Reconnecting with nature

SMART VIEW

SMART VIEW - Factory as Ecology

SMART VIEW is a nature-inspired user interface that enables workers to see the status of

parts manufacture in real-time, showing progress as growing trees and coral. Co-

designed with workers, this solution offers a new way of visualising real-time data, enhancing nature connections and improving worker wellbeing.

parts manufacture in real-time, showing progress as growing trees and coral. Co-

designed with workers, this solution offers a new way of visualising real-time data, enhancing nature connections and improving worker wellbeing.

Portugal

Local

Marinha Grande, Portugal

It addresses urban-rural linkages

It refers to other types of transformations (soft investment)

Yes

2024-03-01

Yes

Horizon2020 / Horizon Europe

No

No

As an individual partnership with other persons/organisation(s)

SMART-VIEW addresses the problem of the communication gap between management and shop-floor workers in production factories. It is a collaboration between visual artist Kristina Pulejkova, tech provider Octavic, and Famolde, a mould making factory. The project was carried out through the Better Factory programme, funded by Horizon 2020 grant.

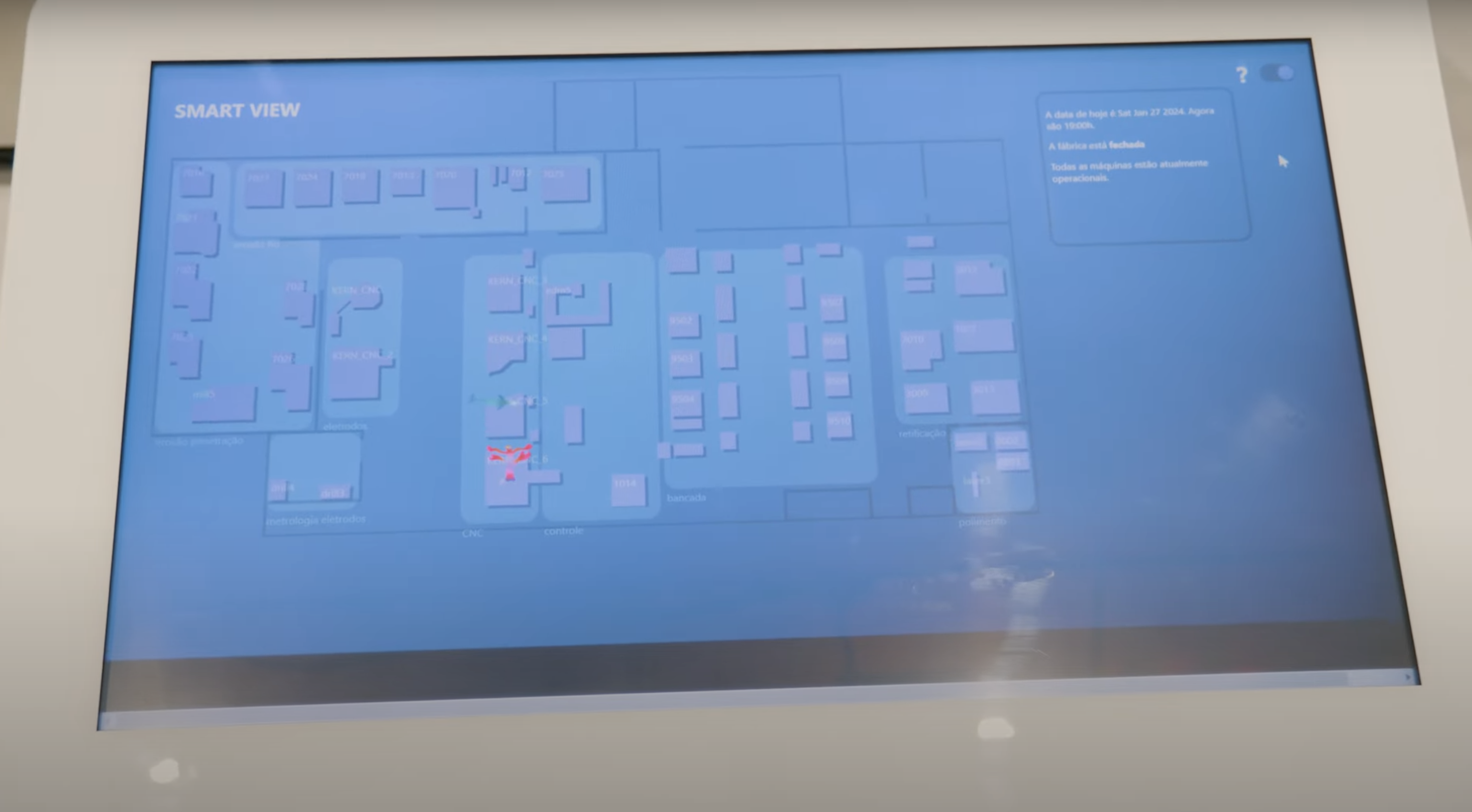

The lack of process overview and cross-departmental communication was affecting the workers’ wellbeing and consequently the production output. The main challenge identified was the lack of systemic overview of the factory processes for all stakeholders involved. Although there were tracking systems in place, they were lacking ease of access and interdepartmental overview of the ongoing work stages. (Design, part making, quality control, assembly etc.) This lack of overview created confusion and gaps between departments, particularly emphasising the management / shop-floor divide. The aim of the project was to empower employees and improve worker wellbeing by applying nature-based strategies and nature-inspired design, increase production output while reducing waste and minimising energy consumption for improved sustainability. With this approach the artist, alongside the tech provider partners Octavic, co-created a live data process-tracking system which had an innovative data visualisation interface, inspired by the local ecological environment. The tool allowed all employees to oversee actual real time status of the factory processes at a glance. By using nature-inspired design, the aim was to create visualisations that presented the factory as an ecology, and opened spaces for reinterpretation of the familiar overview dashboard and contributed to an measurably improved wellbeing in the factory. SMART VIEW delivered excellent results and exceeded expectations on all objectives, providing a scalable, replicable model for connecting people with nature through digital processes whilst improving worker wellbeing and connection.

The lack of process overview and cross-departmental communication was affecting the workers’ wellbeing and consequently the production output. The main challenge identified was the lack of systemic overview of the factory processes for all stakeholders involved. Although there were tracking systems in place, they were lacking ease of access and interdepartmental overview of the ongoing work stages. (Design, part making, quality control, assembly etc.) This lack of overview created confusion and gaps between departments, particularly emphasising the management / shop-floor divide. The aim of the project was to empower employees and improve worker wellbeing by applying nature-based strategies and nature-inspired design, increase production output while reducing waste and minimising energy consumption for improved sustainability. With this approach the artist, alongside the tech provider partners Octavic, co-created a live data process-tracking system which had an innovative data visualisation interface, inspired by the local ecological environment. The tool allowed all employees to oversee actual real time status of the factory processes at a glance. By using nature-inspired design, the aim was to create visualisations that presented the factory as an ecology, and opened spaces for reinterpretation of the familiar overview dashboard and contributed to an measurably improved wellbeing in the factory. SMART VIEW delivered excellent results and exceeded expectations on all objectives, providing a scalable, replicable model for connecting people with nature through digital processes whilst improving worker wellbeing and connection.

Factory worker wellbeing

nature connection

factory as ecology

sustainability

nature-inspired interface

The SMART VIEW prototype set out to reduce factory waste and energy consumption due to its smart processes, machine tracking and management system, enabling the factory to become a more sustainable manufacturer with less waste, energy consumption and carbon emissions. Furthermore, it set out to improve worker wellbeing, cross-departmental communication and human-machine interaction. The smart process-tracking system developed by the partnership was deployed at the factory, with data gathered since its deployment in March 2024. The collected data gave the following results and projections: Waste Reduction of 2.2 – 3.5 tonnes of scrap per year, Energy Consumption was reduced by 5%, with savings of up to 43.6 MWh in one single year. The system enables potential future measurement and reduction of Greenhouse Gasses emissions.

When it comes to sustainability, it's important to also think about worker retention and satisfaction. The experiences from the workers using the interface showed: 25% increase of satisfaction in cross-departmental communication, 35% increase of satisfaction in human-machine communication and an incredible 58% increase in wellbeing, when using the nature-inspired system.

The project assessment combined the data gathered from the two key strands:

1. Environmental results and process improvement within the factory

2. Worker wellbeing and satisfaction; worker retention

The results showed overwhelming proof that implementing this innovative nature-inspired interface can be a great example for other factories from any industry to take up the solution and implement it in their manufacturing process.

When it comes to sustainability, it's important to also think about worker retention and satisfaction. The experiences from the workers using the interface showed: 25% increase of satisfaction in cross-departmental communication, 35% increase of satisfaction in human-machine communication and an incredible 58% increase in wellbeing, when using the nature-inspired system.

The project assessment combined the data gathered from the two key strands:

1. Environmental results and process improvement within the factory

2. Worker wellbeing and satisfaction; worker retention

The results showed overwhelming proof that implementing this innovative nature-inspired interface can be a great example for other factories from any industry to take up the solution and implement it in their manufacturing process.

The key objectives in terms of aesthetics and quality of experience were to create a nature-inspired interface that improves worker wellbeing, improves communication between shop-floor workers and management and empowers workers to track processes in real time whilst connecting them to their immediate environment. Another important aspect was to create the interface aesthetic in collaboration with the workers, allowing for their voice and vision to come through, enabling them to have ownership to the system we created for the factory.

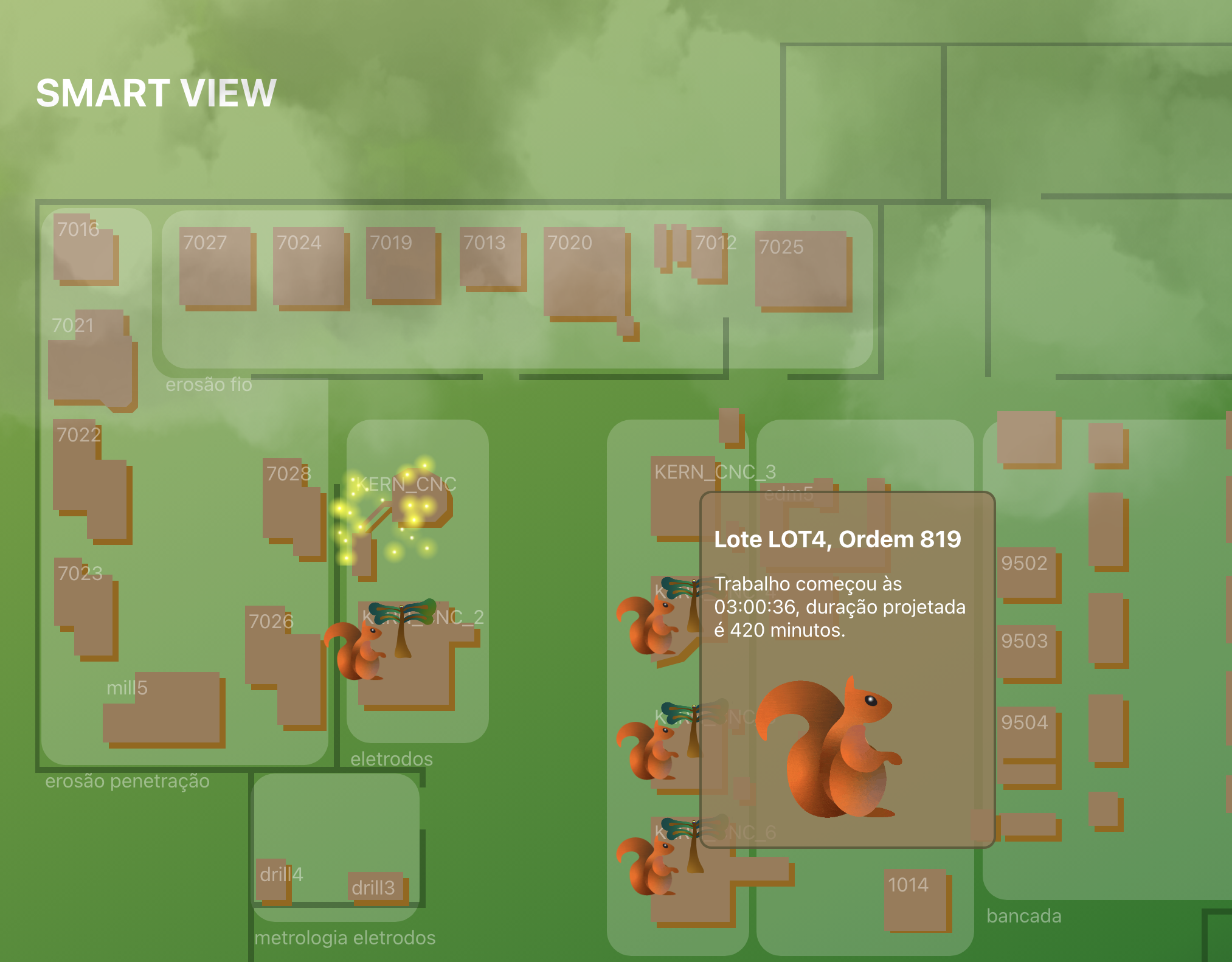

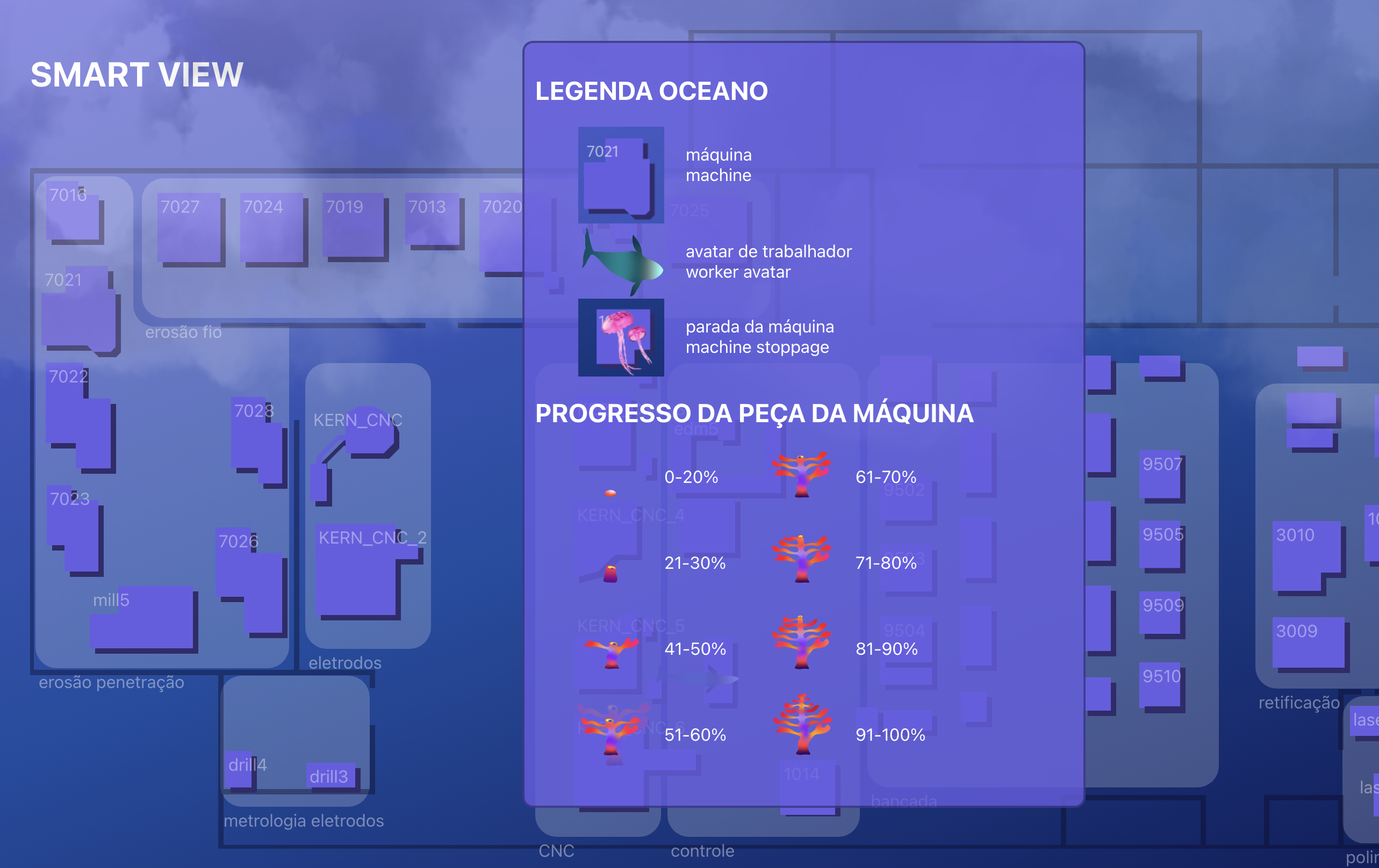

Through several rapid prototyping workshops with the workers, we came up with a solution that involved two scenarios: The Forest and The Ocean - both environments that can be found next to the Famolde factory.

Inspired by the Leiria forest and the Atlantic Ocean, the interface uses nature as a metaphor for the factory process, showing product production as growing trees and coral, and the worker avatars as squirrels and whales.

Another aspect was to use real-time weather data, and visualise the weather outside the factory, as the shop-floor had very little natural light with the workers unable to see what is happening outside.

The results were overwhelmingly positive, with workers reporting 58% increase in wellbeing when using the interface and a 94,8% of workers reviewed the usability of the system as good and very good. The SMART VIEW approach reduced the gap between departments and optimised the workers wellbeing, benefiting all factory processes. Besides that, it also helped retain talent in the company and provide better environment for the workers, which helped to get people interested in working at Famolde. Improving worker wellbeing in factories increased productivity, showing a great example of how nature-inspired interface design can help lead a more sustainable and productive factory, without putting extra stress on the workers.

Through several rapid prototyping workshops with the workers, we came up with a solution that involved two scenarios: The Forest and The Ocean - both environments that can be found next to the Famolde factory.

Inspired by the Leiria forest and the Atlantic Ocean, the interface uses nature as a metaphor for the factory process, showing product production as growing trees and coral, and the worker avatars as squirrels and whales.

Another aspect was to use real-time weather data, and visualise the weather outside the factory, as the shop-floor had very little natural light with the workers unable to see what is happening outside.

The results were overwhelmingly positive, with workers reporting 58% increase in wellbeing when using the interface and a 94,8% of workers reviewed the usability of the system as good and very good. The SMART VIEW approach reduced the gap between departments and optimised the workers wellbeing, benefiting all factory processes. Besides that, it also helped retain talent in the company and provide better environment for the workers, which helped to get people interested in working at Famolde. Improving worker wellbeing in factories increased productivity, showing a great example of how nature-inspired interface design can help lead a more sustainable and productive factory, without putting extra stress on the workers.

One of the main objectives in the making of the solution was to improve the communication between shop-floor workers and management structures and create an egalitarian "horizontal" way of observing key process information. By implementing an interface, installed on a touch screen on the factory shop-floor, the workers were enabled to observe the real time data on all factory processes, something that was only available to management before the project's implementation. Through the process of co-creation, the workers were included in the process and much happier to adopt the new system. Unlike the standard "top-down" factory optimisation approach, where worker's experience and opinions are commonly overlooked thhis inclusive approach empowered the workers that the factory is most dependent on in terms of manufacture. From the results of the SMART VIEW project, it was evident that this type of inclusion, access to data and co-creation creates a better working environment, saves money and increases sustainability across the factory.

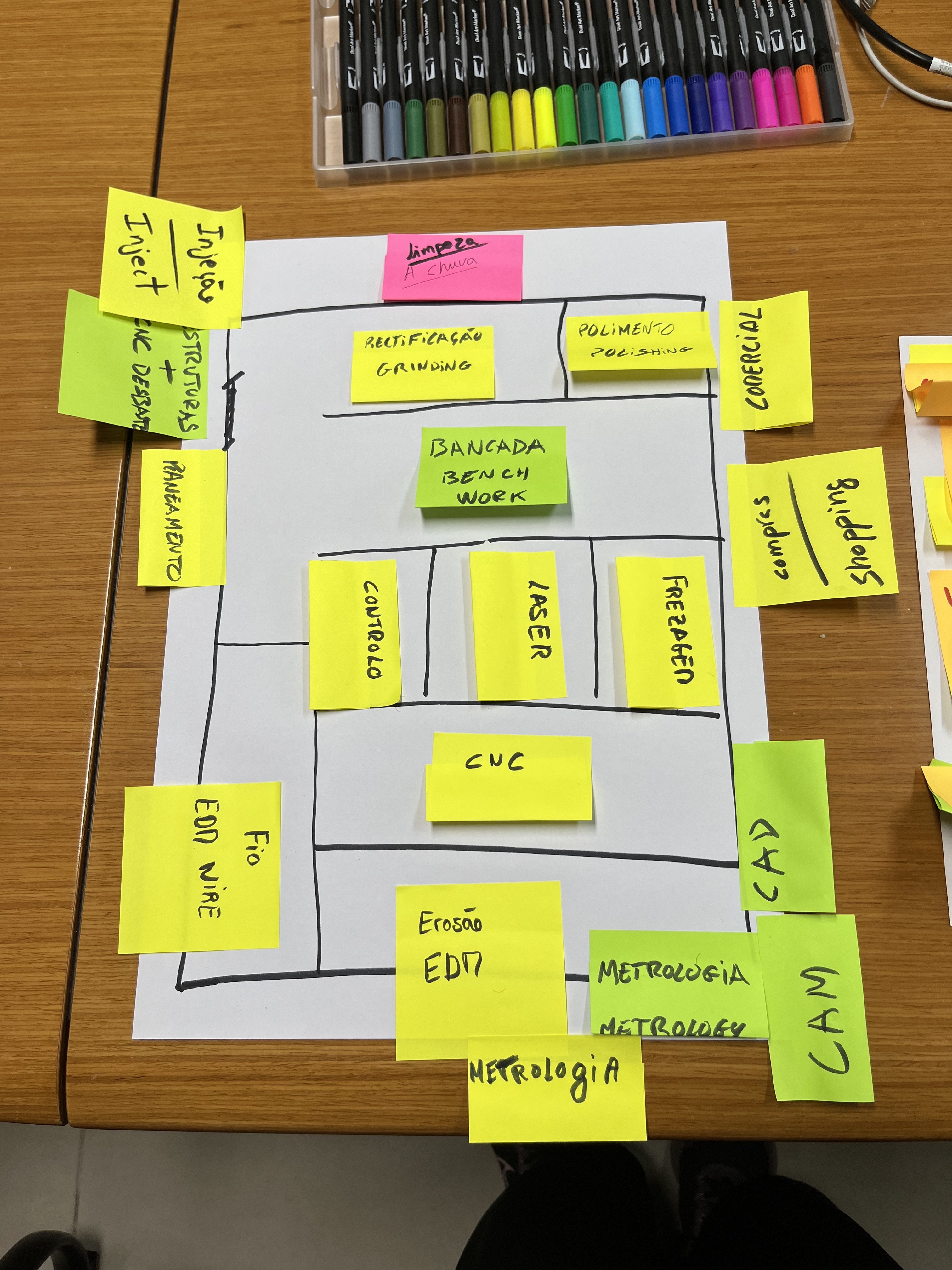

As said before, the shop-floor workers were involved in the co-creation of the interface, deciding on every aspect of the scenarios. Throughout the one year duration of the project, three workshops were carried out involving workers at Famolde factory in the designing process together with the artist Kristina Pulejkova. Using rapid prototyping and iterative design methods, the workers were involved from the very start or the ideation stage, through to the first prototype stage, to the final prototype and deployment stage, co-designing for better usability. Together with the artist they created the nature-inspired aesthetic of the interface. Furthermore Famolde and Kristina Pulejkova created certificates of participation for the workers, further accentuating their invaluable input as co-designers of the work. Without the workers' input as co-designers, the SMART VIEW system wouldn't have had the overwhelmingly positive results that we are proud to show today, with improved worker wellbeing and cross-departmental communication.

The workers from both management and shopfloor teams were involved in the co-creation pricess of the system, specifically the making of the nature-inspired interface. Workers were co-designers of the interface, advising on the aesthetics, usability and memorability of the interface. The added value of this involvement was increased adoption of the system through co-authorship, improved usability that in return improved wellbeing of the workers.

Furthermore, this project delivered tangible improvement results within the EU-funded Better Factory Horizon 2020 programme, creating a prototype ready for deployment across any industry and region.

The cross-European team consisted of:

Factory representatives from Famolde in Portugal, where the project was deployed.

Tech providers Octavic, based in Romania.

Artist Kristina Pulejkova, a Macedonian national, currently based in the UK.

The project was coordinated by In4Art, an independent institute for art-driven responsible technological innovations interested in making connections between science, technology and the arts.

Furthermore, this project delivered tangible improvement results within the EU-funded Better Factory Horizon 2020 programme, creating a prototype ready for deployment across any industry and region.

The cross-European team consisted of:

Factory representatives from Famolde in Portugal, where the project was deployed.

Tech providers Octavic, based in Romania.

Artist Kristina Pulejkova, a Macedonian national, currently based in the UK.

The project was coordinated by In4Art, an independent institute for art-driven responsible technological innovations interested in making connections between science, technology and the arts.

For the design and implementation of the project, we used rapid prototyping and iterative design processes, improving on our prototypes on three-month long cycles throughout the year-long duration of the project. The Tech provider used smart processes and automation, AI powered analytics to design the process tracking backend of the system and testing / deploying this onto one machine on the shop-floor. The nature-inspired interface used co-designing workshops with workers at the Famolde factory, data analysis from questionaries and interviews with the workers. Digital designing and programming processes created the innovative, two scenario interface that makes SMART VIEW unique. For the making of the system, artist Kristina Pulejkova worked closely with tech providers Octavic to make backend and frontend meet in order to build a beautiful and robust system. Together with Famolde who hosted the system on their shop-floor, all partners worked to create a system that supports workers' productivity, communication and wellbeing. Famolde oversaw the implementation of the system on the shop-floor and liaised with both Tech Provider and Artist to get information and also organise the co-design woprkshops with the workers at Famolde. The value of this cross-disciplinary collaboration is the innovative system that is built for workers in collaboration with workers, creating a more harmonious workplace with a "horizontal" structure.

Smart process tracking systems are available on the market, but are mainly focusing on often inaccessible data visualisations, and are available to the management departments only, excluding workers from the overview of the entire factory's process. By implementing nature-inspired design, co-designing with the workers and opening data access to everyone on the shop-floor, SMART VIEW created a more levelled organisational structure, allowing access to data by everyone involved in the manufacturing process. This increased communication between departments because everyone could see where a particular product part is in the process in real time and most importantly, it increased worker wellbeing by connecting them with nature through the co-designed user interface.

The project used iterative design process, creating experiments and prototypes in three cycles. Furthermore, rapid prototyping and workshop-based co-creation was used to design the aesthetic and look of the nature-inspired user interface.

SMART VIEW can be replicated and scaled for any factory environment, regardless of the manufacturing industry, as it relates to the workers and the machining processes. The results show that this is a valuable tool that helps improve worker wellbeing whilst improving productivity and saving energy, promoting worker happiness and worker retention. The co-creation model of designing the interface together with the workers, using locally-inspired natural environments as the starting point can be replicated in any production environment.

The project addresses a very often overlooked aspect of manufacturing - worker wellbeing. Connecting workers that are surrounded with machines and noisy, risky environments with nature through digital means has proven to have a very good impact for both worker wellbeing and the factory productivity and sustainability. By seeing the factory processes as an ecology, workers are feeling better in a highly stressful environment.

The results of the SMART VIEW project are a valuable aid for the manufacturing process (in particular in the Mould market), especially in the areas of simulation and digital twin, the integration of Industry 4.0 and the practice of sustainable solutions.

The Octavic tool will help predict and optimize mould performance, allowing real-time monitoring of the machine. Also, the process will be improved in terms of productivity, quality control and predictive maintenance, reducing unnecessary iterations and giving Famolde data analytics to create a smarter factory.

Sustainable practices such as energy-efficient processes, and waste reduction strategies to minimize the environmental footprint of mould manufacturing operations will also be positively affected by the solution, as well as the improved wellbeing of the workers, provided by the different scenarios that Kristina has created to see the data provided from the machine and also the information from the different departments at Famolde, as the workers feel more integrated in the overall environment of the factory.

Our results of the project:

- Energy consumption savings up to 5%, Up to 43.6 MWh in one year

- Waste Reduction by at least 5-8%, 2.2 – 3.5 tonnes of scrap per year

- 25% increase of satisfaction in cross-departmental communication.

- 35% increase of satisfaction in human-machine communication

- 58% increase in worker wellbeing when using the nature-inspired system.

The Octavic tool will help predict and optimize mould performance, allowing real-time monitoring of the machine. Also, the process will be improved in terms of productivity, quality control and predictive maintenance, reducing unnecessary iterations and giving Famolde data analytics to create a smarter factory.

Sustainable practices such as energy-efficient processes, and waste reduction strategies to minimize the environmental footprint of mould manufacturing operations will also be positively affected by the solution, as well as the improved wellbeing of the workers, provided by the different scenarios that Kristina has created to see the data provided from the machine and also the information from the different departments at Famolde, as the workers feel more integrated in the overall environment of the factory.

Our results of the project:

- Energy consumption savings up to 5%, Up to 43.6 MWh in one year

- Waste Reduction by at least 5-8%, 2.2 – 3.5 tonnes of scrap per year

- 25% increase of satisfaction in cross-departmental communication.

- 35% increase of satisfaction in human-machine communication

- 58% increase in worker wellbeing when using the nature-inspired system.