Recycle in 3D

Basic information

Project Title

Recycle in 3D

Full project title

Recycling, reuse and valorisation of waste materials for 3D printing applied to design

Category

Shaping a circular industrial ecosystem and supporting life-cycle thinking

Project Description

The project implements innovative strategies for the recycling, reuse and valorisation of waste materials from industrial and handicraft processes in Apulia and Basilicata for production of 3D printing materials applied to design. The aim is create a scalable and easily transferable method, to applied starting with a small investment and technologies within everyone's reach, to obtaining materials and objects unique for traceability and texture from 3D printed waste materials.

Geographical Scope

Regional

Project Region

Puglia and Basilicata, Italy

Urban or rural issues

It addresses urban-rural linkages

Physical or other transformations

It refers to other types of transformations (soft investment)

EU Programme or fund

No

Description of the project

Summary

Customisation, repairability of a product, replacement of parts and on-site production are concepts inherent to artisan production, but not only that, they are also concepts underlying the use of Additive Manufacturing (AM) technologies. Two sectors apparently so distant from each other but which can dialogue with each other. In what way? Why is it that technologies such as AM, which have now become available to everyone, are having difficulty taking off in the world of craft production? Can design intervene in the economic and industrial development processes of the craft sector by working on sustainability, circular economy and the use of additive printing technologies?

Starting from these questions and working on the themes of intelligent and sustainable industry and creativity industry, which intends to promote positive changes by also leveraging basic and applied research through the involvement of citizens with actions dedicated to the transfer of knowledge and technologies in favour of territories and enterprises, the project 'Innovative strategies for recycling, reuse and valorisation of waste materials for 3D printing applied to design' works on the themes of sustainability, new technologies and territory.

This project is concerned with intervening in a specific sector, involving craftsmen and small and medium-sized companies with production facilities located in the Apulia and Basilicata regions, to develop biocomposite materials, obtained from processing waste, useful for the production of objects made with 3D printing technologies. The work carried out and the materials produced have shown that it is possible to hit the target and create a scalable method, to be applied starting from reduced investments, with technologies within everyone's reach, but which allows obtaining unique materials in terms of traceability and texture.

Starting from these questions and working on the themes of intelligent and sustainable industry and creativity industry, which intends to promote positive changes by also leveraging basic and applied research through the involvement of citizens with actions dedicated to the transfer of knowledge and technologies in favour of territories and enterprises, the project 'Innovative strategies for recycling, reuse and valorisation of waste materials for 3D printing applied to design' works on the themes of sustainability, new technologies and territory.

This project is concerned with intervening in a specific sector, involving craftsmen and small and medium-sized companies with production facilities located in the Apulia and Basilicata regions, to develop biocomposite materials, obtained from processing waste, useful for the production of objects made with 3D printing technologies. The work carried out and the materials produced have shown that it is possible to hit the target and create a scalable method, to be applied starting from reduced investments, with technologies within everyone's reach, but which allows obtaining unique materials in terms of traceability and texture.

Key objectives for sustainability

Recycle in 3D aims to develop innovative strategies for the recycling, reuse and valorization of materials derived from production waste through the design of composite materials for 3D printing obtained by mixing several types of waste (wood, stone, ceramics, etc.) with a biodegradable polymer matrix, to promote the technological development of small and medium-sized enterprises and craft workshops.

These biomaterials are formulated by mixing thermoplastic materials, such as polylactic acid (PLA), which is biodegradable, inexpensive and easy to use, with a variety of waste materials, thus creating new materials. These waste materials, generally produced by industry, can also be recovered by small businesses in the area to enable them to reduce disposal costs, reintroduce waste into a new life cycle, and introduce new technologies into activities often linked to tradition and craftsmanship. This is why we can speak of a double sustainability, environmental and economic, because even small producers can exploit the waste of raw materials, mostly derived from exhaustible sources, that they process or produce, increasing their financial revenue through sales of new materials and products.

The project involved consulting numerous studies and statistical data regarding the production of municipal waste and waste derived from industrial and artisanal processing, with a particular focus on the case of "Puglia." Local handicrafts, a vital economic resource for the entire region, are diverse and boast knowledge spread throughout the region. Through the identification of raw materials and main processes in the Apulian territory, the main production categories, the raw materials they exploit and the waste they produce were extrapolated. From this analysis, the first wastes used to produce the materials produced in the Recycle in 3D project were identified.

These biomaterials are formulated by mixing thermoplastic materials, such as polylactic acid (PLA), which is biodegradable, inexpensive and easy to use, with a variety of waste materials, thus creating new materials. These waste materials, generally produced by industry, can also be recovered by small businesses in the area to enable them to reduce disposal costs, reintroduce waste into a new life cycle, and introduce new technologies into activities often linked to tradition and craftsmanship. This is why we can speak of a double sustainability, environmental and economic, because even small producers can exploit the waste of raw materials, mostly derived from exhaustible sources, that they process or produce, increasing their financial revenue through sales of new materials and products.

The project involved consulting numerous studies and statistical data regarding the production of municipal waste and waste derived from industrial and artisanal processing, with a particular focus on the case of "Puglia." Local handicrafts, a vital economic resource for the entire region, are diverse and boast knowledge spread throughout the region. Through the identification of raw materials and main processes in the Apulian territory, the main production categories, the raw materials they exploit and the waste they produce were extrapolated. From this analysis, the first wastes used to produce the materials produced in the Recycle in 3D project were identified.

Key objectives for aesthetics and quality

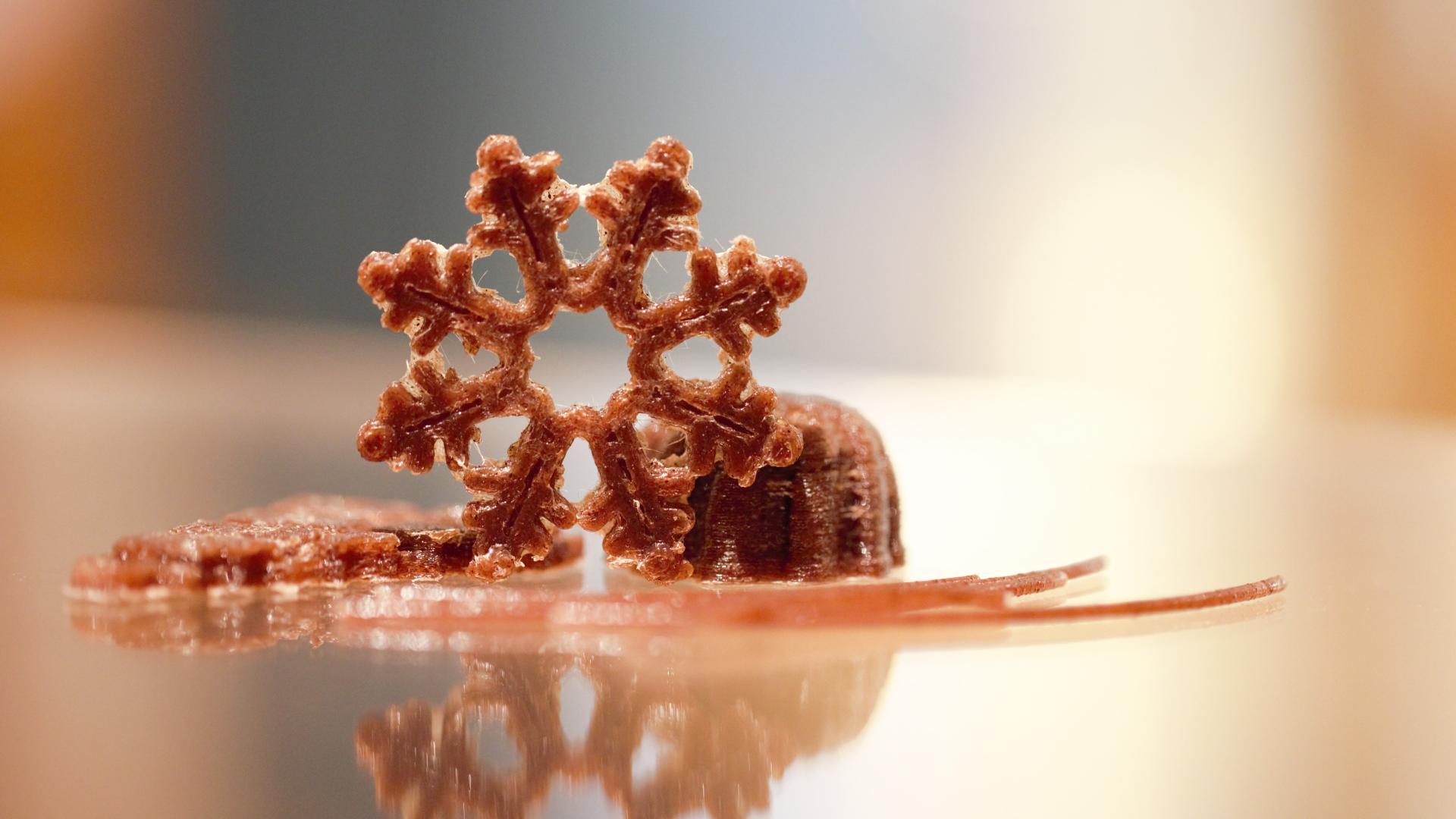

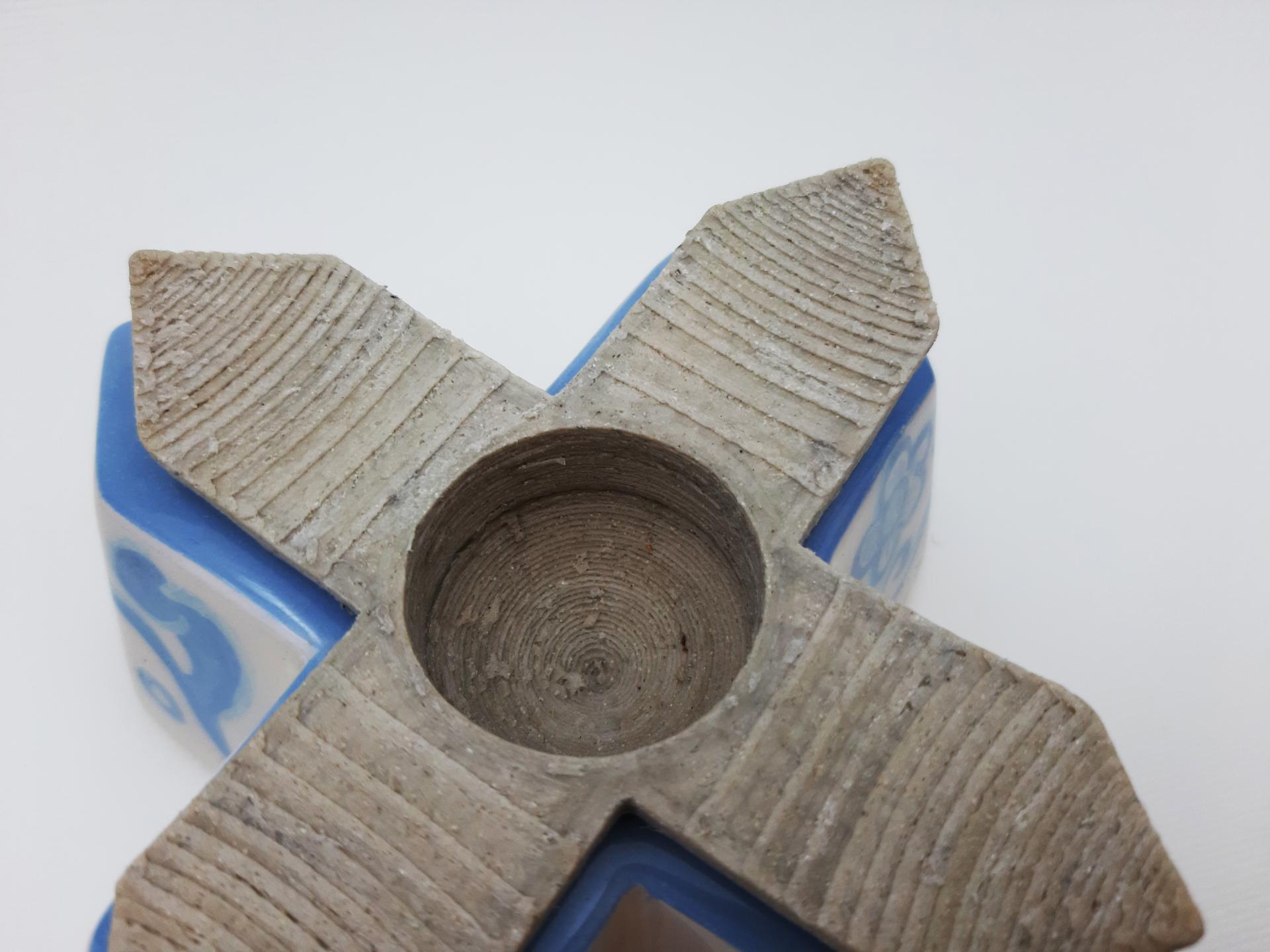

The production of objects sees as a key element the use of specific materials, with their own colors and textures, which characterize the products depending on their function and the context in which they will be placed, also playing a key role in emotional design. Handcrafted productions use materials such as ceramics, wood, stone and metals, and are now seeing the well-established use of computer numerical control (CNC) subtractive techniques, which allow for complex processing in reduced time. While the most popular additive technologies are based on the use of thermoplastic polymers, materials that are far removed from traditional craftsmanship. This implies a reduced field of application of products obtained with these additive techniques because the plastics used are often unsuitable in terms of aesthetics to be inserted in specific contexts, as well as often not stimulating the user from an emotional and tactile point of view. Precisely for this reason, during the development of the materials, we paid great attention to preserving the original color of the raw materials derived from the waste, and also worked on the texture, trying to obtain materials as close as possible to the original material, preserving in some cases even the smell.

Through the process devised in the Recycle in 3D project, the craftsman or designer can intervene in the production of the material by recovering waste produced by traditional processing to obtain a new material for 3D printing by defining its color and texture through the selection and mixing of waste to create materials applicable to unique and highly customizable designs.

Through the process devised in the Recycle in 3D project, the craftsman or designer can intervene in the production of the material by recovering waste produced by traditional processing to obtain a new material for 3D printing by defining its color and texture through the selection and mixing of waste to create materials applicable to unique and highly customizable designs.

Key objectives for inclusion

Communities revolving around the world of makers produce independently and sustainably, experimenting with new approaches to production based on low-cost technologies and information sharing. They work on concepts such as customization, repairability of a product, replacement of parts, and on-site production, concepts that are also characteristic of artisan production. Building on these considerations, the key objectives in terms of project inclusion are listed below.

- Involvement of artisans and small and medium-sized companies with productions located on the territory of Puglia and Basilicata, working with them on the recovery of waste and at applications of the new materials produced.

- Involvement of students from the Degree Course in Industrial Engineering of the University of Salento and the master's degree Course in Industrial design of the Polytechnic University of Bari to produce, analyze and test the different materials and verify their effective use in production with 3D printing.

- Involving associations, makers and designers to design new products using the materials obtained and produce them in 3D printing.

- Creating a scalable and transferable method that is possible to apply starting with low investment, with technologies that are affordable for everyone but allow for unique materials in terms of traceability and texture.

In this scenario, it is possible to bring together the expertise of universities, companies, artisans, and designers for a design that starts from the production of the material to its use, optimizing the entire production process from waste recovery to the actual production of the product, contributing, through the design and engineering of innovative bio composite materials, to dual environmental and economic sustainability.

- Involvement of artisans and small and medium-sized companies with productions located on the territory of Puglia and Basilicata, working with them on the recovery of waste and at applications of the new materials produced.

- Involvement of students from the Degree Course in Industrial Engineering of the University of Salento and the master's degree Course in Industrial design of the Polytechnic University of Bari to produce, analyze and test the different materials and verify their effective use in production with 3D printing.

- Involving associations, makers and designers to design new products using the materials obtained and produce them in 3D printing.

- Creating a scalable and transferable method that is possible to apply starting with low investment, with technologies that are affordable for everyone but allow for unique materials in terms of traceability and texture.

In this scenario, it is possible to bring together the expertise of universities, companies, artisans, and designers for a design that starts from the production of the material to its use, optimizing the entire production process from waste recovery to the actual production of the product, contributing, through the design and engineering of innovative bio composite materials, to dual environmental and economic sustainability.

Results in relation to category

The first materials developed involved the use of polylactic acid (PLA) and materials derived from the processing of

- olive wood

- ceramics (white earthenware, impasto majolica and fired and glazed earthenware)

- lecce stone

- marbles

- MDF (Medium Density Fibreboard)

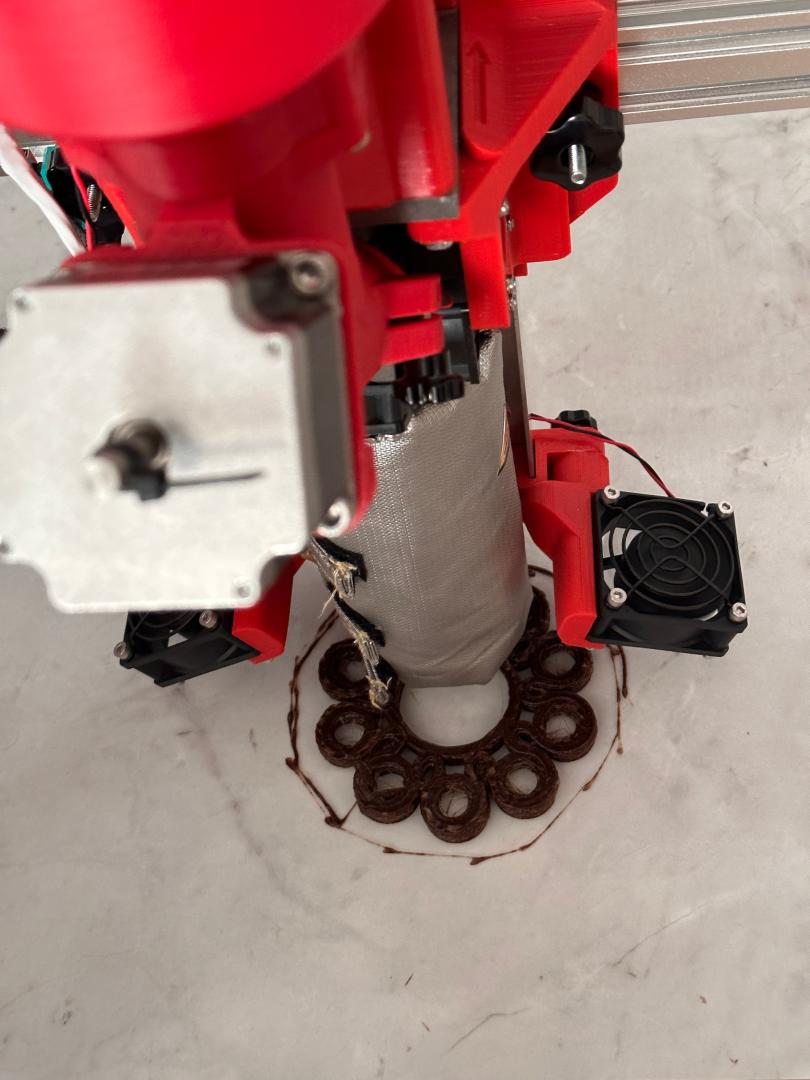

- cocoa bean husks, chocolate processing residues.

Each scrap was treated individually and then mixed with PLA, resulting in the production of filaments and granules based on different PLA/waste ratios.

For each material obtained were analysed: morphological, structural and dimensional characteristics and thermo-mechanical properties and was verified its suitability for the 3D printing technique.

The best PLA/waste ratio was identified for each material developed.

Samples, demonstrators and objects were printed to verify the actual use of these materials in 3D-printed production.

Scientific articles have been published in trade journals. In the study Development and characterisation of sustainable PLA/Olive wood waste composites for rehabilitation applications using Fused Filament Fabrication (FFF) [Fico et al. Journal of Building Engineering, Volume 56, 2022, https://doi.org/10.1016/j.jobe.2022 .104673], to assess the environmental benefits of composite filaments derived from wood waste, impact indicators were also quantified by means of life cycle assessment (LCA), which highlighted the environmental benefits of including wood waste in PLA filaments (20% of wood corresponds to a 10% impact reduction), supporting further research in this area.

- olive wood

- ceramics (white earthenware, impasto majolica and fired and glazed earthenware)

- lecce stone

- marbles

- MDF (Medium Density Fibreboard)

- cocoa bean husks, chocolate processing residues.

Each scrap was treated individually and then mixed with PLA, resulting in the production of filaments and granules based on different PLA/waste ratios.

For each material obtained were analysed: morphological, structural and dimensional characteristics and thermo-mechanical properties and was verified its suitability for the 3D printing technique.

The best PLA/waste ratio was identified for each material developed.

Samples, demonstrators and objects were printed to verify the actual use of these materials in 3D-printed production.

Scientific articles have been published in trade journals. In the study Development and characterisation of sustainable PLA/Olive wood waste composites for rehabilitation applications using Fused Filament Fabrication (FFF) [Fico et al. Journal of Building Engineering, Volume 56, 2022, https://doi.org/10.1016/j.jobe.2022 .104673], to assess the environmental benefits of composite filaments derived from wood waste, impact indicators were also quantified by means of life cycle assessment (LCA), which highlighted the environmental benefits of including wood waste in PLA filaments (20% of wood corresponds to a 10% impact reduction), supporting further research in this area.

How Citizens benefit

The first step in launching the project involved artisans and small and medium-sized companies with production facilities located in Apulia and Basilicata. With them, processing scraps suitable to produce filaments and pellets for 3D printing were selected, and a dialogue was opened on the applications of the new materials produced, proposing the design of useful objects to be inserted within their own production cycle or catalogue.

The first materials developed involved the use of Polylactic Acid (PLA) and materials derived from the production waste of some craftsmen who are members of the Fatto in Bottega Association (Fasano - Brindisi):

- olive wood provided by the artisan workshop of I Lumi del Faso di Musa;

- ceramics: white earthenware, majolica paste and fired and glazed flame earth, derived from processing scraps from Valentina De Carolis's design and ceramics studio and Vito Pugliese's Maioliche Pugliese.

Other scraps were collected with the involvement of craftsmen and companies in Puglia and Basilicata:

- waste based on MDF (Medium Density Fibreboard) from the Matera-based company Thegg, which operates in the field of interior design;

- food scraps provided by the company Maglio Cioccolato (Maglie, Lecce), which provided cocoa bean husks left over from chocolate processing;

- waste from marble processing by Gurrado Marmi s.r.l. in Gravina di Puglia.

From the production waste, it was possible to obtain various printable materials; the process involved the artisans and the companies that supplied the waste to share the results and to deepen the design of some products or demonstrative elements. The next step is the transfer of the process and the production of new materials and objects.

The first materials developed involved the use of Polylactic Acid (PLA) and materials derived from the production waste of some craftsmen who are members of the Fatto in Bottega Association (Fasano - Brindisi):

- olive wood provided by the artisan workshop of I Lumi del Faso di Musa;

- ceramics: white earthenware, majolica paste and fired and glazed flame earth, derived from processing scraps from Valentina De Carolis's design and ceramics studio and Vito Pugliese's Maioliche Pugliese.

Other scraps were collected with the involvement of craftsmen and companies in Puglia and Basilicata:

- waste based on MDF (Medium Density Fibreboard) from the Matera-based company Thegg, which operates in the field of interior design;

- food scraps provided by the company Maglio Cioccolato (Maglie, Lecce), which provided cocoa bean husks left over from chocolate processing;

- waste from marble processing by Gurrado Marmi s.r.l. in Gravina di Puglia.

From the production waste, it was possible to obtain various printable materials; the process involved the artisans and the companies that supplied the waste to share the results and to deepen the design of some products or demonstrative elements. The next step is the transfer of the process and the production of new materials and objects.

Physical or other transformations

It refers to other types of transformations (soft investment)

Innovative character

Recycle in 3D aims to recycle waste materials from craft and/or industrial processes to obtain materials for small and large-format 3D printing, to expand the possibilities of using these technologies within more traditional production realities, producing customisable, unique and traceable materials with low-cost investments.

The plastics used in 3D printing are often unattractive in some applications, which is why one of the innovative aspects of this project lies in the attention paid to preserving the original colour and texture of the raw materials derived from waste, trying to obtain materials as close as possible to the original material, in some cases even preserving the smell.

Unlike traditional processes for the development and production of materials for 3D printing, the project envisages the direct involvement of all figures who can contribute to the development, production and marketing of materials and products, creating a supply chain based on the transfer of knowledge.

The innovative aspect is also demonstrated from a scientific point of view, the list of contributions published in relevant journals:

1. Sustainable production of polymer composites through 3D printing technologies using recycled polymers and fillers. Fico et al. 2022, Polymers 14, https://doi.org/10.3390/polym14183756

2. Development and characterisation of sustainable PLA/olive wood waste composites for rehabilitation applications using Fused Filament Fabrication (FFF). Fico et al. Journal of Building Engineering, Volume 56, 2022, https://doi.org/10.1016/j.jobe.2022.104673

3. From Apulian waste to original design objects: Fused Filament Fabrication (FFF) as a sustainable solution. Rizzo et al. In: Future of Heritage Science and Technologies. Florence Heri-Tech 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-17594-7_10

The plastics used in 3D printing are often unattractive in some applications, which is why one of the innovative aspects of this project lies in the attention paid to preserving the original colour and texture of the raw materials derived from waste, trying to obtain materials as close as possible to the original material, in some cases even preserving the smell.

Unlike traditional processes for the development and production of materials for 3D printing, the project envisages the direct involvement of all figures who can contribute to the development, production and marketing of materials and products, creating a supply chain based on the transfer of knowledge.

The innovative aspect is also demonstrated from a scientific point of view, the list of contributions published in relevant journals:

1. Sustainable production of polymer composites through 3D printing technologies using recycled polymers and fillers. Fico et al. 2022, Polymers 14, https://doi.org/10.3390/polym14183756

2. Development and characterisation of sustainable PLA/olive wood waste composites for rehabilitation applications using Fused Filament Fabrication (FFF). Fico et al. Journal of Building Engineering, Volume 56, 2022, https://doi.org/10.1016/j.jobe.2022.104673

3. From Apulian waste to original design objects: Fused Filament Fabrication (FFF) as a sustainable solution. Rizzo et al. In: Future of Heritage Science and Technologies. Florence Heri-Tech 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-17594-7_10

Disciplines/knowledge reflected

The project has an interdisciplinary development involving at various levels different professionals and experts in fields ranging from materials engineering to design, via craftsmanship.

Valentina De Carolis designer and PhD student in Material, Structure and Nanotechnology engineering oversaw involving the craftsmen and some of the companies, selecting the materials, starting production and analysis, tutoring the students and designing and 3D printing some of the objects.

Prof. Carola Esposito Corcione coordinated the scientific and research activities, involving her research group in the development of tests and analyses, the verification of results, and the drafting of published scientific articles.

The students worked under the coordination of Professor Corcione and me to produce, analyse and test materials and verify their effective use in 3D printing production.

The experimental activity was carried out by working on the production of filaments based on different matrix/filler ratios, analysing the morphological, structural and dimensional characteristics and thermo-mechanical properties for each one, and their suitability for the additive manufacturing technique was verified within the laboratories of the University of Salento.

The craftsmen and companies involved participated in the selection of the waste, the verification of the results and the design of some demonstrator products or elements.

Valentina De Carolis designer and PhD student in Material, Structure and Nanotechnology engineering oversaw involving the craftsmen and some of the companies, selecting the materials, starting production and analysis, tutoring the students and designing and 3D printing some of the objects.

Prof. Carola Esposito Corcione coordinated the scientific and research activities, involving her research group in the development of tests and analyses, the verification of results, and the drafting of published scientific articles.

The students worked under the coordination of Professor Corcione and me to produce, analyse and test materials and verify their effective use in 3D printing production.

The experimental activity was carried out by working on the production of filaments based on different matrix/filler ratios, analysing the morphological, structural and dimensional characteristics and thermo-mechanical properties for each one, and their suitability for the additive manufacturing technique was verified within the laboratories of the University of Salento.

The craftsmen and companies involved participated in the selection of the waste, the verification of the results and the design of some demonstrator products or elements.

Methodology used

In response to the objectives listed above, a scalable and easily transferable method was developed to produce materials using waste from various productions. Below are its steps:

1. identification of small and medium-sized enterprises operating in the area under consideration and selection of production waste suitable for processing.

2. Production and characterisation of composite filaments and pellets produced by mixing several types of waste with a polymer matrix (PLA). This phase involves carrying out tests to obtain the best formulation, analysis and characterisation of the waste materials collected and the granules and/or filaments obtained before and after their use with 3D printers.

3. Design and 3D printing, development of proposals on the possible uses of these materials in the production of products and/or components to be marketed to promote the technological development of small and medium-sized enterprises and selected craft workshops. Design of new production lines or integration into existing processes of materials obtained from waste using 3D printers to promote the use of innovative technologies within the production chains, thus encouraging the recovery of production waste from processes through innovative strategies for the optimisation of processes and products and proposing solutions relevant to the issues of Environmental Sustainability, Circular Economy and Sustainable Economic Development.

Through this work we intend to highlight the importance of the use of 3D printing within the production chains of small and medium-sized enterprises and the advantages generated in terms of reduction of raw materials used, recovery and recycling of waste materials, reduction of the carbon footprint, possibility of obtaining small series and customised products offering greater flexibility in production.

1. identification of small and medium-sized enterprises operating in the area under consideration and selection of production waste suitable for processing.

2. Production and characterisation of composite filaments and pellets produced by mixing several types of waste with a polymer matrix (PLA). This phase involves carrying out tests to obtain the best formulation, analysis and characterisation of the waste materials collected and the granules and/or filaments obtained before and after their use with 3D printers.

3. Design and 3D printing, development of proposals on the possible uses of these materials in the production of products and/or components to be marketed to promote the technological development of small and medium-sized enterprises and selected craft workshops. Design of new production lines or integration into existing processes of materials obtained from waste using 3D printers to promote the use of innovative technologies within the production chains, thus encouraging the recovery of production waste from processes through innovative strategies for the optimisation of processes and products and proposing solutions relevant to the issues of Environmental Sustainability, Circular Economy and Sustainable Economic Development.

Through this work we intend to highlight the importance of the use of 3D printing within the production chains of small and medium-sized enterprises and the advantages generated in terms of reduction of raw materials used, recovery and recycling of waste materials, reduction of the carbon footprint, possibility of obtaining small series and customised products offering greater flexibility in production.

How stakeholders are engaged

Recycle in 3D stems from the project 'Innovative strategies for recycling, reuse and valorisation of waste materials for 3D printing applied to design', which is part of the science and technology area of the PhD in 'Material, Structure and Nanotechnology engineering' at the University of Salento. All the experimental work was conducted under the coordination of tutor Carola Esposito Corcione and with the collaboration of her research group.

More than thirty students from the Degree Course in Industrial Engineering at the University of Salento chose this topic for their bachelor's theses and worked on the various stages of materials production and analysis.

Three students from the master's degree Course in Industrial Design at the Polytechnic University of Bari, under the coordination of Professor Annalisa Di Roma, worked on the development of some of the materials and the design of demonstrators for their use in new products for their master's theses.

The La Capagrossa association in Ruvo di Puglia enabled the first 3D pellet printing tests to be carried out using the materials obtained.

More than thirty students from the Degree Course in Industrial Engineering at the University of Salento chose this topic for their bachelor's theses and worked on the various stages of materials production and analysis.

Three students from the master's degree Course in Industrial Design at the Polytechnic University of Bari, under the coordination of Professor Annalisa Di Roma, worked on the development of some of the materials and the design of demonstrators for their use in new products for their master's theses.

The La Capagrossa association in Ruvo di Puglia enabled the first 3D pellet printing tests to be carried out using the materials obtained.

Global challenges

Recycle in 3D proposes solutions relevant to the issues of environmental sustainability, the circular economy and sustainable economic development that are part of the global challenges identified by the world's major development plans. It envisages the development of production processes based on sustainability, the production of innovative and environmentally friendly materials, and the use of adaptive processes for customised production. In fact, it also identifies the use of technologies for advanced design, digital craftsmanship and technologies for reducing environmental impact (green engines) as priorities.

The proposal also considers the global objectives that intend to promote positive changes by also leveraging basic and applied research through the involvement of citizens with dedicated actions of knowledge and technology transfer in favour of territories and enterprises and to foster local environmental, economic, social and cultural sustainability. Based on these themes, the project is concerned with intervening in a specific sector, involving artisans and small and medium-sized companies with production located in the Apulia and Basilicata regions, to develop bio composite materials, obtained from processing waste, useful to produce objects made with 3D printing technologies. The process therefore provides local solutions, with the development of materials obtained by collecting production waste in a specific territory, to address global issues, developing a method that can be replicated, transferred and scaled up anywhere in the world.

The proposal also considers the global objectives that intend to promote positive changes by also leveraging basic and applied research through the involvement of citizens with dedicated actions of knowledge and technology transfer in favour of territories and enterprises and to foster local environmental, economic, social and cultural sustainability. Based on these themes, the project is concerned with intervening in a specific sector, involving artisans and small and medium-sized companies with production located in the Apulia and Basilicata regions, to develop bio composite materials, obtained from processing waste, useful to produce objects made with 3D printing technologies. The process therefore provides local solutions, with the development of materials obtained by collecting production waste in a specific territory, to address global issues, developing a method that can be replicated, transferred and scaled up anywhere in the world.

Learning transferred to other parties

Thanks to the development of the method set up and listed in the previous section, each step of the work can be repeated in any geographical area. As shown in all the steps outlined so far, the project is based on being replicable, transferable and scalable.

Through the transfer of knowledge and the use of low-cost and easily accessible tools, it is possible to replicate the experience and develop materials using waste from specific geographical areas. For each context, it is also possible to create strategic partnerships with multiple actors such as craftsmen and companies, universities, research centres, associations, designers, artists, makers and FabLabs that can contribute to the production of materials and their use and dissemination.

Through the transfer of knowledge and the use of low-cost and easily accessible tools, it is possible to replicate the experience and develop materials using waste from specific geographical areas. For each context, it is also possible to create strategic partnerships with multiple actors such as craftsmen and companies, universities, research centres, associations, designers, artists, makers and FabLabs that can contribute to the production of materials and their use and dissemination.

Keywords

recycle waste

Innovative material

3D printing

Sustainability

craftsmanship and design