Shaping a circular industrial ecosystem and supporting life-cycle thinking

Innovative building made of wood waste

Innovative structure made of wood-based materials for sustainable construction

This project resulted in four new products, namely innovative wooden exterior and interior wall coverings, partition and load-bearing walls for sustainable construction from underutilized wood species and waste material generated in the factory in order to ensure long-term sustainable development and greater efficiency with positive environmental impact.

Croatia

National

It addresses urban-rural linkages

It refers to other types of transformations (soft investment)

Yes

2023-12-31

Yes

ERDF : European Regional Development Fund

No

Yes

Yes

Yes

As a representative of an organisation, in partnership with other organisations

The purpose of the project was to conduct scientific research activities and make new step towards the development and the production of exterior and interior wooden wall coverings (paneling and cladding), as well as partition and load-bearing walls, with a significant proportion of Slavonian oak veneer and sawn oak or ash elements. Alternatively, other hard and soft deciduous wood species (in the middle layer of the sandwich) could be used. The use of wood residues is applicable to all factories engaged in wood processing with the aim of developing new products and increasing the share of final finished products in the applicant's total production. The newly developed products are intended for sustainable construction of residential and public buildings. The research resulted in the selection of materials for the basic construction of panels and filling materials (a combination of wood residues) to achieve appropriate thermal and sound insulation. Structural wood elements are usually produced from coniferous wood, and the developed innovative wall decors will be produced from oak veneer. Partition and load-bearing walls will have oak cladding in the interior and exterior, representing a novelty for the macro-region market and the global market, as partition and load-bearing wooden walls are not yet produced in this way. Finally, these products are not only long lasting and visually attractive but they significantly increase the yield of highly valued oak wood logs thus contributing to reach sustainability of not only our natural resources but the sustainability of the wood-based sector as well.

Sustainable construction

innovative wooden wall coverings

partition walls

load-bearing walls

residual material

The wood sector plays a crucial role in promoting sustainability by using renewable resources. Sustainable forestry practices ensure that trees are harvested responsibly, allowing forests to regenerate naturally. However, the main problem of woodworking factories in general is the low yield and significant amount of wood residues. Therefore, innovations in wood processing and manufacturing are essential for reducing waste and increasing the efficiency of used natural resources. To preserve the environment and mitigate climate change, it is crucial to note that wood stores carbon during its growth, with carbon making up about 25% of wood's mass. Globally, conventional buildings and constructions are responsible for ~40% of CO2 emissions and 70% of energy consumption, with steel and concrete production each accounting for 5% of global CO2 emissions. By replacing steel and concrete with wooden building materials, we can significantly mitigate climate change. Wood products have lower embodied energy, much lower air and water pollution, and a lower carbon footprint than concrete and steel, and wood can also contribute to a building's energy efficiency. The carbon footprint of a wooden building is about four times smaller than that of a conventional concrete and steel building. Sustainable wood products can be recycled or repurposed, extending their lifecycle and reducing landfill waste. By developing and modelling properties of new materials made of wood waste, we created alternative materials with good thermal properties and increased yield of high valued logs. Even more LCA (Life Cycle Assessment) was used as a tool to demonstrate the environmental impact of these products. By choosing sustainable wood products, consumers can contribute to environmental conservation and climate change mitigation. The industry is increasingly adopting circular economy principles, where wood waste is minimized and reused.

The growing impact of climate change and environmental issues indicates that the planet is approaching the limits of its sustainability. As a result of developing an innovative product from reused or recycled material, the emission of harmful greenhouse gases (GHG), which are the main cause of the greenhouse effect, will be reduced. On the other hand, wooden products offer a natural beauty that enhances the visual appeal of any space thanks to the unique grain patterns and texture which add character and warmth to interiors, allowing it to be used in both traditional and modern design styles. For the development and optimization of the wooden wall, we conducted industrial research in veneer production, tested the properties of wood materials and their impact on sandwich construction, investigated the thermal and acoustic properties of the developed sandwich panels, and the durability of the developed products in exterior and interior environments. The project resulted in the development of new practices that enable the production of innovative wood products, which is a prerequisite for the production of more complex products, currently unavailable in many wood industry factories. The project developed a modular wall cladding with a high content of waste oak veneer and modular partitions and load-bearing walls with a significantly higher content of wood residue, as this creates a better carbon footprint and greater well-being with natural beauty that enhances the visual appeal of any space. The final result of the project is a modular wooden wall cladding and sandwich construction, i.e. wall (partition and load-bearing), presented and integrated into the experimental bungalow, creating a design object that becomes attractive due to its elegant appearance. Finally, project results – the experimental bungalow has been already presented via open days, international conferences and media like TV.

The project aimed to regulate and increase the use of low-value waste materials in wood production as new products. Main idea is accessibility and reuse of raw materials, ensuring that individuals and the wood industry can benefit from innovation and reused waste materials. This involved designing user-friendly products and services and incorporating universal design principles. Another critical aspect is accessibility, as the project seeks to make sustainable and financially affordable solutions for different groups of end users. The project aims to reduce the costs of regular production without compromising quality and standard products and to increase profits by using low-value raw materials in new products, designing and optimizing production processes. Reusing materials and incorporating them into new products could reduce product prices, directly benefiting low-income producers and communities.

Inclusive management systems were integral to the project’s success. The project involved a variety of stakeholders, such as designers, producers, engineers and scientists. Community members, industry experts, policymakers and factory owners were also involved, ensuring that the solutions developed reflected the needs and preferences of all groups.

Furthermore, the project emphasized the need for education and raising awareness about the reuse of wood waste as a valuable raw material, which is part of the new European Bauhaus plan and a sustainable future for all.

Inclusive management systems were integral to the project’s success. The project involved a variety of stakeholders, such as designers, producers, engineers and scientists. Community members, industry experts, policymakers and factory owners were also involved, ensuring that the solutions developed reflected the needs and preferences of all groups.

Furthermore, the project emphasized the need for education and raising awareness about the reuse of wood waste as a valuable raw material, which is part of the new European Bauhaus plan and a sustainable future for all.

Future trends in overall construction relate to improving energy efficiency and reaching nZEB standard. Additionally, special attention was paid to ensure that the final product has the most favourable carbon footprint, i.e., to achieve eco-innovation. Currently, a large part of producer's product range consists of low-completion level products, i.e., products with low added value, which classifies producers as a producer of semi-finished products rather than high-value finished products. By implementing the results of this project, producers could transform their semi-products and waste material into high-value finished products for local and international markets. The innovation of the solution relates to energy efficiency and environmental friendliness with direct benefits for end users and civil society.

The increasing global population and decreasing availability of natural resources require market solutions that improve the energy efficiency of materials used in construction and creation of modular sustainable buildings that meet nZEB standard. The difference between future and existing solutions lies in energy efficiency and balancing thickness and type of materials to achieve optimal product properties. According to results of citizen survey as part of project, designs of products and needs were integrated in final products. The innovative wooden cladding are designed as: a) modular, but predominantly made of wood; b) lightweight – easier to handle – less energy consumption for transport; c) economical – by selecting materials, elements of the smallest possible thickness were achieved to meet the physical and mechanical properties of the building (load-bearing, thermal, and sound insulation); d) environmentally friendly – wood raw material requires much less energy in production than concrete, steel, aluminium, and plastic – creating a healthier environment by reducing the emission of harmful gases into the atmosphere, products.

The increasing global population and decreasing availability of natural resources require market solutions that improve the energy efficiency of materials used in construction and creation of modular sustainable buildings that meet nZEB standard. The difference between future and existing solutions lies in energy efficiency and balancing thickness and type of materials to achieve optimal product properties. According to results of citizen survey as part of project, designs of products and needs were integrated in final products. The innovative wooden cladding are designed as: a) modular, but predominantly made of wood; b) lightweight – easier to handle – less energy consumption for transport; c) economical – by selecting materials, elements of the smallest possible thickness were achieved to meet the physical and mechanical properties of the building (load-bearing, thermal, and sound insulation); d) environmentally friendly – wood raw material requires much less energy in production than concrete, steel, aluminium, and plastic – creating a healthier environment by reducing the emission of harmful gases into the atmosphere, products.

Today's market demands are much more complex than just the price-quality ratio. Current requirements also focus on resource sustainability, as described in EU-level documents (Horizon 2020 – societal challenges), where one of the long-term goals of the Europe 2020 Strategy is to invest in research and development at the level of 3% of the EU's GDP and to achieve the climate-energy goal "20/20/20". Additionally, we were aware of social responsibility in the local and wider community, especially since they used a valuable resource – Slavonian oak. Implementing of the project involved collaboration between the Faculty of Forestry and Wood Technology of the University of Zagreb and the Faculty of Civil Engineering and Architecture in Osijek (Josip Juraj Strossmayer University) and company Spačva d.d. Faculties designed, developed and tested materials and products, developed designs, processing parameters and components, and the factory Spačva prepared testing materials, human resources and implemented all the solutions in testing products. Each of the partners had their role in the project, but all the results together made the project successful - the development of newly added value products. The project was co-funded by European Regional Development Fund in Croatia.

The result of the project is innovative wooden wall cladding, partition, and load-bearing walls for sustainable construction, representing new industrial products that were applied for a patent.

The result of the project is innovative wooden wall cladding, partition, and load-bearing walls for sustainable construction, representing new industrial products that were applied for a patent.

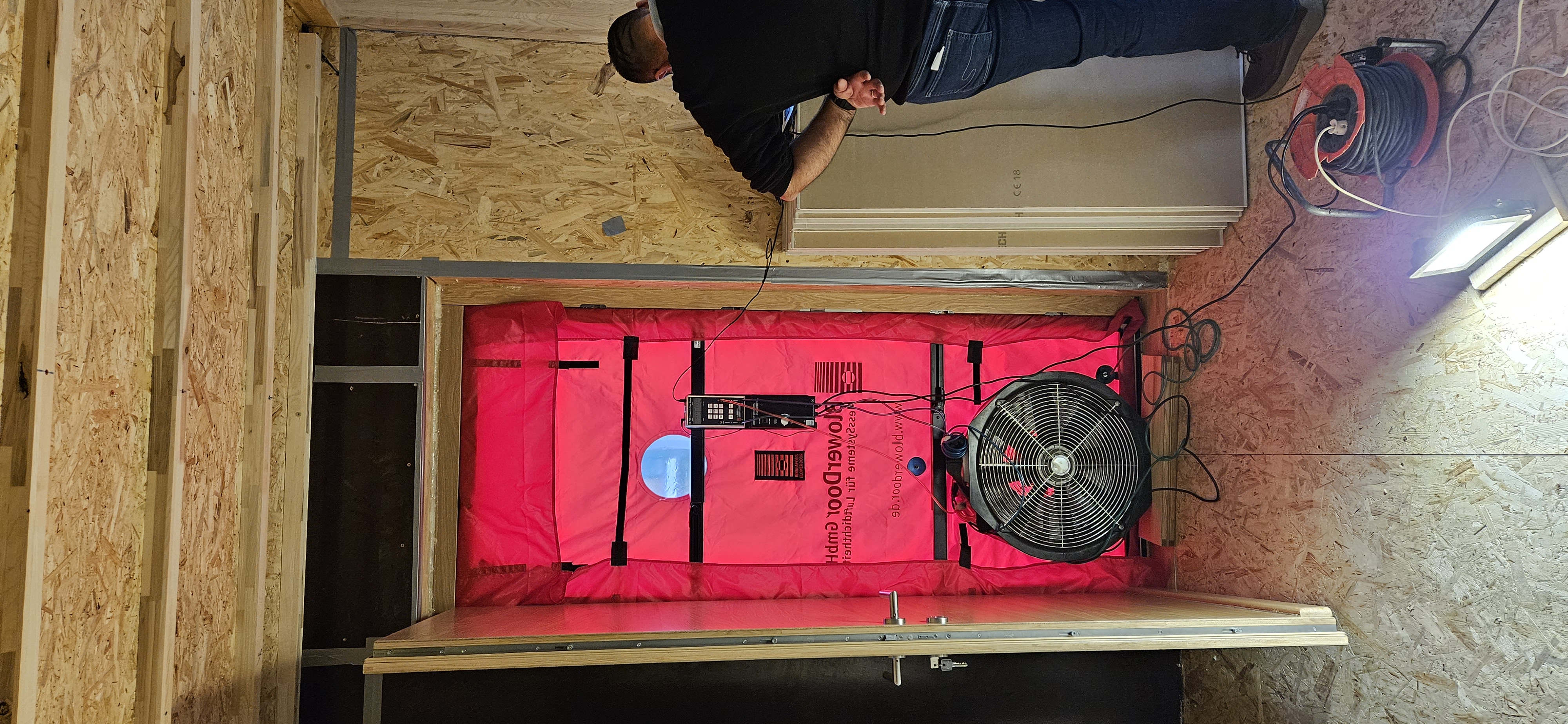

The project team was consisted of researchers with background in design, architecture, civil engineering, material science and wood technology. Representatives of the Faculty of Forestry and Wood Technology, University of Zagreb and the Faculty of Civil Engineering and Architecture, Osijek faculties formed essentially two working groups – one working mainly on the identification of residual materials and product design, and the other that focused on sample preparation, material testing, construction of experimental bungalow and in situ testing. Prior to in situ testing members of the project team dealt with optimization, development of wooden wall coverings and partition and load-bearing walls, LCA life cycle assesment, aesthetic design solutions, promotion and calculation of the load-bearing capacity of the structure. Team members from Spačva company took part in discussions on production optimization and assisted in preparation of samples.

The basis of the proposed project is precisely the development of an innovative product which contributes to the growth of economic activity through increased productivity and strengthening the intensity of knowledge and human capital in the area S3 (ENERGY AND SUSTAINABLE ENVIRONMENT and FOOD AND BIOECONOMY), i.e. the sub-thematic priority areas Energy technologies, systems and equipment - Environmentally acceptable technologies, equipment and advanced materials and Sustainable wood production and processing (new/advanced technologies in the production of solid furniture, wood cladding, passive buildings and other wood products).

To achieve all project goals, meetings were held monthly with all partners to create sustainable added-value products according to the company's needs, project goals and technological requirements.

The basis of the proposed project is precisely the development of an innovative product which contributes to the growth of economic activity through increased productivity and strengthening the intensity of knowledge and human capital in the area S3 (ENERGY AND SUSTAINABLE ENVIRONMENT and FOOD AND BIOECONOMY), i.e. the sub-thematic priority areas Energy technologies, systems and equipment - Environmentally acceptable technologies, equipment and advanced materials and Sustainable wood production and processing (new/advanced technologies in the production of solid furniture, wood cladding, passive buildings and other wood products).

To achieve all project goals, meetings were held monthly with all partners to create sustainable added-value products according to the company's needs, project goals and technological requirements.

The goal of this activity was to develop an innovative and technologically significantly improved product – innovative oak wall claddings and sandwich panels for partition and load-bearing walls and ceilings.

Areas of innovation include: modularity, lightweight, economical and ecological benefits.

Modularity – by combining finished modules, it is possible to create buildings of different sizes. To achieve modularity, elements of partition and load-bearing walls, as well as floor and ceiling panels, are designed as a kind of sandwich consisting of a load-bearing frame made of solid or laminated wood, fillings of thermal and sound insulation materials, outer cladding that stiffens the frame and ensures waterproofing, and additional cladding that, in the case of wall panels, represents the facade element in the exterior or decorative wall cladding in the interior. Floor panels additionally include floor coverings, and ceiling panels have final roof waterproofing on the outside and decorative ceiling cladding on the inside.

Lightweight – elements of lower mass are easier to handle, and there is less energy consumption for transport, thus having a more favorable environmental impact.

Economical – by carefully selecting materials, we aim to design elements of the smallest possible dimensions to meet all the physical and mechanical properties of the building (load-bearing capacity, thermal and sound insulation, ventilation, etc.) to optimally utilize space and achieve the largest possible usable area in the gross developed area of the building.

Environmentally friendly - converting wood residues from regular production that are usually used as energy source into highly value added and long lasting products directly increases yield of the raw material thus creating benefit for the environment.

Areas of innovation include: modularity, lightweight, economical and ecological benefits.

Modularity – by combining finished modules, it is possible to create buildings of different sizes. To achieve modularity, elements of partition and load-bearing walls, as well as floor and ceiling panels, are designed as a kind of sandwich consisting of a load-bearing frame made of solid or laminated wood, fillings of thermal and sound insulation materials, outer cladding that stiffens the frame and ensures waterproofing, and additional cladding that, in the case of wall panels, represents the facade element in the exterior or decorative wall cladding in the interior. Floor panels additionally include floor coverings, and ceiling panels have final roof waterproofing on the outside and decorative ceiling cladding on the inside.

Lightweight – elements of lower mass are easier to handle, and there is less energy consumption for transport, thus having a more favorable environmental impact.

Economical – by carefully selecting materials, we aim to design elements of the smallest possible dimensions to meet all the physical and mechanical properties of the building (load-bearing capacity, thermal and sound insulation, ventilation, etc.) to optimally utilize space and achieve the largest possible usable area in the gross developed area of the building.

Environmentally friendly - converting wood residues from regular production that are usually used as energy source into highly value added and long lasting products directly increases yield of the raw material thus creating benefit for the environment.

Our approach to developing a new project was divided into several phases. In the first phase, we defined objectives that clearly outline the projects' goals, focusing on sustainability, innovation, and market needs. After that, we engaged key stakeholders and identified their needs, those of other organizations and partners, and potential customers to gather insights and support.

The second phase was research and analysis of technological problems, and comprehensive market research was conducted to understand current trends and consumer preferences in sustainable products. Then, we evaluated existing products and processes to identify areas for improvement regarding environmental impact, resource efficiency, and lifecycle sustainability. In the next step, after developing innovative concepts of new products incorporating eco-friendly materials and energy-efficient designs with partners, we created and integrated prototypes of the proposed products using sustainable materials and technologies into the bungalow. For all new products, we performed a Lifecycle Assesment (LCA), a detailed to assess the ecological impact of the product from raw material extraction to end-of-life disposal. The final step was developing a production plan that incorporates sustainable manufacturing practices, such as waste reduction, energy efficiency, and the use of renewable resources as a company strategy and business decision. As part of the project, we created a pilot object at the Faculty of Forestry and Wood Technology. The goal of this activity was to refine processes and address any issues before full-scale production. During the last installation process, control measurement units were implemented in the bungalow to ensure quality, long-term monitoring, and performance investigations of final products meet sustainability and performance standards. All results were documented, and the sustainability achievements were reported, showcasing the benefits and lessons learned.

The second phase was research and analysis of technological problems, and comprehensive market research was conducted to understand current trends and consumer preferences in sustainable products. Then, we evaluated existing products and processes to identify areas for improvement regarding environmental impact, resource efficiency, and lifecycle sustainability. In the next step, after developing innovative concepts of new products incorporating eco-friendly materials and energy-efficient designs with partners, we created and integrated prototypes of the proposed products using sustainable materials and technologies into the bungalow. For all new products, we performed a Lifecycle Assesment (LCA), a detailed to assess the ecological impact of the product from raw material extraction to end-of-life disposal. The final step was developing a production plan that incorporates sustainable manufacturing practices, such as waste reduction, energy efficiency, and the use of renewable resources as a company strategy and business decision. As part of the project, we created a pilot object at the Faculty of Forestry and Wood Technology. The goal of this activity was to refine processes and address any issues before full-scale production. During the last installation process, control measurement units were implemented in the bungalow to ensure quality, long-term monitoring, and performance investigations of final products meet sustainability and performance standards. All results were documented, and the sustainability achievements were reported, showcasing the benefits and lessons learned.

The project encompasses several elements that can be replicated or transferred to other locations, beneficiary groups, and contexts, ensuring sustainability such as:

Methodology: The project’s comprehensive approach to sustainable product development can be adapted to various contexts. This includes stakeholder engagement, market research, lifecycle analysis (LCA), and participatory design processes.

Technology: The innovative technologies developed for producing wooden wall claddings and sandwich panels can be transferred to other companies. Different manufacturers can adopt these technologies to produce similar sustainable products.

Processes: The sustainable manufacturing processes implemented in the project, such as waste reduction, energy-efficient production, and the use of renewable resources, can be replicated in other wood processing and construction industries.

Products: The modular wooden wall claddings, partitions, and load-bearing walls developed in the project can be adapted for use in different buildings and environments. These versatile products meet the specific requirements of residential, commercial, and public buildings in various regions.

Learnings: The project's results, including best practices for sustainable construction, challenges encountered, and solutions developed, can be shared with other stakeholders.

Community Engagement: The project’s emphasis on involving local communities and stakeholders in the development process can be replicated to ensure that solutions are inclusive and address the needs of diverse groups. This participatory approach fosters ownership and ensures the sustainability of the initiatives.

Environmental Impact: The project’s focus on reducing carbon footprint, preserving resources, and promoting biodiversity can be replicated in other environmental initiatives. The methodologies for assessing and minimizing environmental impact can be applied to various projects aiming for sustainability.

Methodology: The project’s comprehensive approach to sustainable product development can be adapted to various contexts. This includes stakeholder engagement, market research, lifecycle analysis (LCA), and participatory design processes.

Technology: The innovative technologies developed for producing wooden wall claddings and sandwich panels can be transferred to other companies. Different manufacturers can adopt these technologies to produce similar sustainable products.

Processes: The sustainable manufacturing processes implemented in the project, such as waste reduction, energy-efficient production, and the use of renewable resources, can be replicated in other wood processing and construction industries.

Products: The modular wooden wall claddings, partitions, and load-bearing walls developed in the project can be adapted for use in different buildings and environments. These versatile products meet the specific requirements of residential, commercial, and public buildings in various regions.

Learnings: The project's results, including best practices for sustainable construction, challenges encountered, and solutions developed, can be shared with other stakeholders.

Community Engagement: The project’s emphasis on involving local communities and stakeholders in the development process can be replicated to ensure that solutions are inclusive and address the needs of diverse groups. This participatory approach fosters ownership and ensures the sustainability of the initiatives.

Environmental Impact: The project’s focus on reducing carbon footprint, preserving resources, and promoting biodiversity can be replicated in other environmental initiatives. The methodologies for assessing and minimizing environmental impact can be applied to various projects aiming for sustainability.

From our point of view there are several global challenges to which the project directly contributes:

Economic development: The project supports local economies by creating jobs in sustainable forestry, wood processing, and construction, fostering economic growth and resilience in local communities.

Health and well-being: wooden houses and products offer healthier living environments. They use natural materials that improve indoor air quality and create a sense of well-being, enhancing residents' quality of life.

Climate change mitigation: wooden houses/products significantly reduce carbon emissions by using sustainable materials and energy-efficient designs, contributing to the fight against global warming.

Rational use of resources: The project promotes the use of renewable wood resources and sustainable forestry practices, helping to conserve finite natural resources and ensure their long-term availability.

Waste management: Converting wood waste from the factory into construction materials reduces waste generation and supports a circular economy, minimizing the environmental impact of construction activities.

Energy consumption: Wooden houses are designed for energy efficiency, lowering the overall energy demand for heating and cooling. This addresses global energy challenges and reduces reliance on non-renewable energy sources.

Urbanization - the modular houses provides flexible and adaptable housing solutions to accommodate the growing urban population, easing the pressure on urban infrastructure.

Last but not least, affordable housing - by optimizing production processes and using cost-effective materials, the project makes sustainable housing more affordable and accessible, particularly for low-income communities.

By addressing these global challenges with innovative local solutions, the project contributes to a more sustainable, equitable, and resilient future.

Economic development: The project supports local economies by creating jobs in sustainable forestry, wood processing, and construction, fostering economic growth and resilience in local communities.

Health and well-being: wooden houses and products offer healthier living environments. They use natural materials that improve indoor air quality and create a sense of well-being, enhancing residents' quality of life.

Climate change mitigation: wooden houses/products significantly reduce carbon emissions by using sustainable materials and energy-efficient designs, contributing to the fight against global warming.

Rational use of resources: The project promotes the use of renewable wood resources and sustainable forestry practices, helping to conserve finite natural resources and ensure their long-term availability.

Waste management: Converting wood waste from the factory into construction materials reduces waste generation and supports a circular economy, minimizing the environmental impact of construction activities.

Energy consumption: Wooden houses are designed for energy efficiency, lowering the overall energy demand for heating and cooling. This addresses global energy challenges and reduces reliance on non-renewable energy sources.

Urbanization - the modular houses provides flexible and adaptable housing solutions to accommodate the growing urban population, easing the pressure on urban infrastructure.

Last but not least, affordable housing - by optimizing production processes and using cost-effective materials, the project makes sustainable housing more affordable and accessible, particularly for low-income communities.

By addressing these global challenges with innovative local solutions, the project contributes to a more sustainable, equitable, and resilient future.

According to the attached pictures, which demonstrate the results of project, it is clear that waste residual material could be converted into long lasting and visually attractive products with high-added value. Also, there is a short YouTube video recorded by Croatian National Television HRT in the show EKO ZONA (https://www.youtube.com/watch?v=6Sp8Zl1wpL8) which generally promotes eco friendly solutions. Some research results were presented in scientific papers. When we are speaking about the project's benefits for direct and indirect beneficiaries, we can say that the direct benefit has the wood industries using their own residual and waste materials – low-value materials turned into high-value products for the local community and export markets. In 2020 in Croatia was an earthquake of magnitude 6.4 Mw, with the epicenter located 3 km west-southwest of Petrinja. The adversely affected areas were mostly in the Sisak-Moslavina County and a lot of our citizens lost their houses. Using low-value material, residuals could also be a good alternative to help people with reasonable prices of elements but with extraordinary products at the ends. Please see the attached pictures of final products with integrated new elements. Other advantages of using wood as a building material is that wood is a renewable resource, meaning it can be replenished naturally over time, unlike competitive materials such as metals and plastics. Wood stores carbon dioxide absorbed during tree growth, helping to reduce greenhouse gases in the atmosphere; wood is biodegradable, meaning it can decompose naturally without harming the environment; unlike synthetic materials, wood can be reused and recycled into new products, extending its lifecycle and reducing the need for new origin materials. An additional advantage of using wood as a reused material is that it supports the principles of a circular economy, where resources are kept in use for as long as possible, minimizing environmental impact.