Common Sands

Basic information

Project Title

Category

Project Description

Common Sands is a collection of recycled glass products made from the glass components found in discarded electronic appliances. Common Sands was developed by Studio Plastique in collaboration with experts, scientists and craftsmen alike as the result of more than 3 years of research and experimentation. The project addresses both silicate scarcity and growing volumes of electronic waste, with the aim of creating new value for an abundant yet unexploited group of materials.

Geographical Scope

Project Region

Urban or rural issues

Physical or other transformations

EU Programme or fund

Which funds

Description of the project

Summary

Developing new applications for currently non-recycled E-Waste glass, Common Sands positively leverages the unique properties of composition, colour, and structure inherent in the waste material into a series of products, ranging from homeware to glass tiles. Through these applications, Common Sands embraces the variance and complexity already embedded in the glass components. A focus has been set on waste glass from household appliances to demonstrate the aesthetic depth, function and potential of the material, without limiting the project to this stream alone.

The Common Sands — Homeware collection was developed by elevating the varying features inherent to the glass components, such as metal oxide coatings on the glass, coloured glass and varying glass compositions, to become defining for the added value of this material stream. The collection consists of vases, wall hooks and candleholders; all produced following a rigorously designed process efficiently using the energy, tools and craftsmanship to produce a collection of affordable hand-made objects.

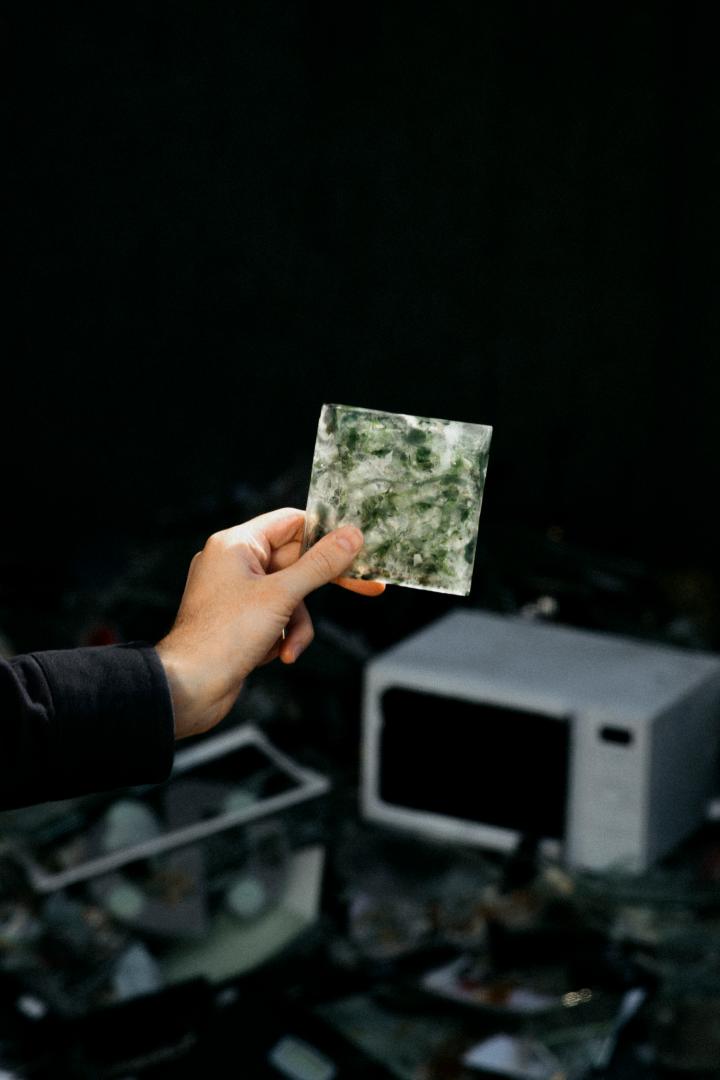

The Common Sands — Forite glass tiles are developed in the aim of creating sustainable, smart and refined architectural products. Additionally, the partial translucency of the glass tiles makes them applicable to semi-transparent exterior walls and divisions for interior spaces. Finally, tiles are the ideal production system in which this material finds a new use. The technical requirements for the production of glass tiles are compatible with existing protocols for ceramic tile production, seamlessly facilitating both production and implementation.

This project is a strong example of what can be achieved in terms of real, game changing, circular and sustainable design. Working across disciplines and specialisations, the collaboration between Studio Plastique, Renewi, Rombachs Glass, Snøhetta and Fornace Brioni meets contemporary challenges with ambitious, pragmatic and scalable solutions.

Key objectives for sustainability

Currently, an estimated amount of 3 300 000 million MT of e-waste glass are not being re-used world-wide. This is equivalent to a missed economic turnover of 99 000 000 €. This stands in contrast to the exploitation of natural resources such as sand, which stand under increasing stress such as disappearing beaches and river deltas.

E-waste glass is currently not recycled, despite the very good recycling qualities of glass. Standard industrial glass production, no matter what application context, generates perfectly homogenous glass that is either transparent or coloured. Using E-waste glass heavily interferes with those standards of production, rendering this glass stream unusable by the industry of scale.

By identifying applications and production processes in which the specific properties of the glass create new opportunities rather than undesired interference, the project proposes a range of innovative products and production processes. The products facilitate the recycling of these materials by setting up agreements and collection systems with the e-waste recycling sector. The production is circular through the use efficient processes, resulting in a comparative 30% energy reduction, enhanced by avoiding exploitation of natural materials. The products are recyclable in their turn.

Common Sands was initiated from the observation that a perfectly recyclable resource is currently dumped in landfill. Through collaborative efforts with stakeholders such as recyclers, craftspeople, scientists, tile production industry, architecture, design and retail, it was attempted to identify applications for which those materials are especially suited and design those applications to be circular and sustainable.

Currently no context exists for the judicious use of e-waste glass and we believe that the rigorous application of sustainable values and the design of closed cycles, make the project exemplary in terms of responsibility and innovation through design.

Key objectives for aesthetics and quality

Using second cycle materials shouldn't mean secondary quality or experience.

The homeware collection was designed to fulfil a functional purpose whilst being attractive aesthetically. The vase is shaped to be timeless but uses unexpected textures of the glass to its advantage, such as for example fine air bubble inclusions, colour swirls and varying colours. This generates some unseen effects for serial objects of this typology. The wall hooks are unexpected in materiality for their function but recognisable in their shape. By challenging the assumed fragility of glass and applying it as a weight-bearing item, it is intended to draw attention to the unique tensile strength of glass when shaped in this way. The candleholders use the parallel between the liquid state of the glass and the liquid state of the candle wax as an aesthetic reference. All those products have in common that they rely on the hand-made qualities that come with glass production of this scale, making each of the items clearly belonging and recognisable yet unique in appearance. Visible laser engravings label the items and material for their origin, date and place of transformation in an attempt to include the consumer in the journey of the materials and objects.

The tiles use the e-waste glass components to create a seaweed-like pattern that is very distinctly innovative in the world of tiles. The partial translucency of the tiles add to the novel aesthetic and functional potential of the tiles. Furthermore, the visual depth created to the partial translucency give surfaces tiled with the tiles a unique visual depth through play with light and reflections.

Letting the material become a part of the storytelling, both in the shapes as in the materiality, is an important feature of the project. It generates an attraction and understanding of origin and ultimately a relationship with the items we surround ourselves with. Qualitative design will generate qualitative aesthetic experience.

Key objectives for inclusion

The project is set up as a close collaboration and contribution of stakeholders; including the recycling industry, scientists, production industry, craftspeople, architecture, design and retail. The input of each of those contexts has contributed to the project becoming a realisation of more than one party, including their interests.

With the recycling industry currently paying up to €100/MT for e-waste glass, their interest in the project is mainly economic. In return, setting-up collection schemes and agreements with Renewi and Stena has guaranteed a material flow for the project to exist.

The collaboration of Studio Plastique with scientists and craftspeople has been essential to creating strong case-studies on feasibility for working with these material streams. This has resulted in the design of the collection of homeware items, in close collaboration with the retail industry. In this case The Home of Sustainable Things from London has played an important role in collecting feedback from consumers, leading to the necessary adjustments in terms of pricing, aesthetic quality and functionality.

The collaboration of Studio Plastique with architecture and tile manufacturing industry has led to production on a larger scale and thus of greater impact. Working closely with the producer Fornace Brioni has led to the design of efficient and qualitative production processes whereas the collaboration with the architects at Snøhetta helped define the technical requirements for tiles suitable to their purpose. In the end of the day, these collaborations also often result in the implementation of the products by those parties.

All products have been kept affordable to ensure a reach as large as possible as it is the ambition to use the project to communicate values and engage with further interested parties. The retail price of the homeware is kept around 65€ per item. The tiles are sold at around €150/sqm.

Results in relation to category

Considering that this material is currently not recycled, the project achieves a lot in terms of circularity and sustainability.

Common Sands generates value by creating an economic value cycle for a currently discarded material and ecological value by avoiding exploitation of natural resources from fragile ecosystems and saving energy resources. In doing so the project creates many novelties, in design as well as in processes. Common Sands — Forite glass tiles are unique aesthetically and the first product of its kind made from e-waste glass whilst remaining completely recyclable at the end-of-life. Common Sands — Homeware are unique aesthetically in terms of shape and materiality by using e-waste glass whilst remaining completely recyclable at the end-of-life.

Including the recycling industry in the project has generated new agreements in regards to sorting and collecting methodologies set-up for the project. This sets a basis for future developments, those being initiated by us or the recycling companies.

Furthermore, the project is uniquely positioned by proposing competitive products on the market; where often circular projects remain exclusive due to the expensive processes or smaller scale. The homeware products are retailed around €65/piece and the tiles around €150/sqm. This has been important for all stakeholders to maximise the impact on the environment, the socio-economical context and the exemplary value of the project.

How Citizens benefit

The main public has been made aware of the project through two main channels:

- communication through exhibitions, public lectures and conferences as well as social media and press.

- retail experience through sales of the items in shops. Initially these retailers also had the function of collecting customer feedback on the products. This has led to shape and minor finishing adaptations of the products.

Furthermore it is important to stress the fact that the laser engraved labels on the products are aimed at establishing renewed interest and involvement of the consumer in the relationships with resource, production and design.

Physical or other transformations

Innovative character

When glass is used in homeware applications or for tiling purposes, standard industrially produced glass is used. This glass is formed based on virgin raw materials and includes a certain percentage of recycled float glass (flat sheets of transparent glass from windows f.e.).

The cost on the planet for this type of production in terms of energy and resourcing is tremendous. Not to forget that this scale requires a continuous flow of production.

The results are serial products of identical appearance without any soul or character. One can justify such requirements for car windshields or windows but it is in no way a requirement for a whole lot of other applications; such as homeware f.e. Many products with such features contribute to the loss of interest of user in their products because they can be cheaply exchanged for an exact copy or the newest model. As a result, the relationship between consumer, resource and product is broken.

The Common Sands project proposes instead to acknowledge the areas of life where materials with unique characteristics can be applied in a meaningful way. Products with standard appearance are mainstream and commonplace but were never a market requirement. Rather, these features are the byproduct of the economy of scale which can only propose us products that are identical. The project designs the whole process, from the material collection, to its use/transformation process, product design themselves and the end of life - use design to create an informed relationship between resource, producer and user. Letting the material become a part of the storytelling, both in the shapes as in the materiality, is an important feature of the project. It generates an attraction and understanding of origin and ultimately a relationship with the items we surround ourselves with. Qualitative design will generate qualitative aesthetic experience.

Learning transferred to other parties

Attached schematic representation illustrates the identified contexts and their influence on the project. The learnings from this journey are unique because of the wide range of feedback generated by the many actors that were included around the table. It easily can form the basis for new contexts but we designed the project with the main intention of creating a new paradigm in terms of transdisciplinary collaboration, sustainable production, circular design and aesthetic perception.

The methodology used is based on understanding the forces at play. Currently, an estimated amount of 3 300 000 million MT of e-waste glass are not being re-used world-wide. This is equivalent to a missed economic turnover of 99 000 000 €. The potential of a context is defined by the current costs in relation to potential that can be established. In order to incentivise collaboration on such topics, it is essential to understand this economic potential. The gains that industry can make based on this project can be transferred to other contexts and collaborative networks.

This step is followed by the design of potential. In this step design skills are essential to bridge between technical requirements, aesthetic values and production possibilities and innovations. Here again, where required support from experts is called upon.

And finally this whole process is transferred to product prototypes, which are used to study the market and collect feedback from the stakeholders.

In turn, these prototypes and feedback can be used to set-up collaboration agreements with industry, in our case with the recycling industry and production industry. First prototypes often generate further interest of third parties for bespoke applications of the developed work.