Timber_Earth_Slab

Basic information

Project Title

Full project title

Category

Project Description

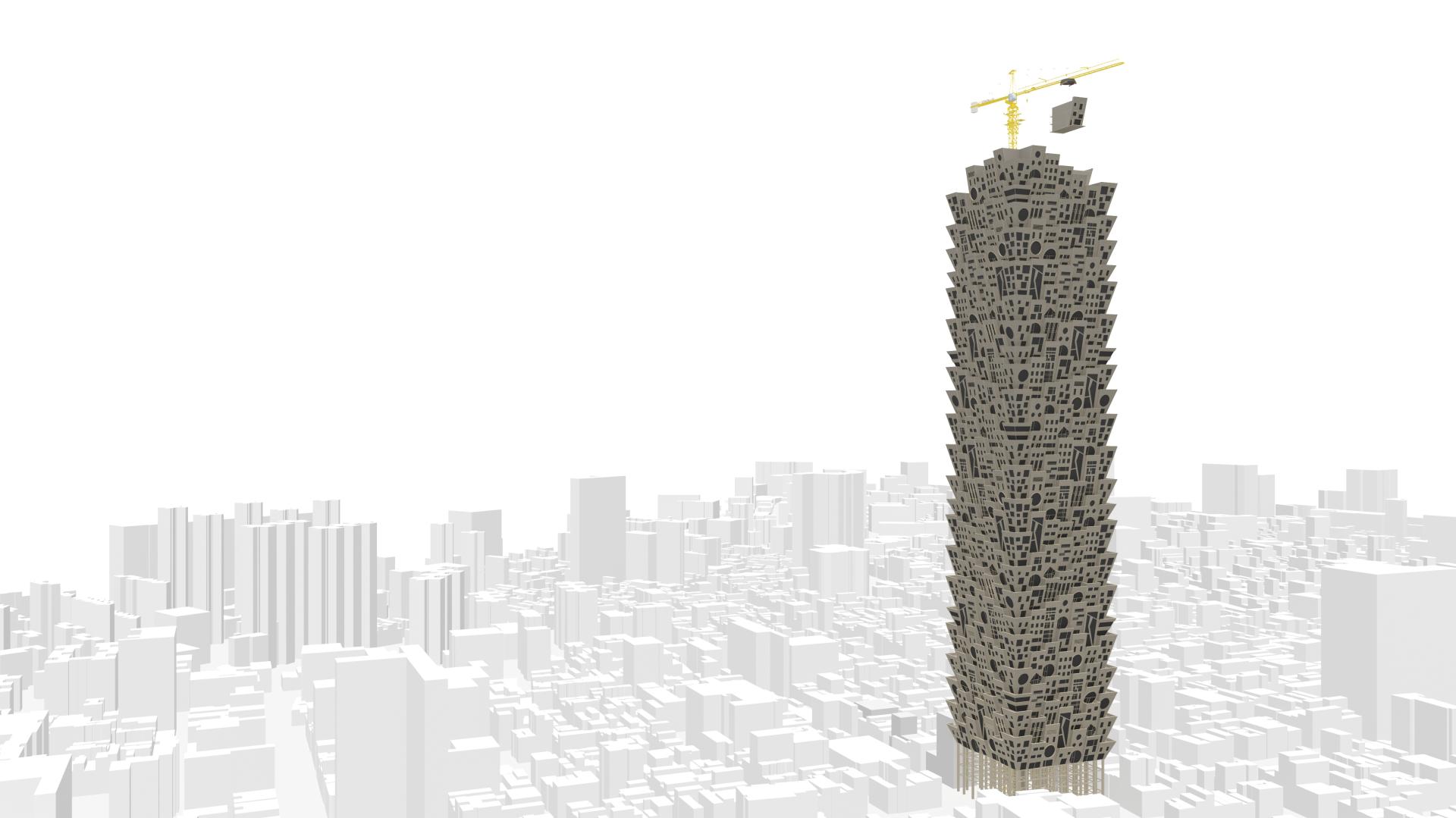

Can we build our cities of the future only with wood and earth? We believe we can and we are not alone. While the global climate suffers under the effects of conventional concrete and steel construction (cement production alone accounts for 8% of CO2 emissions) we are developing a minimalist construction system composed solely of timber and earth that, utilizing the most recent advances in automation and material science, promises to be not only ecological but performative and mass-producible.

Geographical Scope

Project Region

Urban or rural issues

Physical or other transformations

EU Programme or fund

Which funds

Description of the project

Summary

While cement production alone accounts for 8% of global CO2 emissions, finding alternatives to conventional concrete and brick construction is not easy. Timber construction promises to be one, but it comes with its own issues, including fire resistance - which is usually responded to with increased material usage and, again, the implementation of concrete - and a lack of thermal mass, making it unattractive for hot climates and leading to increased energy demand that can easily compensate the initial CO2 savings.

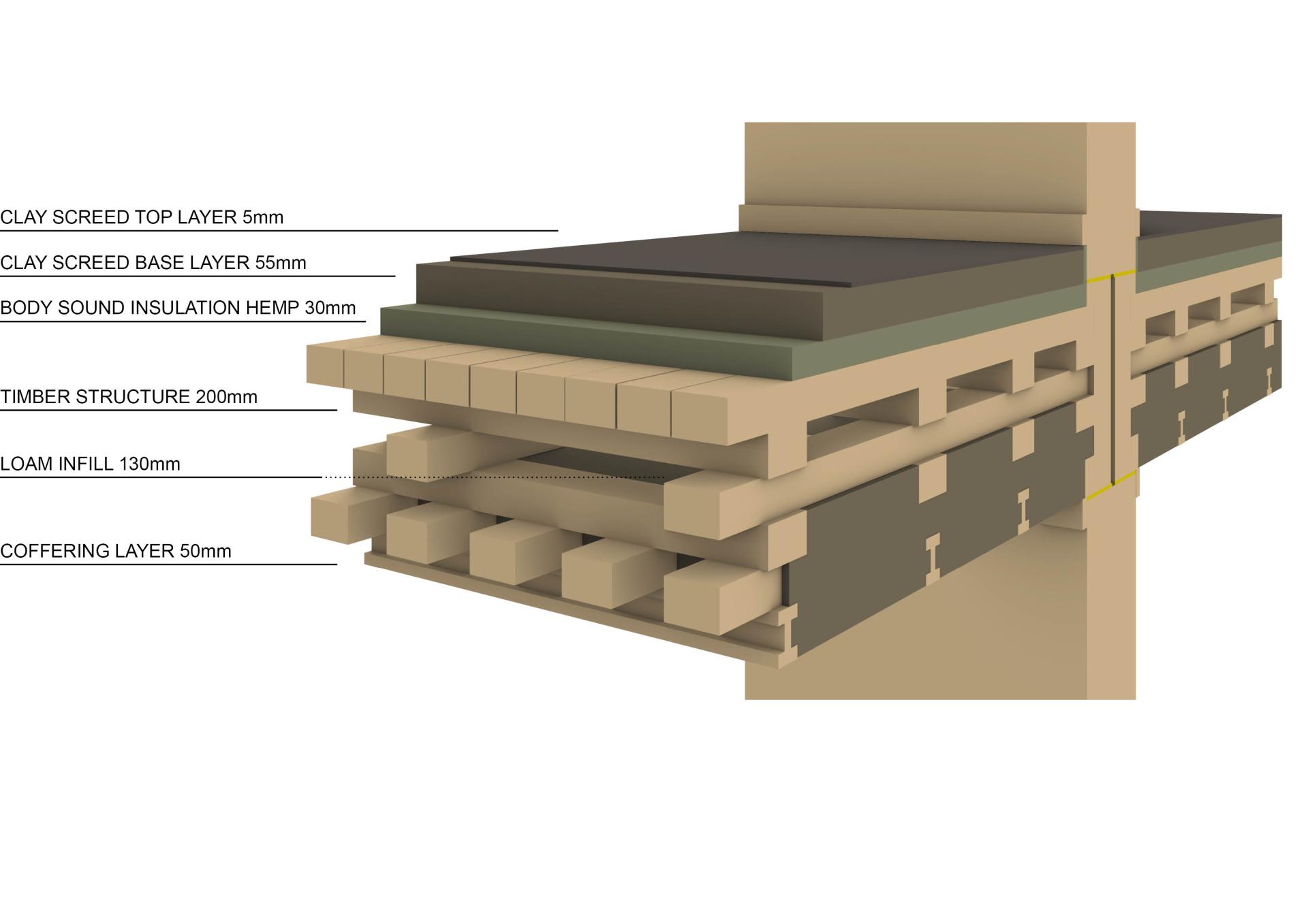

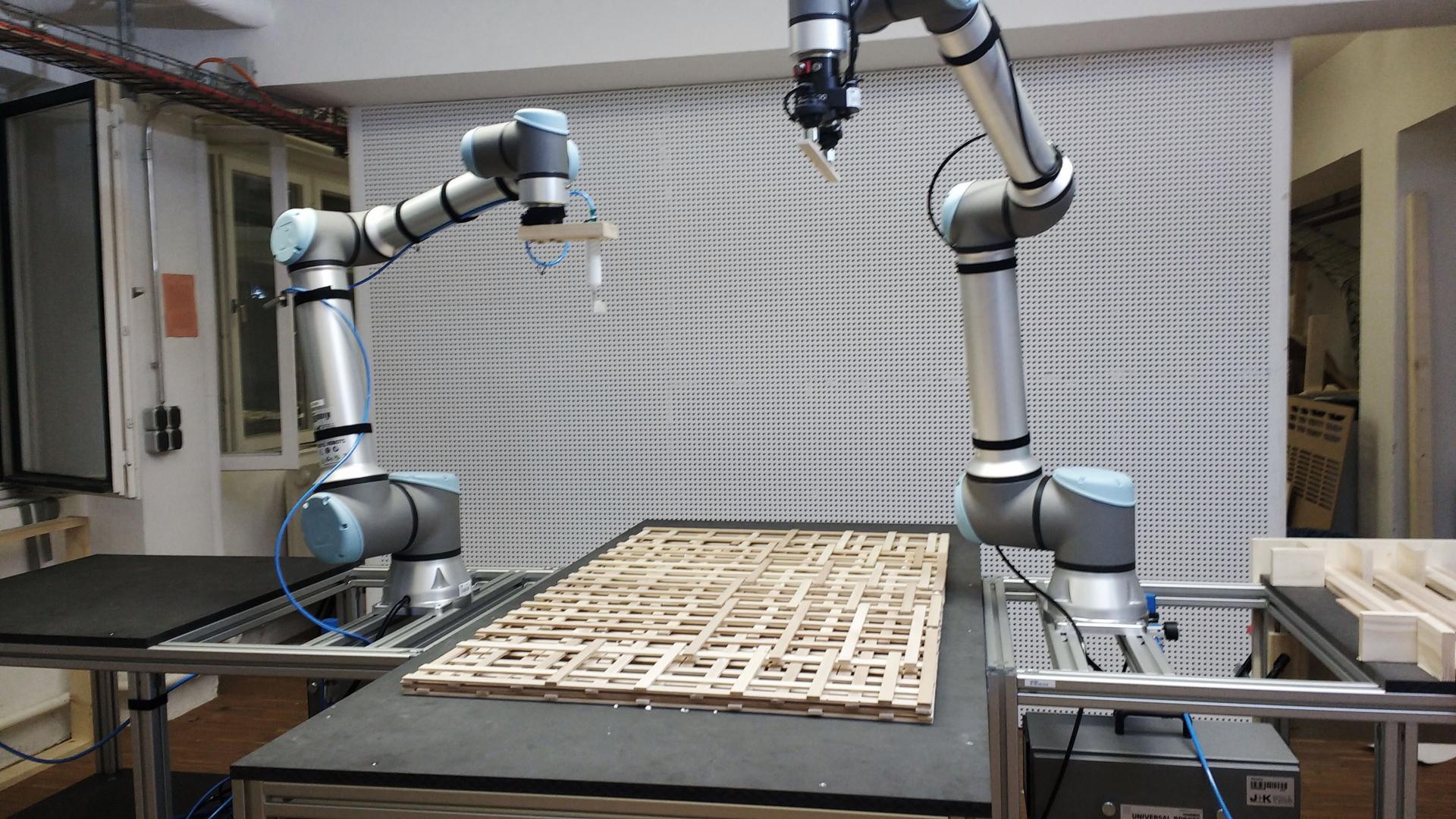

Trying to combine the best of the two worlds - the CO2 negativity and recyclability of timber and the fire resistance and thermal mass of concrete - with an automatable mass-production process, we came up with Timber Earth Slab. It consists of a load-bearing, robotically assembled timber structure into which a self-supporting earth infill is cast, which is to provide fire resistance, sound insulation, and thermal mass. Utilizing the material technology of ETH-spinoff Oxara, the infill does not need to be rammed but can simply be cast like concrete.

We focused on floor slabs "not because they are easy, but because they are hard". They have to satisfy the highest requirements on fire resistance, sound insulation, and structural rigidity. If this system can deal with them, it can deal with everything. For this purpose, we spent months building 1:1 prototypes in the workshop and put them under bending and vibrations. Contrary to our and everyone else's expectations, timber and earth formed a solid bond that underwent all our tests without any visible problems. Within weeks, this triggered the attention of several companies with whom we are now developing the system further.

This project has originated at TU Munich in the course of an interdisciplinary master's thesis. Find visual concept description under: https://www.youtube.com/watch?v=y-rVafr7vfc&ab_channel=JulianKlausTrummer

Key objectives for sustainability

In one phrase: Decarbonization of construction processes without loss of affordability or functionality.

With the exception of tiny amounts of natural, mineral admixtures, flax fibers, and glue (of which we are about to get rid at the moment), Timber Earth Slab solely consists of timber and earth. By relying on the two most archaic materials of human history, CO2 emissions in production can be kept to a minimum and, with timber being CO2-negative, a net-zero balance achieved. Being under airtight encapsulation by the earth infill, the timber does not need to be treated in any way. After the use phase, the elements can, as we tested in the prototyping process, be separated into timber and earth to be either reused or decomposed. Particularly the earth infill is very easy to reuse as it only needs to be reliquefied.

Beyond the construction and destruction process, the system includes features for keeping energy consumption low during the use phase. The earth infill provides thermal mass which is crucial for preventing overheating in summer, therefore saving potential cooling energy. When active heating or cooling cannot be avoided, the thermal and core activation capabilities of the infill allow for energy to be induced whenever an abundance of energy is available, therefore counterbalancing the fluctuations that are particularly characteristic of renewable energy sources. Moreover, thanks to the large exposed surface area, low-temperature heat sources, such as waste energy from server centers, can be utilized for heating.

In many ways, the Timber Earth Slab tries to combine the best of two worlds: The possibilities for minimizing energy consumption via thermal mass and core activation that concrete components provide with the carbon-negativity and circularity of timber components.

Key objectives for aesthetics and quality

In timber construction, fire regulations tend to make it impossible for the users to experience the natural character of the building, as timber elements often have to be encapsulated by (not exactly environment-friendly) gypsum boards. This is not only a pity from an architectural perspective, but discourages people from building with timber and leads to solutions like CLT, where excessive amounts of wood and glue are implemented just to be able to have some exposed timber surfaces.

The natural earth finish of Timber Earth Slab can be exposed and various processes such as colorization and surface polishing allow for a great array of design possibilities. This way, the biophilic character of the building can be made tangible to the users, letting them experience the revolution in construction with their own eyes, hands, and nose.

Key objectives for inclusion

From the very beginning, the development of Timber Earth Slab is based on the idea that a sustainable concept can only have a positive effect if it is actually affordable. The design is therefore based on the idea of automation and mass production. By designing the timber structure based on a robotic assembly process and covering sound insulation and fire resistance with an earth infill that only has to be cast into the structure, we developed a minimalistic design that requires hardly any human labor. Furthermore, we utilize robotic fabrication to minimize material consumption, placing timber only where it is structurally necessary.

Furthermore, a sustainable concept can only have a positive effect if it can actually be applied in many instances. It is for this reason that a high degree of thermal mass, sound insulation, and fire resistance was such a central aspect of the design from the very beginning: We wanted to make sure it would be fit for surroundings with high demands, be it the fire resistance required in multi-storey construction, or the thermal mass required to keep buildings cool in warmer climates, where mainly for this very reason timber construction usually doesn't play a big role at the moment.

Physical or other transformations

Innovative character

From the very beginning of the design process, it was crucial that environmental sustainability, aesthetics, affordability (and functionality) must not be a contradiction. Design ideas violating this principle were not followed upon. Hence the minimalistic design approach: Few materials/layers means few working steps (=affordability) and easier recycling (=sustainability) and multi-functional layers without additional encapsulations (=aesthetics).

While earth is in theory cheap (available in abundance), functional (coming with fire resistance, sound insulation, and thermal mass), environmentally sustainable (no burning processes in production), these qualities haven't been successfully utilized in a mass-production scenario so far. The main reasons are the difficult handling of the material, which usually has to be rammed, as well as its poor structural strength and its water solubility. While our partner Oxara has developed natural, mineral admixtures that allow earth to be cast like concrete, allowing us to skip the labor-intense ramming process, utilizing earth in a non-structural way means that its poor structural strength and water-solubility do not pose an issue anymore. The latter even becomes an advantage as it allows for reliquefying and therefore reusing the material.