Shaping a circular industrial ecosystem and supporting life-cycle thinking

Indusbath

Prototyping and Analysis of Modular Bathroom Industrialization for Residential Construction

INDUSBATH revolutionizes construction with plug & play modular bathrooms, reducing time, costs, and waste. Designed for social housing, rentals, student residences, and hotels, it combines efficiency, sustainability, and high-quality design, paving the way for a faster, circular, and adaptable future in construction.

Spain

National

Mainly urban

It refers to a physical transformation of the built environment (hard investment)

Yes

2024-12-31

No

No

No

As a representative of an organisation, in partnership with other organisations

INDUSBATH aims to revolutionize the construction sector by developing modular, industrialized bathroom solutions tailored for residential buildings. The project seeks to enhance efficiency, sustainability, and quality in construction through prefabricated bathroom modules that reduce onsite labor, optimize costs, and minimize environmental impact.

Target Groups

Our modular bathroom solutions are designed for diverse residential segments, including:

• Build-to-Rent (BTR): Durable and cost-effective solutions for rental housing.

• Social Housing (VPO): Affordable and standardized designs ensuring high efficiency.

• Student Residences: Practical and robust modules for shared accommodations.

• Hospitality Sector: High-quality, customizable solutions for hotels.

Specific Objectives

• Develop and prototype four modular bathroom designs (BTR, BTS_1, BTS_2, STUDENT) adaptable to different market needs.

• Ensure sustainability by integrating low-carbon materials, energy-efficient fixtures, and modular design principles.

• Reduce construction time and costs by implementing plug & play installation, reducing waste, and improving logistics.

• Validate industrialized bathroom solutions through real-world testing in a residential building pilot project.

Target Groups

Our modular bathroom solutions are designed for diverse residential segments, including:

• Build-to-Rent (BTR): Durable and cost-effective solutions for rental housing.

• Social Housing (VPO): Affordable and standardized designs ensuring high efficiency.

• Student Residences: Practical and robust modules for shared accommodations.

• Hospitality Sector: High-quality, customizable solutions for hotels.

Specific Objectives

• Develop and prototype four modular bathroom designs (BTR, BTS_1, BTS_2, STUDENT) adaptable to different market needs.

• Ensure sustainability by integrating low-carbon materials, energy-efficient fixtures, and modular design principles.

• Reduce construction time and costs by implementing plug & play installation, reducing waste, and improving logistics.

• Validate industrialized bathroom solutions through real-world testing in a residential building pilot project.

Prefabricated Bathroom Modules

Low-Carbon Construction

Modular Construction

Plug & Play Installation

BIM-Driven Design

INDUSBATH has been designed with sustainability at its core, focusing on reducing the environmental impact of bathroom construction through industrialized, modular solutions. One of its main objectives is to minimize the carbon footprint associated with traditional onsite bathroom construction. By shifting to an offsite prefabrication model, the project significantly reduces CO₂ emissions linked to material transportation, inefficient construction processes, and excessive onsite labor. The bathroom modules incorporate low-carbon materials, such as lightweight drywall and prefabricated concrete bases, while future plans include obtaining life cycle assessment (LCA) certification to validate the project's carbon reduction strategies.

Another key sustainability goal is resource efficiency, ensuring that materials are used optimally to minimize waste. INDUSBATH achieves this by standardizing and industrializing the bathroom design, making it possible to reduce material waste by up to 30% compared to traditional construction. The use of digital modeling with BIM and Autodesk Revit enables precise material estimation, reducing excess production and improving efficiency. Additionally, the plug & play installation system eliminates errors in execution, reducing the need for rework and additional resource consumption.

The project also prioritizes water and energy efficiency by integrating low-flow plumbing fixtures that significantly reduce water consumption, in line with EU efficiency standards. The modular bathroom units are designed with optimized thermal insulation and smart ventilation systems, contributing to lower energy consumption in the buildings where they are installed. This ensures long-term sustainability by enhancing the energy performance of residential and hospitality spaces.

Another key sustainability goal is resource efficiency, ensuring that materials are used optimally to minimize waste. INDUSBATH achieves this by standardizing and industrializing the bathroom design, making it possible to reduce material waste by up to 30% compared to traditional construction. The use of digital modeling with BIM and Autodesk Revit enables precise material estimation, reducing excess production and improving efficiency. Additionally, the plug & play installation system eliminates errors in execution, reducing the need for rework and additional resource consumption.

The project also prioritizes water and energy efficiency by integrating low-flow plumbing fixtures that significantly reduce water consumption, in line with EU efficiency standards. The modular bathroom units are designed with optimized thermal insulation and smart ventilation systems, contributing to lower energy consumption in the buildings where they are installed. This ensures long-term sustainability by enhancing the energy performance of residential and hospitality spaces.

INDUSBATH is designed not only as a functional and sustainable solution but also as an aesthetically refined and user-centered approach to bathroom construction. The project aims to elevate the quality of experience for end-users by integrating high-quality design, customizable aesthetics, and ergonomic principles while maintaining the efficiency and scalability of modular construction. By rethinking the traditional perception of prefabricated bathrooms, INDUSBATH combines sophisticated design choices, material versatility, and cultural adaptability to enhance both the visual and sensory experience of users.

A key objective is to ensure high-end aesthetics and adaptability within the constraints of modular construction. The design process was guided by BIM and Autodesk Revit modeling, allowing for meticulous detailing of materials, textures, and finishes. Unlike conventional prefabricated bathrooms, which often compromise on aesthetics for efficiency, INDUSBATH prioritizes clean, modern, and timeless design elements. The use of minimalist forms, high-quality finishes, and refined material combinations results in visually appealing spaces that seamlessly integrate into different architectural contexts.

A key objective is to ensure high-end aesthetics and adaptability within the constraints of modular construction. The design process was guided by BIM and Autodesk Revit modeling, allowing for meticulous detailing of materials, textures, and finishes. Unlike conventional prefabricated bathrooms, which often compromise on aesthetics for efficiency, INDUSBATH prioritizes clean, modern, and timeless design elements. The use of minimalist forms, high-quality finishes, and refined material combinations results in visually appealing spaces that seamlessly integrate into different architectural contexts.

INDUSBATH is designed with a strong commitment to inclusion, ensuring that modular, prefabricated bathroom solutions are not only accessible and affordable but also adaptable to diverse social and economic contexts. The project seeks to address barriers in construction by making high-quality, sustainable bathrooms available to a wide range of users, including those in social housing, student accommodations, rental housing, and hospitality. By combining universal design principles, cost-effective industrialization, and flexible integration into various building types, INDUSBATH promotes an equitable approach to architecture and construction.

A fundamental objective is to enhance accessibility through universal design principles. The modular bathrooms can be configured to meet barrier-free accessibility standards, ensuring that individuals with reduced mobility or specific needs can use the facilities comfortably. Features such as optimized layouts, accessible entry points, and adaptable fixture placements make these units inclusive for all users. In addition, the plug & play installation system facilitates the incorporation of customized accessibility features, allowing for adjustments based on different regulations or project requirements.

A fundamental objective is to enhance accessibility through universal design principles. The modular bathrooms can be configured to meet barrier-free accessibility standards, ensuring that individuals with reduced mobility or specific needs can use the facilities comfortably. Features such as optimized layouts, accessible entry points, and adaptable fixture placements make these units inclusive for all users. In addition, the plug & play installation system facilitates the incorporation of customized accessibility features, allowing for adjustments based on different regulations or project requirements.

INDUSBATH has actively engaged citizens, end-users, and civil society throughout its development to ensure that the modular bathroom solutions are not only technically and environmentally efficient but also user-centered, accessible, and adaptable to real needs. The involvement of key stakeholders has played a crucial role in shaping the project’s design, functionality, and overall impact.

To better understand the preferences, expectations, and accessibility needs of users, INDUSBATH conducted consultations with residents, social housing tenants, and property developers. These insights helped refine the design of the bathroom modules, ensuring ergonomic layouts, adaptable accessibility features, and improved ease of use. This engagement was particularly significant for social housing and Build-to-Rent projects, where affordability and durability are essential factors.

The project also collaborated with housing agencies and urban development organizations to align INDUSBATH’s solutions with broader affordable housing and sustainability initiatives. By integrating their feedback, the project ensured that its modular bathrooms comply with accessibility regulations, optimize space in compact residential units, and support long-term energy efficiency goals.

Moreover, civil society organizations focused on inclusive design and circular economy principles contributed to shaping INDUSBATH’s sustainability strategy. Their input reinforced the importance of using recyclable materials, ensuring ease of disassembly, and minimizing waste generation, all of which are fundamental to the project’s commitment to life-cycle thinking and circular construction practices.

The impact of this engagement has been substantial, leading to bathroom modules that are more inclusive, adaptable, and environmentally responsible. The collaboration with different stakeholders has strengthened INDUSBATH’s potential to be replicated, making sustainable, high-quality modular solutions.

To better understand the preferences, expectations, and accessibility needs of users, INDUSBATH conducted consultations with residents, social housing tenants, and property developers. These insights helped refine the design of the bathroom modules, ensuring ergonomic layouts, adaptable accessibility features, and improved ease of use. This engagement was particularly significant for social housing and Build-to-Rent projects, where affordability and durability are essential factors.

The project also collaborated with housing agencies and urban development organizations to align INDUSBATH’s solutions with broader affordable housing and sustainability initiatives. By integrating their feedback, the project ensured that its modular bathrooms comply with accessibility regulations, optimize space in compact residential units, and support long-term energy efficiency goals.

Moreover, civil society organizations focused on inclusive design and circular economy principles contributed to shaping INDUSBATH’s sustainability strategy. Their input reinforced the importance of using recyclable materials, ensuring ease of disassembly, and minimizing waste generation, all of which are fundamental to the project’s commitment to life-cycle thinking and circular construction practices.

The impact of this engagement has been substantial, leading to bathroom modules that are more inclusive, adaptable, and environmentally responsible. The collaboration with different stakeholders has strengthened INDUSBATH’s potential to be replicated, making sustainable, high-quality modular solutions.

INDUSBATH has engaged stakeholders at local, regional, national, and European levels, ensuring a comprehensive and collaborative approach in the design and implementation of the project. This multi-level engagement has contributed to the project’s technical development, market scalability, and alignment with sustainability and housing policies.

At the local level, INDUSBATH collaborated with municipal housing agencies, social housing providers, and construction companies to ensure that the modular bathroom solutions align with urban housing needs, accessibility regulations, and real-world construction constraints. These collaborations provided essential feedback on space efficiency, adaptability, and ease of installation, which directly influenced the design and functionality of the prefabricated units.

At the regional level, the project benefited from the involvement of Basque industry clusters, research institutions, and sustainability organizations. Through these partnerships, INDUSBATH integrated advanced industrialized construction methods, circular economy strategies, and energy-efficient technologies. This regional support also facilitated pilot project testing, ensuring the solutions were validated in real housing developments.

At the national level, engagement with housing policymakers, construction industry associations, and public-private partnerships played a crucial role in aligning INDUSBATH with Spain’s sustainable construction strategies and affordable housing policies. National stakeholders provided insights into standardization, regulatory compliance, and market adoption, helping to position INDUSBATH as a scalable solution for large-scale residential projects.

At the European level, INDUSBATH connects with EU initiatives promoting circular economy principles, industrialized construction, and sustainable urban development.

At the local level, INDUSBATH collaborated with municipal housing agencies, social housing providers, and construction companies to ensure that the modular bathroom solutions align with urban housing needs, accessibility regulations, and real-world construction constraints. These collaborations provided essential feedback on space efficiency, adaptability, and ease of installation, which directly influenced the design and functionality of the prefabricated units.

At the regional level, the project benefited from the involvement of Basque industry clusters, research institutions, and sustainability organizations. Through these partnerships, INDUSBATH integrated advanced industrialized construction methods, circular economy strategies, and energy-efficient technologies. This regional support also facilitated pilot project testing, ensuring the solutions were validated in real housing developments.

At the national level, engagement with housing policymakers, construction industry associations, and public-private partnerships played a crucial role in aligning INDUSBATH with Spain’s sustainable construction strategies and affordable housing policies. National stakeholders provided insights into standardization, regulatory compliance, and market adoption, helping to position INDUSBATH as a scalable solution for large-scale residential projects.

At the European level, INDUSBATH connects with EU initiatives promoting circular economy principles, industrialized construction, and sustainable urban development.

INDUSBATH has been developed through a highly interdisciplinary approach, integrating expertise from architecture, engineering, industrial design, sustainability, logistics, and construction management. This collaboration ensures that the modular bathroom system is technically feasible, aesthetically refined, sustainable, and efficiently manufacturable. The interaction between these fields has created a synergistic workflow, driving innovation in design, material selection, production processes, and installation methods. INDUSHOUSE has led the technical and aesthetic design of the bathroom modules, developing BIM models and Revit-based digital prototypes to allow precise planning and integration into building projects. It has also focused on structural integrity, energy efficiency, and sustainable materials, designing and optimizing plumbing and electrical systems for plug & play installation while ensuring thermal performance and low-carbon solutions. Additionally, INDUSHOUSE has managed the manufacturing process, ensuring efficient large-scale production, modular adaptability, and streamlined logistics. The company has overseen the prototyping phase, testing materials and configurations before scaling production, and has provided expertise in site integration, coordinating real-world testing to validate installation feasibility and long-term performance. Cluster HABIC, as project manager, has facilitated cross-disciplinary collaboration, ensuring smooth communication between architects, engineers, manufacturers, and developers. It has also managed compliance with funding requirements (Eraikal 2023) and coordinated documentation and dissemination of results. Furthermore, HABIC has engaged industry and policy stakeholders, promoting INDUSBATH at sector events like the Basque Tech Summit to drive adoption and scalability. Through this strategic partnership, INDUSBATH establishes itself as an innovative, scalable, and sustainable solution.

INDUSBATH redefines modular bathroom construction by combining customization, sustainability, and industrial efficiency, setting it apart from conventional prefabricated solutions.

Unlike mainstream prefabricated bathrooms, which are often rigid and uniform, INDUSBATH offers highly customizable, modular designs tailored to diverse housing needs, including social housing, rentals, student residences, and hotels. The use of BIM and Autodesk Revit ensures precision, optimizing both design flexibility and production efficiency.

The project also integrates plug & play installation, drastically reducing onsite labor, waste, and construction time compared to traditional methods. Additionally, its low-carbon materials, circular economy approach, and planned life cycle assessments go beyond current industry sustainability standards.

By bridging industrialized construction with high-end design and real-world adaptability, INDUSBATH challenges the perception of prefabrication, offering a scalable, efficient, and aesthetically refined alternative to conventional building methods.

Unlike mainstream prefabricated bathrooms, which are often rigid and uniform, INDUSBATH offers highly customizable, modular designs tailored to diverse housing needs, including social housing, rentals, student residences, and hotels. The use of BIM and Autodesk Revit ensures precision, optimizing both design flexibility and production efficiency.

The project also integrates plug & play installation, drastically reducing onsite labor, waste, and construction time compared to traditional methods. Additionally, its low-carbon materials, circular economy approach, and planned life cycle assessments go beyond current industry sustainability standards.

By bridging industrialized construction with high-end design and real-world adaptability, INDUSBATH challenges the perception of prefabrication, offering a scalable, efficient, and aesthetically refined alternative to conventional building methods.

INDUSBATH follows a multidisciplinary, iterative, and user-centered approach to developing modular, industrialized bathroom solutions. The methodology integrates digital design, prefabrication, sustainability, and real-world testing, ensuring that the final product is both efficient and adaptable to different housing models.

The project began with BIM-based digital modeling (Autodesk Revit) to create detailed prototypes, allowing for precise material calculations, structural testing, and optimization of production processes before physical fabrication. A collaborative workflow between architects, engineers, and manufacturers ensured that design, technical feasibility, and industrial scalability were aligned from the start.

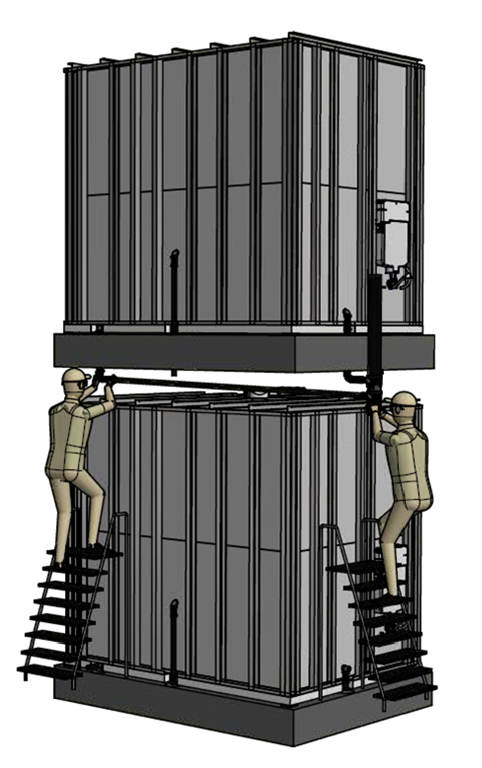

The prefabrication process was refined through prototype testing, where four different modular bathroom models were manufactured and evaluated for structural integrity, plumbing, electrical efficiency, and ease of installation. A plug & play system was implemented to streamline onsite integration, significantly reducing construction time, material waste, and labor requirements.

A key part of the methodology was sustainability assessment, focusing on low-carbon materials, circular economy principles, and long-term energy efficiency. Future life cycle assessments (LCA) and carbon footprint certifications are planned to further validate INDUSBATH’s environmental impact.

Finally, real-world validation was secured through collaboration with public housing developers (VISESA), ensuring the system’s practical application in affordable and large-scale residential projects. This iterative testing and stakeholder engagement allowed for continuous improvements, making INDUSBATH a scalable, market-ready solution for sustainable modular construction.

The project began with BIM-based digital modeling (Autodesk Revit) to create detailed prototypes, allowing for precise material calculations, structural testing, and optimization of production processes before physical fabrication. A collaborative workflow between architects, engineers, and manufacturers ensured that design, technical feasibility, and industrial scalability were aligned from the start.

The prefabrication process was refined through prototype testing, where four different modular bathroom models were manufactured and evaluated for structural integrity, plumbing, electrical efficiency, and ease of installation. A plug & play system was implemented to streamline onsite integration, significantly reducing construction time, material waste, and labor requirements.

A key part of the methodology was sustainability assessment, focusing on low-carbon materials, circular economy principles, and long-term energy efficiency. Future life cycle assessments (LCA) and carbon footprint certifications are planned to further validate INDUSBATH’s environmental impact.

Finally, real-world validation was secured through collaboration with public housing developers (VISESA), ensuring the system’s practical application in affordable and large-scale residential projects. This iterative testing and stakeholder engagement allowed for continuous improvements, making INDUSBATH a scalable, market-ready solution for sustainable modular construction.

INDUSBATH’s modular, prefabricated bathroom system is designed to be highly scalable and adaptable, making it transferable to various geographic locations, housing sectors, and construction contexts. Its methodology, technology, and production processes offer multiple elements that can be replicated or customized for different environments.

The BIM-based digital design approach (Autodesk Revit) enables precise planning and seamless integration into diverse architectural projects, making the system adaptable to different building typologies worldwide. This allows architects, engineers, and developers to easily modify or optimize the modules based on local regulations, climate conditions, or user needs.

The plug & play prefabrication system significantly reduces onsite labor, material waste, and construction time, making it ideal for high-density urban developments, emergency housing, and large-scale residential projects. This approach is scalable to other regions, particularly in areas facing housing shortages, labor constraints, or strict environmental regulations.

INDUSBATH’s sustainability model, which includes low-carbon materials, circular economy principles, and planned life cycle assessments (LCA), can also be replicated in other industrialized construction projects. The use of standardized yet customizable components allows for adaptation to different cultural preferences, economic conditions, and housing markets, from social housing and rental units to student accommodations and hotels.

Additionally, collaborative governance and stakeholder engagement have been key to the project’s success. The partnership model between public institutions, private developers, and construction experts can be transferred to other regions looking to implement efficient, affordable, and sustainable building solutions.

The BIM-based digital design approach (Autodesk Revit) enables precise planning and seamless integration into diverse architectural projects, making the system adaptable to different building typologies worldwide. This allows architects, engineers, and developers to easily modify or optimize the modules based on local regulations, climate conditions, or user needs.

The plug & play prefabrication system significantly reduces onsite labor, material waste, and construction time, making it ideal for high-density urban developments, emergency housing, and large-scale residential projects. This approach is scalable to other regions, particularly in areas facing housing shortages, labor constraints, or strict environmental regulations.

INDUSBATH’s sustainability model, which includes low-carbon materials, circular economy principles, and planned life cycle assessments (LCA), can also be replicated in other industrialized construction projects. The use of standardized yet customizable components allows for adaptation to different cultural preferences, economic conditions, and housing markets, from social housing and rental units to student accommodations and hotels.

Additionally, collaborative governance and stakeholder engagement have been key to the project’s success. The partnership model between public institutions, private developers, and construction experts can be transferred to other regions looking to implement efficient, affordable, and sustainable building solutions.

INDUSBATH addresses critical global challenges in housing, sustainability, and construction efficiency by providing innovative, locally developed solutions.

One of the main global challenges is the housing crisis, particularly the need for affordable, high-quality housing in urban environments. Traditional construction methods often struggle to meet demand due to high costs, long project timelines, and labor shortages. INDUSBATH tackles this issue by offering modular, prefabricated bathroom solutions that significantly reduce construction time and costs, making housing projects more efficient and accessible.

Another major challenge is environmental sustainability. The construction industry is responsible for a large percentage of global carbon emissions and material waste. INDUSBATH addresses this by integrating low-carbon materials, circular economy principles, and energy-efficient fixtures, ensuring that each modular bathroom reduces environmental impact. The plug & play system further minimizes waste by optimizing resource use and avoiding common inefficiencies in traditional construction.

Additionally, INDUSBATH provides solutions to the need for resilient and adaptable urban infrastructure. As cities grow and evolve, there is a demand for construction methods that are scalable, flexible, and adaptable to different housing models. INDUSBATH’s modular approach allows its solutions to be implemented in various sectors, from social housing and Build-to-Rent developments to student accommodations and hotels, ensuring that different housing needs are met efficiently.

By applying these solutions locally in Spain, INDUSBATH creates a model that can be replicated and adapted globally, contributing to sustainable urban development, improved housing affordability, and reduced environmental impact on a broader scale.

One of the main global challenges is the housing crisis, particularly the need for affordable, high-quality housing in urban environments. Traditional construction methods often struggle to meet demand due to high costs, long project timelines, and labor shortages. INDUSBATH tackles this issue by offering modular, prefabricated bathroom solutions that significantly reduce construction time and costs, making housing projects more efficient and accessible.

Another major challenge is environmental sustainability. The construction industry is responsible for a large percentage of global carbon emissions and material waste. INDUSBATH addresses this by integrating low-carbon materials, circular economy principles, and energy-efficient fixtures, ensuring that each modular bathroom reduces environmental impact. The plug & play system further minimizes waste by optimizing resource use and avoiding common inefficiencies in traditional construction.

Additionally, INDUSBATH provides solutions to the need for resilient and adaptable urban infrastructure. As cities grow and evolve, there is a demand for construction methods that are scalable, flexible, and adaptable to different housing models. INDUSBATH’s modular approach allows its solutions to be implemented in various sectors, from social housing and Build-to-Rent developments to student accommodations and hotels, ensuring that different housing needs are met efficiently.

By applying these solutions locally in Spain, INDUSBATH creates a model that can be replicated and adapted globally, contributing to sustainable urban development, improved housing affordability, and reduced environmental impact on a broader scale.

INDUSBATH has achieved significant results in sustainability, efficiency, and industrial scalability, directly contributing to the "Shaping a circular industrial ecosystem and supporting life-cycle thinking" category. The project has demonstrated how modular, prefabricated bathrooms can transform construction by reducing waste, optimizing resources, and improving building sustainability. By integrating low-carbon materials, such as lightweight drywall and prefabricated concrete bases, INDUSBATH reduces CO₂ emissions associated with transportation and traditional construction. Additionally, optimized manufacturing processes cut material waste by up to 30%, while water- and energy-efficient fixtures align with EU standards, promoting sustainable building practices. The industrialization of bathroom construction has led to the development and prototyping of four modular bathroom models, each tailored to different market needs, including Build-to-Rent, social housing, student residences, and hospitality. The implementation of a plug & play installation system reduces onsite labor and accelerates construction timelines by 50%, while BIM-driven design ensures precise material estimation, eliminating execution errors and enhancing efficiency. INDUSBATH also integrates circular economy principles, with modular units designed for easy disassembly and material recovery, extending product life cycles and minimizing waste. Additionally, future Life Cycle Assessment (LCA) certification will validate its long-term sustainability impact. The project has benefited multiple stakeholders, including developers and builders, who experience reduced costs and faster project completion, and end-users, who gain high-quality, eco-friendly, and accessible bathroom spaces. Moreover, manufacturers and suppliers benefit from increased demand for industrialized, sustainable solutions, while the construction sector as a whole moves towards more efficient and circular practices.