Shaping a circular industrial ecosystem and supporting life-cycle thinking

House Shadow

Scaling homes back to planetary boundaries

House Shadow is an example of how reduced consumption of resources for construction, industrial circular economy, and minimalism can bring building and living back within the planetary carrying capacity.

Finland

Local

City of Lohja, South-West Finland

It addresses urban-rural linkages

It refers to a physical transformation of the built environment (hard investment)

Yes

2024-10-25

No

No

Yes

Yes

Yes

As an individual partnership with other persons/organisation(s)

House Shadow explores minimalism in three ways: First, it is a study of how the consumption of resources for construction can be significantly reduced through industrial circular economy. Second, it aims at introducing voluntary simplicity as a lifestyle ideal for larger audiences. Third, the project seeks to develop circularity-based minimalism for generating a contemplative living environment for supporting behavioural change towards living within the planetary boundaries. Inspired by Junichiro Tanizaki´s “In praise of shadows”, the building suggests that there cannot be architectural beauty, if environmental and social damage is caused in the realisation of the building.

Built in Finland, the project is an unofficial record in the amount of reused and recycled materials in a build, and the first building realised with fossil-free and fully scrap-based steel structures. It serves as a national proof-of-concept for reducing emissions from construction, so that Finland´s goal of becoming carbon neutral by 2035 would be possible even though its forest carbon sinks are rapidly diminishing. In the conservative context of the Finnish building sector, the project demonstrates that it is possible to industrialise circular construction and that this will dramatically cut the consumption of land, energy and materials, while reducing life cycle GHG emissions.

Built in Finland, the project is an unofficial record in the amount of reused and recycled materials in a build, and the first building realised with fossil-free and fully scrap-based steel structures. It serves as a national proof-of-concept for reducing emissions from construction, so that Finland´s goal of becoming carbon neutral by 2035 would be possible even though its forest carbon sinks are rapidly diminishing. In the conservative context of the Finnish building sector, the project demonstrates that it is possible to industrialise circular construction and that this will dramatically cut the consumption of land, energy and materials, while reducing life cycle GHG emissions.

Sufficiency

Minimalism

Living within the planetary boundaries

Regenerative architecture

Industrial circular economy

House Shadow is a study of building within the carrying capacity of our planet. The intention was to explore how to build with reused products and recycled materials in an industrial, modular manner. We aimed at strong reduction of resource use, including materials, energy, space, and land. For achieving this, we optimised the size of the home for multi-functional use, built it with high degree of energy efficiency, searched for reusable products, and realised the project by disturbing the site and soil as little as possible.

As a result, we achieved to use 43% less land area, 84% less materials, 59% less energy, and project to cause 56% less life cycle GHG emissions per capita, when compared to a typical detached home.

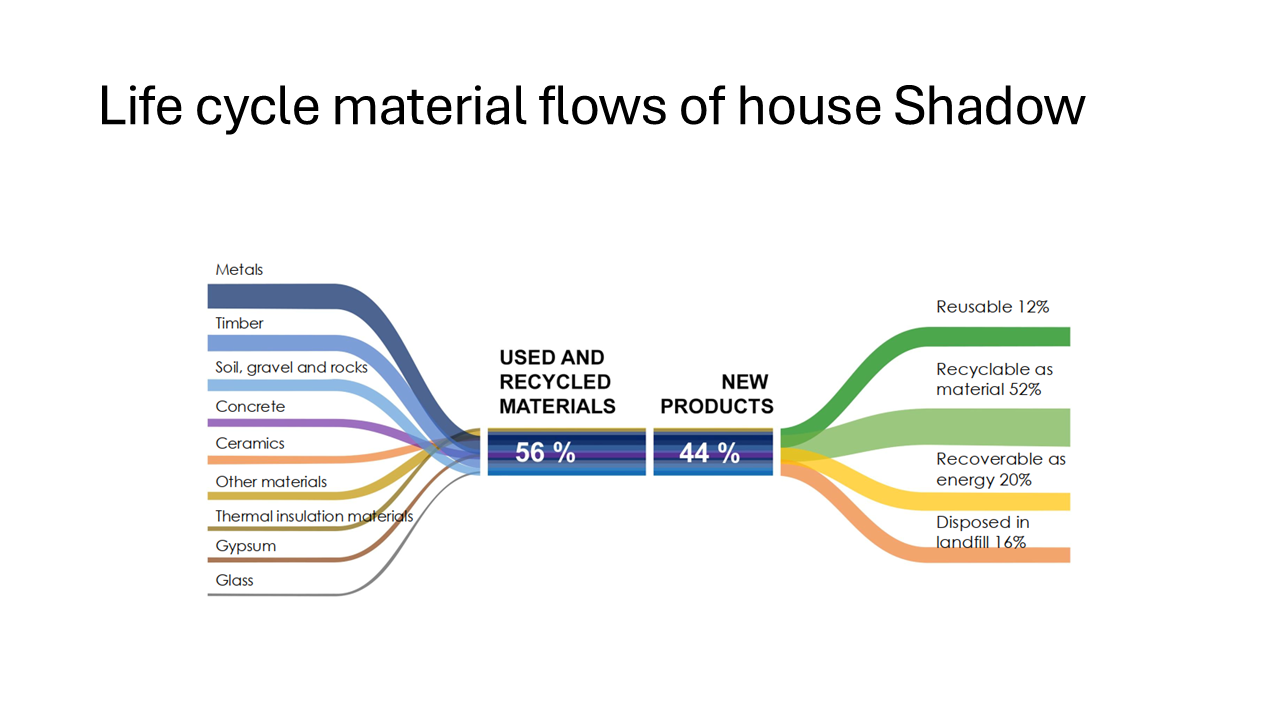

Overall, 56% of the weight of the building consists of reused products, or recycled materials. The material palette consists of:

• Reused doors, windows, and façade claddings.

• Recycled wood and plastics in interior surfaces.

• Fossil-free steel (100% recycled content) in the frame and parts of the façade.

• Insulation made almost entirely from recycled materials.

• Rubber roofing from old car tyres.

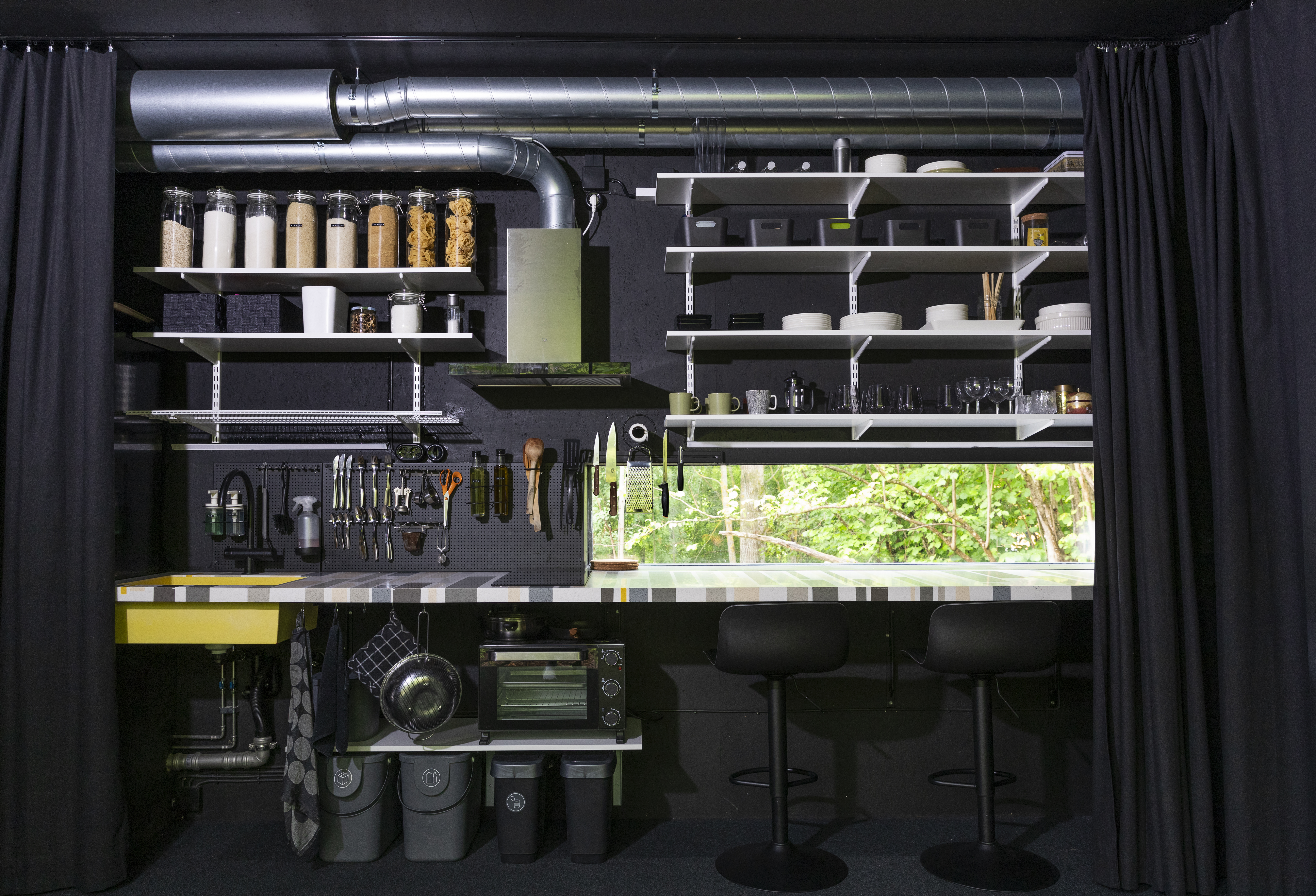

• Reused bathroom and kitchen fixtures and appliances (taps, toilet seat, oven, sinks, fridge etc.)

• Reused furniture

As a result, we achieved to use 43% less land area, 84% less materials, 59% less energy, and project to cause 56% less life cycle GHG emissions per capita, when compared to a typical detached home.

Overall, 56% of the weight of the building consists of reused products, or recycled materials. The material palette consists of:

• Reused doors, windows, and façade claddings.

• Recycled wood and plastics in interior surfaces.

• Fossil-free steel (100% recycled content) in the frame and parts of the façade.

• Insulation made almost entirely from recycled materials.

• Rubber roofing from old car tyres.

• Reused bathroom and kitchen fixtures and appliances (taps, toilet seat, oven, sinks, fridge etc.)

• Reused furniture

“Were it not for shadows, there would be no beauty”, wrote Junichiro Tanizaki in the classic ‘In Praise of Shadows’. This project is a study in the aesthetics and quality of imperfect and overlooked resources on two levels: The relevance for the residents of the house, and the broader socio-cultural relevance of the aesthetic shift that the circular economy necessarily implies.

Following Tanizaki´s remark, the aesthetics of the project are interpreting two different types of “shadows”. First, the buildings surfaces are meant for studying the interplay of light and shadow. The reused planks of the façade make a relief that changes its appearance in relation to Earth´s rotation. Inside, the walls are covered with black, translucent and softly undulating full-height curtains. Together with black floor and ceiling, they generate a calming, meditative environment. As a radical paradigm shift to a fully circular economy begins with change of values, house Shadow offers a safe space for contemplating new ways of building and living in harmony with our home planet.

Shadows are also a metaphor of wasted resources. We approach discarded, misfit, and marginalised products and materials by accepting their wear and tear. The circular economy in construction – when applied on the highest levels of EU´s waste hierarchy – necessarily includes tolerance of heterogenous visual and haptic qualities of surfaces and spaces. Hence, a different understanding of “beauty” is needed. House Shadow can be considered as an anti-thesis to the modernist ideal of bright, shining, glazed spaces – and especially to the associated overconsumption of resources for construction.

In this project, we are seeking aesthetics in the shadows of our consumerist, linear economy by using salvaged wood, faded cement boards, old car tyres, broken glass, and discarded plastics. By doing so, we can show the average homebuilder that there are alternatives to new materials, and excess amount of space.

Following Tanizaki´s remark, the aesthetics of the project are interpreting two different types of “shadows”. First, the buildings surfaces are meant for studying the interplay of light and shadow. The reused planks of the façade make a relief that changes its appearance in relation to Earth´s rotation. Inside, the walls are covered with black, translucent and softly undulating full-height curtains. Together with black floor and ceiling, they generate a calming, meditative environment. As a radical paradigm shift to a fully circular economy begins with change of values, house Shadow offers a safe space for contemplating new ways of building and living in harmony with our home planet.

Shadows are also a metaphor of wasted resources. We approach discarded, misfit, and marginalised products and materials by accepting their wear and tear. The circular economy in construction – when applied on the highest levels of EU´s waste hierarchy – necessarily includes tolerance of heterogenous visual and haptic qualities of surfaces and spaces. Hence, a different understanding of “beauty” is needed. House Shadow can be considered as an anti-thesis to the modernist ideal of bright, shining, glazed spaces – and especially to the associated overconsumption of resources for construction.

In this project, we are seeking aesthetics in the shadows of our consumerist, linear economy by using salvaged wood, faded cement boards, old car tyres, broken glass, and discarded plastics. By doing so, we can show the average homebuilder that there are alternatives to new materials, and excess amount of space.

Sustainable living should be a basic human right. If finite natural resources were considered as “budget”, then smaller and more resource-efficient buildings would be the only logical consequence of global population growth. House Shadow exemplifies an alternative to comfortable living that does not overconsume rapidly diminishing construction resources.

We will need 2 billion new homes this Century, while reducing 80…90% of emissions from construction. To achieve both goals simultaneously, radically different approaches to building and living are needed. On one hand, basic human needs and living quality must be met, especially in the developing countries where population growth is strongest. On the other hand, reduction of construction resources needs to be dramatic, particularly in those developed countries that do not need to reconstruct after wars or natural disasters.

The use of resources for construction needs to be strongly reduced in countries and communities where living standards are sufficient. As different building typologies have different resource intensities per floor area – detached homes being worst – the focus should be in favouring such typologies that are most efficient. Hence, if any new detached homes would be built, they would need to be extremely resource efficient. Otherwise, it is difficult to see their justification.

Smaller buildings are not cheaper to produce, but also more economic to operate. Reducing the amount of space cuts costs of both heating and cooling. Low operative costs are, however, not the greatest economic advantage. House Shadow has been designed to be easily relocated by lifting it from pre-installed reinforced hooks to a trailer. This makes it possible to adjust to changes in life, while preserving the value of the building independent of the land's price trends. Hence, the value invested in the building would not be lost, even if the region suffers from an economic downturn.

We will need 2 billion new homes this Century, while reducing 80…90% of emissions from construction. To achieve both goals simultaneously, radically different approaches to building and living are needed. On one hand, basic human needs and living quality must be met, especially in the developing countries where population growth is strongest. On the other hand, reduction of construction resources needs to be dramatic, particularly in those developed countries that do not need to reconstruct after wars or natural disasters.

The use of resources for construction needs to be strongly reduced in countries and communities where living standards are sufficient. As different building typologies have different resource intensities per floor area – detached homes being worst – the focus should be in favouring such typologies that are most efficient. Hence, if any new detached homes would be built, they would need to be extremely resource efficient. Otherwise, it is difficult to see their justification.

Smaller buildings are not cheaper to produce, but also more economic to operate. Reducing the amount of space cuts costs of both heating and cooling. Low operative costs are, however, not the greatest economic advantage. House Shadow has been designed to be easily relocated by lifting it from pre-installed reinforced hooks to a trailer. This makes it possible to adjust to changes in life, while preserving the value of the building independent of the land's price trends. Hence, the value invested in the building would not be lost, even if the region suffers from an economic downturn.

House Shadow has been used as a national example for building and living with less resource consumption. It has been widely published in national newspapers, and it´s presentation is among the most viewed videos on Aalto University´s YouTube channel. The building has been visited by local and international groups of experts and citizens already during the first months after its completion. House Shadow was also exhibited in 2024 NEB Festival in Brussels, and in COP29 in Baku.

There was no external funding, the demonstration project is privately financed.

There was no external funding, the demonstration project is privately financed.

The project is based on the collaboration with local and national stakeholders: designers, construction companies, and product manufacturers. Nationally, it is also a demonstration and test case of the forth-coming regulation on climate and material declarations. European-wide, the project attempts to bridge large industrial solutions for circular economy (e.g., fossil-free steel and recycled plastics) with local disassembly and reassembly of old building products (timber, doors, windows, concrete blocks).

The demonstration was carried out in a collaboration between Aalto University and 10 construction sector companies. There was no previous collaboration between the companies. During the project, companies co-developed new circular products and are currently preparing a follow-up project that has even higher ambition. Stakeholders and their role is further described in this application.

The project was part of an exhibition in 2024 NEB Festival and COP29 in Baku. In both events, the demonstrated solutions raised interest in utilising already existing, low-hanging fruits of the circular economy.

The demonstration was carried out in a collaboration between Aalto University and 10 construction sector companies. There was no previous collaboration between the companies. During the project, companies co-developed new circular products and are currently preparing a follow-up project that has even higher ambition. Stakeholders and their role is further described in this application.

The project was part of an exhibition in 2024 NEB Festival and COP29 in Baku. In both events, the demonstrated solutions raised interest in utilising already existing, low-hanging fruits of the circular economy.

The project was a test case for industrial circular economy in the Finnish construction sector. Despite of political declarations, the Finnish construction sector is the most material intensive sector in the country, and Finland is the only EU country that has not yet reached EU´s minimum levels for the utilisation of construction and demolition waste. In this conservative context, we gathered a group of companies to work on the reassembly of discarded building products, and to develop new building products from waste and industrial side streams. The core skills were architecture, structural engineering, energy technology, chemistry, and photography. We developed completely new interior surfaces and products from recycled plastics and industrial side streams for the bathroom and kitchen. We applied for the first time fully fossil-free steel structures that were made 100% from recycled scrap and realised the first bitumen roofing made from old car tyres. We integrated art into the space-saving, transparent sliding doors by collaborating with a local award-winning nature photographer Heikki Willamo. We developed a new line of sliding doors that combine fossil-free frame, and door panel made either from recycled plastic, recycled sawdust and lignin resin, or glass with meditative black-and-white nature photos from the boreal forests. These became possible by bringing various disciplines and companies together, it was a creative snow-balling process that yielded positive surprises.

Partners involved were Aalto University (life cycle assessment and material flow analysis) Aulis Lundell (prefabrication and construction), SSAB and Vesivek (fossil-free steel and products), Durat (recycled plastics), Kerabit (recycled tyres for bitumen), Isover (recycled insulation materials), Forbo (recycled plastic carpets), Koskisen (recycled chipboards), Airfi (AI-powered ventilation), and Rosk´n´Roll (access to waste materials).

Partners involved were Aalto University (life cycle assessment and material flow analysis) Aulis Lundell (prefabrication and construction), SSAB and Vesivek (fossil-free steel and products), Durat (recycled plastics), Kerabit (recycled tyres for bitumen), Isover (recycled insulation materials), Forbo (recycled plastic carpets), Koskisen (recycled chipboards), Airfi (AI-powered ventilation), and Rosk´n´Roll (access to waste materials).

The multi-disciplinary experimentation led into the development of new products from recycled materials, and into a new concept of an industrially prefabricated modular building reassembled from reused products and new circular products. For the first time, it was possible to test how different product ideas work together and perform on the level of a building. The project was carried out deliberately with higher risks than normal construction projects.

As an innovation niche, the house has probably the smallest wood-fired sauna in the country. It has less than 2 m2 floor area but is built in two floors. The platform that is directly above the stove is a downsized reinterpretation of the historical type of multifunctional saunas in the Häme region that had platforms for bathing and for drying food. This small sauna offers bath for two and is partially built from the trunks of the aspens that were cut from the site. They are sawn into discs and installed to the ceiling. Hence, the cells of the wood are open for maximising the moisture buffering effect. This small detail maximises the quality of the steam and makes the bath experience very enjoyable while reducing the need for energy.

As an innovation niche, the house has probably the smallest wood-fired sauna in the country. It has less than 2 m2 floor area but is built in two floors. The platform that is directly above the stove is a downsized reinterpretation of the historical type of multifunctional saunas in the Häme region that had platforms for bathing and for drying food. This small sauna offers bath for two and is partially built from the trunks of the aspens that were cut from the site. They are sawn into discs and installed to the ceiling. Hence, the cells of the wood are open for maximising the moisture buffering effect. This small detail maximises the quality of the steam and makes the bath experience very enjoyable while reducing the need for energy.

The design was based on the qualitative comparison of building products and the assessment of the building´s material flows, energy consumption, carbon footprint, and carbon handprint. These assessments were done according to the forthcoming national legislation for whole-life carbon assessment and material declarations of buildings. The results were compared to life cycle analyses of conventional and tiny houses. The construction work was based on prefabrication in a factory.

The products and approaches developed in the project have high replicability. First, the design of an economically and physically accessible detached home that fits within the planetary carrying capacity is of novelty. Second, the project yielded new products and innovations through the collaboration of companies (plastic, steel, wood, glass, rubber), and these have commercial potential. Third, the importance of the ideology of strongly reducing resource consumption while developing comfortable and creative living environments is much needed for meeting the global housing needs and climate goals simultaneously.

The products and approaches developed in the project have high replicability. First, the design of an economically and physically accessible detached home that fits within the planetary carrying capacity is of novelty. Second, the project yielded new products and innovations through the collaboration of companies (plastic, steel, wood, glass, rubber), and these have commercial potential. Third, the importance of the ideology of strongly reducing resource consumption while developing comfortable and creative living environments is much needed for meeting the global housing needs and climate goals simultaneously.

The project is an important national milestone in circular construction. Although there are several inspiring international examples, the Finnish construction sector is very conservative and resource intensive. According to Eurostat, Finland is the most material intensive economy in the EU, consuming over three times as much materials per capita as the EU average. According to our national statistics, construction is the most material intensive sector in the country, consuming some 116 million tonnes yearly. In terms of circular economy, Finland has EU´s lowest rate in the utilisation of construction and demolition waste, being the only country who has not yet achieved the minimum waste utilisation requirements. Even though Finland has an ambitious goal of reaching carbon neutrality by 2035, the country now struggles with rapidly diminishing forest carbon sinks. Hence, Finland faces the needs to cut emissions further from other sectors, construction sector included. In this context, the project is an important national example and proof of concept for building and living with less resources and less emissions.