Shaping a circular industrial ecosystem and supporting life-cycle thinking

CRCLR HUT

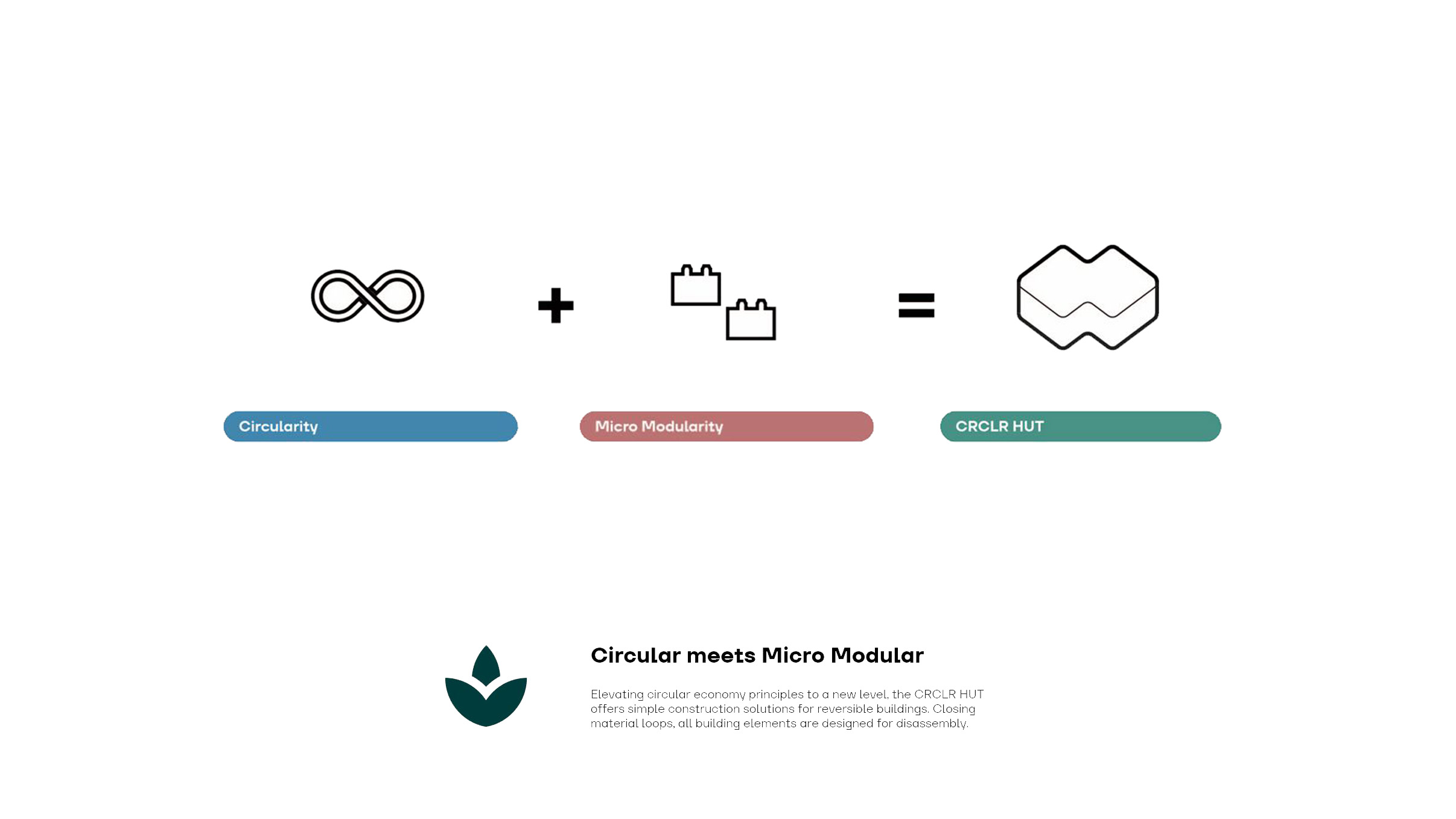

Micro-Modular and circular construction for scalable and affordable buildings.

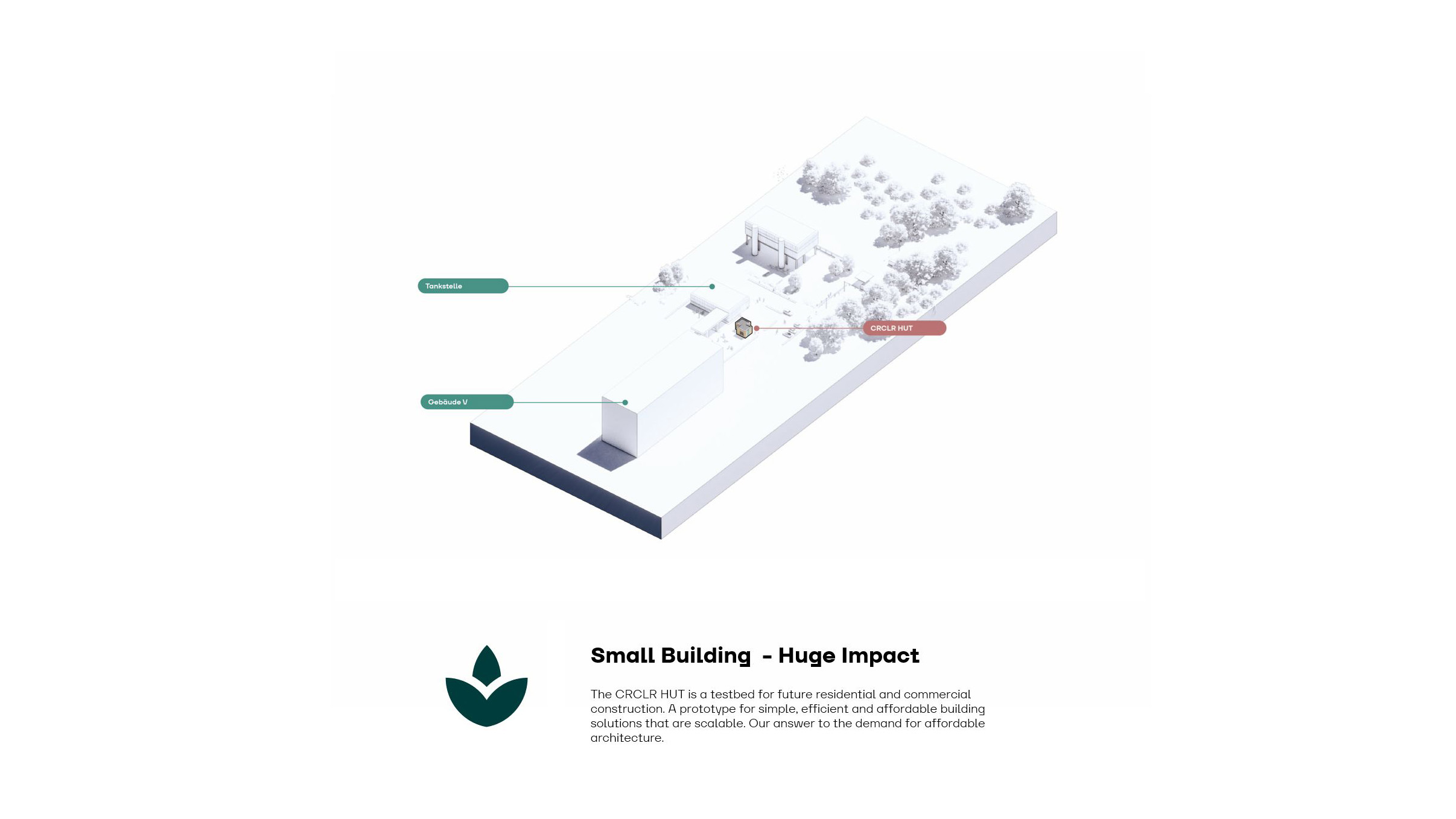

CRCLR HUT is Berlin TXL Urban Tech Republic’s first circular timber building, paving the way for Europe’s largest timber quarter, Schumacher Quartier. This pilot project showcases sustainable construction using only reusable elements dismantlable without site intrusion. The pavilion integrates modern technologies and materials meeting the highest ecological standards. A micro-modular approach with circular timber bricks and innovative solutions demonstrates scalable circular building practices.

Germany

Local

Berlin

Mainly urban

It refers to a physical transformation of the built environment (hard investment)

Yes

2024-09-10

No

No

No

As a representative of an organisation, in partnership with other organisations

The CRCLR HUT is a groundbreaking example of circular construction, demonstrating how a zero-waste, CO₂-negative building can be realized at scale. Located in Berlin TXL’s Urban Tech Republic, this pilot project—initiated by TRIQBRIQ and Beta Realities—sets a new standard for sustainable buildings by integrating micro-modularity, digital innovation, and circular economy principles.

By using TRIQBRIQ’s circular timber system, alongside innovative material tracking and design-for-disassembly, the CRCLR HUT functions as a material depot, where over 70% of its components can be dismantled and reused. The structure is built entirely with non-invasive, reversible methods, eliminating construction waste and maximizing flexibility. A shared digital twin and BIM model ensured seamless collaboration between planners, architects, and construction teams, optimizing workflows and supporting life-cycle thinking. Lean construction management further reduced material waste, improved efficiency, and shortened build time.

The project creates value across multiple sectors. Planners and developers gain a replicable model for circular, low-carbon buildings. Construction companies benefit from faster, more efficient processes using lean methods. Future residents will have affordable, adaptable housing that evolves with their needs, while cities and policymakers gain insights into how circular construction can support climate-friendly urban development. The use of sustainably sourced timber not only reduces embodied carbon but also acts as a carbon sink, offsetting emissions and making the building CO₂ negative.

Through its scalable and transferable approach, the CRCLR HUT offers a real-world blueprint for how life-cycle thinking can reshape the built environment, proving that circular construction is not just an aspiration—but an achievable reality.

By using TRIQBRIQ’s circular timber system, alongside innovative material tracking and design-for-disassembly, the CRCLR HUT functions as a material depot, where over 70% of its components can be dismantled and reused. The structure is built entirely with non-invasive, reversible methods, eliminating construction waste and maximizing flexibility. A shared digital twin and BIM model ensured seamless collaboration between planners, architects, and construction teams, optimizing workflows and supporting life-cycle thinking. Lean construction management further reduced material waste, improved efficiency, and shortened build time.

The project creates value across multiple sectors. Planners and developers gain a replicable model for circular, low-carbon buildings. Construction companies benefit from faster, more efficient processes using lean methods. Future residents will have affordable, adaptable housing that evolves with their needs, while cities and policymakers gain insights into how circular construction can support climate-friendly urban development. The use of sustainably sourced timber not only reduces embodied carbon but also acts as a carbon sink, offsetting emissions and making the building CO₂ negative.

Through its scalable and transferable approach, the CRCLR HUT offers a real-world blueprint for how life-cycle thinking can reshape the built environment, proving that circular construction is not just an aspiration—but an achievable reality.

Circular Construction

Sustainable Building

Zero Waste

CO2 negative construction

Life-Cycle Thinking

The CRCLR HUT demonstrates what’s already possible in sustainable, circular construction. It symbolizes our industry's future viability and the power of partnerships. A circular timber brick system by TRIQBRIQ, combined with partners' solutions, proves how circular construction can be realized.

The pavilion integrates modern technologies and materials meeting the highest ecological standards in both production and reuse. With Madaster, we calculated that over 70% of materials can be dismantled and reused—unprecedented in an industry responsible for 60% of resource consumption and 40% of global CO₂ emissions.

A key element is the FUTR HUT, Berlin’s sustainable urban construction hub in Berlin TXL. It rethinks future construction, fostering collaboration in research, testing, and production, with a focus on wood and other renewable materials.

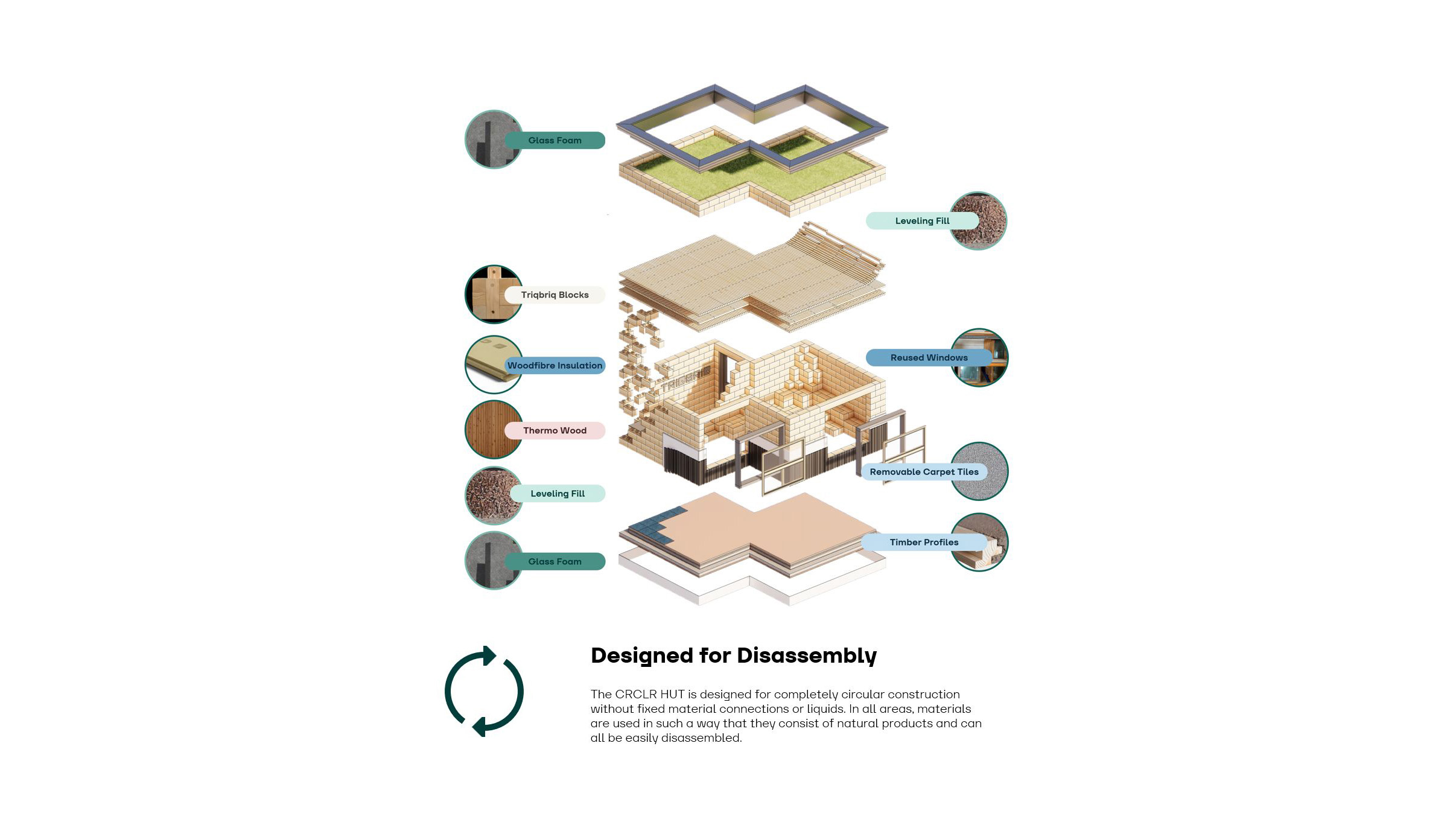

The CRCLR HUT, the site’s first temporary wooden structure, will be rebuilt as a permanent building in May 2025. This real-life lab proves circular, zero-waste construction is not only feasible but enables future flexibility—in this case allowing transformation into a different typology, site, and volume. Every component, including roof and foundation, is circular and modular, with no fixed connections.

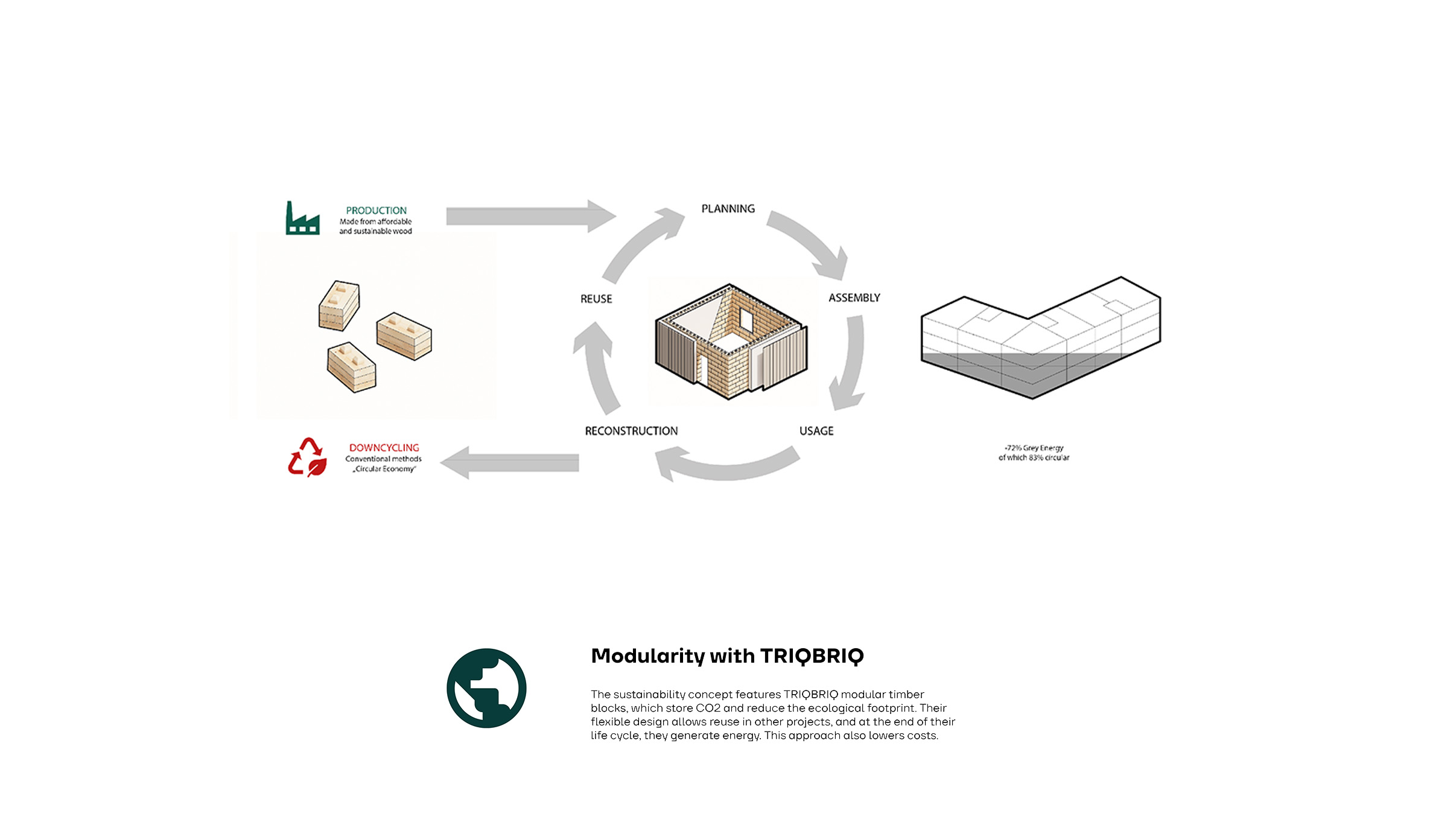

The TRIQBRIQ system uses sustainably sourced industrial and calamity wood to create reusable timber blocks. Assembled with dowels, they require no artificial connectors, ensuring fast, flexible construction. After use, BRIQs are fully reclaimable, making TRIQBRIQ a circular, sustainable solution. Reusing building components like windows and doors from Concular further enhances resource efficiency and minimizes waste.

The pavilion integrates modern technologies and materials meeting the highest ecological standards in both production and reuse. With Madaster, we calculated that over 70% of materials can be dismantled and reused—unprecedented in an industry responsible for 60% of resource consumption and 40% of global CO₂ emissions.

A key element is the FUTR HUT, Berlin’s sustainable urban construction hub in Berlin TXL. It rethinks future construction, fostering collaboration in research, testing, and production, with a focus on wood and other renewable materials.

The CRCLR HUT, the site’s first temporary wooden structure, will be rebuilt as a permanent building in May 2025. This real-life lab proves circular, zero-waste construction is not only feasible but enables future flexibility—in this case allowing transformation into a different typology, site, and volume. Every component, including roof and foundation, is circular and modular, with no fixed connections.

The TRIQBRIQ system uses sustainably sourced industrial and calamity wood to create reusable timber blocks. Assembled with dowels, they require no artificial connectors, ensuring fast, flexible construction. After use, BRIQs are fully reclaimable, making TRIQBRIQ a circular, sustainable solution. Reusing building components like windows and doors from Concular further enhances resource efficiency and minimizes waste.

The CRCLR HUT stands as a symbol of architectural creativity, the vision for a sustainable, circular construction method, and represents the potential of innovative partnerships in the construction industry. Buildings built with circular elements bring new aesthetics, allowing for interaction in both design and functionality. The micro-modular approach is visible inside, where timber bricks seamlessly merge façade and interior furniture into a holistic principle that can evolve over time.

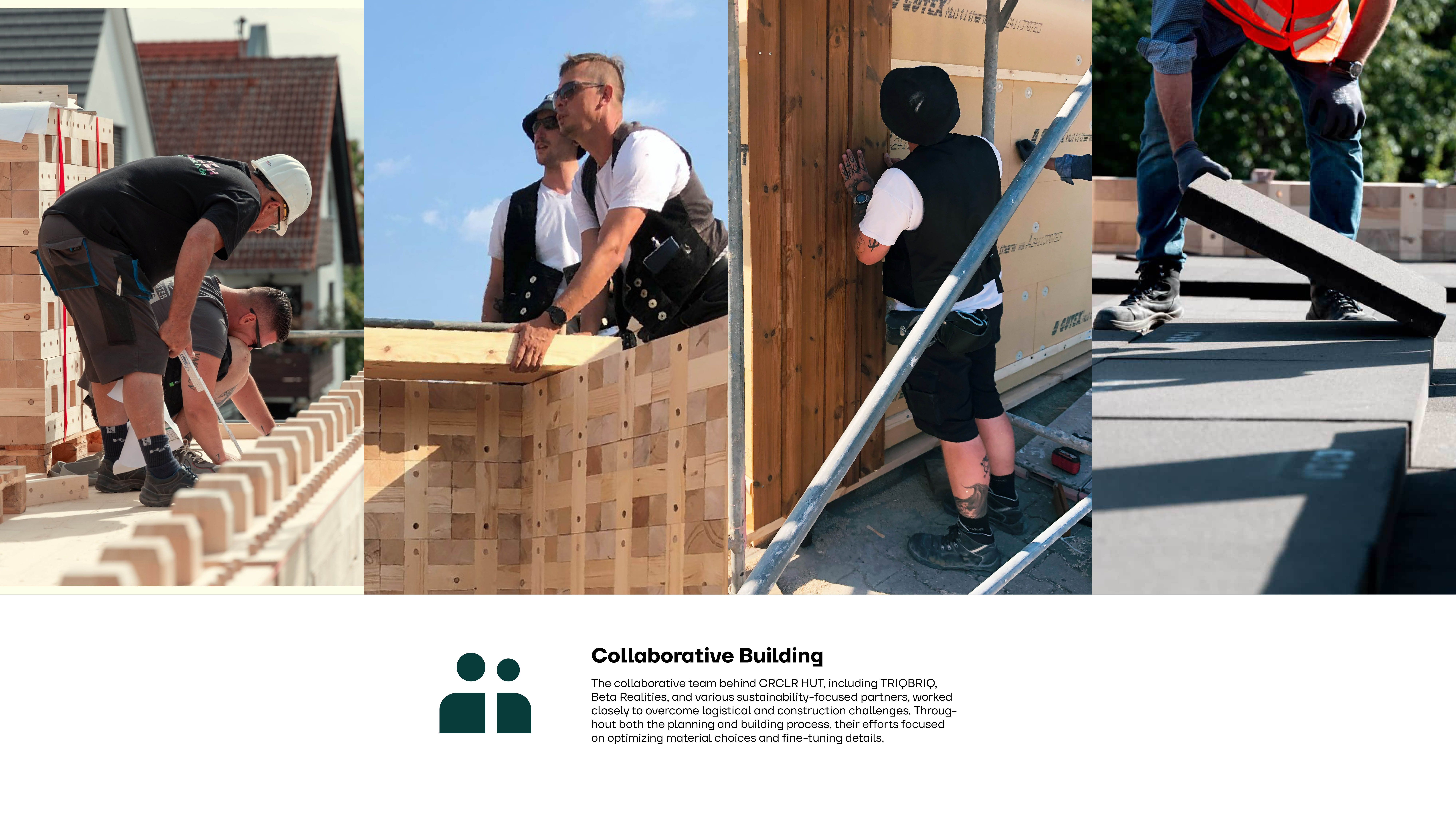

The project exemplifies a collaborative construction process, bringing together a network of partners with specialized value chains. This approach enables the integration of innovative, sustainable materials and techniques while fostering a dynamic exchange of knowledge. Working together, the partners ensure an efficient building process aligned with circular principles, advancing sustainable building practices.

The first wooden building in Berlin TXL serves as a venue for workshops on circular construction, educating builders, homeowners, architects, and other stakeholders on the possibilities of circular building. After the real-life laboratory phase, the building will be disassembled and relocated to a permanent site at Berlin’s former TXL airport. We educated a wide variety of participants on circular construction, hands-on use cases, and benefits across various sectors and building typologies.

Additionally, the CRCLR HUT was featured in the exhibition MATERIAL CULTURE BERLIN TXL 2024. A Building for the Future, displayed in the information center from September 7th to November 30th. The building not only contributes to Berlin’s construction future but also serves as an initiator for a broader movement in circular, waste-free, and carbon-negative construction in Europe, with Berlin TXL as a competence center for sustainable building. The project sends a vital message for the building transition, uniting suppliers, manufacturers, builders, and planners toward a common goal.

The project exemplifies a collaborative construction process, bringing together a network of partners with specialized value chains. This approach enables the integration of innovative, sustainable materials and techniques while fostering a dynamic exchange of knowledge. Working together, the partners ensure an efficient building process aligned with circular principles, advancing sustainable building practices.

The first wooden building in Berlin TXL serves as a venue for workshops on circular construction, educating builders, homeowners, architects, and other stakeholders on the possibilities of circular building. After the real-life laboratory phase, the building will be disassembled and relocated to a permanent site at Berlin’s former TXL airport. We educated a wide variety of participants on circular construction, hands-on use cases, and benefits across various sectors and building typologies.

Additionally, the CRCLR HUT was featured in the exhibition MATERIAL CULTURE BERLIN TXL 2024. A Building for the Future, displayed in the information center from September 7th to November 30th. The building not only contributes to Berlin’s construction future but also serves as an initiator for a broader movement in circular, waste-free, and carbon-negative construction in Europe, with Berlin TXL as a competence center for sustainable building. The project sends a vital message for the building transition, uniting suppliers, manufacturers, builders, and planners toward a common goal.

The CRCLR HUT project is an example of how circular construction can drive inclusivity, accessibility, and affordability in the built environment. By prioritizing a circular, reusable system, the project addresses both environmental and social challenges while creating spaces that meet diverse needs. The micro-modular design allows for flexible use, enabling adaptation over time, and providing an affordable solution for a range of stakeholders—from builders to future residents.

A key objective of the CRCLR HUT is to demonstrate that sustainable building methods can be cost-effective today, with even greater affordability through each reuse cycle. This approach not only reduces waste but also ensures that the building materials retain value, promoting long-term affordability. In this way, the project exemplifies how circular construction can foster accessible housing solutions and reduce construction costs over time.

Inclusivity is embedded in every aspect of the project, from its design principles to its construction process. The building's micro-modular system offers design for all, ensuring that the structure can evolve with changing needs. The CRCLR HUT serves as an educational hub, offering workshops and hands-on experiences that involve various communities in the conversation about sustainable and inclusive construction. This participatory approach ensures that people from different backgrounds, skill levels, and perspectives can contribute to the future of sustainable architecture.

Through collaboration with a diverse range of partners and stakeholders, the CRCLR HUT exemplifies a new societal model where innovation, circularity, and inclusivity drive progress in construction. It shows how collective effort and shared knowledge can create affordable, accessible, and adaptable buildings that have a lasting positive impact on both people and the environment.

A key objective of the CRCLR HUT is to demonstrate that sustainable building methods can be cost-effective today, with even greater affordability through each reuse cycle. This approach not only reduces waste but also ensures that the building materials retain value, promoting long-term affordability. In this way, the project exemplifies how circular construction can foster accessible housing solutions and reduce construction costs over time.

Inclusivity is embedded in every aspect of the project, from its design principles to its construction process. The building's micro-modular system offers design for all, ensuring that the structure can evolve with changing needs. The CRCLR HUT serves as an educational hub, offering workshops and hands-on experiences that involve various communities in the conversation about sustainable and inclusive construction. This participatory approach ensures that people from different backgrounds, skill levels, and perspectives can contribute to the future of sustainable architecture.

Through collaboration with a diverse range of partners and stakeholders, the CRCLR HUT exemplifies a new societal model where innovation, circularity, and inclusivity drive progress in construction. It shows how collective effort and shared knowledge can create affordable, accessible, and adaptable buildings that have a lasting positive impact on both people and the environment.

The project recognizes that the success and sustainability of urban transformation depend on the active participation of those directly impacted by the CRCLR HUT. As a dynamic space, it serves as both a physical and conceptual hub for promoting collaboration, education, and collective action, with a particular focus on circular and adaptive construction and its benefits for civil society and future generations.

In 2024, the CRCLR HUT hosted various formats that brought together a diverse range of participants. These included workshops on circular construction, sustainability, and eco-urbanism, where both experts and laypeople engaged in discussions and hands-on activities to develop solutions for future living environments. The workshops aimed to educate and empower participants, enabling them to explore and contribute to innovative methodologies in building and urban planning. Future residents, architects, builders, planners, and other stakeholders shared their ideas, helping to shape developments that address social and environmental challenges.

The project also involved local and international visitors through events and guided tours, fostering cross-cultural exchange and raising awareness of sustainable practices. The educational aspect of the CRCLR HUT has been vital in showcasing the potential of circular construction for creating healthier, more affordable, and adaptable living spaces. Active media and public outreach contributed to the visibility of these initiatives, demonstrating the power of collaboration between policymakers and citizens.

In 2024, the CRCLR HUT hosted various formats that brought together a diverse range of participants. These included workshops on circular construction, sustainability, and eco-urbanism, where both experts and laypeople engaged in discussions and hands-on activities to develop solutions for future living environments. The workshops aimed to educate and empower participants, enabling them to explore and contribute to innovative methodologies in building and urban planning. Future residents, architects, builders, planners, and other stakeholders shared their ideas, helping to shape developments that address social and environmental challenges.

The project also involved local and international visitors through events and guided tours, fostering cross-cultural exchange and raising awareness of sustainable practices. The educational aspect of the CRCLR HUT has been vital in showcasing the potential of circular construction for creating healthier, more affordable, and adaptable living spaces. Active media and public outreach contributed to the visibility of these initiatives, demonstrating the power of collaboration between policymakers and citizens.

The CRCLR HUT project created a collaborative environment connecting key players from the construction, urban development, and sustainability sectors, fostering innovation and knowledge exchange.

At the local level, the project partnered with Tegel Project GmbH, a subsidiary of the state of Berlin, overseeing the development of the Urban Tech Republic and the Schuhmacher Quarter, part of Europe’s largest sustainable urban transformation. Their involvement ensured integration with Berlin’s broader vision as a hub for urban innovation, with international impact.

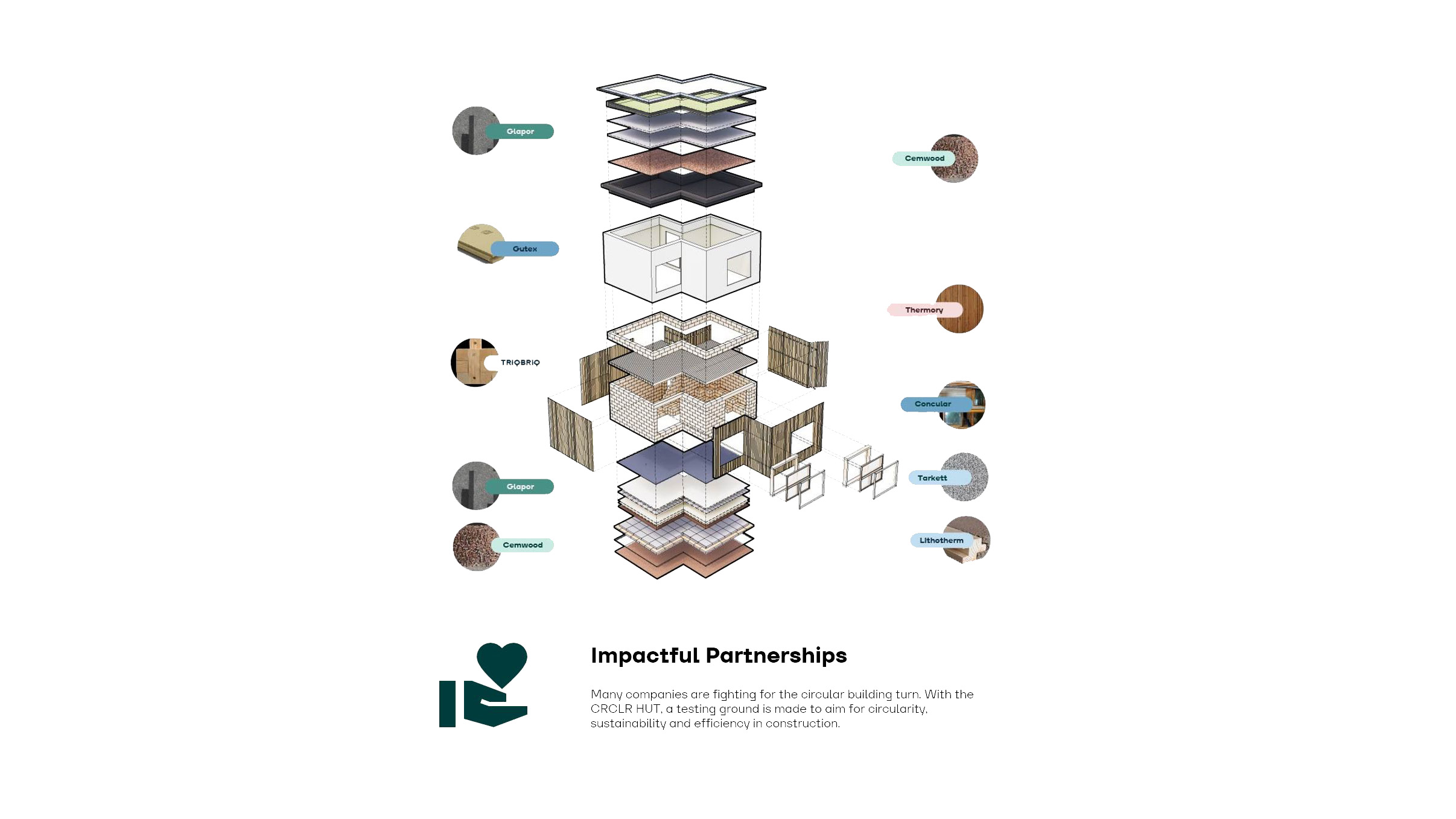

Nationally, TRIQBRIQ and Beta Realities led the design and implementation, driving circular construction forward. Their collaboration with sustainable building companies resulted in scalable solutions. Notable local contributors included Concular and Alba Berlin, providing reused windows and doors, while Glapor and CemWood supplied reusable floor and roof structures made from recycled glass and mineral-coated wood chips. Gutex, Thermory, and Tarkett contributed renewable materials like sustainable wood fiber insulation boards, durable timber facades, and reusable carpet tiles. Lithotherm’s reusable dry screed was used for flooring.

The involvement of major industry players, such as the HOCHTIEF group, ensured that the pavilion met high standards of quality and sustainability. HOCHTIEF worked closely with TRIQBRIQ’s brand ambassador, Andreas R. Becher, refining the construction process. Madaster’s role in quantifying the sustainability and circularity factors of the CRCLR HUT provided valuable insights that will inform future projects. The engagement of diverse stakeholders enhanced the project’s development and impact, enabling knowledge exchange and fostering a shared commitment to circular construction practices. Companies unfamiliar with this field gained insights into sustainable building, spreading awareness and inspiring industry-wide change toward a circular economy and sustainable urban development.

At the local level, the project partnered with Tegel Project GmbH, a subsidiary of the state of Berlin, overseeing the development of the Urban Tech Republic and the Schuhmacher Quarter, part of Europe’s largest sustainable urban transformation. Their involvement ensured integration with Berlin’s broader vision as a hub for urban innovation, with international impact.

Nationally, TRIQBRIQ and Beta Realities led the design and implementation, driving circular construction forward. Their collaboration with sustainable building companies resulted in scalable solutions. Notable local contributors included Concular and Alba Berlin, providing reused windows and doors, while Glapor and CemWood supplied reusable floor and roof structures made from recycled glass and mineral-coated wood chips. Gutex, Thermory, and Tarkett contributed renewable materials like sustainable wood fiber insulation boards, durable timber facades, and reusable carpet tiles. Lithotherm’s reusable dry screed was used for flooring.

The involvement of major industry players, such as the HOCHTIEF group, ensured that the pavilion met high standards of quality and sustainability. HOCHTIEF worked closely with TRIQBRIQ’s brand ambassador, Andreas R. Becher, refining the construction process. Madaster’s role in quantifying the sustainability and circularity factors of the CRCLR HUT provided valuable insights that will inform future projects. The engagement of diverse stakeholders enhanced the project’s development and impact, enabling knowledge exchange and fostering a shared commitment to circular construction practices. Companies unfamiliar with this field gained insights into sustainable building, spreading awareness and inspiring industry-wide change toward a circular economy and sustainable urban development.

The CRCLR HUT project brought together a diverse range of disciplines, reflecting the full value chain of sustainable construction. Initiators Beta Realities and TRIQBRIQ, experts in urban planning, architecture, and material ecology, led the project with a focus on integrated, future-proof solutions. They collaborated with Tegel Projekt GmbH, ensuring alignment with Berlin’s broader sustainable development vision.

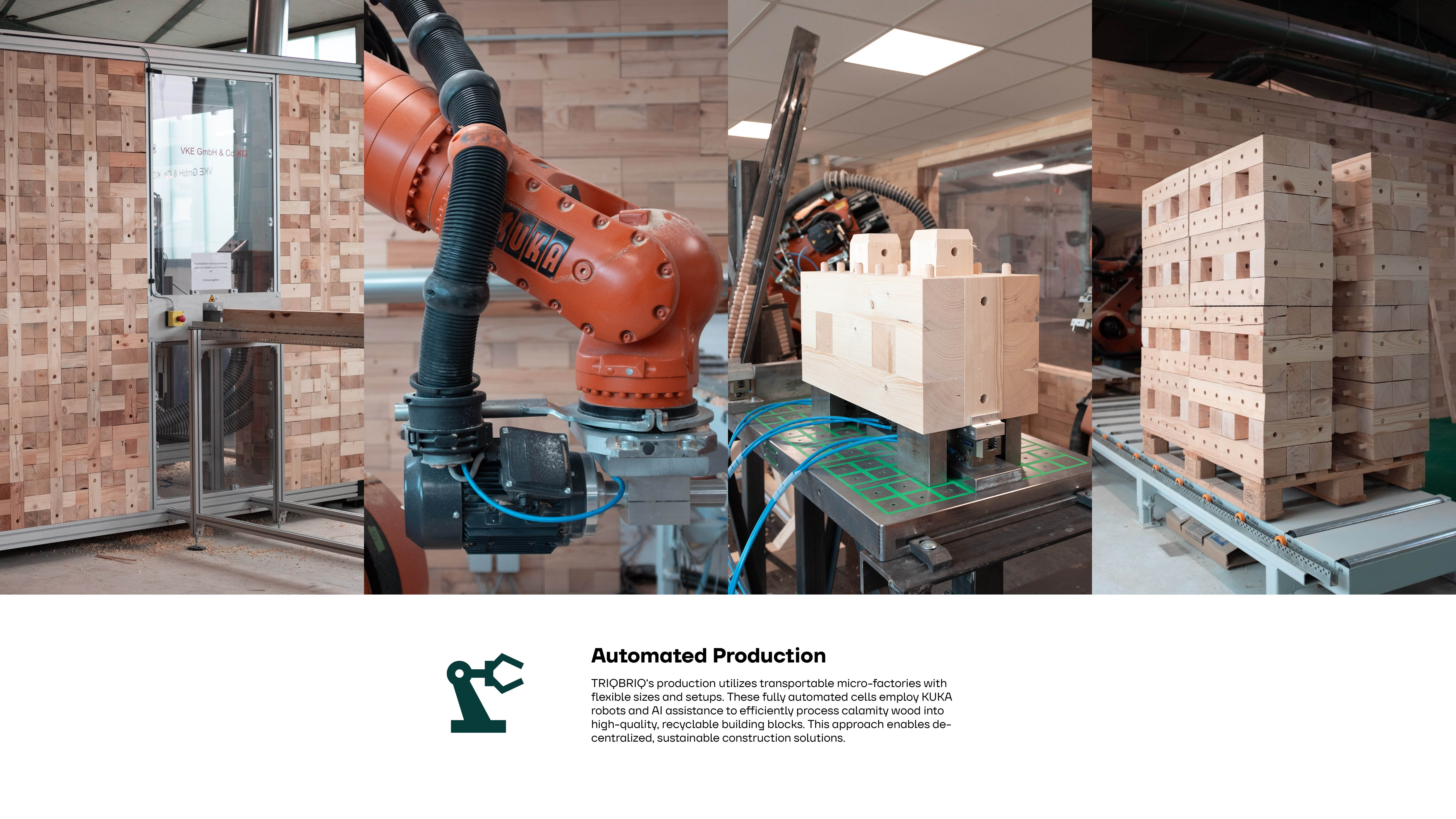

HOCHTIEF was responsible for lean construction processes, using digital planning tools to enable rapid implementation. Their expertise in efficient project delivery, combined with a digital approach, allowed the project to go from idea to building in under 10 weeks.

Material contributors such as Concular, Madaster, Glapor, CemWood, Lithotherm, Tarkett, Gutex, and Thermory each brought in specialized knowledge of sustainable materials. Concular and Madaster focused on circularity, providing reclaimed materials and creating material passports to ensure full traceability. Glapor and CemWood provided floor and roof structures made from 100% recycled glass and mineral-coated wood chips. Lithotherm contributed a reusable dry screed, while Tarkett enabled the use of reusable carpet tiles. Gutex supplied sustainable wood fiber insulation boards, and Thermory offered durable wooden facades. Each of these companies is an expert in their respective sustainable product, ensuring the highest quality and performance.

All stakeholders worked together within a digital twin framework, facilitating seamless collaboration and tracking of the construction and material lifecycle. This process allowed for scalable and efficient implementation of circular construction methods.

The collaborative, cross-disciplinary approach added significant value by optimizing workflows, reducing waste, and advancing the use of sustainable, reusable materials—setting a new standard for future urban development projects.

HOCHTIEF was responsible for lean construction processes, using digital planning tools to enable rapid implementation. Their expertise in efficient project delivery, combined with a digital approach, allowed the project to go from idea to building in under 10 weeks.

Material contributors such as Concular, Madaster, Glapor, CemWood, Lithotherm, Tarkett, Gutex, and Thermory each brought in specialized knowledge of sustainable materials. Concular and Madaster focused on circularity, providing reclaimed materials and creating material passports to ensure full traceability. Glapor and CemWood provided floor and roof structures made from 100% recycled glass and mineral-coated wood chips. Lithotherm contributed a reusable dry screed, while Tarkett enabled the use of reusable carpet tiles. Gutex supplied sustainable wood fiber insulation boards, and Thermory offered durable wooden facades. Each of these companies is an expert in their respective sustainable product, ensuring the highest quality and performance.

All stakeholders worked together within a digital twin framework, facilitating seamless collaboration and tracking of the construction and material lifecycle. This process allowed for scalable and efficient implementation of circular construction methods.

The collaborative, cross-disciplinary approach added significant value by optimizing workflows, reducing waste, and advancing the use of sustainable, reusable materials—setting a new standard for future urban development projects.

The CRCLR HUT stands out for its innovative approach to construction, contrasting sharply with traditional methods. Unlike conventional buildings, it avoids the use of liquids and permanent elements on-site, making it non-invasive and easily adaptable. The design for disassembly principle allows the structure to be dismantled and reconfigured in new locations, establishing it as the first permanent timber building in Berlin TXL with the flexibility for future reuse.

Key to its innovation is the use of micro-modular elements for walls, floors, and ceilings, paired with digital twins and lean construction methods. This combination enabled the CRCLR HUT to be completed 50% faster than a traditional building of the same size. The efficiency of this approach not only reduces time and costs but also minimizes errors and redundancies in both planning and construction.

The project’s circular timber construction system is complemented by the solutions of partner companies, showcasing how circular practices can be implemented in the building industry. Over 70% of the materials used are calculated to be dismantlable and reusable, a significant departure from standard construction practices. This represents a major step forward in addressing the construction industry’s global impact, which is responsible for 60% of resource consumption and 40% of CO2 emissions.

In essence, the CRCLR HUT exemplifies the shift toward a sustainable, circular economy in construction, setting a new standard for future building practices.

Key to its innovation is the use of micro-modular elements for walls, floors, and ceilings, paired with digital twins and lean construction methods. This combination enabled the CRCLR HUT to be completed 50% faster than a traditional building of the same size. The efficiency of this approach not only reduces time and costs but also minimizes errors and redundancies in both planning and construction.

The project’s circular timber construction system is complemented by the solutions of partner companies, showcasing how circular practices can be implemented in the building industry. Over 70% of the materials used are calculated to be dismantlable and reusable, a significant departure from standard construction practices. This represents a major step forward in addressing the construction industry’s global impact, which is responsible for 60% of resource consumption and 40% of CO2 emissions.

In essence, the CRCLR HUT exemplifies the shift toward a sustainable, circular economy in construction, setting a new standard for future building practices.

The CRCLR HUT employs a groundbreaking methodology centered around digitalization and modularity to revolutionize circular construction. At its core is the digital twin, a virtual model that enables precise planning, real-time tracking, and seamless collaboration across disciplines. This shared digital infrastructure allowed architects, engineers, and material suppliers to work together efficiently, optimizing workflows and ensuring that each construction element was traceable and reusable. By integrating material passports, the project enhances transparency in resource management, supporting circular construction principles.

Another key innovation is the micro-modular construction approach, which simplifies assembly and disassembly. The buildings mainly consists of prefabricated timber elements from TRIQBRIQ, forming the walls and furniture. Unlike conventional construction, which often leads to material waste and irreversible structures, this method ensures flexibility and adaptability. The micro-modular system, combined with lean construction techniques, enabled the CRCLR HUT to be built 50% faster than traditional buildings, significantly reducing costs, errors, and inefficiencies.

These digital and modular strategies were reinforced by a collaborative planning process, where experts from different fields—architecture, engineering, material science, and circular economy—worked together in a fully integrated digital environment. This interdisciplinary exchange ensured that the CRCLR HUT not only served as a prototype for circular timber construction but also provided a scalable model for future projects.

Another key innovation is the micro-modular construction approach, which simplifies assembly and disassembly. The buildings mainly consists of prefabricated timber elements from TRIQBRIQ, forming the walls and furniture. Unlike conventional construction, which often leads to material waste and irreversible structures, this method ensures flexibility and adaptability. The micro-modular system, combined with lean construction techniques, enabled the CRCLR HUT to be built 50% faster than traditional buildings, significantly reducing costs, errors, and inefficiencies.

These digital and modular strategies were reinforced by a collaborative planning process, where experts from different fields—architecture, engineering, material science, and circular economy—worked together in a fully integrated digital environment. This interdisciplinary exchange ensured that the CRCLR HUT not only served as a prototype for circular timber construction but also provided a scalable model for future projects.

All planning and construction processes were tracked and evaluated, ensuring scalability and transferability. A shared digital twin facilitated real-time collaboration between architects, planners, and material suppliers, optimizing workflows, reducing errors, and enabling efficient resource management. Combined with material passports, this system creates a comprehensive database of material lifecycle information, including ecological impact, condition, and value, essential for reuse and circular construction strategies. In this context, the building itself serves as a material depot, with every component cataloged for potential reuse.

Material passports are central to this approach, digitally tracking each material from sourcing to reuse. They store crucial data such as certifications, embodied carbon, and circular potential, allowing for informed decision-making in construction and supply chains. By integrating material passports with a secondary material marketplace, materials can be resold, repurposed, or reintegrated into new projects, extending their lifecycle and reducing waste.

A key transferable element is the micro-modular construction approach, which enabled rapid assembly and full disassembly. Unlike traditional methods, the CRCLR HUT avoided liquids and permanent materials, making it adaptable, mobile, and easily reconfigurable. The project also developed innovative material joinery techniques, ensuring that elements can be disassembled without damage, a crucial step toward scalable circular construction.

By ensuring data transparency on material origin, carbon impact, and financial value, this methodology supports future regulatory frameworks for material reuse and embodied carbon tracking. As policies evolve, the CRCLR HUT serves as a pilot project, showcasing scalable solutions that can be applied across urban development and affordable housing projects, accelerating the shift toward a circular construction economy.

Material passports are central to this approach, digitally tracking each material from sourcing to reuse. They store crucial data such as certifications, embodied carbon, and circular potential, allowing for informed decision-making in construction and supply chains. By integrating material passports with a secondary material marketplace, materials can be resold, repurposed, or reintegrated into new projects, extending their lifecycle and reducing waste.

A key transferable element is the micro-modular construction approach, which enabled rapid assembly and full disassembly. Unlike traditional methods, the CRCLR HUT avoided liquids and permanent materials, making it adaptable, mobile, and easily reconfigurable. The project also developed innovative material joinery techniques, ensuring that elements can be disassembled without damage, a crucial step toward scalable circular construction.

By ensuring data transparency on material origin, carbon impact, and financial value, this methodology supports future regulatory frameworks for material reuse and embodied carbon tracking. As policies evolve, the CRCLR HUT serves as a pilot project, showcasing scalable solutions that can be applied across urban development and affordable housing projects, accelerating the shift toward a circular construction economy.

The project addresses two major global challenges: the housing crisis and the environmental impact of the construction industry. As urban populations grow, the demand for high-quality, affordable housing increases. However, conventional construction is slow, costly, and highly wasteful. To meet this demand, the industry must shift toward faster, more adaptable, and resource-efficient building methods.

This project provides a scalable local solution by integrating modularity, digitalization, and circular principles. The use of micro-modular construction enables rapid assembly, reducing costs and material waste. The design for disassembly ensures that buildings can be adapted, relocated, or reconfigured instead of being demolished, extending their lifespan and preventing unnecessary waste.

A key innovation is the use of digital twins and material passports, creating a fully tracked system that enables real-time collaboration, process optimization, and transparent lifecycle assessment. This approach ensures that materials retain their value and can be reused efficiently. The building itself serves as a material depot, where every component is tracked with ecological data, condition, and value, making reuse more effective and economically viable.

Beyond circularity, the CRCLR HUT actively contributes to climate action. The construction industry is responsible for 60% of global resource consumption and 40% of CO₂ emissions. By prioritizing renewable materials, particularly timber, the building acts as a carbon sink, storing atmospheric CO₂ rather than emitting it. Furthermore, the CRCLR HUT’s lifecycle emissions decrease with each reuse cycle, leading to a carbon-negative construction model.

By demonstrating scalable, digitally tracked circular construction methods, the project provides a replicable model for reducing emissions, conserving resources, and accelerating the transition to a sustainable built environment worldwide.

This project provides a scalable local solution by integrating modularity, digitalization, and circular principles. The use of micro-modular construction enables rapid assembly, reducing costs and material waste. The design for disassembly ensures that buildings can be adapted, relocated, or reconfigured instead of being demolished, extending their lifespan and preventing unnecessary waste.

A key innovation is the use of digital twins and material passports, creating a fully tracked system that enables real-time collaboration, process optimization, and transparent lifecycle assessment. This approach ensures that materials retain their value and can be reused efficiently. The building itself serves as a material depot, where every component is tracked with ecological data, condition, and value, making reuse more effective and economically viable.

Beyond circularity, the CRCLR HUT actively contributes to climate action. The construction industry is responsible for 60% of global resource consumption and 40% of CO₂ emissions. By prioritizing renewable materials, particularly timber, the building acts as a carbon sink, storing atmospheric CO₂ rather than emitting it. Furthermore, the CRCLR HUT’s lifecycle emissions decrease with each reuse cycle, leading to a carbon-negative construction model.

By demonstrating scalable, digitally tracked circular construction methods, the project provides a replicable model for reducing emissions, conserving resources, and accelerating the transition to a sustainable built environment worldwide.

The project has successfully demonstrated how a circular industrial ecosystem can be implemented through digitalization, lean processes, and sustainable materials, benefiting a wide range of stakeholders.

Planning stakeholders benefited from the use of digital twins and shared BIM models, which improved coordination, minimized errors, and optimized material flows. This data-driven approach enhances transparency and scalability, making circular construction more accessible for future projects.

Construction stakeholders gained insights into lean construction management, significantly reducing waste, inefficiencies, and time on-site. The design for disassembly approach and mikro-modular prefabrication methods streamlined construction, ensuring adaptability and future reuse of materials.

Future users and residents will benefit from an affordable and scalable housing model that adapts over time. The flexible, circular design allows for reconfiguration, creating long-term value while minimizing demolition and waste.

Ecologically, the project reduces environmental impact by prioritizing renewable and recycled materials. The timber-based construction acts as a carbon sink, capturing CO₂ and leading to a carbon-negative footprint that improves with each reuse cycle.

Socially, the project raises awareness of circularity, demonstrating its feasibility in urban development. By involving industry leaders, planners, and policymakers, it fosters collaboration toward a more sustainable built environment.

Governance is supported by the project’s alignment with circular economy principles, offering a replicable model that informs policy and regulatory frameworks. The transparent tracking of materials ensures compliance with emerging sustainability legislation, positioning circular construction as a viable mainstream solution.

Overall, the project delivers scalable solutions for a circular economy, setting new standards for life cycle thinking in construction.

Planning stakeholders benefited from the use of digital twins and shared BIM models, which improved coordination, minimized errors, and optimized material flows. This data-driven approach enhances transparency and scalability, making circular construction more accessible for future projects.

Construction stakeholders gained insights into lean construction management, significantly reducing waste, inefficiencies, and time on-site. The design for disassembly approach and mikro-modular prefabrication methods streamlined construction, ensuring adaptability and future reuse of materials.

Future users and residents will benefit from an affordable and scalable housing model that adapts over time. The flexible, circular design allows for reconfiguration, creating long-term value while minimizing demolition and waste.

Ecologically, the project reduces environmental impact by prioritizing renewable and recycled materials. The timber-based construction acts as a carbon sink, capturing CO₂ and leading to a carbon-negative footprint that improves with each reuse cycle.

Socially, the project raises awareness of circularity, demonstrating its feasibility in urban development. By involving industry leaders, planners, and policymakers, it fosters collaboration toward a more sustainable built environment.

Governance is supported by the project’s alignment with circular economy principles, offering a replicable model that informs policy and regulatory frameworks. The transparent tracking of materials ensures compliance with emerging sustainability legislation, positioning circular construction as a viable mainstream solution.

Overall, the project delivers scalable solutions for a circular economy, setting new standards for life cycle thinking in construction.