Superwood - Waste as a future ressource

Basic information

Project Title

Full project title

Category

Project Description

Superwood is a new material that consists only of residual materials. It is made from recycled wood fibers mixed with casein and pressed into boards. We dispense with formaldehyde, a toxic glue used in 95% of all MDF boards. We obtain our binder from residues of the dairy industry. In this way, we combine two waste materials available in large quantities to create a new circular material. This not only makes our domestic space healthier, but also conserves natural resources such as our forests.

Geographical Scope

Project Region

Urban or rural issues

Physical or other transformations

EU Programme or fund

Which funds

Description of the project

Summary

Superwood is an aesthetic, sustainable material that uses no petrochemical binders, making it formaldehyde-free. It is made from recycled components. The topic of "sustainable living" is illuminated holistically and the importance of circular materials is brought into people's awareness. In addition to the importance of wood as a raw material for the ecosystem, the focus is on waste management, the fast furniture industry and the alternative potential of bio-based materials. We believe the best way to live indoors sustainably and healthily is to raise awareness of ingredients in furniture and building materials while providing viable high quality alternatives that are good for people and the environment.

In Central Europe, people spend most of their time indoors. The rooms and furniture that surround us should therefore be understood as elementary living space. It is all the more important to think about the materials from which they are built. What resources are they made from? Are residues used sensibly and are substances that are harmful to the environment and health avoided?

The consumption of renewable raw materials increases every year. Wood is perceived very positively by consumers as a renewable raw material. However, this resource also comes up against its limitedness. Furthermore, the production and consumption of so-called fast furniture lead to short-lived material and product solutions. They contain harmful substances and cannot be recycled. Adhesives are invisible to the consumer, but they slowly emit pollutants over the years.

By combining research and design, we have succeeded in communicating the need for circular action while offering a cost-effective aesthetic alternative.

Key objectives for sustainability

With Fraunhofer Institute for Wood Research, we have developed a casein-based adhesive to replace formaldehyde. Casein glue is a non-toxic binder made from milk proteins. It was used in ancient times for boat and furniture construction. It was forgotten and was never used in a larger industrial context. We gain it from milk waste.

Every year, 2 million liters of milk cannot be used because it is a perishable food that is strictly controlled. Milk is a product that must be disposed of quickly because of strict food regulations. Two million liters per year have to be thrown away in Germany. The milk proteins obtained from these leftovers can be used to produce a natural adhesive. So despite its agricultural origin, there is no competition with food.

Superwood has been subjected to various quality tests. It exceeds the highest stability standards for MDF according to DIN and is biodegradable. We have refined an industrial process and improved the properties of the adhesive to be able to use the material without coatings. An important condition for recycling.

In summary, we have developed a new biodegradable material from waste that can be reused and recycled. Our development is therefore sustainable and contributes to a circular system. Furthermore, it is an example of demonstrating that sustainable circular materials do not have to compromise on quality compared to conventional materials.

Key objectives for aesthetics and quality

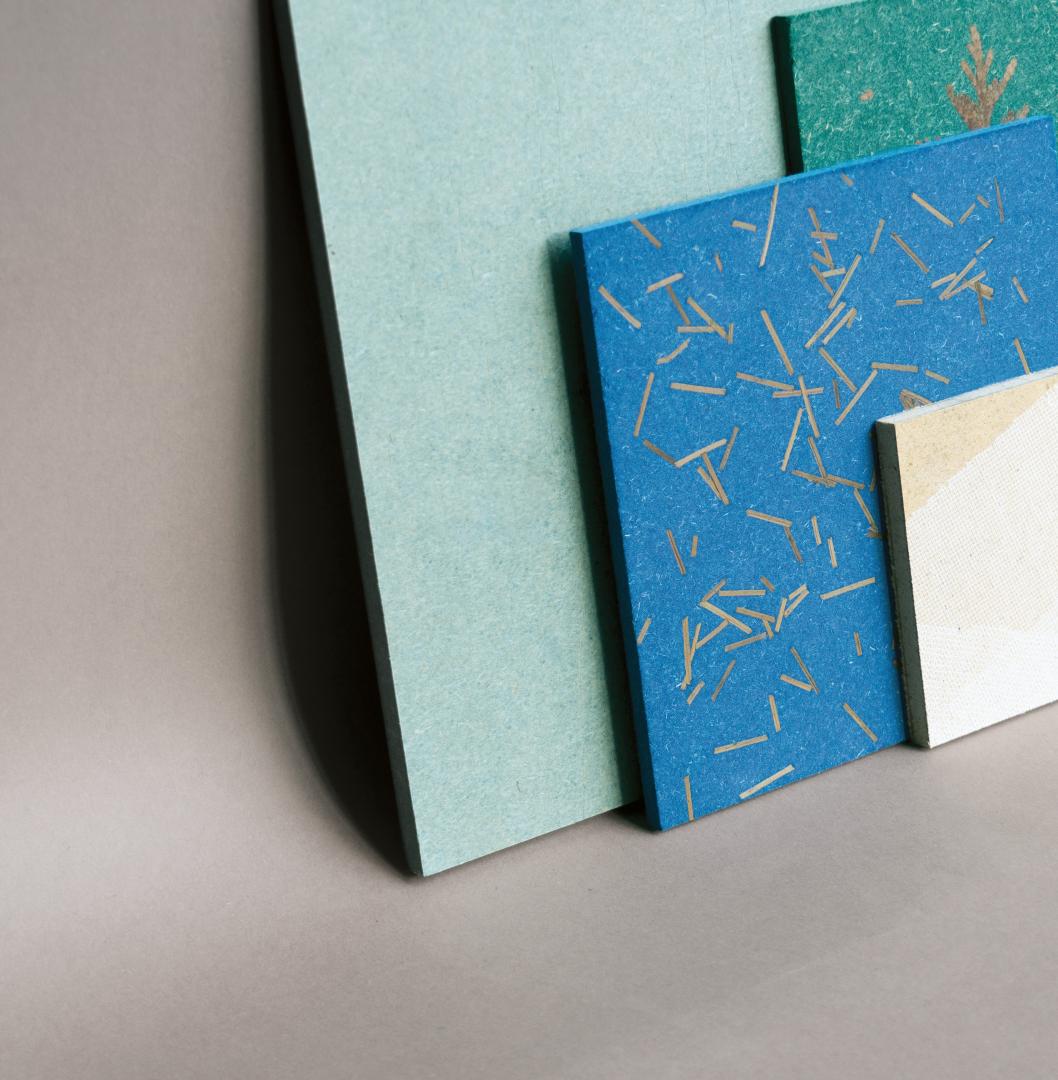

In the design process, we first analyzed and classified the production waste to create a unique material from waste raw materials. We examined waste and also kept the collection of all off cuts from our own production with the aim of transferring them into the design. Leftovers and off cuts were used for new design ideas and showed that these shapes have their own unique aesthetics. With rich colors and individual textures, we also wanted to change the expectations of eco-friendly materials.

Superwood visually conveys the idea of recycling, raises Mdf material out of anonymity, and contributes to awareness through design.

To make the development process understandable to citizens, the development of the project was communicated through various media from the beginning and the background of the underlying work was explained. Complex topics were translated into understandable, tangible scenarios.

Communication formats such as videos on the development process, graphics on the background of the recycling system and the design of a label aroused interest in the topic of circular economy and offered various points of contact.

Through an aesthetically coherent design and a transparent storytelling process, we created an example of holistic and interdisciplinary design. In addition, we raised the environmental awareness of citizens and conveyed values that go beyond functionality.

Key objectives for inclusion

The production of Superwood is based on existing industrial technologies and local infrastructure, which simplifies production. It is easy to process, as the glued fibers can be stored for 4 weeks before pressing. This allows an easy production on demand. Since we use waste materials, the cost of the components used is lower than for standard materials. Therefore, our material is affordable and accessible.

By including a label in the material, we classify waste materials and provide the user with easy-to-understand background information on ingredients, contributing to public environmental education.

Through lectures and an exhibition on the project, we have been able to enter into dialogue with the public and help raise awareness of material developments and interdisciplinary work through design and science.

Using understandable communication, lectures and exhibitions, we raise consumer awareness of sustainable consumption choices, the importance of interdisciplinary work, while offering a low-cost, locally produced alternative.

Results in relation to category

We have succeeded in modifying the glue so that it can be processed in the existing machines used in industrial Mdf production. This means that the material can be produced in large quantities and is no more expensive than conventional Mdf boards. Our material also exceeds the Din standard in terms of stability and strength, so it is in no way inferior to existing fiberboards. It is a sustainable circular material and a replacement for existing unsustainable products. Therefore, it contributes to the creation of a circular industrial ecosystem.

Through our transparent communication and the label we developed, we have created a sustainable product and educated people about the origin and components of the materials that surround us. We have thus contributed to supporting life-cycle thinking.

In summary, as many people as possible can benefit from the development and consciously choose a high-quality, sustainable solution without sacrificing quality standards.

How Citizens benefit

By giving lectures at universities, the project was able to inspire young designers to understand their responsibility as an essential part of the production chain. Furthermore, the importance of cooperations with scientific institutions such as the Fraunhofer Institute could be communicated. Through Design X Science meetings, we were able to show that the integration of different approaches has great potential to combine different solution approaches and develop an aesthetically sustainable solution.

Through exhibitions such as the Direktorenhaus and the Futurium Museum Berlin, the use of the material enabled a dialogue with visitors about the decoupling of finite, petroleum-based raw materials, which will become more expensive in the future. Scientific work thus became more transparent and was perceived even more as an effective tool for future challenges.

Finally, by conducting concrete research, we were able to bring a sustainable issue to the public's attention and thus encourage social change in the sense of circular rethinking and taking action.

Physical or other transformations

Innovative character

For the production of wood-based materials, formaldehyde-containing resins of petrochemical origin are used as standard. These include melamine resins (MUF), phenolic resins (PF or PRF) or urea formaldehyde resins (UF). Isocyanates can also be used (pMDI). Formaldehyde is produced on a large scale from methanol and is suspected of being carcinogenic. Therefore, the World Health Organization (WHO) and the EU have classified the substance as carcinogenic (Regulation 605/2014). The limit values have been drastically lowered as a result (0.1 ppm). Wood-based material manufacturers are therefore forced to use alternatives in order to comply with the limit values.

Currently, there is no adhesive made from residual materials, nor is there a biodegradable cost-effective adhesive that can be processed in industrial plants in large scale.

Learning transferred to other parties

The project is particularly focused on communication between design and science and aims to further develop concrete applications together. Through formats such as Design x Science, the successful collaboration between research and design can be further developed, documented and evaluated so that it can be used for further cross-disciplinary cooperation.

The design of application-oriented, functional-aesthetic solutions offers the chance to make scientific work tangible and enter in a dialog with other interested parties.

Ultimately, the project offers the chance to make a sustainable topic public by means of concrete research work and thus to initiate social transformations in terms of circular rethinking and action. In this way, the project can be used as an example to demonstrate the responsible use of renewable raw materials for an aesthetic solution.