Regenstech

Basic information

Project Title

Regenstech

Full project title

Regenstech, regenerative technology

Category

Shaping a circular industrial ecosystem and supporting life-cycle thinking

Project Description

The technology developed by Regenstech allows us to accelerate the sustainable transition of the fashion sector through the use of an innovative system for the transformation of industrial and civil waste, giving life to a new secondary raw material, with multiple potential applications.

Geographical Scope

National

Project Region

Italy

Urban or rural issues

Mainly urban

Physical or other transformations

It refers to other types of transformations (soft investment)

EU Programme or fund

No

Description of the project

Summary

Regenstech has developed a process for transforming civil and industrial textile waste from the home textile and fashion sector into Secondary Raw Material. The innovative technological solution combines a mechanical transformation process (which leads to the pulverisation of waste) with a powder transformation process thanks to "green chemistry". These two integrated technologies allow waste to be transformed into a new material with thermoplastic properties and therefore printable (with 3D printers, injection printing or anthropomorphic robots). Waste from the fashion sector (fabrics and leather) can therefore become new furnishings, fashion or design accessories, packaging, giving life to a fully circular economy.

The transformation process of Regenstech was developed thanks to the structured comparison with companies specialised in mechanical and moulding technologies (36 NDAs signed), with Research Centers and by discussing their needs with potential customer companies (12 NDAs signed). The aim of the overall project is to open an opportunity for the fashion industry to regenerate their waste materials, building up a circular process. In this way, the company would have the opportunity to create a new standard in the sustainability field.

Regenstech is able to offer a validated process from the waste to the final products, made of: industrial implant, maintenance and upkeep services, spare parts and the Respetto® Mix formula.

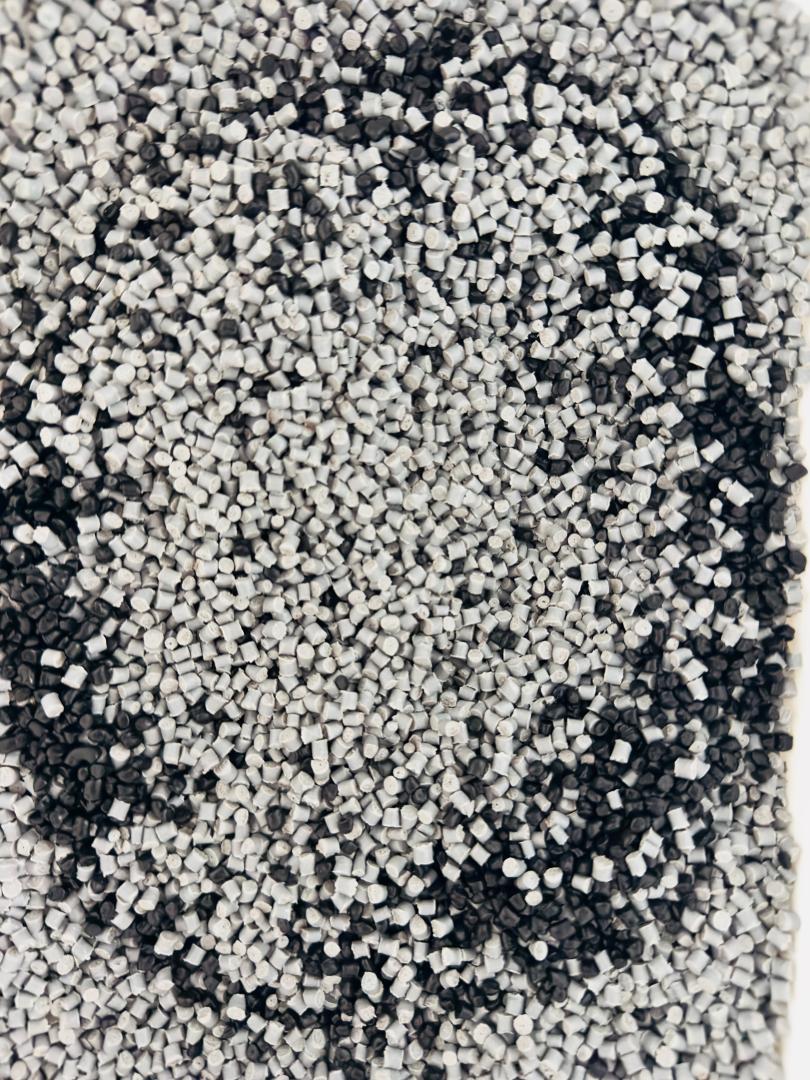

The Respetto® Mix is a versatile thermoplastic material made out of textile waste mixed with bio-based or recycled plastic materials. The 80 formulas already available have different functional and aesthetic responses applicable to different sectors, including fashion, furniture and design with the possibility of adding minimal additives and pigments to customise colour or add further properties. At the end of its life, the material is recyclable within the same production process, starting from grinding.

The transformation process of Regenstech was developed thanks to the structured comparison with companies specialised in mechanical and moulding technologies (36 NDAs signed), with Research Centers and by discussing their needs with potential customer companies (12 NDAs signed). The aim of the overall project is to open an opportunity for the fashion industry to regenerate their waste materials, building up a circular process. In this way, the company would have the opportunity to create a new standard in the sustainability field.

Regenstech is able to offer a validated process from the waste to the final products, made of: industrial implant, maintenance and upkeep services, spare parts and the Respetto® Mix formula.

The Respetto® Mix is a versatile thermoplastic material made out of textile waste mixed with bio-based or recycled plastic materials. The 80 formulas already available have different functional and aesthetic responses applicable to different sectors, including fashion, furniture and design with the possibility of adding minimal additives and pigments to customise colour or add further properties. At the end of its life, the material is recyclable within the same production process, starting from grinding.

Key objectives for sustainability

The Regenstech technology aims to reduce the waste generated from the textile industry in Europe. At our plant, sustainability is a core principle that shapes our operations. We prioritize environmental responsibility and eco-friendly practices, reflecting our commitment to reducing our environmental impact: we've selected low energy machinery to maintain an electrical consumption level below 15 kW, aligning with our mission to minimise our carbon footprint and promote energy efficiency.

Our water usage is also limited, since it is used primarily for cooling the secondary raw material during the transformation phase. We employ a closed-loop system with minimal turnover to ensure efficient and sustainable water usage. We use a maximum of 100 litres of water per month In line with Industry 4.0 principles, our plant machinery is interconnected and monitored through a sophisticated platform. This integration optimises processes, enhances efficiency, and reduces waste, reflecting our commitment to smarter and more sustainable manufacturing.

We employ advanced 3D printing and injection methods that not only enhance product quality but also significantly minimise material waste. This demonstrates our dedication to responsible production and environmental responsibility.

Our sustainability commitment goes beyond practices; it's an integral part of our culture. We believe that by implementing these measures, we can set an industry example for sustainable manufacturing while producing high-quality products. Our eco-friendly approach is a testament to our ability to make a positive environmental impact.

Our water usage is also limited, since it is used primarily for cooling the secondary raw material during the transformation phase. We employ a closed-loop system with minimal turnover to ensure efficient and sustainable water usage. We use a maximum of 100 litres of water per month In line with Industry 4.0 principles, our plant machinery is interconnected and monitored through a sophisticated platform. This integration optimises processes, enhances efficiency, and reduces waste, reflecting our commitment to smarter and more sustainable manufacturing.

We employ advanced 3D printing and injection methods that not only enhance product quality but also significantly minimise material waste. This demonstrates our dedication to responsible production and environmental responsibility.

Our sustainability commitment goes beyond practices; it's an integral part of our culture. We believe that by implementing these measures, we can set an industry example for sustainable manufacturing while producing high-quality products. Our eco-friendly approach is a testament to our ability to make a positive environmental impact.

Key objectives for aesthetics and quality

The key objective of Regenstech with the Respetto® Mix is to have a new material with peculiar aesthetic characteristics that engage the new trends of the fashion industry and design studios. The company, as a benefit corporation, intends to pursue, in the exercise of its economic activities, operate in an ethical, responsible, and sustainable manner towards individuals, communities, territories, the environment, cultural and social assets, entities, associations, and other stakeholders. In particular, the company pursues common benefit objectives in the following areas:

a) In favor of the environment: by implementing the principles of the circular economy to contribute to: reducing CO2 emissions in the air through the creation of recycled materials; decreasing the presence of waste on the planet by transforming them into new resources; producing goods responsibly, favouring recyclable and/or reusable goods;

b) In favor of society: by promoting environmental respect as a fundamental principle, through awareness and information activities in the territory and towards the community, to contribute to the development of a "culture of sustainability."

Regenstech wants to give a new nobility to the waste material and elevate the circularity process to the new normal. Infact, the Respetto® Mix is customizable with additives and pigments in minimal quantities to customise colour, anti-odor properties, UV protection, and compatibility with the food industry. Regenstech's technology provides a technological solution for textile waste treatment on one hand and introduces an innovative secondary raw material to the market, which can replace virgin materials. Furthermore, the mechanical recycling technologies available on the market have the limitation of sorting input materials, a task typically done manually or with semi-automatic technologies, which are slow, expensive, and not always effective. Hence, the monomaterial process is sometimes not feasible.

a) In favor of the environment: by implementing the principles of the circular economy to contribute to: reducing CO2 emissions in the air through the creation of recycled materials; decreasing the presence of waste on the planet by transforming them into new resources; producing goods responsibly, favouring recyclable and/or reusable goods;

b) In favor of society: by promoting environmental respect as a fundamental principle, through awareness and information activities in the territory and towards the community, to contribute to the development of a "culture of sustainability."

Regenstech wants to give a new nobility to the waste material and elevate the circularity process to the new normal. Infact, the Respetto® Mix is customizable with additives and pigments in minimal quantities to customise colour, anti-odor properties, UV protection, and compatibility with the food industry. Regenstech's technology provides a technological solution for textile waste treatment on one hand and introduces an innovative secondary raw material to the market, which can replace virgin materials. Furthermore, the mechanical recycling technologies available on the market have the limitation of sorting input materials, a task typically done manually or with semi-automatic technologies, which are slow, expensive, and not always effective. Hence, the monomaterial process is sometimes not feasible.

Key objectives for inclusion

The versatile nature of the Respetto technology makes it suitable for a wide range of applications within various segments of the fashion, product and interior industry, offering a multifaceted solution that can be tailored to meet the unique needs and challenges faced by different players in the field.

By incorporating this cutting-edge technology into their operations, fashion and home textile companies can ensure compliance with the latest European laws and regulations governing (e.g. Directive 2008/98/EC on waste and Directive (EU) 2018/851 on EPR system) environmental sustainability. This proactive approach not only minimises the risk of legal complications but also fosters a culture of responsibility and stewardship towards the environment.

In the modern era, consumers are increasingly conscious of the ecological impact of their purchases. They demand products that align with their values and demonstrate a commitment to sustainability. By implementing this versatile technology, fashion businesses can effectively respond to this growing consumer demand. As a result, they can position themselves as environmentally responsible brands, attracting a more eco-conscious customer base.

It offers tangible benefits for the environment as well. By optimising various processes within the fashion industry, it reduces waste, conserves resources, and minimises the carbon footprint associated with fashion production. This positive impact on the environment is a testament to the technology's ability to effect meaningful change and contribute to a more sustainable future.

This unique selling point can differentiate a brand in a crowded market, attracting environmentally conscious consumers who actively seek out sustainable fashion options.

This versatile technology emerges as a powerful ally in this endeavour, enabling the industry to progress towards a more sustainable and eco-friendly future.

By incorporating this cutting-edge technology into their operations, fashion and home textile companies can ensure compliance with the latest European laws and regulations governing (e.g. Directive 2008/98/EC on waste and Directive (EU) 2018/851 on EPR system) environmental sustainability. This proactive approach not only minimises the risk of legal complications but also fosters a culture of responsibility and stewardship towards the environment.

In the modern era, consumers are increasingly conscious of the ecological impact of their purchases. They demand products that align with their values and demonstrate a commitment to sustainability. By implementing this versatile technology, fashion businesses can effectively respond to this growing consumer demand. As a result, they can position themselves as environmentally responsible brands, attracting a more eco-conscious customer base.

It offers tangible benefits for the environment as well. By optimising various processes within the fashion industry, it reduces waste, conserves resources, and minimises the carbon footprint associated with fashion production. This positive impact on the environment is a testament to the technology's ability to effect meaningful change and contribute to a more sustainable future.

This unique selling point can differentiate a brand in a crowded market, attracting environmentally conscious consumers who actively seek out sustainable fashion options.

This versatile technology emerges as a powerful ally in this endeavour, enabling the industry to progress towards a more sustainable and eco-friendly future.

Results in relation to category

One of the main results was obtained with the collaboration of Egoitaliano and Regenesi. The project was presented at the Design Week fair in Italy 2023 with the aim to valorise and repurpose the textile industry waste. Together with Egoitaliano, we created an object that represents the circular economy principles and the waste recovery.

In fact, the penholder is made entirely out of an innovative material that contains 100% renewable carbon. The composition of the material consists of approximately 50% by volume of thermoplastic polyurethane from industrial waste and 50% by volume of polymeric textile fibres from the recovery of textile waste. Its composition arises from an industrial symbiosis project where the recycled plastics industry intersects and supports textile industry recycling.

The material offers the advantage of reducing the quantity of textile waste destined for disposal, ensuring its valorisation for the sustainable production of furniture and design objects. This is an example of upcycling, as these scraps would not have had another practical recycling option.

The blending of the two components was achieved using a twin-screw extruder, which, through the application of heat and rotation, melts the polymer that encapsulates the inserted fibres.

The process temperature range spans from 170°C at the beginning of the screw to 230°C at the filament exit nozzle.

This type of process does not require solvents, and the temperatures involved are lower than those used, for example, in processing PET (a polymer used for plastic bottle production).

The design of the pen holder has been specifically tailored to fit the concept of Eco-design. Making the various constituent faces of the object composable eliminates the need for any adhesives, as the assembly relies on a "puzzle" fit.

Giving a second life to the waste from this production is an absolute necessity, and this pen holder is a prime example of this approach.

In fact, the penholder is made entirely out of an innovative material that contains 100% renewable carbon. The composition of the material consists of approximately 50% by volume of thermoplastic polyurethane from industrial waste and 50% by volume of polymeric textile fibres from the recovery of textile waste. Its composition arises from an industrial symbiosis project where the recycled plastics industry intersects and supports textile industry recycling.

The material offers the advantage of reducing the quantity of textile waste destined for disposal, ensuring its valorisation for the sustainable production of furniture and design objects. This is an example of upcycling, as these scraps would not have had another practical recycling option.

The blending of the two components was achieved using a twin-screw extruder, which, through the application of heat and rotation, melts the polymer that encapsulates the inserted fibres.

The process temperature range spans from 170°C at the beginning of the screw to 230°C at the filament exit nozzle.

This type of process does not require solvents, and the temperatures involved are lower than those used, for example, in processing PET (a polymer used for plastic bottle production).

The design of the pen holder has been specifically tailored to fit the concept of Eco-design. Making the various constituent faces of the object composable eliminates the need for any adhesives, as the assembly relies on a "puzzle" fit.

Giving a second life to the waste from this production is an absolute necessity, and this pen holder is a prime example of this approach.

How Citizens benefit

Citizens can benefit from the project by gaining access to sustainable and eco-friendly products such as fashion items, furnishings, and design accessories made from regenerated textile waste. This allows them to make more environmentally conscious consumption choices.

The project's focus on circularity and recycling of textile waste helps reduce the environmental impact of the fashion industry, leading to cleaner air, less landfilled waste, and fewer natural resources consumed, which benefits the local environment.

By promoting sustainability and circular economy principles, the project can raise awareness and educate citizens about the importance of responsible consumption and waste reduction.

In conclusion, the Regenstech project has the potential to benefit citizens by offering sustainable products and reducing the environmental impact of the fashion industry. For example, with its 3D Printing Cobot, its able to create new clothes with the support of a mannequin. Civil society involvement can further enhance the project's accountability, community support, and overall impact, making it a more successful and influential initiative in the field of sustainable fashion and circular economy practices. Since the fashion sector is the 4° in line for the impact on the environment (Source: McKinsey & Company 2021; Hellen MacArthur Foundation 2017; UNECE 2020, UE), citizens can benefit from Regenstech as a long term solution to textile waste regeneration.

The project's focus on circularity and recycling of textile waste helps reduce the environmental impact of the fashion industry, leading to cleaner air, less landfilled waste, and fewer natural resources consumed, which benefits the local environment.

By promoting sustainability and circular economy principles, the project can raise awareness and educate citizens about the importance of responsible consumption and waste reduction.

In conclusion, the Regenstech project has the potential to benefit citizens by offering sustainable products and reducing the environmental impact of the fashion industry. For example, with its 3D Printing Cobot, its able to create new clothes with the support of a mannequin. Civil society involvement can further enhance the project's accountability, community support, and overall impact, making it a more successful and influential initiative in the field of sustainable fashion and circular economy practices. Since the fashion sector is the 4° in line for the impact on the environment (Source: McKinsey & Company 2021; Hellen MacArthur Foundation 2017; UNECE 2020, UE), citizens can benefit from Regenstech as a long term solution to textile waste regeneration.

Physical or other transformations

It refers to other types of transformations (soft investment)

Innovative character

Regenstech's innovation stands out both in the field of sustainable waste transformation and the creation of the Secondary Raw Material, when compared to conventional practices. While mainstream actions often focus on specific recycling or upcycling processes, Regenstech adopts a comprehensive approach. It combines mechanical and chemical methods to convert a wide range of textile waste into the versatile Respetto® Mix material.

The Respetto® Mix material is created from various textile waste sources, including plant, animal, synthetic, and composite materials. This diversity allows for a wide range of applications in fashion, furniture, and design, setting Regenstech apart from mainstream actions that often work with single material types.

Not only does Regenstech regenerate material from waste, but it's also designed to be regenerable itself. At the end of its life, the material can be recycled, aligning with the principles of a true circular economy, a feature not commonly found in mainstream initiatives.

The Respetto® Mix material offers extensive customization options, allowing for the addition of additives and pigments to achieve specific properties. This flexibility is distinctive, as mainstream actions often provide limited material customization.

Regenstech's commitment to transparency is evident through structured comparisons, research collaborations, and stakeholder engagement. This level of transparency is often lacking in mainstream actions, which may not prioritise community involvement and accountability.

Both Regenstech technology and Respetto® Mix are patented.

In summary, Regenstech's innovation lies in its comprehensive, regenerable, and customizable approach to transforming textile waste. It sets new standards in sustainability and circular economy practices, making it a pioneering initiative in the field.

The Respetto® Mix material is created from various textile waste sources, including plant, animal, synthetic, and composite materials. This diversity allows for a wide range of applications in fashion, furniture, and design, setting Regenstech apart from mainstream actions that often work with single material types.

Not only does Regenstech regenerate material from waste, but it's also designed to be regenerable itself. At the end of its life, the material can be recycled, aligning with the principles of a true circular economy, a feature not commonly found in mainstream initiatives.

The Respetto® Mix material offers extensive customization options, allowing for the addition of additives and pigments to achieve specific properties. This flexibility is distinctive, as mainstream actions often provide limited material customization.

Regenstech's commitment to transparency is evident through structured comparisons, research collaborations, and stakeholder engagement. This level of transparency is often lacking in mainstream actions, which may not prioritise community involvement and accountability.

Both Regenstech technology and Respetto® Mix are patented.

In summary, Regenstech's innovation lies in its comprehensive, regenerable, and customizable approach to transforming textile waste. It sets new standards in sustainability and circular economy practices, making it a pioneering initiative in the field.

Disciplines/knowledge reflected

The Regenstech project employs a multidisciplinary approach that draws on expertise from a range of fields, enriching its design and execution. This approach involves various key disciplines working together, with each contributing to the project's value:

Environmental Science and Engineering experts are crucial in understanding the environmental impact of textile waste and devising sustainable waste transformation methods. Their collaboration with engineers yields eco-friendly transformation technologies.

Materials Science and Chemistry specialists play a fundamental role in creating the Respetto® Mix material from textile waste, promoting both versatility and sustainability. Working closely with these experts results in the development of novel and sustainable materials.

Circular Economy and Sustainability experts provide a comprehensive perspective, working alongside stakeholders to develop strategies for circularity, waste reduction, and enhanced sustainability.

Engineering and Technology professionals, together with automation engineers expert and collaborative robot technology experts are responsible for developing and optimising mechanical and chemical processes for waste transformation, leading to the creation of efficient and sustainable technological solutions.

This multidisciplinary approach brings substantial value to the project in several ways.

Collaboration among experts fosters innovation and creative solutions, enabling the development of novel materials and processes and ensures that the project considers the environmental impact, product design, and economic feasibility, creating a comprehensive initiative.

Legal and regulatory experts mitigate legal risks and enhance credibility by ensuring compliance with laws and ethical standards.

In summary, the Regenstech project capitalises on a diverse array of disciplines and knowledge fields.

Environmental Science and Engineering experts are crucial in understanding the environmental impact of textile waste and devising sustainable waste transformation methods. Their collaboration with engineers yields eco-friendly transformation technologies.

Materials Science and Chemistry specialists play a fundamental role in creating the Respetto® Mix material from textile waste, promoting both versatility and sustainability. Working closely with these experts results in the development of novel and sustainable materials.

Circular Economy and Sustainability experts provide a comprehensive perspective, working alongside stakeholders to develop strategies for circularity, waste reduction, and enhanced sustainability.

Engineering and Technology professionals, together with automation engineers expert and collaborative robot technology experts are responsible for developing and optimising mechanical and chemical processes for waste transformation, leading to the creation of efficient and sustainable technological solutions.

This multidisciplinary approach brings substantial value to the project in several ways.

Collaboration among experts fosters innovation and creative solutions, enabling the development of novel materials and processes and ensures that the project considers the environmental impact, product design, and economic feasibility, creating a comprehensive initiative.

Legal and regulatory experts mitigate legal risks and enhance credibility by ensuring compliance with laws and ethical standards.

In summary, the Regenstech project capitalises on a diverse array of disciplines and knowledge fields.

Methodology used

The Regenstech project employs a well-defined and innovative methodology for transforming textile waste into the Respetto® Mix material and creating a circular economy in the fashion and design sectors. The process begins with the collection of textile waste from various sources, within the fashion and textile industries.

A critical aspect of the methodology is the mechanical transformation of the textile waste. This involves the use of specialised equipment to pulverise the waste into fine particles. The mechanical transformation breaks down the waste into its base components, preparing it for the subsequent steps. The innovative aspect of the methodology lies in the integration of "green chemistry." This step involves the application of chemical processes that convert the pulverised textile waste into the Respetto® Mix material. Green chemistry ensures that the transformation process is environmentally friendly and that the resulting material is safe for various applications.

Once the waste is transformed into the Respetto® Mix material, it undergoes further development. The material can be customised by adding specific additives, pigments, or properties, such as the colour. This flexibility makes the material suitable for a wide range of applications.

The Respetto® Mix material is used to create a variety of end products, including fashion accessories, clothing, furniture, and design items. The product creation phase ensures that the material is utilised effectively in a circular economy, minimising waste and promoting sustainability.

An essential element is the regenerable nature of the Respetto® Mix material. It can be recycled at the end of its life within the same production process, starting from grinding. This regenerable design aligns with the principles of a true circular economy.

A critical aspect of the methodology is the mechanical transformation of the textile waste. This involves the use of specialised equipment to pulverise the waste into fine particles. The mechanical transformation breaks down the waste into its base components, preparing it for the subsequent steps. The innovative aspect of the methodology lies in the integration of "green chemistry." This step involves the application of chemical processes that convert the pulverised textile waste into the Respetto® Mix material. Green chemistry ensures that the transformation process is environmentally friendly and that the resulting material is safe for various applications.

Once the waste is transformed into the Respetto® Mix material, it undergoes further development. The material can be customised by adding specific additives, pigments, or properties, such as the colour. This flexibility makes the material suitable for a wide range of applications.

The Respetto® Mix material is used to create a variety of end products, including fashion accessories, clothing, furniture, and design items. The product creation phase ensures that the material is utilised effectively in a circular economy, minimising waste and promoting sustainability.

An essential element is the regenerable nature of the Respetto® Mix material. It can be recycled at the end of its life within the same production process, starting from grinding. This regenerable design aligns with the principles of a true circular economy.

How stakeholders are engaged

Engaging stakeholders at various levels, from local to European, is crucial for the success of the Regenstech project. Local businesses, including potential suppliers and service providers, have been partnered with, creating economic opportunities and local support. Regenstech was together with Eni, Fondazione Enrico Mattei part of coLABoRA has also become a part of in-ER, the Incubator Network of the Emilia-Romagna Region, and collaborates with various partners of the High Technology Network of Emilia-Romagna in the project.

The municipality of Ravenna involved us in a regeneration project of a building located in an industrial area undergoing urban redevelopment. Inside, the creation of a digital atelier open to the public and a space that can be used for sustainability events has been planned.

Collaboration with regional environmental agencies ensures regulatory compliance and the acquisition of necessary permits, enhancing the project's credibility.

Engagement with European Union regulatory bodies guarantees adherence to EU regulations and sustainability goals. Collaboration with European research networks facilitates cross-border research, granting access to expertise and valuable resources.

The value of stakeholder engagement is manifold. It brings diverse expertise, enriching the project with innovative ideas and solutions. Engagement provides access to resources, including financial support, infrastructure, and research capabilities that the project may lack independently. It ensures regulatory compliance, reducing the risk of legal issues and regulatory obstacles. Furthermore, it fosters community and consumer acceptance, crucial for the project's success and reputation. Lastly, engagement at the European level expands the project's reach and impact, making it more influential regionally and internationally.

The municipality of Ravenna involved us in a regeneration project of a building located in an industrial area undergoing urban redevelopment. Inside, the creation of a digital atelier open to the public and a space that can be used for sustainability events has been planned.

Collaboration with regional environmental agencies ensures regulatory compliance and the acquisition of necessary permits, enhancing the project's credibility.

Engagement with European Union regulatory bodies guarantees adherence to EU regulations and sustainability goals. Collaboration with European research networks facilitates cross-border research, granting access to expertise and valuable resources.

The value of stakeholder engagement is manifold. It brings diverse expertise, enriching the project with innovative ideas and solutions. Engagement provides access to resources, including financial support, infrastructure, and research capabilities that the project may lack independently. It ensures regulatory compliance, reducing the risk of legal issues and regulatory obstacles. Furthermore, it fosters community and consumer acceptance, crucial for the project's success and reputation. Lastly, engagement at the European level expands the project's reach and impact, making it more influential regionally and internationally.

Global challenges

The Regenstech project addresses several pressing global challenges by providing local solutions that have far-reaching implications. The fashion and textile industry is a significant contributor to environmental degradation through resource-intensive production processes and textile waste. The Regenstech solution is meant to create a circular process inside the industry, and directly tackles this challenge by transforming textile waste into a regenerable material using eco-friendly processes.

The linear "take-make-dispose" model has led to resource depletion and waste accumulation. Regenstech's circular economy approach, implemented at a local level, showcases how waste can be transformed into valuable materials, fostering resource efficiency and reducing the need for new resources. This local circularity model can serve as a blueprint for promoting circular economies worldwide.

By repurposing textile waste into a versatile material, Regenstech's local solution reduces waste at its source. This waste reduction model can be scaled up to address the global issue of textile waste.

Regenstech's methodology, best practices, and lessons learned can be transferred to various contexts, offering solutions to global challenges. The ability to replicate aspects of the project provides a scalable approach to addressing shared global concerns.

In summary, the Regenstech project tackles global challenges such as environmental sustainability, circular economy promotion, waste reduction, green chemistry adoption, community engagement, transparency, and replicability. By providing local solutions with broader applicability, the project contributes to addressing these pressing global issues and serves as a beacon of sustainability and responsible innovation on a worldwide scale.

The linear "take-make-dispose" model has led to resource depletion and waste accumulation. Regenstech's circular economy approach, implemented at a local level, showcases how waste can be transformed into valuable materials, fostering resource efficiency and reducing the need for new resources. This local circularity model can serve as a blueprint for promoting circular economies worldwide.

By repurposing textile waste into a versatile material, Regenstech's local solution reduces waste at its source. This waste reduction model can be scaled up to address the global issue of textile waste.

Regenstech's methodology, best practices, and lessons learned can be transferred to various contexts, offering solutions to global challenges. The ability to replicate aspects of the project provides a scalable approach to addressing shared global concerns.

In summary, the Regenstech project tackles global challenges such as environmental sustainability, circular economy promotion, waste reduction, green chemistry adoption, community engagement, transparency, and replicability. By providing local solutions with broader applicability, the project contributes to addressing these pressing global issues and serves as a beacon of sustainability and responsible innovation on a worldwide scale.

Learning transferred to other parties

Thanks to our technology we are able to transform 270 tons. per year of textile waste and that it is possible to create plants up to 10 times larger for multi-utilities. In this way they will be able to transform 500-1000 kg per hour. The system is produced in Italy but it is planned to be sold throughout Europe.

Several aspects of the Regenstech project, including its methodology, material development, community engagement, transparency standards, regenerable design, and collaborative approaches, can be replicated or transferred to other places, groups of beneficiaries, and contexts. These elements offer valuable lessons and practical solutions for promoting sustainability and circular economy practices in different settings and industries. The implant itself can be customised for any purpose and location size, opening the opportunity to any fashion industry dimension.

Several aspects of the Regenstech project, including its methodology, material development, community engagement, transparency standards, regenerable design, and collaborative approaches, can be replicated or transferred to other places, groups of beneficiaries, and contexts. These elements offer valuable lessons and practical solutions for promoting sustainability and circular economy practices in different settings and industries. The implant itself can be customised for any purpose and location size, opening the opportunity to any fashion industry dimension.

Keywords

Circular Economy

additive manufacturing;

Textile Waste

Ecodesign

Innovation regenerative technology