Reconnecting with nature

Stoolbox

The Modular, Sustainable Furniture Solution

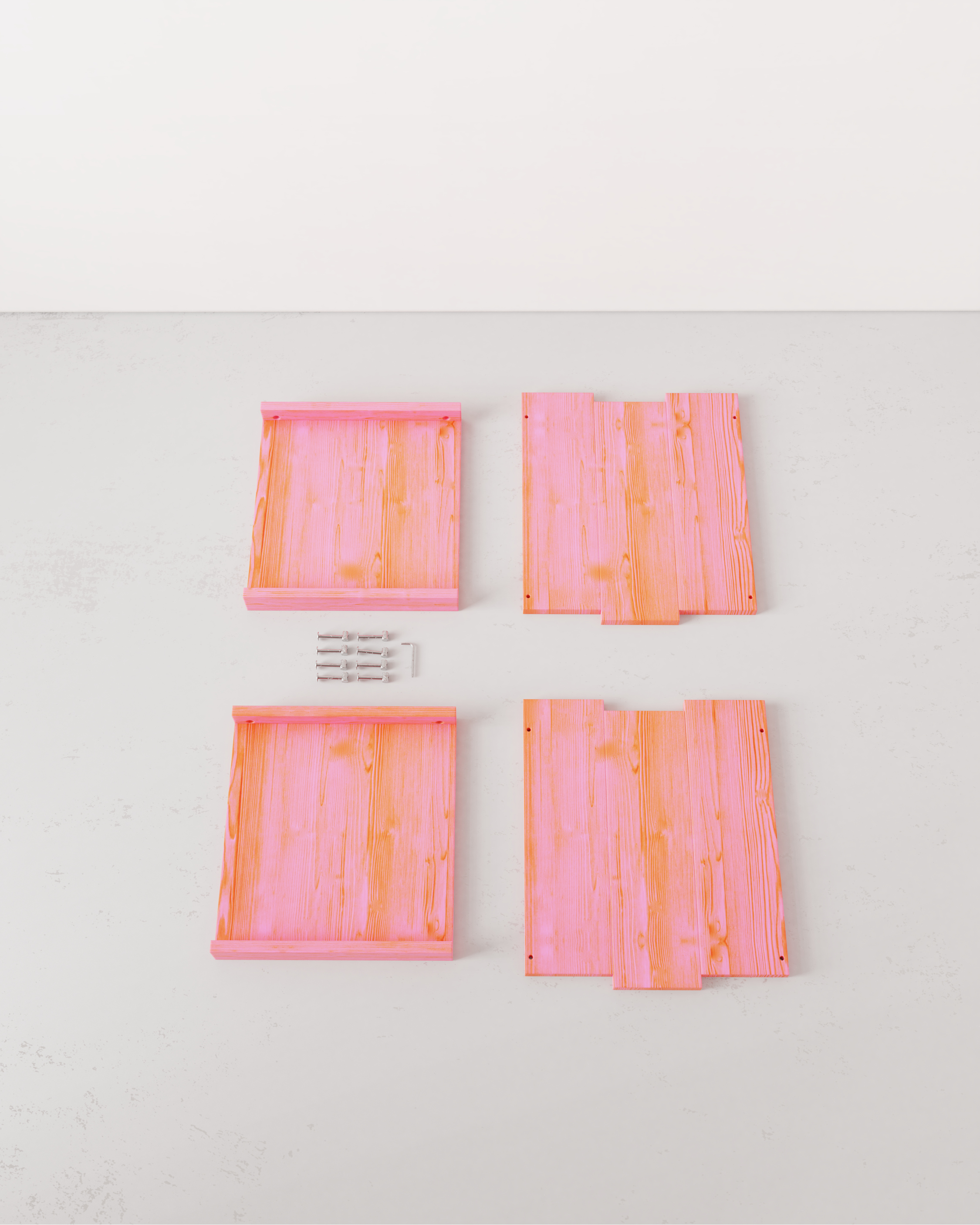

Stoolbox is a versatile, locally manufacturable furniture piece that adapts to your needs. Designed for sustainability and efficiency, it functions as a seat, table, or storage unit, all while minimizing material waste and shipping impact with flat-pack design. Built from FSC-certified wood and optimized for repair and customization, Stoolbox is a forward-thinking solution for modern, flexible living spaces.

Hungary

Regional

Stoolbox is currently being developed at a regional and international level, with a focus on localized production and decentralized manufacturing. The concept allows for adaptation in multiple cities and regions, enabling small workshops and manufacturers to produce it locally, reducing transportation emissions and supporting circular economy principles. This flexible model makes it scalable from local communities to broader national and international markets.

Mainly urban

It refers to a physical transformation of the built environment (hard investment)

Prototype level

No

No

As an individual

Stoolbox is a modular, multifunctional furniture system that integrates space efficiency, sustainability, and circular production principles. Its goal is to transform interior spaces with a flexible, locally manufacturable, and long-lasting solution while reducing production waste and the environmental impact of transportation. The project primarily targets urban residents who need compact and adaptable furniture, as well as co-working spaces and public interiors where flexibility is essential. It also benefits local manufacturers and businesses interested in sustainable production, as it is optimized for decentralized manufacturing. Stoolbox aims to minimize its ecological footprint through a flat-pack design that reduces shipping emissions while remaining easy to produce and repair locally. Made from FSC-certified wood, its modular construction allows for easy repair and customization, extending the product’s lifespan. One of the key outcomes of the project is a scalable, locally produced model that strengthens regional production networks, lowers CO₂ emissions, and contributes to the sustainable transformation of industrial ecosystems. By following circular economy principles, Stoolbox offers a furniture solution that is not only practical and aesthetically refined but also environmentally responsible, fully aligned with the values of the New European Bauhaus.

Sustainability

Modularity

Circular Economy

Local Manufacturing

Adaptability

Reducing Environmental Impact – Stoolbox minimizes its carbon footprint through flat-pack design, which reduces transportation emissions and optimizes storage. Additionally, local manufacturing enables decentralized production, cutting down on long-distance shipping and reliance on large-scale industrial facilities.

Sustainable Material Use – The furniture is made from FSC-certified wood, ensuring responsible sourcing and reducing environmental degradation. The efficient CNC-cutting process minimizes material waste, supporting a more sustainable production cycle.

Circular Economy and Product Longevity – Stoolbox is designed for repairability and modularity, allowing users to replace individual parts rather than discarding the entire product. This approach extends the product’s lifespan and reduces landfill waste, making it a more sustainable alternative to conventional furniture.

Resource-Efficient Manufacturing – The simple, workshop-friendly production process enables small-scale manufacturers to produce Stoolbox locally, supporting a more distributed and sustainable industrial ecosystem. This reduces overproduction and promotes a low-waste, demand-driven manufacturing approach.

Adaptability and Space Efficiency – The multifunctional design allows Stoolbox to serve as a seat, table, or storage unit, reducing the need for multiple furniture pieces and promoting efficient use of resources and living spaces.

Exemplary Impact

Stoolbox demonstrates a scalable and replicable model for circular economy-based furniture, offering a viable alternative to mass-produced, disposable furniture. By integrating sustainable materials, decentralized production, and a long-lasting design, it serves as an example of how design innovation can support environmental responsibility while maintaining affordability and adaptability.

Sustainable Material Use – The furniture is made from FSC-certified wood, ensuring responsible sourcing and reducing environmental degradation. The efficient CNC-cutting process minimizes material waste, supporting a more sustainable production cycle.

Circular Economy and Product Longevity – Stoolbox is designed for repairability and modularity, allowing users to replace individual parts rather than discarding the entire product. This approach extends the product’s lifespan and reduces landfill waste, making it a more sustainable alternative to conventional furniture.

Resource-Efficient Manufacturing – The simple, workshop-friendly production process enables small-scale manufacturers to produce Stoolbox locally, supporting a more distributed and sustainable industrial ecosystem. This reduces overproduction and promotes a low-waste, demand-driven manufacturing approach.

Adaptability and Space Efficiency – The multifunctional design allows Stoolbox to serve as a seat, table, or storage unit, reducing the need for multiple furniture pieces and promoting efficient use of resources and living spaces.

Exemplary Impact

Stoolbox demonstrates a scalable and replicable model for circular economy-based furniture, offering a viable alternative to mass-produced, disposable furniture. By integrating sustainable materials, decentralized production, and a long-lasting design, it serves as an example of how design innovation can support environmental responsibility while maintaining affordability and adaptability.

Timeless Aesthetic and Simplicity – Stoolbox follows a clean, minimalistic design approach, making it adaptable to various interior styles. Its geometric form and natural materiality create a visually harmonious object that complements both contemporary and traditional spaces.

User Experience and Customization – The modular design allows users to assemble, modify, and repurpose Stoolbox according to their needs. This hands-on interaction fosters a personal connection with the furniture, enhancing the user experience and promoting emotional durability.

Cultural and Local Relevance – By emphasizing local manufacturing, Stoolbox supports regional craftsmanship and small-scale production, contributing to the cultural appreciation of sustainable, well-crafted furniture. This strengthens the connection between design, production, and community identity.

Material Authenticity and Tactile Quality – Made from FSC-certified wood, Stoolbox provides a natural, warm material experience that enhances indoor environments. The smooth, precision-cut surfaces and high-quality finishes ensure durability while maintaining a pleasing tactile interaction.

Functionality Meets Emotional Value – Beyond its practical adaptability as a seat, table, or storage unit, Stoolbox is designed to be a long-lasting, cherished object. Its ability to be repaired, upgraded, and modified means it evolves with the user, reinforcing a more mindful approach to furniture ownership.

Exemplary Impact

Stoolbox demonstrates how design can merge aesthetics, functionality, and sustainability to create furniture that is not only beautiful but also culturally and environmentally meaningful. By embracing simplicity, adaptability, and high-quality craftsmanship, it sets an example for future-oriented, experience-driven design that enhances everyday living.

User Experience and Customization – The modular design allows users to assemble, modify, and repurpose Stoolbox according to their needs. This hands-on interaction fosters a personal connection with the furniture, enhancing the user experience and promoting emotional durability.

Cultural and Local Relevance – By emphasizing local manufacturing, Stoolbox supports regional craftsmanship and small-scale production, contributing to the cultural appreciation of sustainable, well-crafted furniture. This strengthens the connection between design, production, and community identity.

Material Authenticity and Tactile Quality – Made from FSC-certified wood, Stoolbox provides a natural, warm material experience that enhances indoor environments. The smooth, precision-cut surfaces and high-quality finishes ensure durability while maintaining a pleasing tactile interaction.

Functionality Meets Emotional Value – Beyond its practical adaptability as a seat, table, or storage unit, Stoolbox is designed to be a long-lasting, cherished object. Its ability to be repaired, upgraded, and modified means it evolves with the user, reinforcing a more mindful approach to furniture ownership.

Exemplary Impact

Stoolbox demonstrates how design can merge aesthetics, functionality, and sustainability to create furniture that is not only beautiful but also culturally and environmentally meaningful. By embracing simplicity, adaptability, and high-quality craftsmanship, it sets an example for future-oriented, experience-driven design that enhances everyday living.

Affordability – Stoolbox is optimized for cost-effective production by using locally available materials and a simple CNC-based manufacturing process. This makes high-quality, sustainable furniture financially accessible to a broader audience without relying on expensive industrial manufacturing.

Design for All – Modular and Adaptable Use – The versatile, multifunctional design allows Stoolbox to serve as a seat, table, or storage unit, adapting to different living and working conditions. Its flat-pack, easy-to-assemble construction ensures that anyone, regardless of skill level, can put it together, making it an accessible and practical solution for diverse users.

Decentralized Production for Local Empowerment – The open, workshop-friendly manufacturing model enables small-scale businesses, local craftsmen, and community workshops to produce Stoolbox. This supports local economies, creates jobs, and allows for regional adaptations, fostering a more inclusive production system.

Accessibility – Stoolbox follows universal design principles, ensuring ergonomic usability, stability, and comfortable interaction for all age groups. The lightweight, modular structure makes it easy to move, assemble, and repurpose, accommodating different mobility needs.

Sustainability as Social Inclusion – By providing a repairable, long-lasting alternative to disposable furniture, Stoolbox helps make sustainability an accessible choice for people who may not typically afford environmentally friendly products. The ability to replace parts instead of discarding the whole piece promotes long-term, responsible consumption.

Stoolbox serves as a model for how inclusive design can reshape the furniture industry, making sustainability and quality more accessible to all. By combining affordable, adaptable, and locally manufacturable solutions, it challenges traditional production systems and offers a more inclusive, community-driven alternative to mass-produced furniture.

Design for All – Modular and Adaptable Use – The versatile, multifunctional design allows Stoolbox to serve as a seat, table, or storage unit, adapting to different living and working conditions. Its flat-pack, easy-to-assemble construction ensures that anyone, regardless of skill level, can put it together, making it an accessible and practical solution for diverse users.

Decentralized Production for Local Empowerment – The open, workshop-friendly manufacturing model enables small-scale businesses, local craftsmen, and community workshops to produce Stoolbox. This supports local economies, creates jobs, and allows for regional adaptations, fostering a more inclusive production system.

Accessibility – Stoolbox follows universal design principles, ensuring ergonomic usability, stability, and comfortable interaction for all age groups. The lightweight, modular structure makes it easy to move, assemble, and repurpose, accommodating different mobility needs.

Sustainability as Social Inclusion – By providing a repairable, long-lasting alternative to disposable furniture, Stoolbox helps make sustainability an accessible choice for people who may not typically afford environmentally friendly products. The ability to replace parts instead of discarding the whole piece promotes long-term, responsible consumption.

Stoolbox serves as a model for how inclusive design can reshape the furniture industry, making sustainability and quality more accessible to all. By combining affordable, adaptable, and locally manufacturable solutions, it challenges traditional production systems and offers a more inclusive, community-driven alternative to mass-produced furniture.

User-Centered Design and Feedback – The concept was developed based on real-life needs, particularly among urban dwellers with limited space. Through workshops and discussions, potential users provided valuable insights on functionality, adaptability, and usability, helping refine the modular, multifunctional nature of the furniture.

Local Manufacturing and Empowerment – Stoolbox promotes decentralized, small-scale production, allowing local workshops, artisans, and makerspaces to manufacture it. This empowers regional economies and creates more equitable access to sustainable furniture by making production skills and tools more accessible.

Sustainability Awareness and Education – The project fosters a circular economy mindset by encouraging repairability and modularity, reducing waste and overconsumption. By involving local design communities and sustainability advocates, Stoolbox helps educate and inspire consumers to make more responsible choices.

Accessibility Through Open Design – By simplifying the manufacturing process, Stoolbox can be produced in various regions, ensuring that more communities can access sustainable, high-quality furniture. The project also explores collaborations with social enterprises, integrating inclusive labor practices and supporting disadvantaged groups.

Impact of Citizen Involvement

Product improvements based on real user needs, ensuring practicality and versatility.

Support for local craftsmanship and small businesses, reducing reliance on mass production.

Increased awareness of sustainable consumption through repairability and resource efficiency.

More inclusive design and production processes, allowing for regional adaptations.

By integrating citizen engagement, local production, and sustainable design, Stoolbox exemplifies a participatory, community-driven approach that redefines how furniture is designed, manufactured, and used.

Local Manufacturing and Empowerment – Stoolbox promotes decentralized, small-scale production, allowing local workshops, artisans, and makerspaces to manufacture it. This empowers regional economies and creates more equitable access to sustainable furniture by making production skills and tools more accessible.

Sustainability Awareness and Education – The project fosters a circular economy mindset by encouraging repairability and modularity, reducing waste and overconsumption. By involving local design communities and sustainability advocates, Stoolbox helps educate and inspire consumers to make more responsible choices.

Accessibility Through Open Design – By simplifying the manufacturing process, Stoolbox can be produced in various regions, ensuring that more communities can access sustainable, high-quality furniture. The project also explores collaborations with social enterprises, integrating inclusive labor practices and supporting disadvantaged groups.

Impact of Citizen Involvement

Product improvements based on real user needs, ensuring practicality and versatility.

Support for local craftsmanship and small businesses, reducing reliance on mass production.

Increased awareness of sustainable consumption through repairability and resource efficiency.

More inclusive design and production processes, allowing for regional adaptations.

By integrating citizen engagement, local production, and sustainable design, Stoolbox exemplifies a participatory, community-driven approach that redefines how furniture is designed, manufactured, and used.

Stoolbox is a collaborative, multi-level project focused on sustainability, accessibility, and scalability, involving stakeholders from local to European levels. The engagement of these diverse groups has shaped the design, production, and implementation of the project, ensuring its impact.

Local Level: Makerspaces, Small Workshops, and End-Users

Makerspaces and local workshops, such as FabLab Budapest, provided technical input for prototype development, ensuring that Stoolbox is easy to manufacture and repair locally. End-users, including urban residents and co-working spaces, participated in testing and provided feedback, refining the modular design. Local sustainability advocates helped with material sourcing and circular design principles.

Added Value: Ensures practical, repairable, and locally manufacturable design.

Regional Level: Independent Designers and Small-Scale Manufacturers

Regional manufacturers optimized production, focusing on material efficiency and waste reduction through CNC-cutting. Independent designers shaped the modularity and customization options of the design.

Added Value: Strengthens regional production, reduces reliance on mass production, and lowers emissions.

National Level: Industry Experts and Circular Economy Networks

Sustainability experts and design organizations aligned Stoolbox with national circular economy strategies. Furniture industry professionals ensured scalability and market competitiveness.

Added Value: Integrates Stoolbox into national sustainability initiatives, enhancing its economic and environmental impact.

European Level: New European Bauhaus and Circular Economy Networks

Aligned with the New European Bauhaus initiative, Stoolbox emphasizes sustainability, inclusivity, and aesthetics. European networks offer platforms for collaboration and further development.

Added Value: Positions Stoolbox as a replicable solution across Europe, promoting localized sustainable production.

Local Level: Makerspaces, Small Workshops, and End-Users

Makerspaces and local workshops, such as FabLab Budapest, provided technical input for prototype development, ensuring that Stoolbox is easy to manufacture and repair locally. End-users, including urban residents and co-working spaces, participated in testing and provided feedback, refining the modular design. Local sustainability advocates helped with material sourcing and circular design principles.

Added Value: Ensures practical, repairable, and locally manufacturable design.

Regional Level: Independent Designers and Small-Scale Manufacturers

Regional manufacturers optimized production, focusing on material efficiency and waste reduction through CNC-cutting. Independent designers shaped the modularity and customization options of the design.

Added Value: Strengthens regional production, reduces reliance on mass production, and lowers emissions.

National Level: Industry Experts and Circular Economy Networks

Sustainability experts and design organizations aligned Stoolbox with national circular economy strategies. Furniture industry professionals ensured scalability and market competitiveness.

Added Value: Integrates Stoolbox into national sustainability initiatives, enhancing its economic and environmental impact.

European Level: New European Bauhaus and Circular Economy Networks

Aligned with the New European Bauhaus initiative, Stoolbox emphasizes sustainability, inclusivity, and aesthetics. European networks offer platforms for collaboration and further development.

Added Value: Positions Stoolbox as a replicable solution across Europe, promoting localized sustainable production.

The design and implementation of Stoolbox incorporated various disciplines, fostering a multidisciplinary approach to ensure its practicality, sustainability, and scalability.

Industrial Design and Product Development

Industrial designers created the modular, multifunctional design, focusing on practicality and adaptability. They collaborated with engineers to ensure manufacturability using local resources and technologies.

Sustainability and Circular Economy

Sustainability experts guided the project to adhere to circular economy principles, ensuring efficient material sourcing, production processes, and a product life cycle that minimizes waste. They worked closely with designers and manufacturers to select sustainable materials and optimize production efficiency.

Engineering and Manufacturing

Engineers and local manufacturers focused on turning the design into a functional product, optimizing production through CNC cutting and local sourcing. They worked with designers to ensure technical feasibility and efficient assembly.

User Experience and Feedback

End-users, including urban residents and co-working spaces, provided valuable insights on usability. Designers and sustainability experts integrated their feedback into iterative design improvements, ensuring Stoolbox met real-life needs.

Business and Market Viability

Business experts and furniture industry professionals ensured Stoolbox was market-ready, assessing its economic viability and scalability. They collaborated with the team to balance sustainability with affordability and competitiveness.

Added Value of Collaboration

This cross-disciplinary collaboration allowed Stoolbox to combine creativity, technical feasibility, and sustainability. It resulted in a product that is not only functional and aesthetically appealing but also environmentally responsible and economically viable, offering a scalable solution to modern furniture needs.

Industrial Design and Product Development

Industrial designers created the modular, multifunctional design, focusing on practicality and adaptability. They collaborated with engineers to ensure manufacturability using local resources and technologies.

Sustainability and Circular Economy

Sustainability experts guided the project to adhere to circular economy principles, ensuring efficient material sourcing, production processes, and a product life cycle that minimizes waste. They worked closely with designers and manufacturers to select sustainable materials and optimize production efficiency.

Engineering and Manufacturing

Engineers and local manufacturers focused on turning the design into a functional product, optimizing production through CNC cutting and local sourcing. They worked with designers to ensure technical feasibility and efficient assembly.

User Experience and Feedback

End-users, including urban residents and co-working spaces, provided valuable insights on usability. Designers and sustainability experts integrated their feedback into iterative design improvements, ensuring Stoolbox met real-life needs.

Business and Market Viability

Business experts and furniture industry professionals ensured Stoolbox was market-ready, assessing its economic viability and scalability. They collaborated with the team to balance sustainability with affordability and competitiveness.

Added Value of Collaboration

This cross-disciplinary collaboration allowed Stoolbox to combine creativity, technical feasibility, and sustainability. It resulted in a product that is not only functional and aesthetically appealing but also environmentally responsible and economically viable, offering a scalable solution to modern furniture needs.

Stoolbox is innovative in several key ways:

1. Modular and Multifunctional Design

Unlike traditional furniture, Stoolbox offers modularity and flexibility, allowing users to customize the product to their needs, which is uncommon in mass-produced furniture.

2. Local Production and Repairability

The project focuses on local manufacturing and repair, reducing reliance on global supply chains and transportation emissions, while promoting sustainability and longer product life through easy repairs.

3. Circular Economy and Sustainability

Stoolbox embraces circular economy principles by using sustainable materials, minimizing waste, and enabling easy disassembly, distinguishing it from mass-produced alternatives that often neglect environmental impact.

4. Stakeholder-Driven Development

Involving a range of stakeholders, from local makers to sustainability experts, Stoolbox ensures the product meets real-world needs and can be locally produced, unlike many traditional top-down projects.

5. Alignment with European Initiatives

By aligning with the New European Bauhaus and circular economy networks, Stoolbox promotes sustainability, inclusivity, and innovation, placing it ahead of mainstream products.

In summary, Stoolbox stands out for its flexible design, local production focus, sustainability, and collaborative development approach.

1. Modular and Multifunctional Design

Unlike traditional furniture, Stoolbox offers modularity and flexibility, allowing users to customize the product to their needs, which is uncommon in mass-produced furniture.

2. Local Production and Repairability

The project focuses on local manufacturing and repair, reducing reliance on global supply chains and transportation emissions, while promoting sustainability and longer product life through easy repairs.

3. Circular Economy and Sustainability

Stoolbox embraces circular economy principles by using sustainable materials, minimizing waste, and enabling easy disassembly, distinguishing it from mass-produced alternatives that often neglect environmental impact.

4. Stakeholder-Driven Development

Involving a range of stakeholders, from local makers to sustainability experts, Stoolbox ensures the product meets real-world needs and can be locally produced, unlike many traditional top-down projects.

5. Alignment with European Initiatives

By aligning with the New European Bauhaus and circular economy networks, Stoolbox promotes sustainability, inclusivity, and innovation, placing it ahead of mainstream products.

In summary, Stoolbox stands out for its flexible design, local production focus, sustainability, and collaborative development approach.

The Stoolbox project used a collaborative, iterative approach focused on sustainability and local production.

1. Collaborative Approach

Stakeholders, including makerspaces, designers, sustainability experts, manufacturers, and end-users, worked together to ensure the design met practical needs and environmental goals, with continuous feedback throughout.

2. Design Thinking and Iterative Development

Prototypes were developed and tested in makerspaces, with user feedback guiding improvements, ensuring functionality and usability.

3. Sustainability and Circular Economy

Circular economy principles guided material sourcing, waste reduction, and product longevity. The design was made for easy disassembly and repair, minimizing environmental impact.

4. Local Production

Local production was prioritized to reduce emissions and support regional economies. The design was optimized for local manufacturers using efficient techniques like CNC cutting.

5. Stakeholder Feedback Integration

Ongoing feedback from all stakeholders helped refine the design, ensuring it met real-world needs and sustainability standards.

In summary, the Stoolbox methodology combined collaborative design, sustainability, local production, and continuous feedback to create a functional, eco-friendly product.

1. Collaborative Approach

Stakeholders, including makerspaces, designers, sustainability experts, manufacturers, and end-users, worked together to ensure the design met practical needs and environmental goals, with continuous feedback throughout.

2. Design Thinking and Iterative Development

Prototypes were developed and tested in makerspaces, with user feedback guiding improvements, ensuring functionality and usability.

3. Sustainability and Circular Economy

Circular economy principles guided material sourcing, waste reduction, and product longevity. The design was made for easy disassembly and repair, minimizing environmental impact.

4. Local Production

Local production was prioritized to reduce emissions and support regional economies. The design was optimized for local manufacturers using efficient techniques like CNC cutting.

5. Stakeholder Feedback Integration

Ongoing feedback from all stakeholders helped refine the design, ensuring it met real-world needs and sustainability standards.

In summary, the Stoolbox methodology combined collaborative design, sustainability, local production, and continuous feedback to create a functional, eco-friendly product.

Several elements of the Stoolbox project can be replicated in other contexts:

1. Collaborative Methodology

The stakeholder-driven approach can be applied in other regions, fostering local innovation and community involvement in design and development.

2. Local Production Model

Focusing on local makerspaces and small workshops can be adapted to other areas, promoting sustainability, reducing emissions, and strengthening local economies.

3. Sustainability and Circular Economy

The project’s circular economy principles—sustainable materials, waste reduction, and repairability—can be applied to other products, promoting eco-friendly design.

4. Design and Prototyping Processes

Rapid prototyping and testing in makerspaces, using technologies like CNC cutting and 3D printing, can be replicated for custom, locally produced solutions.

5. Knowledge Sharing

The lessons learned from Stoolbox can be shared through workshops or partnerships, helping others adopt sustainable, user-centered design practices.

In summary, the project’s methodology, local production, sustainability, and prototyping processes can be easily adapted to other contexts, promoting community-driven, sustainable solutions.

1. Collaborative Methodology

The stakeholder-driven approach can be applied in other regions, fostering local innovation and community involvement in design and development.

2. Local Production Model

Focusing on local makerspaces and small workshops can be adapted to other areas, promoting sustainability, reducing emissions, and strengthening local economies.

3. Sustainability and Circular Economy

The project’s circular economy principles—sustainable materials, waste reduction, and repairability—can be applied to other products, promoting eco-friendly design.

4. Design and Prototyping Processes

Rapid prototyping and testing in makerspaces, using technologies like CNC cutting and 3D printing, can be replicated for custom, locally produced solutions.

5. Knowledge Sharing

The lessons learned from Stoolbox can be shared through workshops or partnerships, helping others adopt sustainable, user-centered design practices.

In summary, the project’s methodology, local production, sustainability, and prototyping processes can be easily adapted to other contexts, promoting community-driven, sustainable solutions.

The Stoolbox project addresses several global challenges with local solutions:

1. Climate Change

By reducing transportation emissions and promoting sustainable material sourcing, Stoolbox lowers the environmental impact of furniture production.

2. Unsustainable Consumption

The modular, customizable design reduces the need for mass-produced, single-use furniture, promoting sustainable consumption.

3. Economic Inequality

Focusing on local production supports small manufacturers, strengthens regional economies, and reduces reliance on large industries.

4. Resource Scarcity

The circular economy approach prioritizes reuse and minimizes waste, helping combat global resource scarcity.

5. Access to Sustainable Products

By engaging local communities, Stoolbox makes sustainable, locally produced solutions accessible to a wide range of consumers.

In summary, Stoolbox addresses climate change, unsustainable consumption, economic inequality, resource scarcity, and limited access to sustainable products by providing scalable, localized solutions.

1. Climate Change

By reducing transportation emissions and promoting sustainable material sourcing, Stoolbox lowers the environmental impact of furniture production.

2. Unsustainable Consumption

The modular, customizable design reduces the need for mass-produced, single-use furniture, promoting sustainable consumption.

3. Economic Inequality

Focusing on local production supports small manufacturers, strengthens regional economies, and reduces reliance on large industries.

4. Resource Scarcity

The circular economy approach prioritizes reuse and minimizes waste, helping combat global resource scarcity.

5. Access to Sustainable Products

By engaging local communities, Stoolbox makes sustainable, locally produced solutions accessible to a wide range of consumers.

In summary, Stoolbox addresses climate change, unsustainable consumption, economic inequality, resource scarcity, and limited access to sustainable products by providing scalable, localized solutions.

In the year following the application, the Stoolbox project will focus on:

1. Finalizing Design and Prototyping

Refining the product design based on user feedback and further testing prototypes to improve functionality and customization.

2. Expanding Local Partnerships

Strengthening collaborations with makerspaces, small manufacturers, and sustainability experts to enhance production capabilities.

3. Pilot Production Run

Conducting a small-scale production run to test manufacturability, assembly, and durability.

4. Community Engagement and Promotion

Increasing outreach through workshops, events, and online campaigns to gather feedback and promote the product.

5. Scaling Production and Distribution

Optimizing production and securing local distribution channels, including exploring collaborations with larger manufacturers.

6. Securing Funding and Partnerships

Seeking funding through grants, investment, or crowdfunding, and expanding European partnerships for further growth.

These steps will help Stoolbox develop as a scalable, sustainable furniture solution.

1. Finalizing Design and Prototyping

Refining the product design based on user feedback and further testing prototypes to improve functionality and customization.

2. Expanding Local Partnerships

Strengthening collaborations with makerspaces, small manufacturers, and sustainability experts to enhance production capabilities.

3. Pilot Production Run

Conducting a small-scale production run to test manufacturability, assembly, and durability.

4. Community Engagement and Promotion

Increasing outreach through workshops, events, and online campaigns to gather feedback and promote the product.

5. Scaling Production and Distribution

Optimizing production and securing local distribution channels, including exploring collaborations with larger manufacturers.

6. Securing Funding and Partnerships

Seeking funding through grants, investment, or crowdfunding, and expanding European partnerships for further growth.

These steps will help Stoolbox develop as a scalable, sustainable furniture solution.