PEEL

Basic information

Project Title

PEEL

Full project title

PEEL - from chestnut to upholstery - a bioconceptual approach

Category

Shaping a circular industrial ecosystem and supporting life-cycle thinking

Project Description

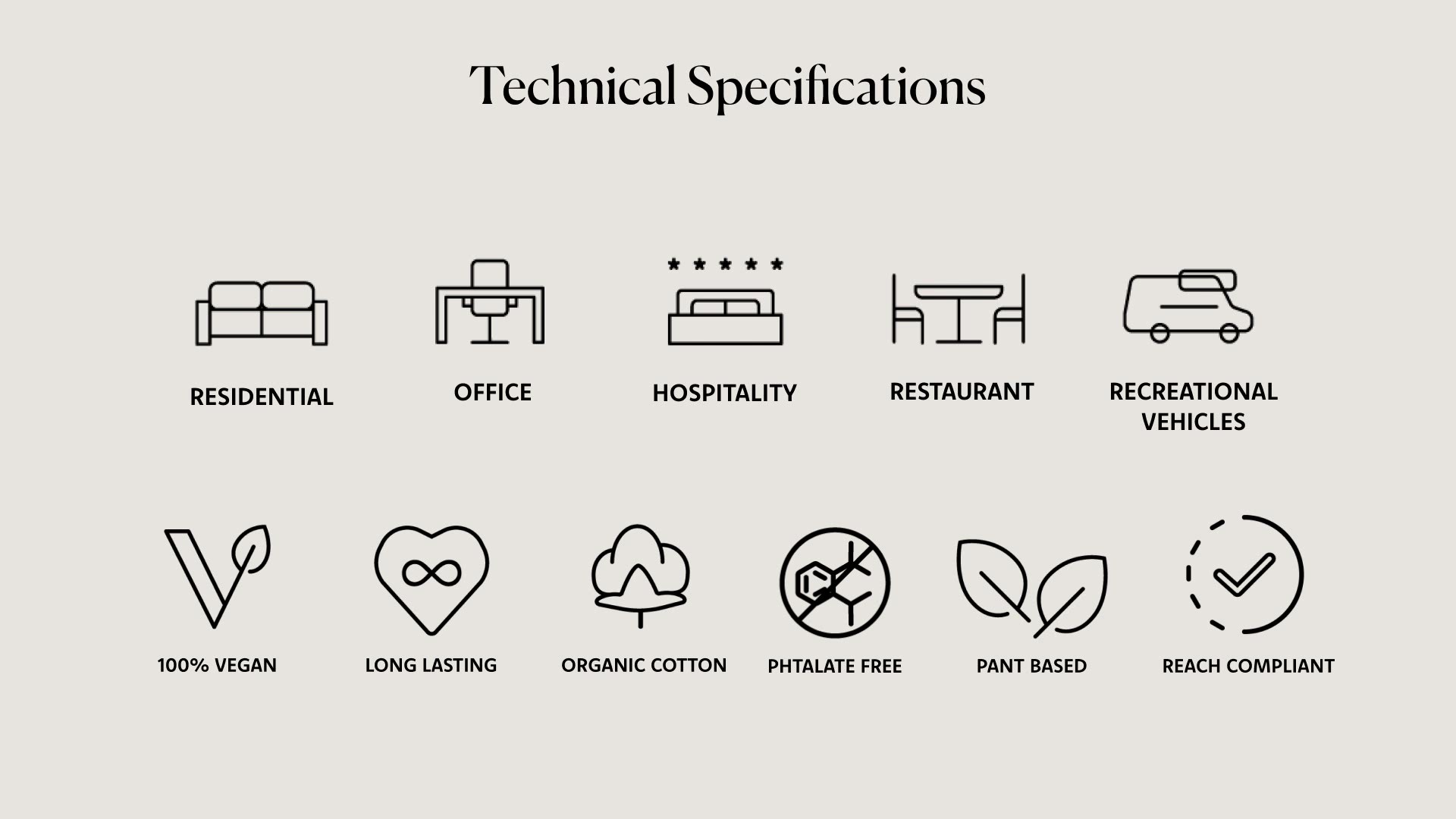

We encourage designers to embrace more conscientious urban decorating with PEEL. It is a 65% plant based upholstery material, upcycling waste from chestnut harvest, associated with an important forest resource to rural population in Portugal. Real transition towards sustainability, must provide also performance, reliability and aesthetics. With PEEL we offer a fully tested bioproduct, complying with the highest upholstery standards, in 8 charming colours and readily available from stock.

Geographical Scope

National

Project Region

Portugal

Urban or rural issues

Mainly urban

Physical or other transformations

It refers to other types of transformations (soft investment)

EU Programme or fund

No

Description of the project

Summary

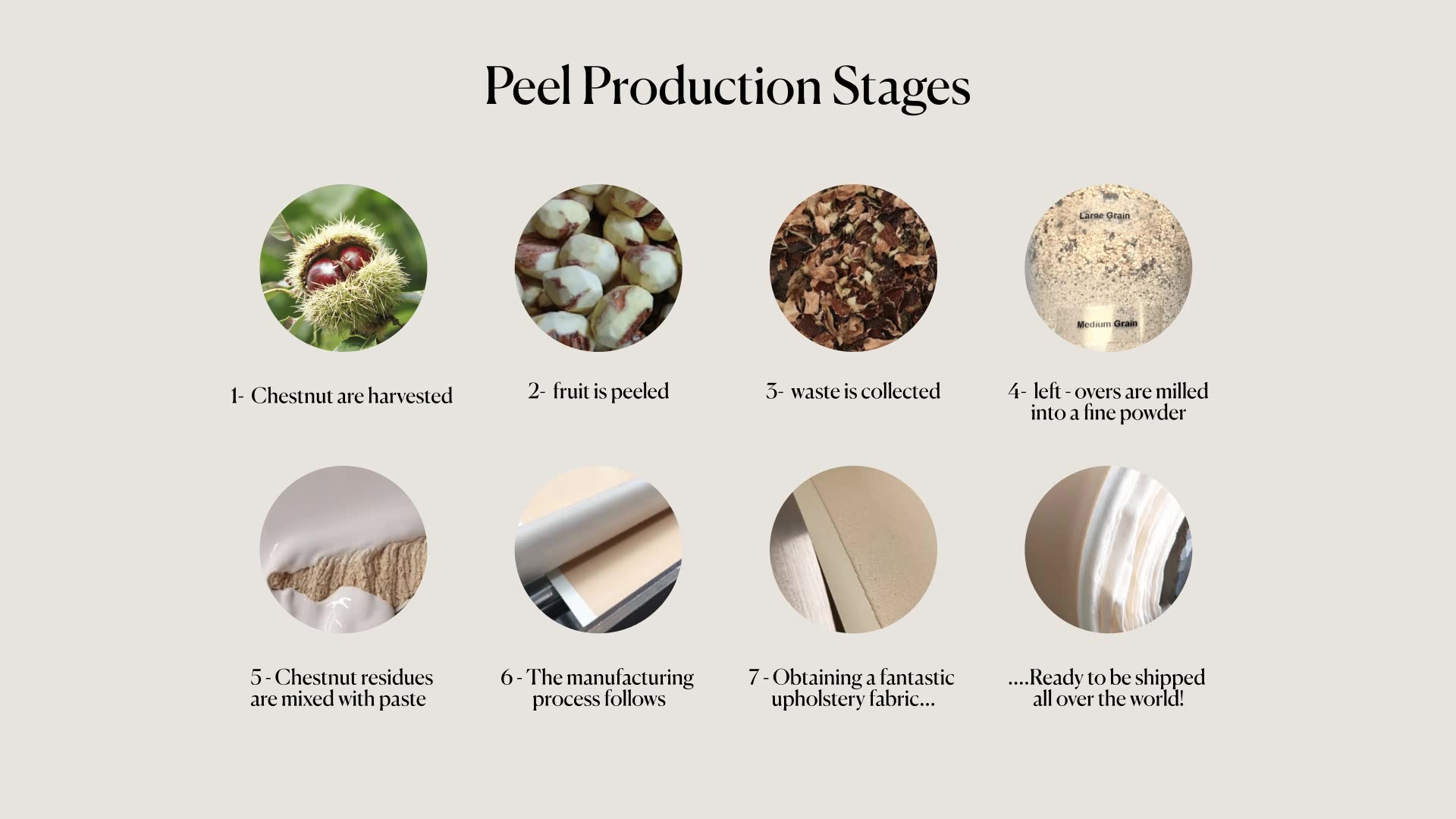

With PEEL we aim at encouraging designers and contractors to embrace a bioconceptual approach towards more conscientious urban decorating. PEEL is a 65% plant based upholstery material incorporating chestnut waste. As coated fabrics experts, we realise the ecological appeal in a bioproduct is not enough to operate a realistic viable transition towards sustainability. Bioproducts need to perform, be reliable and appealing. With PEEL, we upcycle purposeless residues from chestnut harvesting, locally sourced from an activity that, while providing an important income to remote rural populations in Portugal, also allows for the preservation of these endogenous, resilient forests and ecosystems. It took us 7 years of development, from partnering with chestnut producers, until perfecting PEEL to achieve a fully production tested bioproduct that complies with the highest upholstery standards, ensuring a durable solution. With PEEL we also accomplished an appealing aesthetics and sensorial perception through a delicate chestnut smell and an interesting texture in a set of 8 charming colours, readily available from stock. We reached out to the academy to endorse our approach, on several aspects. Firstly, confirming that the life cycle assessment compares positively to the conventional alternative with respect to the impacts on Climate change, Ecotoxicity, Resource use fossils, and Water use. Secondly, we have established that, under certain conditions, PEEL biodegrades much faster than the conventional alternative. Thirdly, we have determined the biocontent according to ASTM D6866, certifying that PEEL has 65% of carbon from natural sources vs. the % carbon from petrochemical sources. Imagining cafés, hotels, theatres, airports, hospitals, etc. all refurbished in in bioproducts such as PEEL, that’s the ambition we have and what makes us believe in this bioconceptual approach.

Key objectives for sustainability

As experts in coated fabrics we fully realise the challenge facing European industries in aligning with the Green Deal, as we are expected to operate a massive production paradigm change while maintaining our businesses viable and future proof. We live Sustainability as one of our values and PEEL is a project inserted in the objectives it encompasses. Demand plays a large role on whether our sustainability projects succeed in becoming economically and environmentally relevant, more than mere curiosity or experiment. Hence, our objective with PEEL is to provide a biobased upholstery material with the same performance conventional alternatives offer, fully tested in production, both reliable and appealing. This way we hope to persuade designers and contractors to prefer and create ambiences with a more conscientious alternative, an option they can trust will do the job, durable and beautiful. Evidence to achieving it is: 1) PEEL is a 65% biobased material validated by a USA entity according to ASTM D6866. If we changed all our production from the conventional alternatives which are on average 95% fossil based to PEEL, we would reduce the extraction of fossil raw materials we use by 63%. Pushed by example and demand, many other producers could replicate this bioconcept, meaning the impact could potentially be very significant. 2) By incorporating Chestnut residues, PEEL upcycles a forestry biomass waste, contributing to preserve these ecosystems. 3) In a life cycle assessment made by independent consultants, PEEL compares positively to the conventional alternative regarding the impacts on Climate change, Ecotoxicity, Resource use fossils, and Water use. 4) We have established that, under certain conditions, PEEL biodegrades much faster than the conventional alternative, so we expect that at the end of its useful life it will be less impactful. 5) PEEL complies with all technical requirements for upholstery end, namely adequate resistance to abrasion and fire.

Key objectives for aesthetics and quality

The decorating industry that we serve is headed by creative and aesthetically sensitive professionals. In this context the success of a product is as much dictated by how it looks and feels and what ambience it creates, as by how it performs or how much it costs. In recognition of this, our goal with PEEL is to associate to the sustainability arguments, carefully thought sensorial properties, hoping to inspire designers and contractors to give preference to a more conscientious alternative, bioconcepts, they can willingly rely on to create beautiful and functional spaces for people.

We have achieved this with PEEL through: 1) A distinctive texture very satisfying to the touch. 2) A collection featuring 8 colours emerging from both recent trends and conservative tones traditionally used in some upholstery applications, resulting in an uncontroversial beautiful palette. 3) A unique subtill chestnutty odour, that helps to tell the story.

A product that tells a story where chestnuts, so dear to the Portuguese and indeed many Europeans, play a part, is an experience that connects people to nature, rural and gastronomical traditions.

Considering contractors, architects and designers are so often trend setters, the choices they make can set examples that will be followed collegially, spreading the concept, the reputation, and setting a real change towards sustainability with impact across the value chain.

We have achieved this with PEEL through: 1) A distinctive texture very satisfying to the touch. 2) A collection featuring 8 colours emerging from both recent trends and conservative tones traditionally used in some upholstery applications, resulting in an uncontroversial beautiful palette. 3) A unique subtill chestnutty odour, that helps to tell the story.

A product that tells a story where chestnuts, so dear to the Portuguese and indeed many Europeans, play a part, is an experience that connects people to nature, rural and gastronomical traditions.

Considering contractors, architects and designers are so often trend setters, the choices they make can set examples that will be followed collegially, spreading the concept, the reputation, and setting a real change towards sustainability with impact across the value chain.

Key objectives for inclusion

A realistic approach to conceiving more sustainable products, cannot be dissociated from its economic viability, spanning from sourcing to the market. PEEL was conceived with such an objective in mind. With respect to sourcing, all components of PEEL are acquired in Europe, namely polymers, natural oils and organic cotton, which is weaved locally, although the raw fibre may have exogenous origin. Sourcing chestnut waste involved Portuguese producer cooperatives and processing facilities in order to adequately modify it at a reasonable cost. This way we hope to encourage a functioning industrial ecosystem that rewards us with dependable supplies at affordable costs, later translating into product prices the market is able to absorb.

Results in relation to category

PEEL is a successful development, full production tested, complying with high upholstery performance standards, namely with respect to abrasion it withstands more than 400.000 ‘Martindale’ (ISO 5470-2) cycles, possesses M2 fire resistance: classifications M2 (NF P 92-507) and CRIB 5 (BS 5852), it is colour fast for example to Ethanol, Bleach (Rubbing ISO 105-X12), among other characteristics.

According to the determination by C14 content (ASTM D6866-22 Method B), 65% of the carbon present in PEEL is of biological origin.

Biodegradations experiments show that, after 4 months of exposure to decomposing in the soil, PEEL lost 3 times more weight than the conventional alternative.

The life cycle assessment within the considered boundaries established that PEEL compares positively to the conventional alternative regarding the impacts on Climate change, Ecotoxicity, Resource use fossils, and Water use.

PEEL is readily available to customers both locally and through distributors we have in some European countries, and we have implemented an efficient catalogue and sample system that quickly responds to any request from any decoration professional.

According to the determination by C14 content (ASTM D6866-22 Method B), 65% of the carbon present in PEEL is of biological origin.

Biodegradations experiments show that, after 4 months of exposure to decomposing in the soil, PEEL lost 3 times more weight than the conventional alternative.

The life cycle assessment within the considered boundaries established that PEEL compares positively to the conventional alternative regarding the impacts on Climate change, Ecotoxicity, Resource use fossils, and Water use.

PEEL is readily available to customers both locally and through distributors we have in some European countries, and we have implemented an efficient catalogue and sample system that quickly responds to any request from any decoration professional.

How Citizens benefit

As a more sustainable alternative, PEEL affects people’s lives in several ways. Firstly, it can work as a source of inspiration for all professionals in the decorating field and operate a bioconceptual change, that is, towards creating more conscientiously decorated spaces. In consequence, this also benefits the people enjoying those spaces, maybe connecting them to the story of the product through a sensorial experience. Finally, it touches all employees across the supply chain as this becomes a source of income that being compatible with the ambitions of the Green Deal, transforms it from threat into confidence. Overall, as this bioconcept is replicated and gains momentum, civil society will benefit also from reducing carbon emissions and other environmental impacts of this activity.

PEEL was matured for 7 years by Monteiro Fabric’s team, composed of chemical engineers, chief production managers, lab technicians and marketing advisors, responsible for sponsoring the value of sustainability, benchmarking, think labs, triaging ideas, networking, investigating, prototyping, testing, redesign, scaling-up and marketizing.

PEEL was matured for 7 years by Monteiro Fabric’s team, composed of chemical engineers, chief production managers, lab technicians and marketing advisors, responsible for sponsoring the value of sustainability, benchmarking, think labs, triaging ideas, networking, investigating, prototyping, testing, redesign, scaling-up and marketizing.

Physical or other transformations

It refers to other types of transformations (soft investment)

Innovative character

The mainstream practice in the production of coated fabrics relies on components mostly originating from petrochemical sources: on one hand, coating formulations are mostly based on polymers synthetized from fossil hydrocarbons; on the other hand, there is a widespread use of backing textiles also synthetized from fossil hydrocarbons, mainly for price target reasons.

PEEL is a biocomposite: the polymeric coating incorporates chestnut residues and vegetable oils, while the backing fabric is an organic cotton textile. The fact that it is the only European coated fabric certifiably 65% biobased complying with high upholstery performance standards, namely enduring more than 400.000 Martindale cyclesand M2 fire resistance, differentiates PEEL as a more sustainable innovative product and promotes awareness towards sustainability to new decoration bioconcepts.

PEEL is a biocomposite: the polymeric coating incorporates chestnut residues and vegetable oils, while the backing fabric is an organic cotton textile. The fact that it is the only European coated fabric certifiably 65% biobased complying with high upholstery performance standards, namely enduring more than 400.000 Martindale cyclesand M2 fire resistance, differentiates PEEL as a more sustainable innovative product and promotes awareness towards sustainability to new decoration bioconcepts.

Disciplines/knowledge reflected

The development of PEEL conjugated several knowledge fields, namely:

Polymer formulating chemistry – allowing for the creation and improvement of the coating incorporating chestnut waste, thus reducing the proportion of fossil based components used.

Biotechnology - allowing for data bases of locally available waste biomasses, establishing its properties and potential compatibility with the other coating components.

Material Engineering – allowing for conceiving and performing the necessary modifications on the chestnut waste to allow its incorporation.

Textile engineering – allowing to adapt the available equipment and know how to special production adaptations the product requires and also for performance testing and improvement.

Contract and decorative design marketing – essential on establishing the product guide lines in terms of expected market demand, regarding performance, aesthetics, look and feel and colour trends.

Internal teamwork allowed for the interaction of these knowledge fields, resulting in a successful bioproduct, which in turn generated more knowledge, useful in further developments.

Polymer formulating chemistry – allowing for the creation and improvement of the coating incorporating chestnut waste, thus reducing the proportion of fossil based components used.

Biotechnology - allowing for data bases of locally available waste biomasses, establishing its properties and potential compatibility with the other coating components.

Material Engineering – allowing for conceiving and performing the necessary modifications on the chestnut waste to allow its incorporation.

Textile engineering – allowing to adapt the available equipment and know how to special production adaptations the product requires and also for performance testing and improvement.

Contract and decorative design marketing – essential on establishing the product guide lines in terms of expected market demand, regarding performance, aesthetics, look and feel and colour trends.

Internal teamwork allowed for the interaction of these knowledge fields, resulting in a successful bioproduct, which in turn generated more knowledge, useful in further developments.

Methodology used

The project culminating with PEEL was prompted by initiative of the company’s board of directors in line with living sustainability as a company value and as valued business strategy. In a bottom-up approach, a multidiscipline team gathered in Monteiro Fabrics presented ideas using acquired experience, benchmarking and technical publications. A triage of the ideas pointed to a line of investigation considering the use of biomass residues. Interaction with the academy and sectorial associations provided the networking to come up with an industrial investigating road-map: 1) Monteiro Fabrics R&D team interacting with external technicians from suppliers – sourcing biocomponents samples; 2) Monteiro Fabrics Lab and Quality team – lab formulating and testing, trial and error, selecting hypothesis through most promising results; suggesting improvements; 3) External contract – modifying biomass waste to necessary improvements; 4) Monteiro Fabrics Lab and Quality team – redefining formulating and testing, trial and error, selecting most promising result to prototype 5) Monteiro Fabrics R&D team – producing prototypes and problem solving; 6) Monteiro Fabrics Lab and Quality team – testing for compliance with envisaged performance; 7) External USA lab testing of prototype for C14 to assess biocontent; 8) University - Instituto Superior de Engenharia de Porto: external experiments for biodegradability of the prototype. 9) Monteiro Fabrics R&D and Marketing – Proto collection development, textures and colours; 11) External contracting – testing the material in different types of upholstered furniture 10) Scalling-up to full production and creating a stock service; 11) Selling and promoting.

How stakeholders are engaged

The board of Monteiro Fabrics was key for the project in the sense that they sponsored internally the development of more sustainable products as a valuable business strategy, thus culminating in PEEL and other products to follow.

European Fabric suppliers also played an important role. As we buy the fabric for the backing of our products, it was essential to rely on one of our European suppliers to provide us with alternatives based in natural fibres, ending up selecting organic cotton.

The involvement of chestnut producer cooperatives from the region of Bragança in the North of Portugal was of fundamental importance in accessing collected amounts of waste, availability, current use, if any, and costs involved in obtaining it.

As the chestnut waste cannot be incorporated in the form it originates, it was also of valuable importance to involve a local company that was able to process the waste into the adequate structure.

With respect to promoting the product we also value our distributors in the Netherlands and France, which proactively reacted to the promotion of PEEL in their local markets.

European Fabric suppliers also played an important role. As we buy the fabric for the backing of our products, it was essential to rely on one of our European suppliers to provide us with alternatives based in natural fibres, ending up selecting organic cotton.

The involvement of chestnut producer cooperatives from the region of Bragança in the North of Portugal was of fundamental importance in accessing collected amounts of waste, availability, current use, if any, and costs involved in obtaining it.

As the chestnut waste cannot be incorporated in the form it originates, it was also of valuable importance to involve a local company that was able to process the waste into the adequate structure.

With respect to promoting the product we also value our distributors in the Netherlands and France, which proactively reacted to the promotion of PEEL in their local markets.

Global challenges

PEEL addresses mainly the global environmental challenges daily present in our lives, namely global warming. As demonstrated by the life cycle assessment, PEEL contributes to the transformation of the Portuguese industry towards the reduction of greenhouse gas emissions and using renewable instead of fossil based sources. The use of Chestnut residues allows for an extra valorisation that contributes to a healthy exploration of an autochthone forest resource, invaluable for rural populations mainly in the district of Bragança in the north of Portugal. In finding here an interesting income, these populations are the best carers of the forest, consequently preserving resilient ecosystems and biodiversity.

Learning transferred to other parties

Our ambition with PEEL goes beyond its use as an alternative upholstery material, we aim at encouraging more sustainable decorating concepts by leading decoration professionals to trust options such as these. To build this trust we hope to set a replicable example in: 1) creating a culture of transparency regarding the sustainability statements, namely by certifying biobased content, performing and publishing the product’s life cycle assessment, traceability and origin of components; 2) offer a fully tested and high performance alternative, rather than an experimental compromised material without a relevant impact; 3) telling a story with the product, something that can engage also the people inhabiting the spaces where PEEL was used.

To this purpose we are using social networks, exhibiting at sectorial fairs, providing free samples for testing and programming webinars as vehicles of our initiative, certainly with selling arguments, but foremost as inviting all players, from the supply chain to the consumer, to join the concept.

To this purpose we are using social networks, exhibiting at sectorial fairs, providing free samples for testing and programming webinars as vehicles of our initiative, certainly with selling arguments, but foremost as inviting all players, from the supply chain to the consumer, to join the concept.

Keywords

plant-based

upholstery

chestnut

biodesign

performance