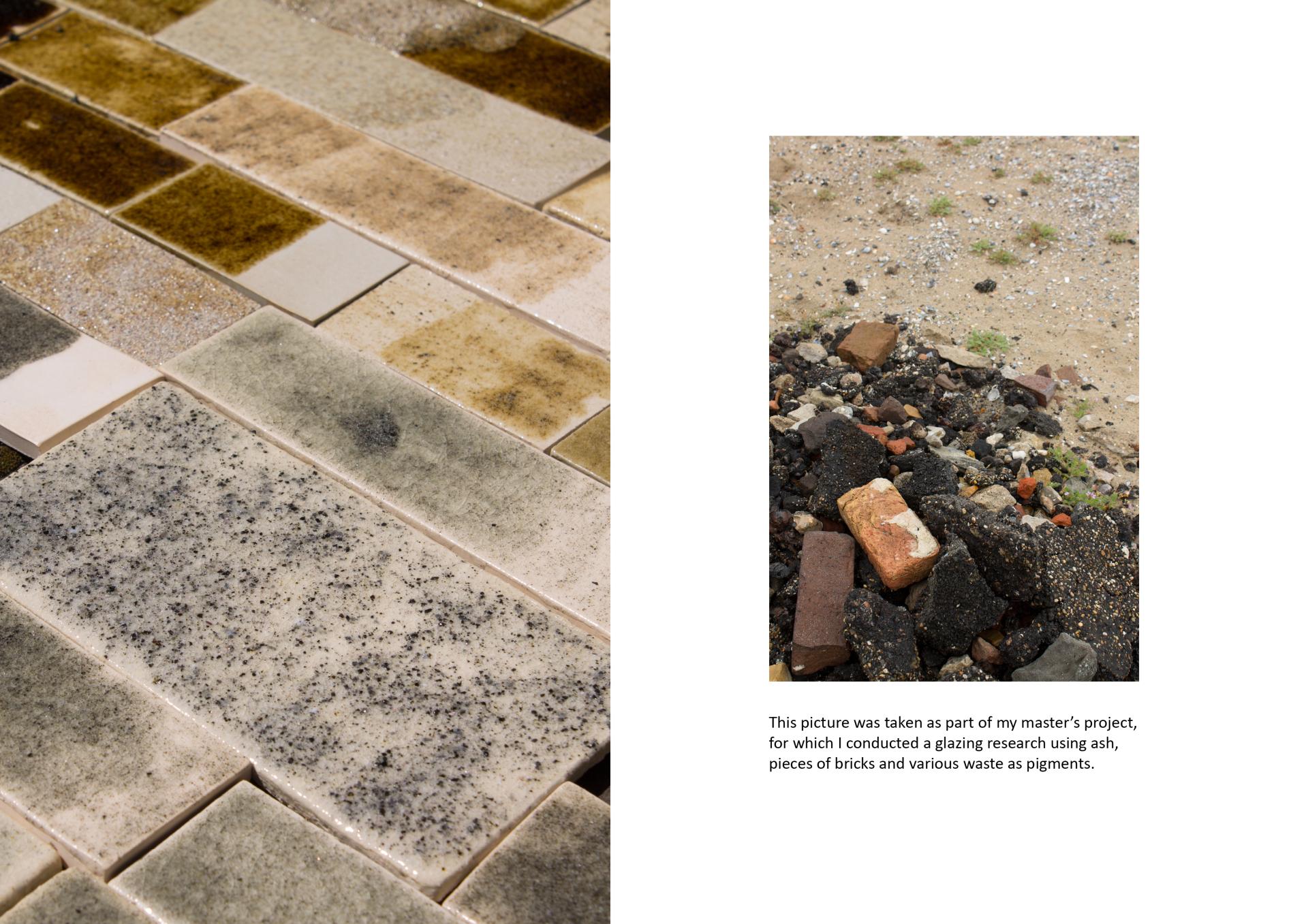

Mobilizing these urban deposits for the development of alternatives to industrial ceramic tiles leads to a new way of reusing the soil. This project is about creating glazed ceramic tiles using excavated soil and demolition waste.

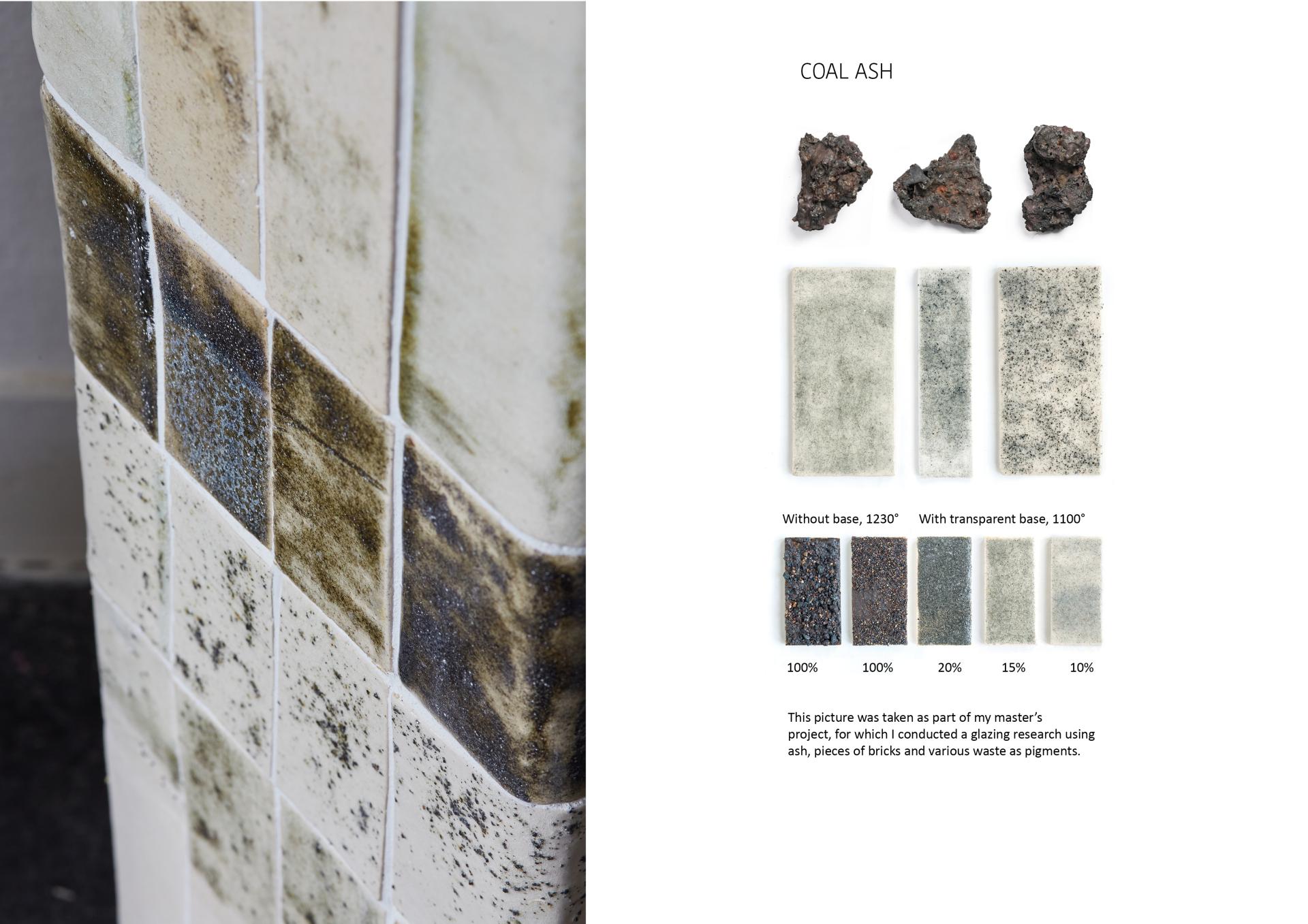

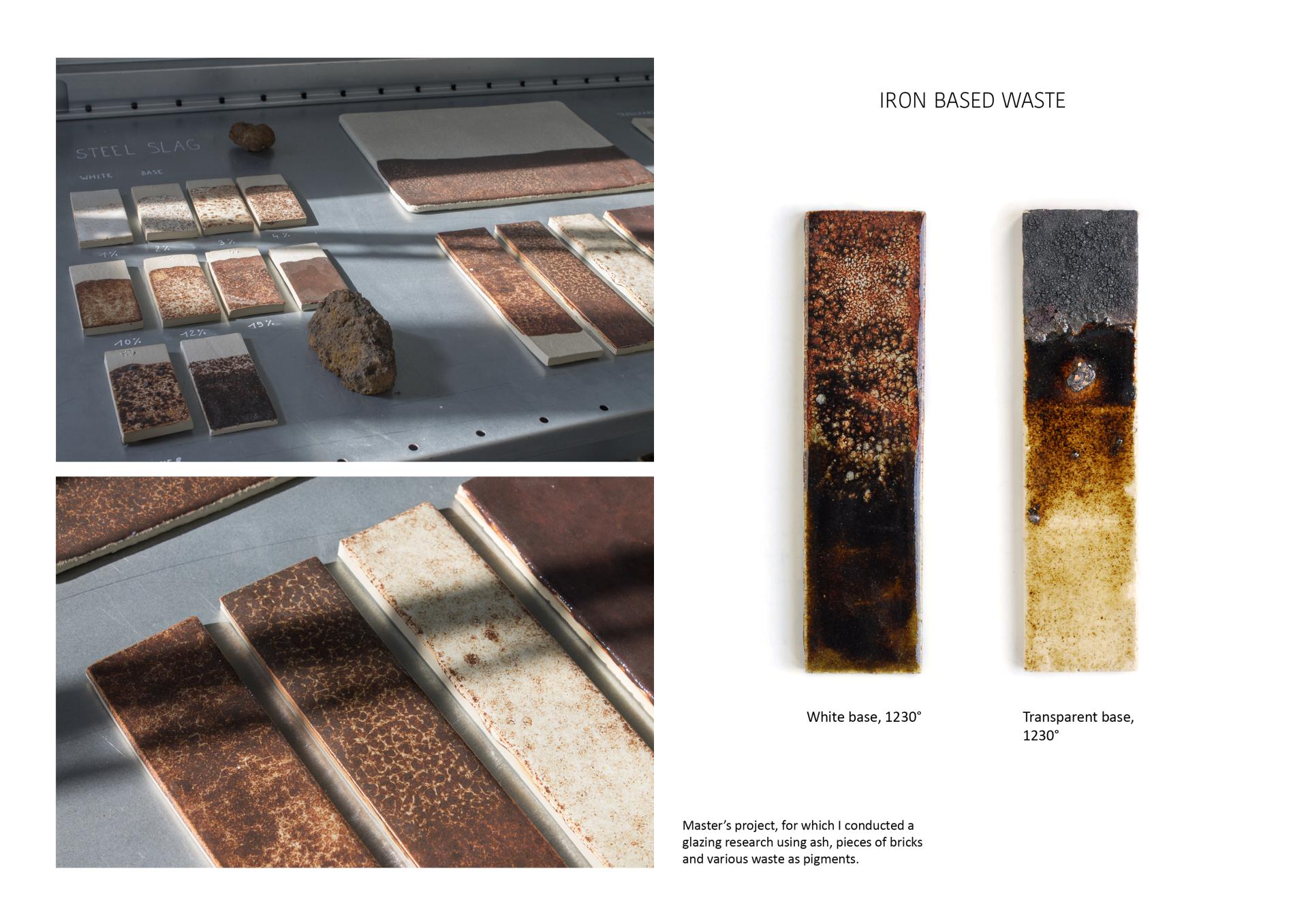

Inert waste (pieces of ceramic, slate and glass…) and non-hazardous waste (metals, bottom ash), can be used as pigments or components of the glaze. The soil can be reused to make the tile support, or be integrated into the glaze recipe. The different types of soils, containing various minerals, generate a rich palette of colors for the glazes, 100% from the Parisian region.The result will be ceramic tiles, locally sourced, that tell a story. This will reduce the amount of materials sent to landfills and the extraction of resources needed to produce new ceramics.

Additionally, workshops would be conducted in schools and community centers, in order to reflect collectively on the possibilities of these materials and the importance of the development of new local economies.

This project started with a grant from FAIRE Paris, an open call launched by the Pavillon de l’Arsenal and various sponsors. Reusing excavated soil is a topic that federates actors from different fields. I work in contact with ceramists, such as Jean Girel, the ceramic department in University Duperré, the National Museum and the manufacture Cité de Sèvres, and the geologist Myriam Duc. Société du Grand Paris, the company in charge of extending the metro lines, as well as the company ECT, that works on reusing excavated soil, provide materials.

Key objectives for sustainability

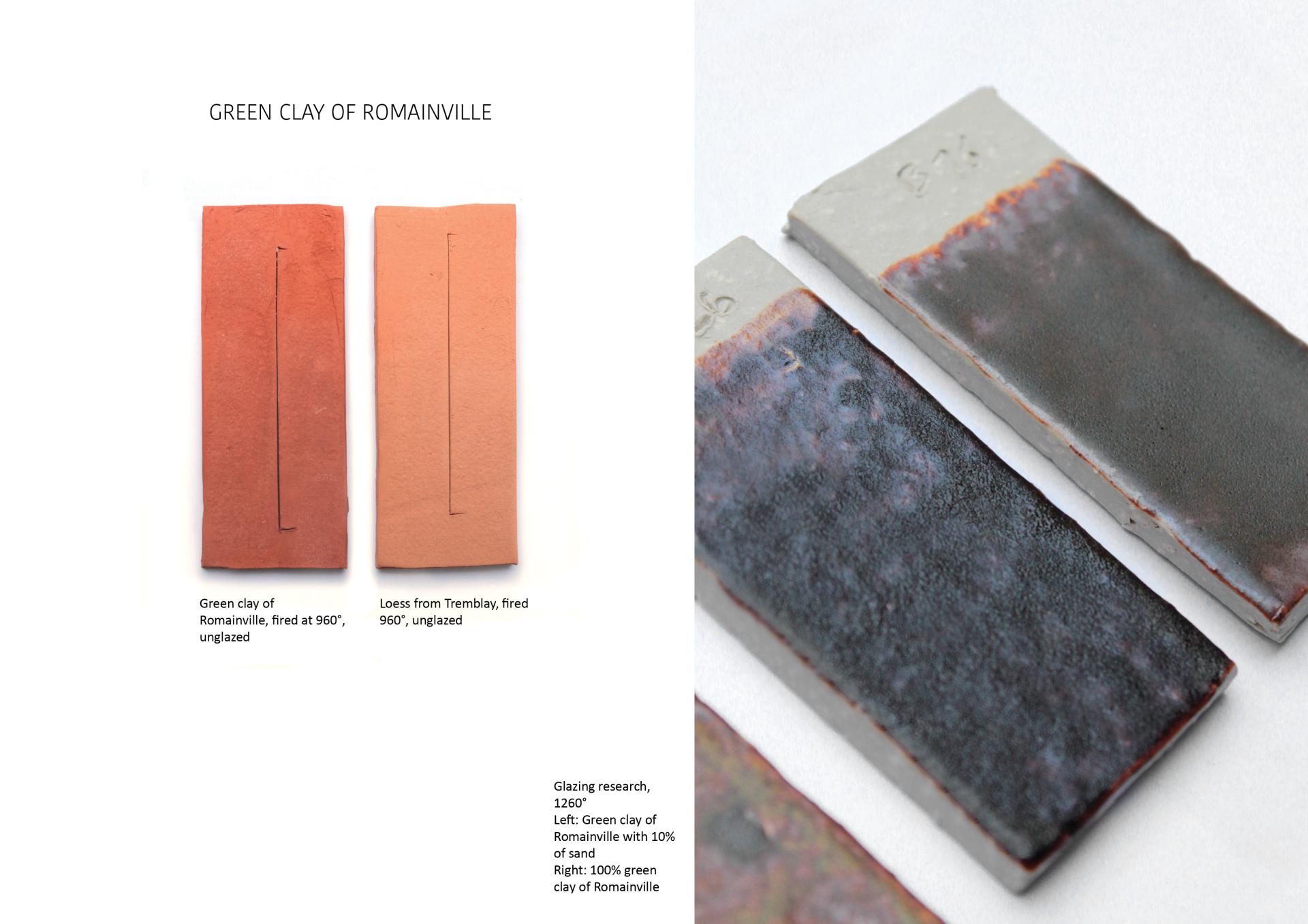

Excavated soils can be reused to make earthenware tiles, or to make glazing for stoneware tiles, since they melt at a high temperature.

I selected the excavated soils based on these criterias: high quantity of available resources, clay’s composition, inert material, not many existing possibilities in recycling already.

Based on soil analysis, to form the clay body of the tile, I focus on the geological formation Green clay of Romainville, the most widely spread clay formation in Paris. This clay can be combined with excavated sand or smashed bricks, forming a 100% waste based clay body. It is a low firing clay (earthenware), and therefore consumes less energy to be fired. The glazing of these earthenware tiles will be pigmented with demolition waste. It doesn’t require a lot of energy to prepare the clay body: the clay doesn’t have to be grinded. It dissolves in water and is filtered.

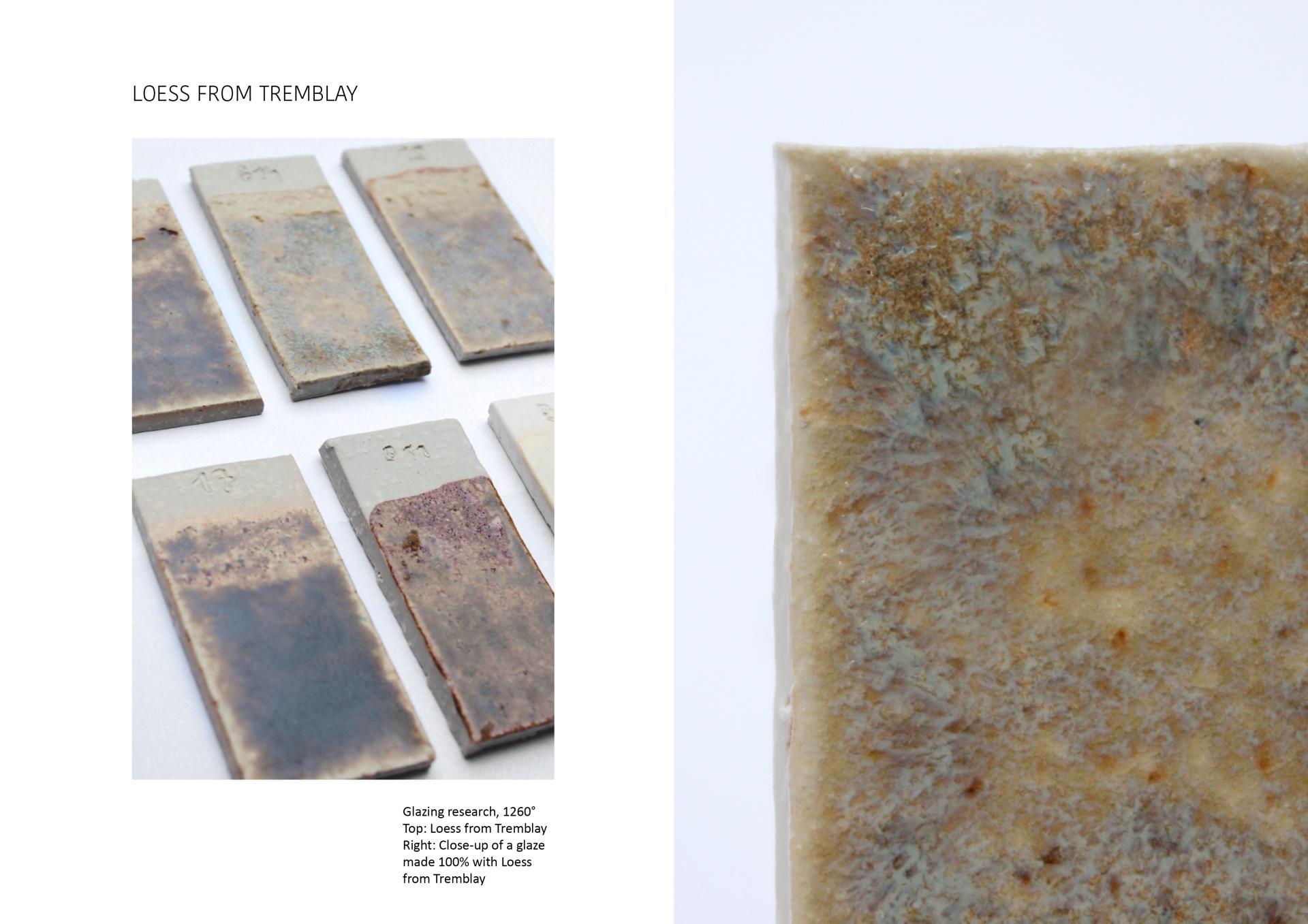

Another part of the research consists in making glazing for stoneware tiles (high firing temperature). Many Parisian clays and marls contain carbonates, which doesn’t allow them to be reused in the clay body, but they are good glazing for stoneware. The glazing will be 100% waste based, using sand, marls, clay, limestone etc. This glazing can also be applied on stoneware tiles coming from re-employment. Therefore, existing white or sandblasted stoneware tiles can be given a new life. Most of the time, a ceramic tile needs to be fired twice. But using clay based glazes allows to bake in single fire, which consumes less energy.

These ceramics are recyclable, and can be re-introduced in the ceramic production’s chain as fired or raw elements. Ceramic tiles are durable materials, that resist humidity, are stain proof and have a lifecycle of more than 50 years.

In order to reuse a significant amount of excavated soil, I work in contact with the manufacture Carre ceramique, to develop the industrial production of the tiles. 1 ton of clay produces 25 to 40 square meters of tiles.

Key objectives for aesthetics and quality

Beauty can be found locally, and in materials that are regarded as not valuable.

This project aims to reveal the broad and interesting colors of the Ile-de-France soil. The different types of soils contain various minerals, and different percentages of iron oxyde. Once fired, these waste materials reveal rich colors, from oranges, reds and browns, to coolers tons, depending on the firing process. Soils have different grains (thin clay to thicker grains of sand), allowing to create various textures, mat to shiny, smooth to rough. Ceramic tiles made from excavated soil allow the building to keep a trace of its previous life, and carries a poetic aspect. Ruins of the previous building are sublimed and its memory is passed on the next building.

It is also a reflection about using materials that are traditionally considered ‘poor’, and ‘not valuable’, such as soil and waste, and in our current context of over production, thinking about how to bring value and beauty to an object while minimizing its energy cost.

This past year, there has been a renewed interest in ceramic, which, according to historian Dr. Stephanie Le Follic Hadida, can be explained by a desire to go back to matter, and a revaluation of the individual through handwork, after the era of the tertiary sector, and the covid crisis. Against the disposable items society, new consumers turn to ceramic, supporters of the ‘slow made’ way of consuming.

In a context of a new economy to invent, with a change of scale in the way we produce, knowing where and how the object is made induces even more appreciation of the material.

Amongst ceramists, there is a growing interest in creating with less materials, locally sourced. The ceramist Valérie Armand conducts entire color researches with just iron.

Ceramic tiles create a warm and comfortable environment, and don’t cause any health problems, being free of volatile organic compounds and hazardous substances.

Key objectives for inclusion

This project aims to produce local ceramic tiles and also to spread knowledge and interest about excavated soil as a local material by co-creating with inhabitants.

The clay is being extracted from metro lines that are being extended to connect suburb cities to Paris. Workshops could take place in cities from which the clay is extracted, in order to think together about what to make with this local resource, to develop new ideas and to avoid the wasting of clay. It is a way to think of a local production and economy at the scale of the neighborhood. These workshops could take place in community houses, or in schools. It would then be a way to exchange and learn while making, discussing topics like sustainability and local production while being introduced to this traditional craft. It also allows to transmit ancestral knowledge while innovating together.

Moreover, While the emergence of lifestyles conditioned by speed and the use of digital technologies could have made ceramics disappear from our environment, clay is more present than ever in our daily lives.

The simplicity and evidence of ceramic is attractive. It doesn’t require a lot of materials, just clay, shaped by hand. It gives value to make Making something with your hands, directly in contact with the soil, adds value to the experience.

Workshops with design or ceramic students would also allow to expand the range of possibilities with this material. Workshops with students from University of Duperré have been been discussed already for the second half of the year.

Regarding the affordability of the tiles, the end products won’t be very expensive, since originally made with waste material.

Physical or other transformations

Innovative character

This project is a realistic production method, that allows to develop beautiful objects with rich textures and colors, locally sourced. Ceramic tiles are finishing materials used to cover the ground and the walls. They need to be both aesthetics and mechanically resisting. Glazing provides aesthetic (color, shine, decoration, shades) and technical (hardness, impermeability, etc.) characteristics.

It is also an experience of local co-creation, that aims to develop workshops in cities where the clay is excavated from, leading the way for many more projects to be developed. Local excavated clay becomes a way to feel more connected to our environment, to our objects, and to promote different ways of addressing the topics of sustainability, through creation.

The materials that are developed can also be used to make ceramic products for the house such as vases and dinnerware, therefore different applications could lead from this project.

With the overabundance of objects surrounding us, it is important to find alternatives to our current ways of producing, using what is already there, and producing locally. In France, the production of ceramic tiles was of 44 million square meters in 2000. According to a research report by PMR, the ceramic tiles market is expected to grow during the period 2019-2029.

Since excavated clay is everywhere, this project is local but scalable and adaptable to many different cities. As Master of art Jean Girl told me, the literature about this topic is almost inexistant, therefore the publication documenting this research would help to proceed excavated clay from other regions. It will hopefully trigger interest amongst ceramists and industrials to start a national and even European movement in the revalue of excavated clay. Discussions with several ceramists (Emmanuelle Cassot, Marie-Lucie Trinquand, Jean Girel..) showed me that there was an existing desire to develop this way of working.