Human Material Loop

Basic information

Project Title

Full project title

Category

Project Description

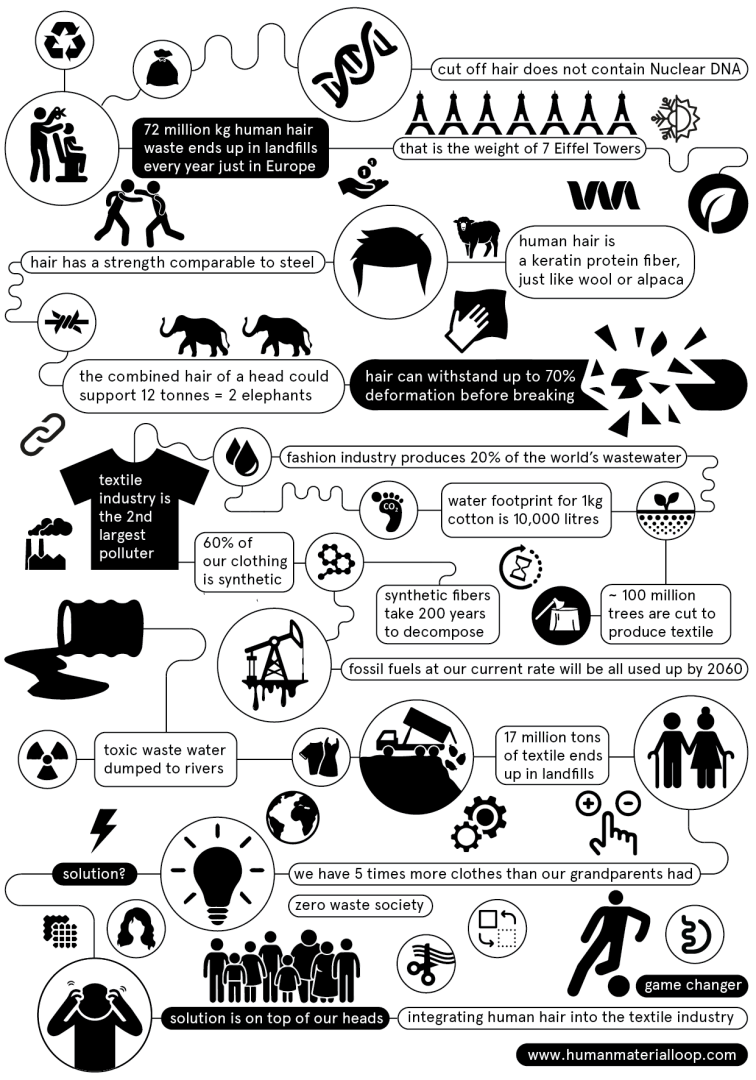

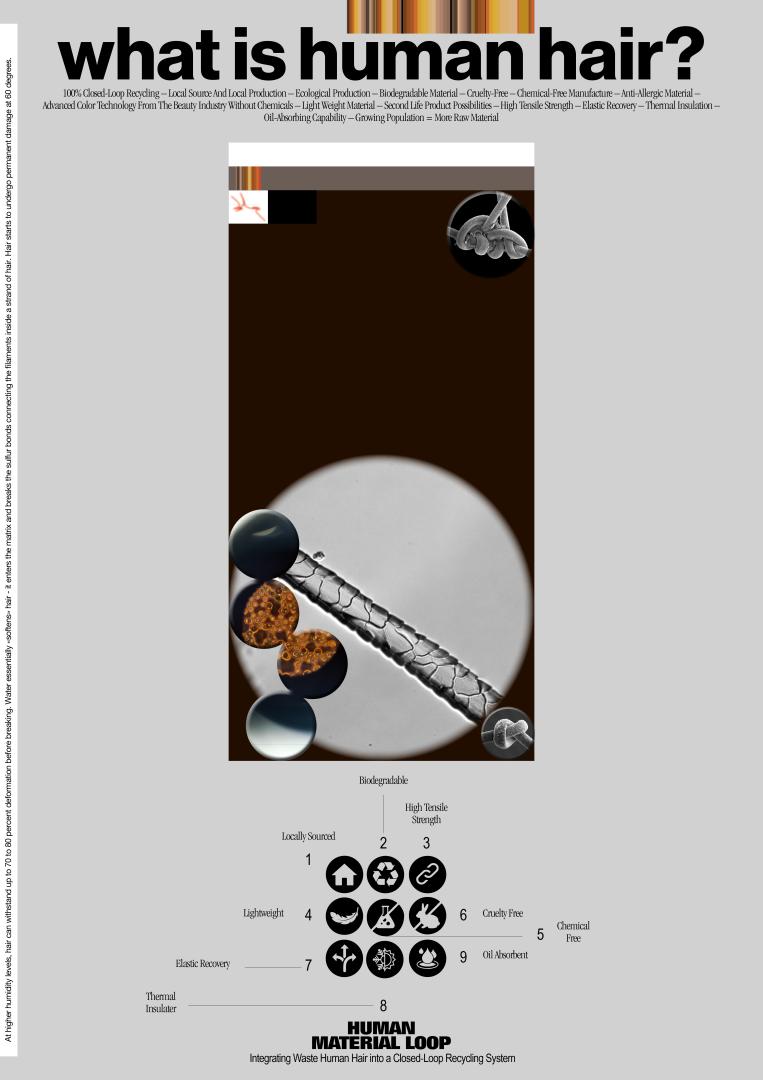

Human Material Loop collects and processes waste human hair and develops high-performance textile with the lowest carbon footprint possible. Integrating waste human hair into a closed-loop recycling system and introducing new material to the textile industry can be a game changer. In Europe, 72 million kg of human hair waste is generated.Human hair is a keratin protein fiber with versatile properties and huge potentials to radicalize the textile industry.

Geographical Scope

Project Region

Urban or rural issues

Physical or other transformations

EU Programme or fund

Which funds

Description of the project

Summary

The textile industry is the second-largest polluter just after the oil industry. We need radical changes if we want to maintain this planet for future generations.

Human Material Loop collects and processes waste human hair and develops high-performance textile with the lowest carbon footprint possible. In Europe, 72 million kg of hair waste is generated. Hair accumulates in the solid waste streams, choking the drainage systems. Human hair is a keratin protein fiber just like wool or alpaca and unlike other materials, human hair does not require any cultivation, the material itself is taken care of by individuals until it is cut off. Hair has a strength-to-weight ratio comparable to steel. It can be stretched up to one and a half times its original length before breaking. The material is collected from hair salons spun into yarns and woven into applicable textile pieces. Human Material Loop offers a globally applicable system, with local sourcing and production, a closed-loop recycling system where value is given to all our waste, and a solution to reach a zero-waste society.

Key objectives for sustainability

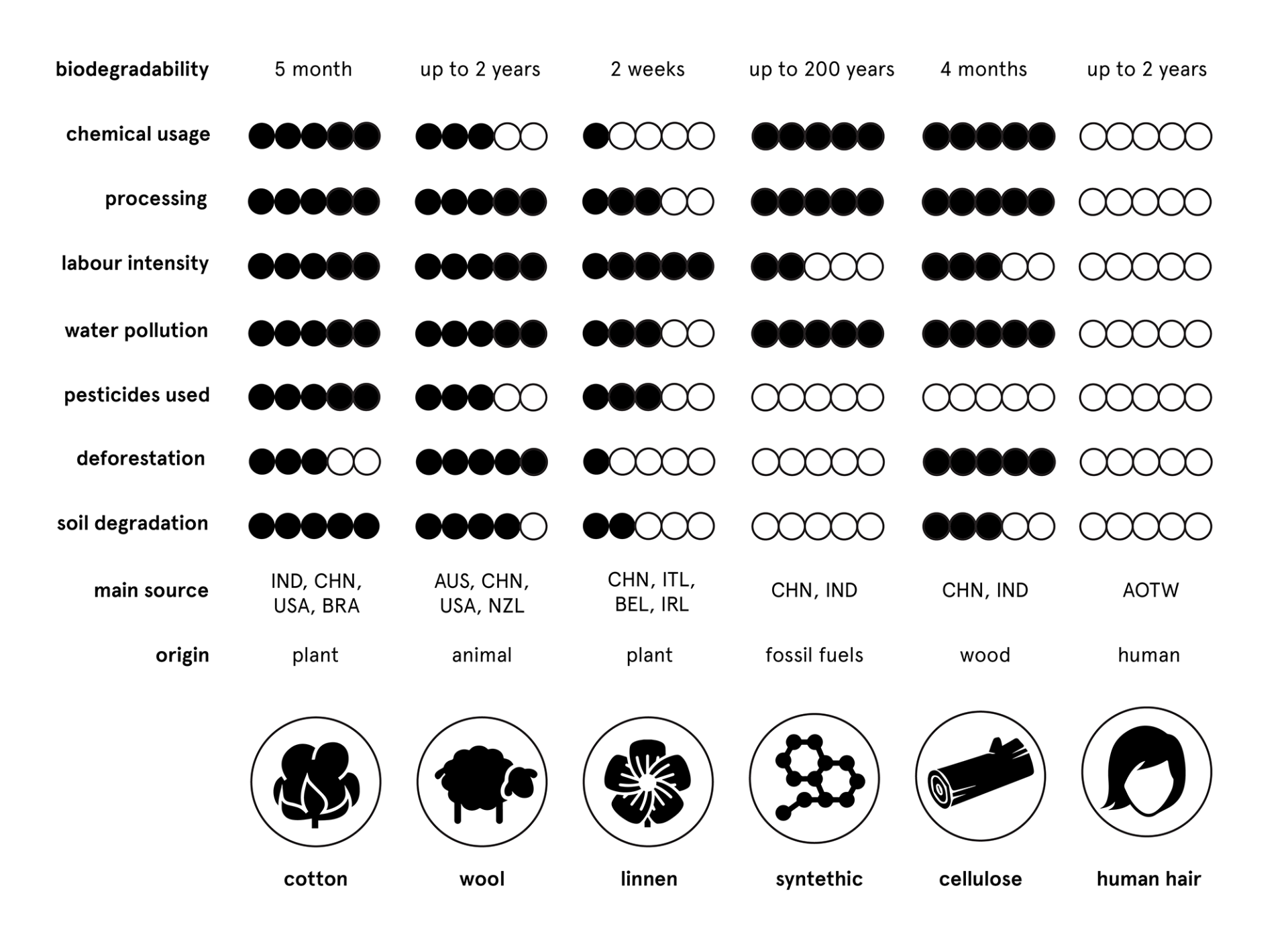

Human Material Loop strives to make an impact on lowering the waste stream of our cities and creating zero waste hair salons. Processing waste hair and integrating it into the textile industry would affect: the current demand for currently used materials (cotton, synthetic fibers, wool) and their negative consequences on our environment, and would push for local and accountable labor. Human Material Loop does not only lower the waste stream of our cities but due to the local production, the manufacturing processes can be closely monitored, products can be manufactured on demand instead of minimum amounts with oversea shipments. Production on demand means avoiding overproduction and creating dead stocks that end up in landfills. A 100% recycled and biodegradable product can exchange synthetic fibers and avoid the accumulation of landfills. Human Materials Loop promotes prosperity while protecting the planet. As a company we are steering our business activities to contribute to several SDGs, effectively using business as a force for good.

Human Material Loop upcycles our waste, uses carbon-neutral transport for its raw material, and boosts local economies with local sourcing and local production. Integrating a biodegradable, natural fiber would reduce the CO2 and related greenhouse gases within the manufacturing and discarding process within the textile industry.

Everybody likes to get pretty by getting a new haircut. Human Material Loop makes it possible to benefit from our beauty obsessions. The left behind hair waste at hair salons is collected and processed for sustainable textile applications.

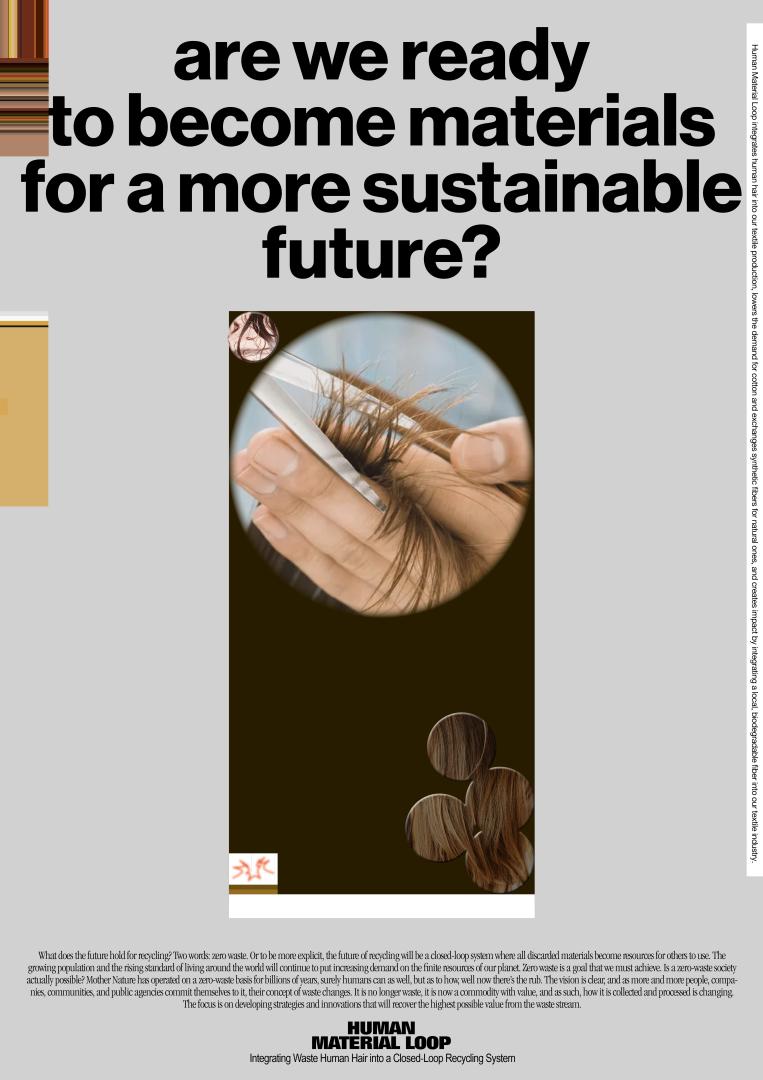

Key objectives for aesthetics and quality

Everybody likes to get pretty by getting a new haircut. Human Material Loop makes it possible to benefit from our beauty obsessions. The left-behind hair waste at hair salons is collected and processed for sustainable textile applications. Human Material Loop believes in a shared economy, where not just the knowledge and technology are shared but also the materials. What is waste for one industry is value for another. The waste hair from the beauty industry is the raw material for the textile industry, the waste material of the hair textile production is fertilizer for agriculture. What makes Human Material Loop unique is the belief in ecocentrism and the view that humans are part of the same ecosystem as every other living being on this planet. It is time to contribute and become material for a sustainable future. There is no other company that involves humans as material for a sustainable future, ethical production from waste material with zero cruelty. A biodegradable fiber that is sourced locally, will not just boost local economies but also assure an environment-friendly product that lasts for a long time due to its high tensile strength. Human Material Loop utilizes all our waste and gives value to them. Human Material Loop makes a step ahead to reach a zero-waste society and treat all our waste with value. Trash is just raw material in the wrong place.

Key objectives for inclusion

The source of the material is provided by hair salons. Hair salons will become zero waste hair salons. Human Material Loop will provide a solution to individuals via their hair salons to contribute to a more sustainable future. Further development after the raw material collection happens within the textile and agriculture industry. Hair fibers are processed together with textile manufacturers and the waste material of the textile production would be handed over to the agriculture industry to develop biofertilizer. Human hair is one of the highest nitrogen-containing organic materials in nature because it is predominantly made up of proteins. In addition, human hair also contains sulfur, carbon, and 20 other elements essential for plants. Recent experiments on horticulture plants show that direct application of human hair to soil provides the necessary plant nutrients for over two to three cropping seasons. Human Material Loop’s main goal is to develop textile to B2B, mostly for brands, designers who apply the textile on their products. The focus on ethical and environmentally friendly materials are increasing among brands and designers. Consumers’ demand for products that are not harming our environment also increases.

Physical or other transformations

Innovative character

Sustainable fabrics often come from plants and animals. Just like food crops, these natural resources are farmed and cost more than synthetic materials that are made of chemicals.

Although many claims that sustainable fashion can be had by all, realistically it can be prohibitively expensive. The base costs that go into sustainable fashion are inherently more expensive due to sourcing costly eco-friendly natural materials and paying people a fair wage for sewing garments. High base costs compounded with retail markups make sustainable fashion inaccessible.

Textiles woven from waste human hair can give accessibility to an affordable product without compromising on the carbon footprint. Our waste becomes the raw material without using land and degrading soil, due to the cleanness of the material water is not required for its processing, lowering the water usage within the textile industry. Local materials mean cutting on transport costs and closely monitoring ethical labor and fair working conditions to local laws.

Treating human hair as any other fiber can offer a sustainable and economically beneficial product that makes sustainable choices affordable for everyone.

Fashion empowered us all, allowed us to express our identities, fashion designers were able to create anything that came to their imagination. But creativity cannot be compromised either our planet.

Fashion designers are at a danger of extinction if we do not provide alternative materials to work with. The most sustainable solution today to get a new addition to our wardrobe is to buy second-hand. That means fashion designers are not needed anymore. Human Material Loop provides a solution to designers by offering material with a carbon footprint close to zero.