Troldtekt® based on FUTURECEM™

Basic information

Project Title

Full project title

Category

Project Description

The construction industry cannot make do with minimising itself out of the climate crisis. Materials are needed that absorb more CO2 than they emit, and which create value in new cycles on reaching the end of their useful lives. A good example is Troldtekt acoustic panels based on the new, patented cement type FUTURECEM.

Troldtekt panels based on FUTURECEM absorb more CO2 than they emit during production. In other words, they have a negative carbon footprint during the production phase. Whic

Geographical Scope

Project Region

Urban or rural issues

Physical or other transformations

EU Programme or fund

Which funds

Description of the project

Summary

For more than 85 years, Troldtekt has produced acoustic panels that benefit a healthy indoor climate in all types of architecture. In 2022, Troldtekt has launched acoustic panels based on the cement type FUTURECEM. What is special about these new panels is that their carbon footprint during production is negative. Combined with a lifespan of 50-70 years and their recycling potential, the panels are a milestone in the green transformation of the construction industry.

FUTURECEM is a new and patented cement type from Danish cement manufacturer Aalborg Portland. FUTURECEM exploits the synergy between calcined clay and lime filler, which enables much of the fired clinker in cement production to be replaced. The result is cement with a 30 per cent lower carbon footprint.

The wood, which is the other raw material in Troldtekt acoustic panels, absorbs more CO2 while the trees are growing in Danish forests than is emitted during the production of FUTURECEM. And as the production of the panels at Troldtekt’s factory in Denmark uses 97,7 per cent renewable energy, the total carbon footprint is negative when factoring in the raw materials, their transport and manufacture.

It is the cement that gives Troldtekt acoustic panels their strength, durability and fire-protective properties without the use of harmful chemicals. At present, these properties are difficult to achieve using binders other than cement. However, with FUTURECEM it is possible reduce the impact on the climate.

In addition to reducing CO2 emissions during production, Troldtekt uses various recycling methods so that as little embedded CO2 as possible is released through incineration when the acoustic panels come to the end of their life after min. 50-70 years. For example, Troldtekt cement-bonded wood wool can be used to produce new cement.

Troldtekt panels based on FUTURECEM are certified at Gold level in the sustainable design concept Cradle to Cradle.

Key objectives for sustainability

Troldtekt’s acoustic panels for ceilings and walls are made of Norway spruce from certified forests in Denmark (FSC®C115450 and PEFC™) and cement from Danish mineral resources. The panels are sold in Denmark and on a wide range of export markets, and they help ensure a healthy indoor climate in all types of buildings.

Troldtekt panels harness the outstanding properties of the raw materials – the strength of cement and the natural breathability of wood. The combination ensures good acoustic properties, and the panels are fire-protective, moisture-tolerant and have a lifespan of min. 50-70 years. Troldtekt’s Cradle to Cradle certification documents that the panels do not contain harmful substances.

The production of cement at Aalborg Portland accounts for virtually all Troldtekt’s carbon footprint. And reducing this carbon footprint is a key focus area for Troldtekt. Therefore, it is a milestone that Troldtekt has launched acoustic panels in which the traditional cement has been replaced by the new cement type FUTURECEM. As a result, the carbon footprint from the cement is significantly lower.

The wood in the panels absorbs more CO2 when the trees are growing in the forests than is emitted during the production of FUTURECEM at Aalborg Portland. And as production at Troldtekt’s factory is almost carbon-neutral (97.7 per cent renewable energy in 2020), the carbon footprint is negative when measuring phases A1-A3 in the building material environmental product declaration (EPD).

Troldtekt is looking at different recycling methods to ensure that as little of the embedded CO2 as possible is released during incineration when the acoustic panels finally reach the end of their lives. Offcuts from Troldtekt’s factory are already being used in the production of new cement at Aalborg Portland. A pilot project will establish how this scheme can be scaled up to also include cement-bonded wood wool waste from the demolition of buildings.

Key objectives for aesthetics and quality

Troldtekt acoustic panels are primarily chosen because they make a big difference to a building’s acoustics. A ceiling or wall surface with Troldtekt absorbs 80-90 per cent of the sound that hits the surface, while a concrete surface, for example, absorbs only 1-2 per cent.

It is crucial that our solutions – in addition to their acoustic properties – make a significant difference in two other areas which are important for architects and professional developers: documented sustainability and design. With Troldtekt based on FUTURECEM, we deliver on both.

For more than a decade, it has been important for us to implement sustainable initiatives in our production in parallel with innovative product development. In other words, we want to offer a broad and documented sustainable product range that gives architects the freedom to use Troldtekt to design healthy buildings.

In the field of design, the crowning achievement is our Cradle to Cradle-certified design series, which was launched in 2019, and which has since won, for example, a German Design Award and an ICONIC Award. The design series can now be combined with the crowning achievement within sustainability, as it is now also available based on FUTURECEM.

In other words, it is not just the classic cement-bonded wood wool panels that are being offered in CO2-negative versions, but also our series of design solutions. Thanks to the special patterns, shapes and other processing techniques, the design solutions provide great flexibility in creating spaces with a special atmosphere – rooms in which the ceilings or walls contribute to superior acoustics while also serving as a distinctive design element.

Key objectives for inclusion

Troldtekt acoustic panels based on FUTURECEM are a result of close dialogue with market representatives and other parties, including architects, developers and building users as well as NGOs and forums that focus on creating healthy buildings in a circular economy. We examine this more closely in the section Please explain how citizens and civil society were involved in the design and/or implementation of the project.

At Troldtekt, our philosophy is that healthy and sustainable architecture should be accessible to as wide a group of users as possible. This also applies to the new Troldtekt panels based on FUTURECEM, which we have introduced at the same price level as panels made with traditional cement.

We are thus offering a product with low life cycle costs compared to many other acoustic solutions. Therefore, Troldtekt is often used in social housing, schools, care centres and institutions where budgets are often tight – but where a healthy indoor environment can be particularly important.

The average citizen living in Northern Europe spends up to 90 per cent of their time indoors. Therefore, it is essential that efforts to design sustainable buildings do not happen at the expense of a healthy indoor climate. In pursuit of energy optimisation, buildings must still be healthy, accommodating and comfortable for people to live in and use. Here, Troldtekt’s new acoustic panels fit the bill.

In addition to its negative carbon footprint, Troldtekt based on FUTURECEM fulfils objectives that are beneficial for users. The panels absorb sound efficiently, so that even in large rooms with hard surfaces it is easy to understand what is being said. This is imperative, not least for the significant proportion of the population suffering from impaired hearing.

Moreover, a thorough analysis of the panels documents that they do not contain any chemical substances that are harmful for people or the environment – – including allergenic substances.

Results in relation to category

Troldtekt’s focus on circular economy and life cycle thinking underpins the company’s Cradle to Cradle strategy. The launch of Troldtekt based on FUTURECEM is the biggest milestone yet.We want to be fully transparent about the environmental impact of our products. Therefore, we have prepared separate environmental product declarations (EPDs) for all our acoustic panels, including eight new EPDs that show the impact of our FUTURECEM-based acoustic panels. This makes the impact of the product transparent.

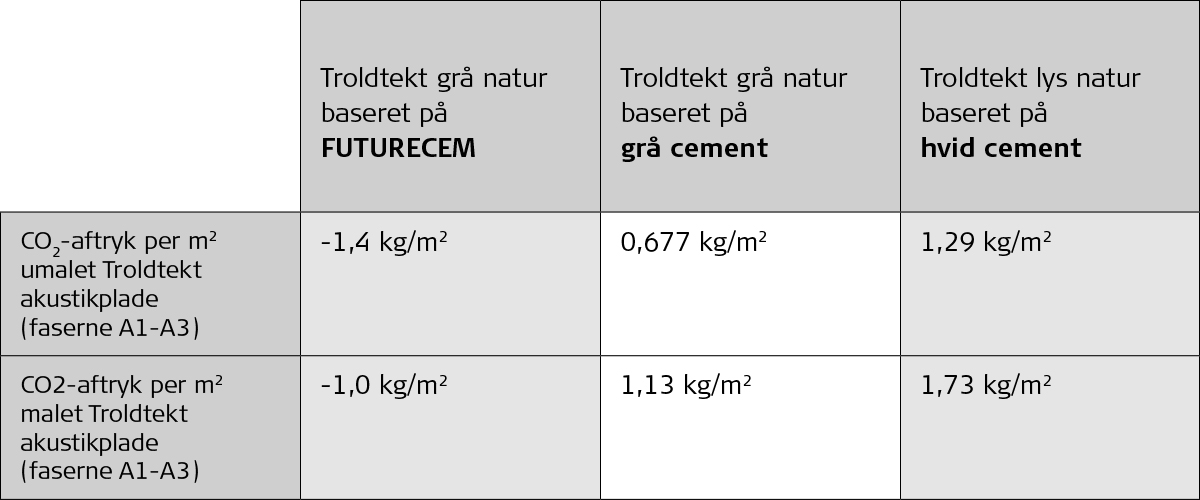

Phases A1-A3, which are mandatory in an EPD, show the environmental footprint of the raw materials, the transport of raw materials to the factory and the manufacture of acoustic panels at the factory. Key figures for phases A1-A3 include:

- Unpainted Troldtekt acoustic panels based on traditional grey cement have a carbon footprint of 0.68 kg per m2

- Unpainted Troldtekt acoustic panels based on traditional white cement have a carbon footprint of 1.29 kg per m2

- Unpainted Troldtekt acoustic panels based on FUTURECEM have a carbon footprint of -1.4 kg per m2

In light of the millions of square metres of Troldtekt acoustic panels produced each year, the new cement type can make a significant difference to our carbon impact. It is only phases A1-A3 that we are fully in control of at the moment. However, we are focusing strategically on what will happen to the panels when, in 50-70 years’ time, they will have served their function in the building. Not least in phase C4 of the EPDs (disposal).

We are working on take-back schemes to ensure that panels are recycled, thereby preventing them from being incinerated and thus releasing the stored CO2 again. We are focusing on the technical cycle, in which the panels, once they have reached the end of their useful life, are used as a resource in new products. Among other things, we are launching a pilot project to collect cement-bonded wood wool waste from recycling centres to be used in the production of new cement.

How Citizens benefit

In close dialogue with the market and society, we are going out of our way to offer solutions which are in demand in the transition towards sustainable building.

In the early 2010s, a demand for documented sustainability, especially from public developers and construction industry consultants, contributed to accelerating our decision to go all-in on Cradle to Cradle. Recently, we have been able to launch a CO2-negative product which boasts all the outstanding properties of panels made with conventional cement.

Troldtekt based on FUTURECEM is the result of a dilemma that we have encountered in our discussions with the market and civil society: On the one hand, cement-based building materials are needed to create robust structures that last long and provide a high degree of fire safety – without the use of harmful chemicals. On the other hand, there is considerable focus on reducing the carbon footprint from the construction industry, where cement is one of the main contributors.

We get input for our product development from our close dialogue with architects and developers who represent the users of the buildings. Our consultants visit architects daily, and we hold events for architects in our showrooms to get their feedback on our solutions and prototypes.

We also hold sustainability courses for people in the construction industry in Denmark. Moreover, we are involved in NGOs and networks that contribute to putting pressure on decision-makers to roll out the Cradle to Cradle approach. In Germany, we support Cradle to Cradle NGO, which works to promote the circular economy throughout society. In Sweden we are a member of Cradlenet, which works for the same purpose.

In addition, we participate in forums aimed at creating healthier buildings based on the needs of citizens and society. For example, Troldtekt participates in a working group engaged in creating a common European materials passport, which will document the health of all building materials.

Physical or other transformations

Innovative character

Troldtekt based on FUTURECEM marks the culmination to date of our strategic efforts to make a positive difference throughout the life cycle of Troldtekt acoustic panels.

For more than a decade, Troldtekt has been a pioneer within the green transition based on the Cradle to Cradle principles. Cradle to Cradle certification was first launched in 2010, and Troldtekt was one of the first Danish companies to be certified – and to let the principles guide its business strategy.

Similarly, we are now one of the first material manufacturers to work with the CO2-reduced FUTURECEM cement in our products. We are not talking about a small corner of our product range – no, the plan is for our entire range to be based on FUTURECEM. From day one, a large proportion of our products will be available based on FUTURECEM, including Troldtekt’s design series, taking the new panels to an even larger target market.

As pioneers, we have not been able to lean on similar industrial SMEs in the process. We have had to invent solutions, solve challenges and motivate suppliers on our own to help us support the green transition – and to some extent still have to do so. It also means that we have been prepared to invest in testing, technology and documentation without any guarantee that the investments will pay off in the short term. For example, early on we produced a large batch of Troldtekt acoustic panels based on FUTURECEM as a pilot project.

Our innovativeness does not stop with the launch of Troldtekt based on FUTURECEM. We also want to set new standards for the documentation that helps developers and consultants choose the new panels. This is why we have already published eight separate EPDs for different variants of acoustic panels based on FUTURECEM. We are being completely transparent and honest about the environmental footprint of the panels throughout their life cycle.

Learning transferred to other parties

Full transparency regarding our processes and environmental footprint has been key for Troldtekt ever since we launched our Cradle to Cradle strategy more than 10 years ago. And the same applies to Troldtekt acoustic panels based on FUTURECEM.

The individual EPDs make it very clear how it is possible to design and produce a cement-based product which has a negative carbon footprint during production. By documenting more product phases than what is mandatory in an EPD, we are also transparent about the challenges that may arise once the product has served its useful life in a building – and about the fact that recycling in new cycles is a prerequisite for ensuring a negative or neutral carbon footprint throughout the entire product life cycle.

In addition to contributing to a greener planet, we also have a commercial interest in not keeping our cards close to our chest – but in being open and transparent about our experience with using new technology to create carbon-negative building materials. The more players in the construction industry who work purposefully and voluntarily with sustainability, the less likely we are to see restrictive legislation in this area.

We hope and believe that Troldtekt based on FUTURECEM can inspire other manufacturers of, in particular, cement-based building materials. It is possible to significantly improve a product’s carbon footprint – even when producing on such a large scale as Troldtekt, which runs 24/7 all year.