Sounds Wood

Basic information

Project Title

Full project title

Category

Project Description

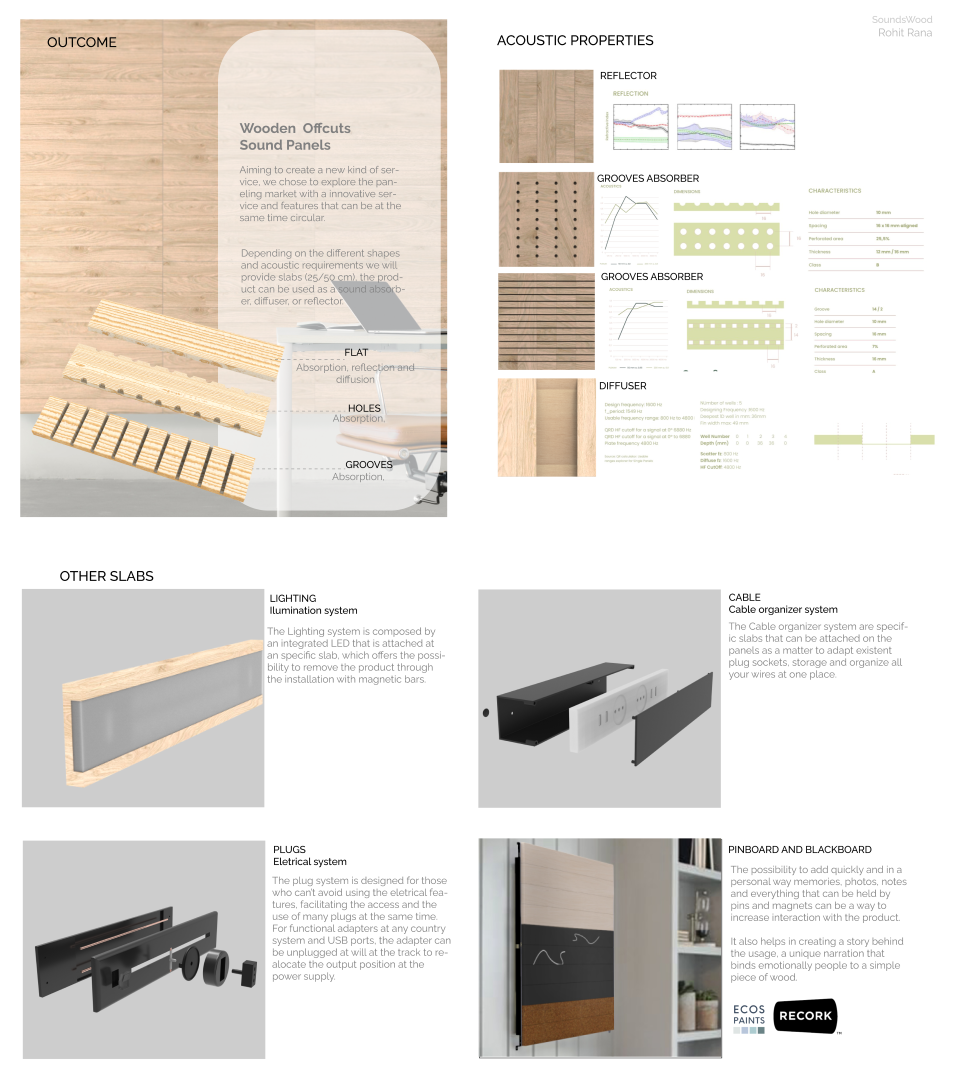

Existing sound panels are usually made of MDF, treated wood, plastic foams, which can be dangerous and polluting once the product comes to the end of life. Moreover, when a panel is damaged, it should be discarded, creating much more waste. By exploiting properties of natural wood offcuts otherwise sent for burning, we target the problems of treated wood dismission and lessen the wood importation, creating a circular furniture system that can rework and reshape pieces during Product life cycle.

Geographical Scope

Project Region

Urban or rural issues

Physical or other transformations

EU Programme or fund

Which funds

Description of the project

Summary

Existing sound panels on the market are usually made of MDF, treated wood, and plastic foams, which can be dangerous and polluting once the product comes to the end of life. Moreover, when a panel is damaged, it should be discarded, creating much more waste. By exploiting more natural wood offcuts otherwise sent for burning, we target the problems of treated wood dismission and lessen the wood importation, creating a circular furniture system that can rework and reshape pieces at the end of their life.

The project Sounds Wood aims at helping people in organizing small and temporary spaces by creating a cozy and focusing environment. It is designed to meet the requirements in home, office, and retail contexts. This system allows a wide range of compositions, giving the possibility to fit the required ambient needs by choosing dispositions and functions of the panels.

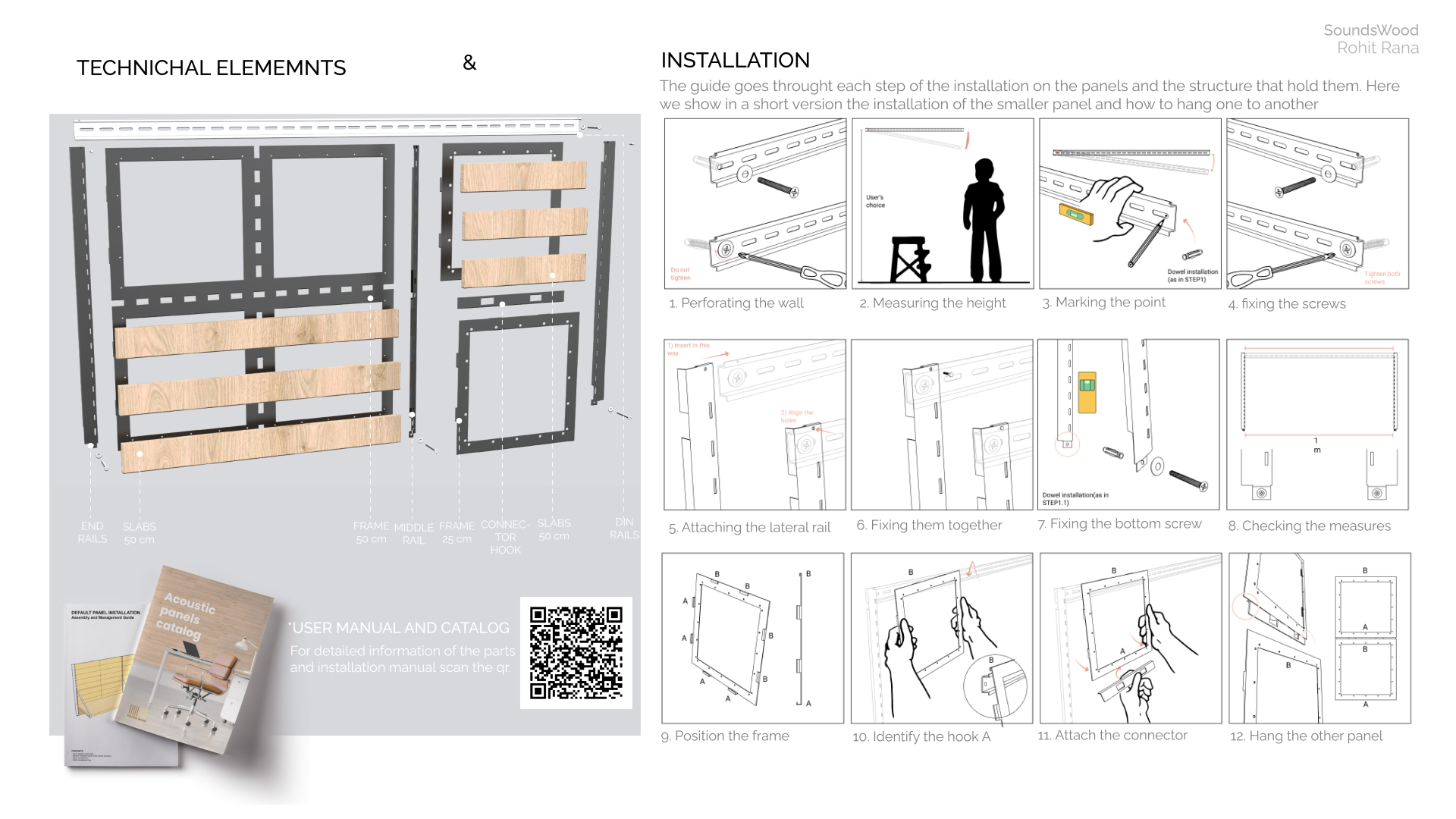

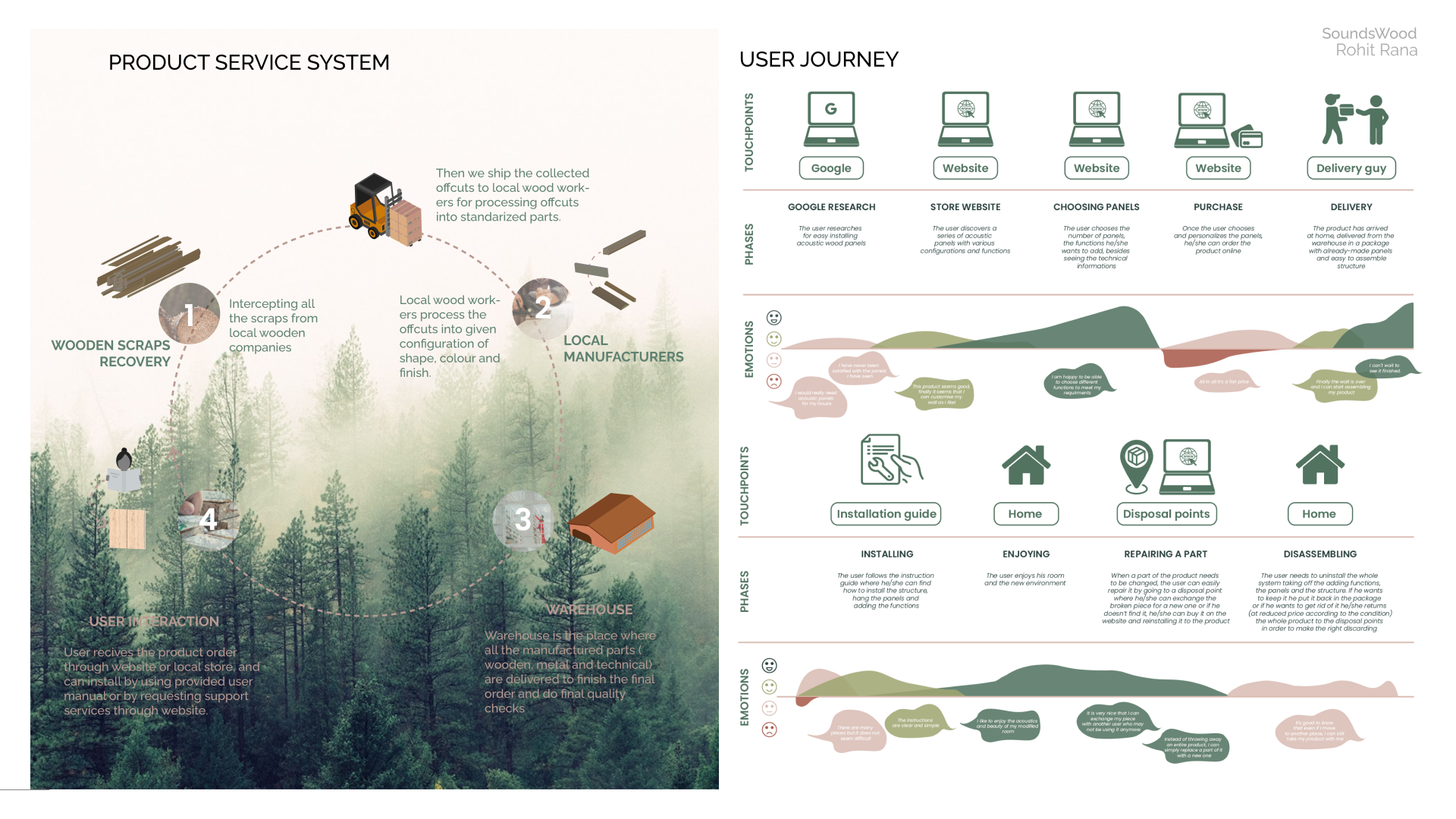

Sounds Wood system is based on the personal needs of the user. The journey starts when the customer decides to install the panels and makes choices about possible dimensions and functions to be applied to the wall. Through our website, the user can freely create a custom configuration. Once the order is sent, the panels are set up and packed to be sent directly and installed quickly. Everything is explained on the guide the customer receives; furthermore, additional information is available online. The online support of the Sounds Wood community also enriches the experience, providing insights and good suggestions that can be different or also hack the system we created.

There are many innovative features this kind of product-service system can bring to the market: it is easy to install, adapt, and repair and made of 100% natural material wood offcuts. This prevents the creation of additional waste and also exploits materials that the furniture sector has to import. The aesthetic qualities contribute to one’s tranquillity, making the living and working soundscape and stimulating place to enjoy.

Key objectives for sustainability

One of the points that circular economy stresses the most are the hidden values that materials and components have in moments usually considered the end of a product’s life. Indeed, one of the essential tasks of circular design is finding structured and creative solutions to effectively extend materials and components’ life by shifting them from one object to another. This is the reason we intercepted at the point of waste generation or end of Product life of the Lumbermill. When the main slabs are generated from the wooden bark.

From a circular economy perspective, when it comes to the massive use of parts or components of end of life objects (e.g. parts of thousands of disused bikes for bike sharing), it is necessary to think of systemic solutions that ensure a circular production of (circular) objects on a scale. Normally all the wooden scrap generated is directed into different fields from grinding it to small pieces for producing panels or animal bedding, sending it for firewood or energy generation applications.

By managing the scarp and sorting it out we can create an efficient system that can reintroduce the natural wood in the supply chain otherwise it ends up in landfills or incinerated.This can also decrease the wooden importation of Italy ( in this scenario) up to 80% of raw wood is imported. If we can add the parts for the required field we can not only decrease the supply of raw material. we can also save the deforestation percentage and CO2 index generated in the shipping.

All the production methods used in our system generate a lower volume of waste and the finishes are eco-friendly. So at the end of the life cycle, these can be reintroduced in other fields or disposed of without generating toxic environmental pollutants.

Key objectives for aesthetics and quality

The main experience starts as soon as the customer enters our website. We help customers to be aware of the acoustic problem by following the three steps having different options, each voice has a specific description and explanation, in this way we can help solve his problem in the most effective and precise way.The requested product configuration is generated on demand and is tested first at the manufacturer and then at the warehouse before shipping it to the customer.

Our color selection has been thought to improve your tranquillity and mental status. For creating a perfect environment we have been inspired by natural elements and gradients. of Greenery, water, sand, and rock. All these elements provide users also with visual wellbeing and comfort. We work with Milk paint. For other functional slabs, the finishing is made thanks to Ecos Paints and Recork partners. All our finished are nontoxic and circular that don't generate any toxic gasses while applying or disposing of the product at the end of the life cycle.

Customers can try on tailored options for your wall! The online customization tool can help customers in better envisioning the Sounds Wood system for the specific usage required. And by placing the configurable AR-tag user can envision his room setting through his mobile or AR headset.The user has a wide range of choices in colors, patterns, and functions. Everything is designed to be as natural as possible and, of course, part of a virtuous circle.

Key objectives for inclusion

Inclusion is a primary factor of our product service system. That works on three different levels Material, Manufacturing, and Experience

Material- Using wooden offcuts allows us to produce affordable yet high-quality functioning and Modular product by using natural pine softwood.

Manufacturing: Our production system is completely decentralized Instead of spending cost and time on setting up the whole production environment. We rely on a bidding system that includes local woodworkers and material suppliers providing everyone an equal opportunity to bid and work at the same prices. This also provides an additional income source for the local woodworker and installation people where we contact the locals for support services.We also use our partner courier service with a minimal carbon footprint.

Experience: Our product comes with a detailed user manual So customers can have a more inclusive experience of building his product that is fair and circular that they can be proud of. The configuration can be modified and personalized according to user needs and aesthetic preferences. But he also requests local help that we can arrange.

We also focus on creating an open-source community of Like-minded people where they can share their design and ideas with other people or our Support team to add some features. The community aims to improve the creativity of our customers and make them feel like protagonists. This not only provides the user a sense of belonging to a Sustainable family but also allows him to connect more people into a transparent system. Customers can also visit disposal/exchange points or share the pieces once he doesn't need them.

Physical or other transformations

Innovative character

Our Product Service System follows a decentralized approach that instead of using the few resources and setup time and cost. It utilizes the already existing things in

1. Material from unwanted wooden offcuts discarded by the timber mill.

2. Manufacturing using the local craftsman and woodworker to provide a contract-based system.

3. Storing only a few pieces instead of creating an inventory that is discarded because not purchased

4. Making users aware of acoustic and visual wellness and the benefit it can provide in different scenarios.

4. Not stocking based on season or trends but creating on-demand and more personalized Solutions.

5. Sharing a sense of co-creation by participating the user in creation and personalization to create a feeling of creating a product for his wellness.

6. Also promoting sustainable behavior by creating a community.

The system utilizes some of the main concepts to create Transaprent Circular, Sharing, and better aesthetics.