Shaping a circular industrial ecosystem and supporting life-cycle thinking

Coffeefrom

Coffeefrom: creating a new value out of coffee grounds

At Coffeefrom, we are bridging the gap between coffee waste and sustainable materials. We collect spent coffee grounds from nearby industries, stock them up, and transform them into innovative polymers. Our materials are ever-evolving through cutting-edge R&D strategies to meet the needs of countless new applications. Our mission is to promote circularity in the coffee supply chain through a model of industrial symbiosis. Working with fragile people, we brew a greener world for all.

Latvia

Regional

Piemonte, Lombardia, Emilia Romagna

Mainly urban

It refers to other types of transformations (soft investment)

Yes

2022-06-12

Yes

EIT Community New European Bauhaus

No

No

As a representative of an organisation

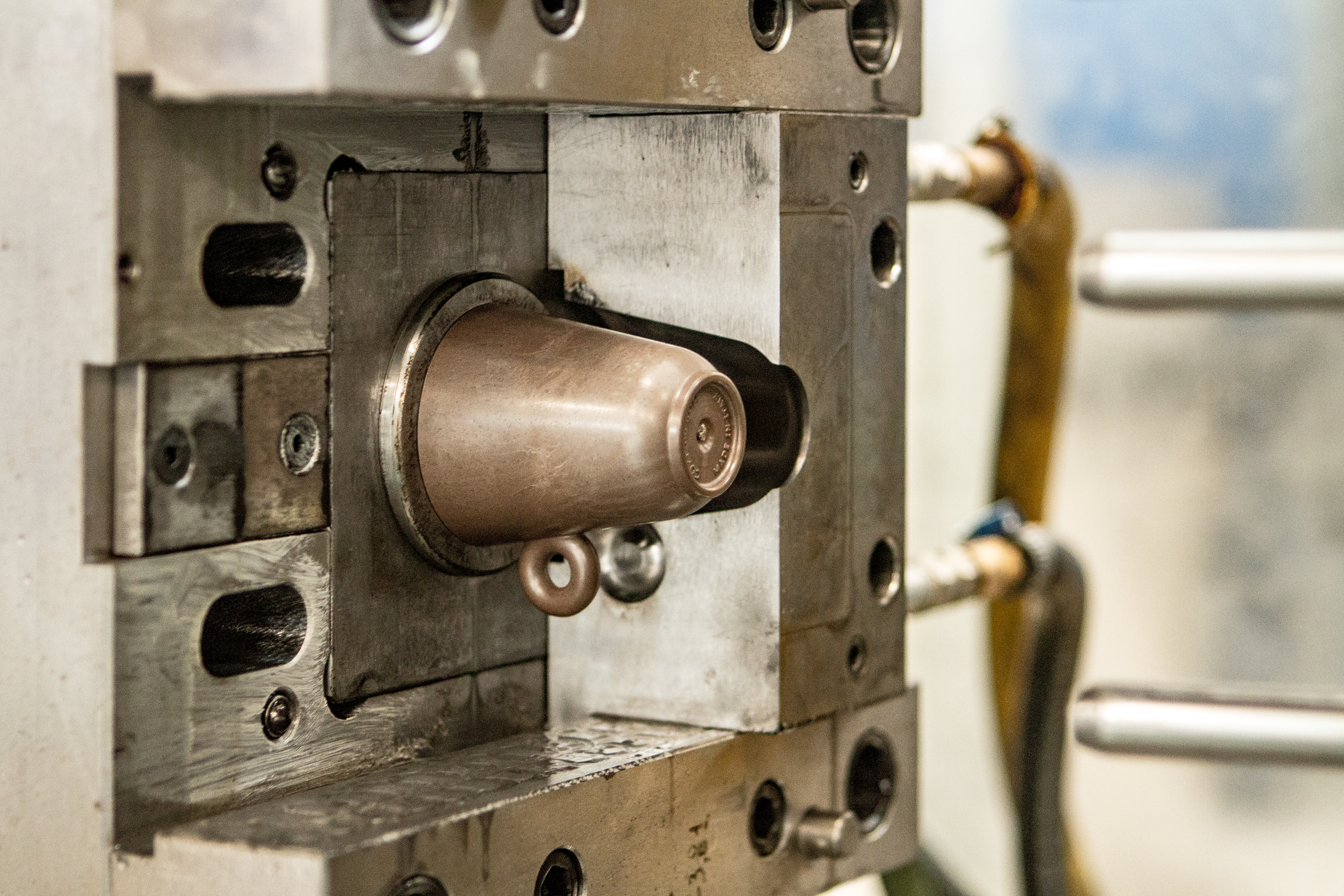

Coffeefrom is changing the way food companies in the EU manage post-production and post-consumer waste by adopting a circular approach that fosters industrial symbiosis. The project aims to create an impact throughout the entire production chain by repurposing waste into valuable resources, with the broader goal of extending this model beyond the food industry to maximize material reuse. At its core, Coffeefrom is committed to sustainability: by developing sustainable plastic granules enriched with spent coffee grounds, we provide a circular solution that helps businesses reduce their carbon footprint while complying with EU regulations requiring at least 30% organic or recycled content in materials. This approach not only decreases reliance on virgin plastic but also prevents waste from ending up in landfills, reducing CO₂ emissions and promoting a more efficient use of resources. However, our vision extends beyond environmental sustainability to embrace aesthetics and the cultural value of circularity. The materials we develop retain the natural texture of coffee, giving the final products a distinctive and unique look, as exemplified by our pilot project with Nestlé, where post-consumer coffee waste was transformed into customized coffee cups for three hotels—blending innovation, design, and quality. Beyond redefining waste, Coffeefrom integrates a strong social component by collaborating with Il Giardinone, a social enterprise that provides employment opportunities for vulnerable individuals, including migrants and people with disabilities. These workers are involved in the collection, storage, and transportation of spent coffee grounds, demonstrating that the transition to a circular economy can and should also be a driver of social inclusion and justice. The tangible results of the project include the reduction of virgin plastic use, the valorization of a byproduct that would otherwise be discarded, and the promotion of a culture that values sustainability.

Coffee waste reuse

Polymers

Circularity

Social Impact

Industrial Symbiosis

Coffeefrom's project leverages the upcycling of used coffee grounds to address environmental concerns by reducing both coffee waste and plastic pollution. Typically, coffee grounds are discarded in landfills, contributing to CO2 emissions, while the production of virgin plastic further impacts the environment through fossil fuel consumption. Our innovative approach seeks to mitigate these issues through a circular economy model.

The project has two primary objectives: first, to reduce the volume of spent coffee grounds, which make up to 90% of coffee waste. By recycling and valorizing these grounds, we close the loop in the coffee production process. Second, we aim to replace a portion of virgin fossil plastic with recycled coffee grounds in our materials. Through our compounding process, we blend polymers with spent coffee ground. This reduces the use of virgin fossil plastics by 20%, yielding a reduction of 0.2 kg of polypropylene (PP) for every 1 kg of Coffeefrom thermoplastic material.

Our production process is energy-efficient, consuming just 0.41 kWh per kg of thermoplastic material, significantly less than the 20.28 kWh required for typical thermoplastics. Our efforts extend to waste management, where we reduce transportation-related emissions. For example, the transport of coffee grounds from the coffee industry to the landfill is reduced by 20 kg/km for every 1 kg of thermoplastics produced.

Coffeefrom's thermoplastics are produced locally in Reggio Emilia, Italy, which significantly reduces transportation distances compared to plastics imported from outside Europe, such as those from Zhejiang, a major plastic-exporting province in China, thus reducing the associated carbon footprint. By upcycling coffee grounds into high-quality materials, Coffeefrom supports a circular economy, contributing to reduced environmental impact across various industries, from manufacturing to food production.

The project has two primary objectives: first, to reduce the volume of spent coffee grounds, which make up to 90% of coffee waste. By recycling and valorizing these grounds, we close the loop in the coffee production process. Second, we aim to replace a portion of virgin fossil plastic with recycled coffee grounds in our materials. Through our compounding process, we blend polymers with spent coffee ground. This reduces the use of virgin fossil plastics by 20%, yielding a reduction of 0.2 kg of polypropylene (PP) for every 1 kg of Coffeefrom thermoplastic material.

Our production process is energy-efficient, consuming just 0.41 kWh per kg of thermoplastic material, significantly less than the 20.28 kWh required for typical thermoplastics. Our efforts extend to waste management, where we reduce transportation-related emissions. For example, the transport of coffee grounds from the coffee industry to the landfill is reduced by 20 kg/km for every 1 kg of thermoplastics produced.

Coffeefrom's thermoplastics are produced locally in Reggio Emilia, Italy, which significantly reduces transportation distances compared to plastics imported from outside Europe, such as those from Zhejiang, a major plastic-exporting province in China, thus reducing the associated carbon footprint. By upcycling coffee grounds into high-quality materials, Coffeefrom supports a circular economy, contributing to reduced environmental impact across various industries, from manufacturing to food production.

At Coffeefrom, we focus on integrating sustainability and craftsmanship into everyday life through thoughtful design. Our materials have a raw, earthy aesthetic, with visible coffee granules embedded in the product. This design not only highlights the material's origin but also adds a tactile, authentic connection to nature. The coffee cups and mugs are designed to demonstrate how sustainable solutions can be seamlessly incorporated into daily habits like drinking coffee, making sustainability not just a choice but a visible part of daily life.

A prime example of our commitment is the Coffeefrom Bio Easter egg cup, created in collaboration with Ad Gentes, Bear Plast, and Dolcem. Made from Coffeefrom Bio, this product blends circular economy principles, social values, and craftsmanship. The earthy texture of the material conveys its sustainable origins, while the reusable design encourages eco-friendly practices. This project highlights the fusion of industrial processes with social responsibility, as we work with fair-trade chocolate producers in the Ivory Coast and celebrate artisanal craftsmanship.

Through this collaboration, we not only offer a product but also tell a story of sustainability and cultural impact. The Coffeefrom Easter egg cup exemplifies how design can influence consumer habits, creating a tangible connection between product use and sustainability. It serves as a model for how aesthetic design, functionality, and social values can be harmoniously integrated, showing how circular economy practices can be applied in everyday products.

A prime example of our commitment is the Coffeefrom Bio Easter egg cup, created in collaboration with Ad Gentes, Bear Plast, and Dolcem. Made from Coffeefrom Bio, this product blends circular economy principles, social values, and craftsmanship. The earthy texture of the material conveys its sustainable origins, while the reusable design encourages eco-friendly practices. This project highlights the fusion of industrial processes with social responsibility, as we work with fair-trade chocolate producers in the Ivory Coast and celebrate artisanal craftsmanship.

Through this collaboration, we not only offer a product but also tell a story of sustainability and cultural impact. The Coffeefrom Easter egg cup exemplifies how design can influence consumer habits, creating a tangible connection between product use and sustainability. It serves as a model for how aesthetic design, functionality, and social values can be harmoniously integrated, showing how circular economy practices can be applied in everyday products.

Inclusion is at the heart of Coffeefrom’s mission, ensuring that sustainability and innovation are not just environmental goals but also drivers of social equity. Our project promotes inclusion on multiple levels, from employment opportunities for vulnerable groups to fostering accessible and affordable circular solutions for businesses and communities.

A key pillar of our inclusive approach is our collaboration with Il Giardinone, a social enterprise that provides work opportunities for migrants, individuals with disabilities, and other vulnerable groups. These workers are directly involved in various stages of our process, from the collection and storage of coffee waste to its transformation into high-value materials. By integrating these individuals into the green economy, Coffeefrom not only offers employment but also fosters social empowerment, enabling workers to gain financial independence and valuable skills in the sustainability sector.

Beyond employment, Coffeefrom actively supports businesses looking to adopt inclusive hiring practices, offering consulting services to companies seeking to integrate social impact principles into their operations. By doing so, we contribute to a broader shift towards inclusive governance models, where sustainability is linked to corporate social responsibility and ethical labor practices.

In terms of accessibility and affordability, our materials provide cost-effective, circular alternatives to virgin plastics, helping businesses transition toward eco-friendly solutions without compromising on quality or scalability. By valorizing a widely available byproduct—spent coffee grounds—we create an accessible resource that companies can adopt, ensuring that sustainability remains inclusive and not an exclusive privilege.

Our project demonstrates that a just transition to a circular econom is possible when sustainability solutions are designed not only for environmental impact but also for econonomic and and social inclusion.

A key pillar of our inclusive approach is our collaboration with Il Giardinone, a social enterprise that provides work opportunities for migrants, individuals with disabilities, and other vulnerable groups. These workers are directly involved in various stages of our process, from the collection and storage of coffee waste to its transformation into high-value materials. By integrating these individuals into the green economy, Coffeefrom not only offers employment but also fosters social empowerment, enabling workers to gain financial independence and valuable skills in the sustainability sector.

Beyond employment, Coffeefrom actively supports businesses looking to adopt inclusive hiring practices, offering consulting services to companies seeking to integrate social impact principles into their operations. By doing so, we contribute to a broader shift towards inclusive governance models, where sustainability is linked to corporate social responsibility and ethical labor practices.

In terms of accessibility and affordability, our materials provide cost-effective, circular alternatives to virgin plastics, helping businesses transition toward eco-friendly solutions without compromising on quality or scalability. By valorizing a widely available byproduct—spent coffee grounds—we create an accessible resource that companies can adopt, ensuring that sustainability remains inclusive and not an exclusive privilege.

Our project demonstrates that a just transition to a circular econom is possible when sustainability solutions are designed not only for environmental impact but also for econonomic and and social inclusion.

The Coffeefrom project has had a significant positive impact on several groups of citizens, particularly on vulnerable workers, including those with migration backgrounds and individuals with psycho-cognitive disabilities. These workers are employed by Il Giardinone, the local social enterprise behind Coffeefrom®, and have been integrated into the entire logistical chain of the project, from production to distribution. By creating a sustainable circular economy model, Coffeefrom has not only provided a meaningful work opportunity for these individuals but has also increased demand for their services, leading to the creation of additional job opportunities.

Through the involvement of these workers, Coffeefrom contributes to social inclusion and empowerment. The project fosters a supportive and inclusive working environment where individuals from marginalized communities gain valuable skills and are able to contribute to the development of innovative, sustainable products. This, in turn, allows them to gain financial independence and achieve a sense of purpose and dignity in their work.

Furthermore, the broader civil society has also played a key role in the project, particularly through collaborations with fair trade organizations and local businesses. For example, the partnership with the fair trade association Ad Gentes ensures that the raw materials, such as cocoa from the Ivory Coast, are ethically sourced, supporting both sustainable farming practices and the livelihoods of small-scale farmers.

The combination of circular economy principles with social responsibility has created a ripple effect within the local community, not only benefiting the vulnerable workers directly involved in Coffeefrom, but also raising awareness about the importance of sustainability and fair trade among consumers. By involving citizens in the project, from production to consumption, Coffeefrom creates products that contribute to both social and environmental well-being.

Through the involvement of these workers, Coffeefrom contributes to social inclusion and empowerment. The project fosters a supportive and inclusive working environment where individuals from marginalized communities gain valuable skills and are able to contribute to the development of innovative, sustainable products. This, in turn, allows them to gain financial independence and achieve a sense of purpose and dignity in their work.

Furthermore, the broader civil society has also played a key role in the project, particularly through collaborations with fair trade organizations and local businesses. For example, the partnership with the fair trade association Ad Gentes ensures that the raw materials, such as cocoa from the Ivory Coast, are ethically sourced, supporting both sustainable farming practices and the livelihoods of small-scale farmers.

The combination of circular economy principles with social responsibility has created a ripple effect within the local community, not only benefiting the vulnerable workers directly involved in Coffeefrom, but also raising awareness about the importance of sustainability and fair trade among consumers. By involving citizens in the project, from production to consumption, Coffeefrom creates products that contribute to both social and environmental well-being.

The Coffeefrom project was made possible through a multi-level stakeholder collaboration, involving key actors at local, regional, national, and European levels, each contributing expertise to its design and implementation.

At the local level, the social enterprise Il Giardinone played a pivotal role in initiating the project, driven by its commitment to sustainability and the circular economy. Recognizing the potential of spent coffee grounds as a valuable resource, Il Giardinone sought technical and industrial partners to scale and operationalize the concept. One of the first key partnerships was with Bearplast, a polymer compounding company based in Reggio Emilia. With its extensive expertise in material science and industrial processing, Bearplast played a fundamental role in testing, validating, and optimizing the polymer blend incorporating coffee waste, ensuring the material’s performance and applicability across industries.

Additionally, local food and beverage companies were engaged to supply post-industrial coffee waste, creating a synergistic model of industrial symbiosis. These collaborations exemplify how waste from one sector can be repurposed as a resource in another, reducing landfill disposal, closing production loops, and enhancing supply chain sustainability.

At the national level, the partnership with Politecnico di Milano was instrumental in developing and refining the processing techniques for integrating coffee waste into high-quality polymer materials. Researchers conducted in-depth scientific studies, evaluating material properties and optimizing the compounding process to maximize performance while maintaining sustainability standards. Their contributions in R&D and material innovation played a key role in ensuring technical feasibility and scaling potential.

On the European level, Coffeefrom took a significant step forward by securing a patent for its unique material, reinforcing the project’s innovation and market potential.

At the local level, the social enterprise Il Giardinone played a pivotal role in initiating the project, driven by its commitment to sustainability and the circular economy. Recognizing the potential of spent coffee grounds as a valuable resource, Il Giardinone sought technical and industrial partners to scale and operationalize the concept. One of the first key partnerships was with Bearplast, a polymer compounding company based in Reggio Emilia. With its extensive expertise in material science and industrial processing, Bearplast played a fundamental role in testing, validating, and optimizing the polymer blend incorporating coffee waste, ensuring the material’s performance and applicability across industries.

Additionally, local food and beverage companies were engaged to supply post-industrial coffee waste, creating a synergistic model of industrial symbiosis. These collaborations exemplify how waste from one sector can be repurposed as a resource in another, reducing landfill disposal, closing production loops, and enhancing supply chain sustainability.

At the national level, the partnership with Politecnico di Milano was instrumental in developing and refining the processing techniques for integrating coffee waste into high-quality polymer materials. Researchers conducted in-depth scientific studies, evaluating material properties and optimizing the compounding process to maximize performance while maintaining sustainability standards. Their contributions in R&D and material innovation played a key role in ensuring technical feasibility and scaling potential.

On the European level, Coffeefrom took a significant step forward by securing a patent for its unique material, reinforcing the project’s innovation and market potential.

The design and implementation of our project brought together expertise from a variety of disciplines, each contributing critical knowledge and skills to bring the innovative circular economy concept to life. These fields include material science, sustainability, polymer engineering, research and development (R&D), and industrial design. The integration of these diverse disciplines not only enriched the project but also enabled the creation of a truly groundbreaking solution to repurpose spent coffee grounds.

At the core of the project was the collaboration between material scientists and polymer engineers, whose knowledge was vital for transforming organic coffee waste into a functional and durable material. Experts from Bearplast, with their deep understanding of polymer compounding, were instrumental in formulating the right polymer blend that could incorporate coffee grounds without compromising the material’s quality or functionality. Their technical expertise was fundamental in addressing the challenges of testing and optimizing the material for commercial use.

Parallel to the engineering process, research scientists from Politecnico di Milano played a critical role in the scientific validation of the concept. Their interdisciplinary research focused on the chemical properties of spent coffee grounds and their potential applications in material production. By studying the feasibility and environmental impact, they ensured the project adhered to sustainability standards while enhancing the scientific robustness of the approach.

Industrial designers were also key players, focusing on how the new material could be integrated into existing products and applications. They collaborated with engineers to ensure the material met aesthetic and functional standards, making it suitable for a wide range of uses across different industries.

This collaboration created a powerful synergy, where experts from different fields learned from each other and overcame challenges

At the core of the project was the collaboration between material scientists and polymer engineers, whose knowledge was vital for transforming organic coffee waste into a functional and durable material. Experts from Bearplast, with their deep understanding of polymer compounding, were instrumental in formulating the right polymer blend that could incorporate coffee grounds without compromising the material’s quality or functionality. Their technical expertise was fundamental in addressing the challenges of testing and optimizing the material for commercial use.

Parallel to the engineering process, research scientists from Politecnico di Milano played a critical role in the scientific validation of the concept. Their interdisciplinary research focused on the chemical properties of spent coffee grounds and their potential applications in material production. By studying the feasibility and environmental impact, they ensured the project adhered to sustainability standards while enhancing the scientific robustness of the approach.

Industrial designers were also key players, focusing on how the new material could be integrated into existing products and applications. They collaborated with engineers to ensure the material met aesthetic and functional standards, making it suitable for a wide range of uses across different industries.

This collaboration created a powerful synergy, where experts from different fields learned from each other and overcame challenges

Coffeefrom stands out for its innovative approach to industrial symbiosis, connecting the food industry's waste production with the compounding sector to create a closed-loop system. By transforming spent coffee grounds, a common byproduct of the food industry, into valuable materials for industrial and manufacturing applications, Coffeefrom establishes a new form of collaboration between sectors that traditionally operate in isolation.

Through this process, we bridge the gap between two industries—food production and plastics manufacturing—by turning coffee waste into high-quality thermoplastics. This not only helps reduce waste and reliance on virgin plastic but also creates new, sustainable materials that can be used across various industries. By doing so, Coffeefrom facilitates a circular economy where waste from one sector becomes a resource for another, promoting sustainability and offering a viable alternative to traditional plastic production.

Furthermore, Coffeefrom contributes to the EU's 2030 agenda for reaching net-zero emissions by providing sustainable materials that align with key environmental targets. Our innovative use of coffee grounds helps reduce carbon footprints and limits the demand for fossil-based plastics, directly supporting efforts to minimize environmental impact. This industrial symbiosis offers a scalable model for other sectors to adopt, highlighting the potential for greater sustainability through cross-industry collaboration and advancing the transition to a more sustainable, circular economy.

Through this process, we bridge the gap between two industries—food production and plastics manufacturing—by turning coffee waste into high-quality thermoplastics. This not only helps reduce waste and reliance on virgin plastic but also creates new, sustainable materials that can be used across various industries. By doing so, Coffeefrom facilitates a circular economy where waste from one sector becomes a resource for another, promoting sustainability and offering a viable alternative to traditional plastic production.

Furthermore, Coffeefrom contributes to the EU's 2030 agenda for reaching net-zero emissions by providing sustainable materials that align with key environmental targets. Our innovative use of coffee grounds helps reduce carbon footprints and limits the demand for fossil-based plastics, directly supporting efforts to minimize environmental impact. This industrial symbiosis offers a scalable model for other sectors to adopt, highlighting the potential for greater sustainability through cross-industry collaboration and advancing the transition to a more sustainable, circular economy.

The Coffeefrom project is driven by a circular and innovative methodology that leverages industrial symbiosis, creating a closed-loop system where resources are reused and waste is minimized. Central to the approach is the repurposing of spent coffee grounds, a typically discarded byproduct, into high-quality polymer materials. By transforming waste into a valuable resource, the project aligns with circular economy principles and addresses the challenge of reducing industrial waste while producing functional, sustainable materials.

At the heart of this methodology is the collaboration between Il Giardinone, a social enterprise, and its industry partners, notably Bear Plast, a leader in polymer compounding. This collaboration exemplifies industrial symbiosis, where industries from different sectors—such as coffee production, the food industry, and material manufacturing—work together. The food sector, which generates significant amounts of coffee waste, provides the spent coffee grounds that become the raw material for Coffeefrom's innovative polymer products. This interconnection between industries creates a positive environmental impact, as waste from the coffee and food sectors is transformed into a valuable material used in new products, reducing reliance on virgin resources.

Coffeefrom is also committed to continuous improvement in sustainability. The company’s vision is to refine the techniques used to incorporate higher percentages of spent coffee into polymer granules. This ongoing R&D effort, supported by experts at Politecnico di Milano, ensures that the material's performance is optimized while maximizing the environmental benefits of using recycled coffee waste. As the project evolves, these innovations will enable even greater quantities of spent coffee to be integrated into the final product, making the material increasingly sustainable.

At the heart of this methodology is the collaboration between Il Giardinone, a social enterprise, and its industry partners, notably Bear Plast, a leader in polymer compounding. This collaboration exemplifies industrial symbiosis, where industries from different sectors—such as coffee production, the food industry, and material manufacturing—work together. The food sector, which generates significant amounts of coffee waste, provides the spent coffee grounds that become the raw material for Coffeefrom's innovative polymer products. This interconnection between industries creates a positive environmental impact, as waste from the coffee and food sectors is transformed into a valuable material used in new products, reducing reliance on virgin resources.

Coffeefrom is also committed to continuous improvement in sustainability. The company’s vision is to refine the techniques used to incorporate higher percentages of spent coffee into polymer granules. This ongoing R&D effort, supported by experts at Politecnico di Milano, ensures that the material's performance is optimized while maximizing the environmental benefits of using recycled coffee waste. As the project evolves, these innovations will enable even greater quantities of spent coffee to be integrated into the final product, making the material increasingly sustainable.

The Coffeefrom project offers several elements that could be replicated or transferred to other locations, groups of beneficiaries, and contexts, thanks to its flexible and scalable approach to sustainability. The methodology focuses on repurposing spent coffee grounds, a widely available waste product, into valuable polymer materials, contributing to resource efficiency and waste reduction. This approach can be applied in regions with high coffee consumption, where significant amounts of coffee grounds are generated and could be redirected toward sustainable use.

Globally, coffee consumption is vast. In 2021/2022, approximately 176 million 60-kilogram bags of coffee were consumed, with Europe accounting for 31% of this total (source: Statista). In Europe, countries like Finland, Denmark, and the Netherlands exhibit some of the highest per capita coffee consumption rates, with Finland leading at 11.8 kg per person (source: European Coffee Federation, 2023). This large-scale consumption results in substantial coffee waste, making it an ideal resource for projects like Coffeefrom that seek to reduce waste while promoting sustainability.

The project has also led to collaborations with companies and research centers across Europe, many of which are interested in co-creating and replicating similar projects for the valorization of spent coffee byproducts, such as cellulose, lignin, and coffee oil. The techniques developed in Coffeefrom can be adapted to various local contexts, where coffee waste or other organic byproducts could be utilized in polymer production, reducing reliance on virgin resources.

By integrating social inclusion, innovation, and sustainability, Coffeefrom offers a replicable framework that can inspire similar circular economy models in different regions, promoting both environmental and social benefits.

Globally, coffee consumption is vast. In 2021/2022, approximately 176 million 60-kilogram bags of coffee were consumed, with Europe accounting for 31% of this total (source: Statista). In Europe, countries like Finland, Denmark, and the Netherlands exhibit some of the highest per capita coffee consumption rates, with Finland leading at 11.8 kg per person (source: European Coffee Federation, 2023). This large-scale consumption results in substantial coffee waste, making it an ideal resource for projects like Coffeefrom that seek to reduce waste while promoting sustainability.

The project has also led to collaborations with companies and research centers across Europe, many of which are interested in co-creating and replicating similar projects for the valorization of spent coffee byproducts, such as cellulose, lignin, and coffee oil. The techniques developed in Coffeefrom can be adapted to various local contexts, where coffee waste or other organic byproducts could be utilized in polymer production, reducing reliance on virgin resources.

By integrating social inclusion, innovation, and sustainability, Coffeefrom offers a replicable framework that can inspire similar circular economy models in different regions, promoting both environmental and social benefits.

The Coffeefrom project addresses several global challenges by providing local solutions aligned with the United Nations' Sustainable Development Goals (SDGs). At its core, the project tackles waste reduction, resource efficiency, and social inclusion, all of which contribute to a more sustainable and equitable world.

The project primarily addresses sustainable consumption and production (SDG 12) by repurposing spent coffee grounds into valuable polymer materials. This process minimizes waste and reduces the need for virgin resources, contributing to a circular economy and promoting more sustainable production practices.

It also supports climate action (SDG 13) by reducing carbon emissions. Traditionally, spent coffee grounds end up in landfills, where they decompose and release methane, a potent greenhouse gas. By transforming coffee waste into useful products, Coffeefrom helps mitigate this environmental impact.

The project promotes decent work and economic growth (SDG 8) by creating job opportunities for vulnerable groups, including individuals with migration backgrounds and psycho-cognitive disabilities. This model fosters social inclusion and economic empowerment, contributing to the goal of promoting sustainable economic growth.

Additionally, Coffeefrom strengthens partnerships for the goals (SDG 17). The project involves collaboration with a wide range of stakeholders, from local social enterprises to multinational companies and research institutions, creating a network that drives sustainable innovation and supports co-creation of solutions.

In conclusion, Coffeefrom provides local solutions to global challenges by transforming coffee waste into sustainable materials, creating jobs, reducing environmental impact, and fostering partnerships to build a more sustainable future.

The project primarily addresses sustainable consumption and production (SDG 12) by repurposing spent coffee grounds into valuable polymer materials. This process minimizes waste and reduces the need for virgin resources, contributing to a circular economy and promoting more sustainable production practices.

It also supports climate action (SDG 13) by reducing carbon emissions. Traditionally, spent coffee grounds end up in landfills, where they decompose and release methane, a potent greenhouse gas. By transforming coffee waste into useful products, Coffeefrom helps mitigate this environmental impact.

The project promotes decent work and economic growth (SDG 8) by creating job opportunities for vulnerable groups, including individuals with migration backgrounds and psycho-cognitive disabilities. This model fosters social inclusion and economic empowerment, contributing to the goal of promoting sustainable economic growth.

Additionally, Coffeefrom strengthens partnerships for the goals (SDG 17). The project involves collaboration with a wide range of stakeholders, from local social enterprises to multinational companies and research institutions, creating a network that drives sustainable innovation and supports co-creation of solutions.

In conclusion, Coffeefrom provides local solutions to global challenges by transforming coffee waste into sustainable materials, creating jobs, reducing environmental impact, and fostering partnerships to build a more sustainable future.

The Coffeefrom project has delivered significant results, outputs, and impacts, advancing sustainability and innovation in line with the EU’s 2030 climate goals.

Results include the development of two successful pilot projects in collaboration with major companies across different industrial sectors. These pilots demonstrated the viability of using spent coffee grounds to create high-performance materials, highlighting the potential for circular economy practices to be applied in various industries. Another key result is the registration of a patent for the extraction of cellulose and nanocellulose from coffee grounds, opening new possibilities for utilizing coffee byproducts in valuable materials.

Outputs of the project are the four materials now available on the market:

Coffeefrom Bio: A 100% biodegradable material made of 20% coffee grounds and 80% PLA, which is compostable if the object thickness is under 0.4 cm.

Coffeefrom Eco: A 100% recycled material made of 80% recycled LDPE and 20% coffee grounds, which is flexible and lightweight.

Coffeefrom Strong: A rigid material composed of 80% HDPE and 20% coffee grounds, resistant to high temperatures .

Coffeefrom Texture: PP and coffee granules, high-resistance with improved mechanical properties.

These materials have allowed Coffeefrom to reduce up to 20% of virgin fossil polymers, contributing to more sustainable production processes.

Impact is seen in the broader environmental and industrial effects. By offering eco-friendly alternatives to traditional plastics, Coffeefrom supports emission reduction goals set by the EU’s 2030 agenda. The project also promotes the transition to a circular economy by providing sustainable material options and creating valuable new markets for coffee waste. Furthermore, the development of these materials provides direct benefits to industries seeking sustainable solutions, while also reducing waste and supporting a greener, more sustainable future.

Results include the development of two successful pilot projects in collaboration with major companies across different industrial sectors. These pilots demonstrated the viability of using spent coffee grounds to create high-performance materials, highlighting the potential for circular economy practices to be applied in various industries. Another key result is the registration of a patent for the extraction of cellulose and nanocellulose from coffee grounds, opening new possibilities for utilizing coffee byproducts in valuable materials.

Outputs of the project are the four materials now available on the market:

Coffeefrom Bio: A 100% biodegradable material made of 20% coffee grounds and 80% PLA, which is compostable if the object thickness is under 0.4 cm.

Coffeefrom Eco: A 100% recycled material made of 80% recycled LDPE and 20% coffee grounds, which is flexible and lightweight.

Coffeefrom Strong: A rigid material composed of 80% HDPE and 20% coffee grounds, resistant to high temperatures .

Coffeefrom Texture: PP and coffee granules, high-resistance with improved mechanical properties.

These materials have allowed Coffeefrom to reduce up to 20% of virgin fossil polymers, contributing to more sustainable production processes.

Impact is seen in the broader environmental and industrial effects. By offering eco-friendly alternatives to traditional plastics, Coffeefrom supports emission reduction goals set by the EU’s 2030 agenda. The project also promotes the transition to a circular economy by providing sustainable material options and creating valuable new markets for coffee waste. Furthermore, the development of these materials provides direct benefits to industries seeking sustainable solutions, while also reducing waste and supporting a greener, more sustainable future.