Shaping a circular industrial ecosystem and supporting life-cycle thinking

UN_SKIN

UN_SKIN - Combining mycelium and bacterial cellulose for a new biomaterial in product design

A steel bench with padded inserts covered with UN_SKIN, an experimental composite biomaterial created by combining mycelium and bacterial cellulose (BC). Mycelium improves BC’s stability and water resistance. Developed through Material Driven Design and DIY approaches, UN_SKIN resembles leather and finds applications in upholstered furniture. The project explores scenarios for sustainable design with modular solutions and a unique aesthetic that challenges traditional materials.

Italy

National

It addresses urban-rural linkages

It refers to other types of transformations (soft investment)

Prototype level

No

No

As an individual

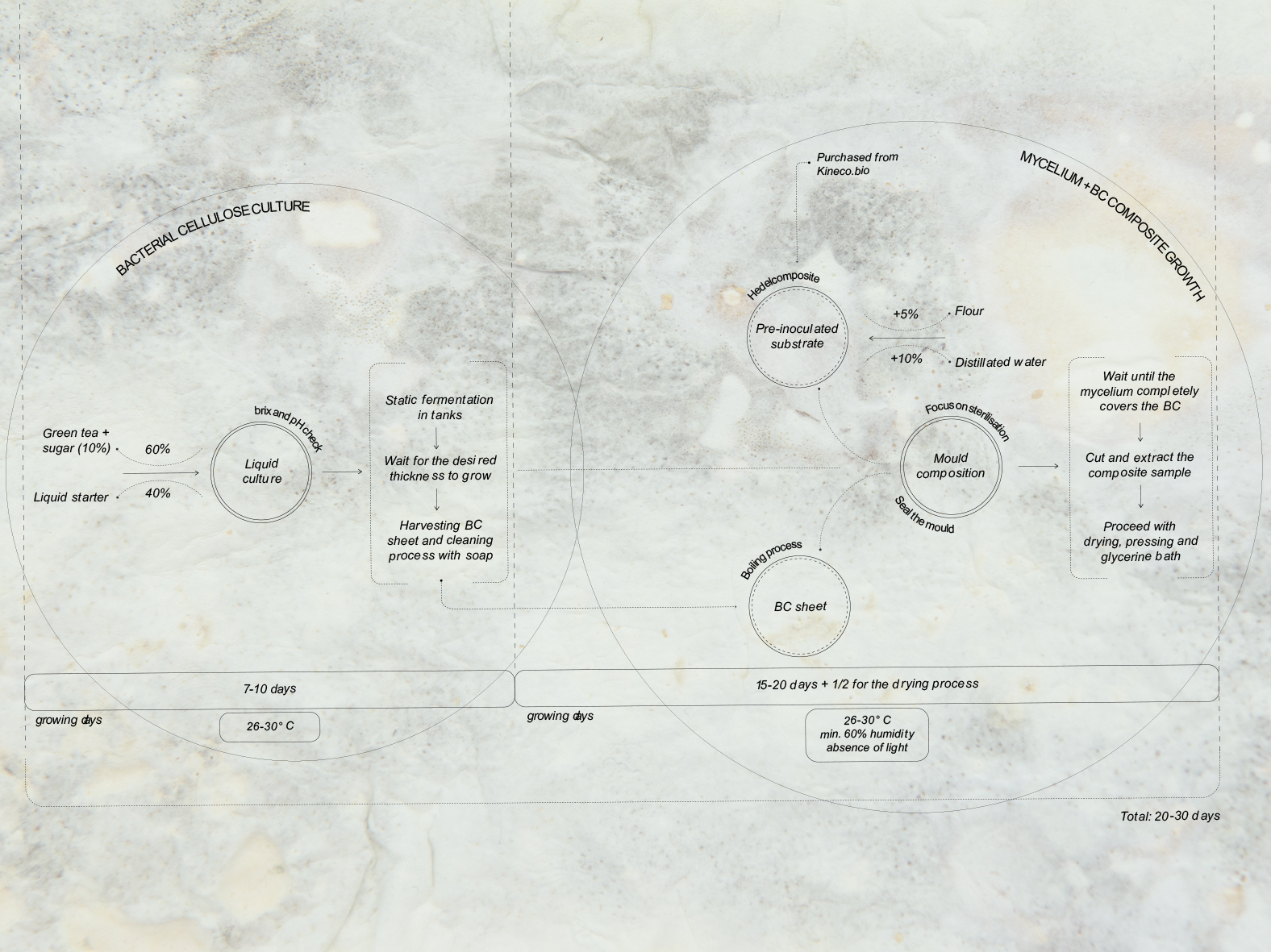

The UN_SKIN project explores the potential of bacterial cellulose (BC) and mycelium to create a new bioassembled material, offering a sustainable and circular alternative for design. Using the Material Driven Design (MDD) methodology and a DIY experimental approach, this research investigates how combining these two organisms can improve material stability, water resistance, and scalability, making it suitable for applications in furniture and fashion.

The project targets designers, researchers, and industries seeking to reduce the environmental impact of synthetic and animal-based materials, promoting more sustainable production practices. The goal is to develop a biodegradable and regenerative material, optimizing growth and processing techniques to overcome the scaling limitations of experimental biofabrication.

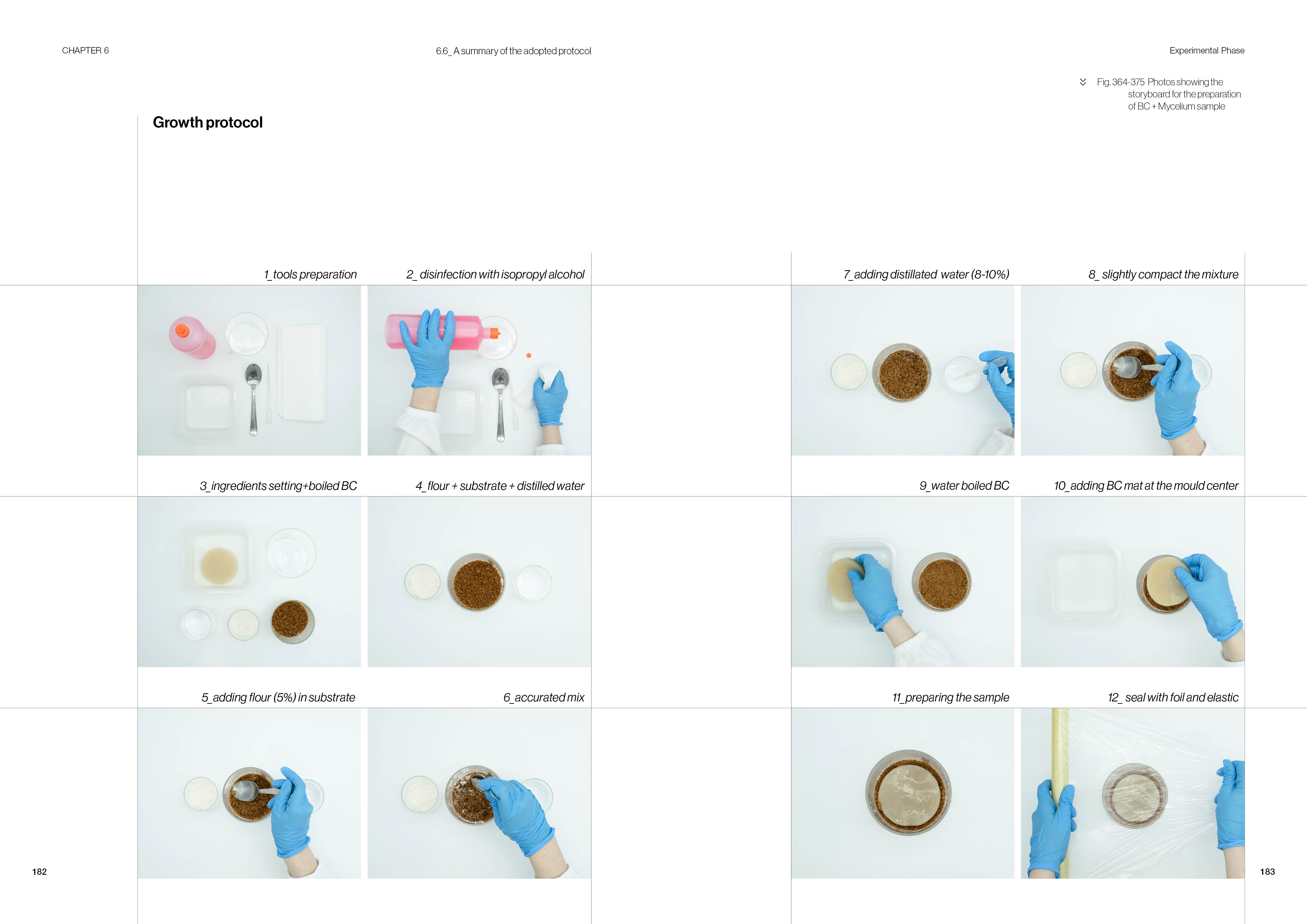

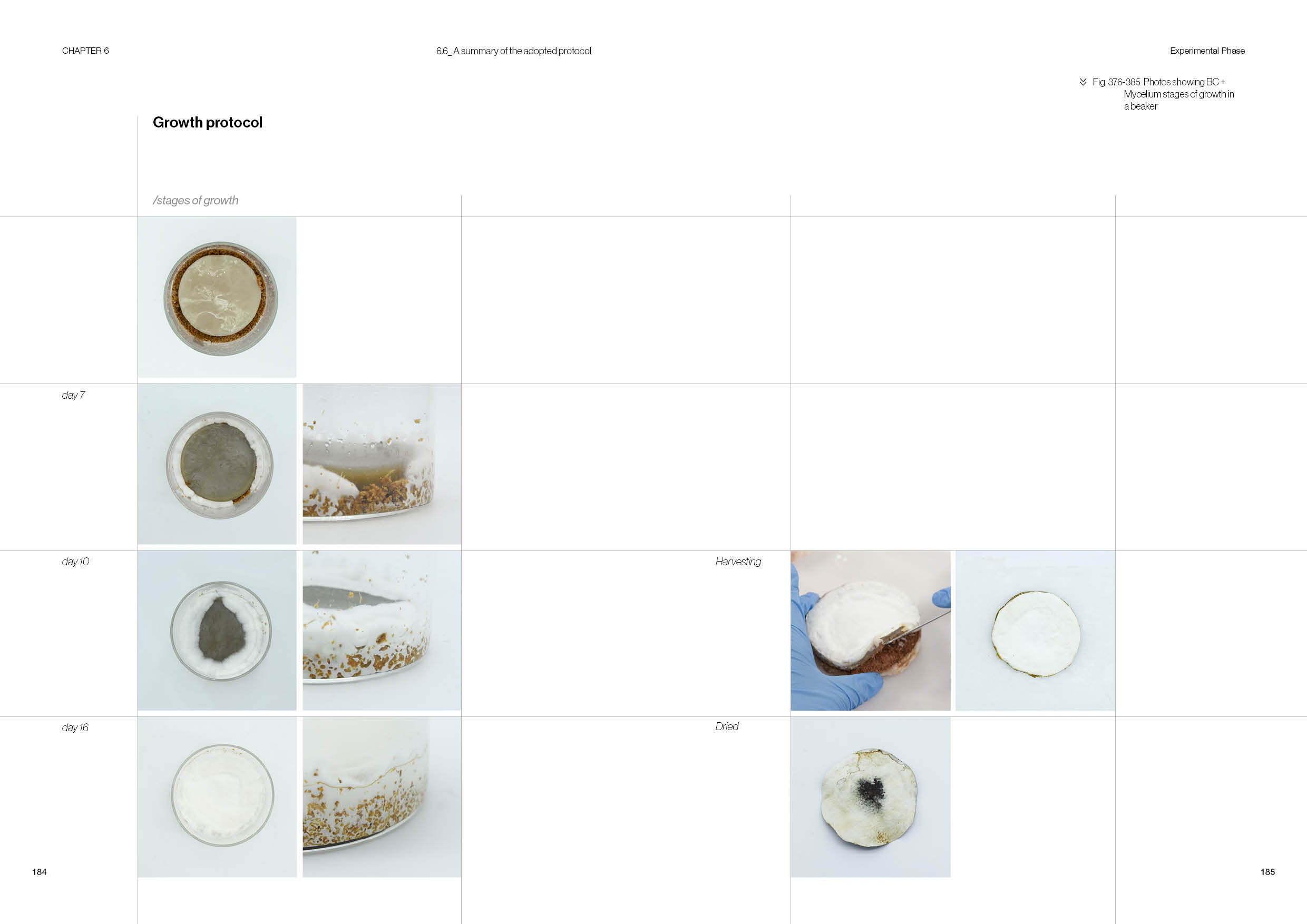

Key outcomes include enhanced mechanical and water-resistant properties compared to pure bacterial cellulose, the implementation of a reproducible protocol for material growth, and the development of a padded furniture prototype showcasing its practical applications. The research highlights the role of design in redefining industrial production by integrating biomaterials into a circular and waste-reducing approach.

Aligned with the principles of the New European Bauhaus, UN_SKIN envisions a future where biofabricated materials transform the industrial sector, offering beautiful, sustainable, and accessible solutions, contributing to a more responsible and innovative ecosystem.

The project targets designers, researchers, and industries seeking to reduce the environmental impact of synthetic and animal-based materials, promoting more sustainable production practices. The goal is to develop a biodegradable and regenerative material, optimizing growth and processing techniques to overcome the scaling limitations of experimental biofabrication.

Key outcomes include enhanced mechanical and water-resistant properties compared to pure bacterial cellulose, the implementation of a reproducible protocol for material growth, and the development of a padded furniture prototype showcasing its practical applications. The research highlights the role of design in redefining industrial production by integrating biomaterials into a circular and waste-reducing approach.

Aligned with the principles of the New European Bauhaus, UN_SKIN envisions a future where biofabricated materials transform the industrial sector, offering beautiful, sustainable, and accessible solutions, contributing to a more responsible and innovative ecosystem.

Biomaterial

Bacterial Cellulose

Mycelium

Biofabrication

Regenerative design

The project aims to develop an innovative bio-composite material combining bacterial cellulose and mycelium, offering a sustainable, regenerative alternative to synthetic and animal-derived materials. By utilizing self-growing resources, it reduces reliance on non-renewable materials and minimizes environmental impact.

To achieve sustainability, the project follows these key strategies:

- Circularity & Waste Reduction: The material is grown, not manufactured, eliminating petroleum-based components and ensuring full biodegradability within a circular economy model.

- Low-Impact Production: Unlike leather and synthetics, its fabrication avoids toxic chemicals and requires minimal water and energy, contributing to sustainable material cycles.

- Furniture & Upholstery Applications: The material is explored as a viable alternative to padding and upholstery, addressing environmental concerns in furniture design.

The project also includes a steel bench, designed following Design for Sustainability principles:

- Design for Disassembly (DfD): Components can be easily separated and recycled.

- Design for Reparability (DfR): Parts can be replaced or repaired, extending its lifespan.

- Design for Material Efficiency (DfME): Optimized material use reduces waste while ensuring durability.

This project stands as a sustainable innovation model, integrating Material Driven Design and DIY Materials to demonstrate how biotechnology enables scalable, eco-conscious solutions. It envisions a future where materials are grown rather than industrially produced, promoting circular and regenerative design.

To achieve sustainability, the project follows these key strategies:

- Circularity & Waste Reduction: The material is grown, not manufactured, eliminating petroleum-based components and ensuring full biodegradability within a circular economy model.

- Low-Impact Production: Unlike leather and synthetics, its fabrication avoids toxic chemicals and requires minimal water and energy, contributing to sustainable material cycles.

- Furniture & Upholstery Applications: The material is explored as a viable alternative to padding and upholstery, addressing environmental concerns in furniture design.

The project also includes a steel bench, designed following Design for Sustainability principles:

- Design for Disassembly (DfD): Components can be easily separated and recycled.

- Design for Reparability (DfR): Parts can be replaced or repaired, extending its lifespan.

- Design for Material Efficiency (DfME): Optimized material use reduces waste while ensuring durability.

This project stands as a sustainable innovation model, integrating Material Driven Design and DIY Materials to demonstrate how biotechnology enables scalable, eco-conscious solutions. It envisions a future where materials are grown rather than industrially produced, promoting circular and regenerative design.

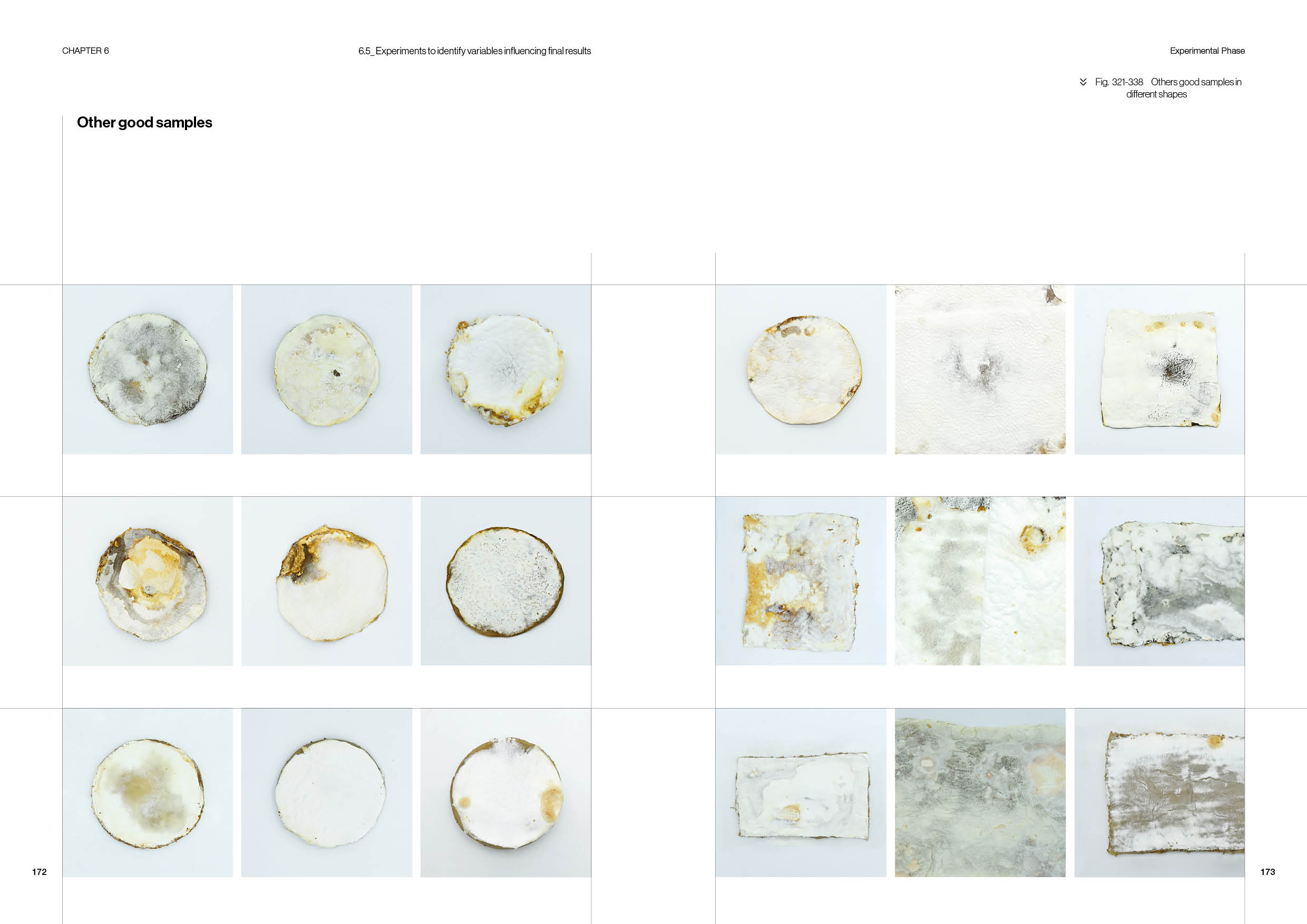

The project explores the aesthetic and experiential potential of bio-based materials, emphasizing their tactility, organic qualities, and natural transformation over time. By integrating bacterial cellulose and mycelium, the material creates a unique sensory experience, offering a living, evolving surface that engages users both visually and physically.

Aesthetics & Sensory Experience

- Material Expressiveness: The material’s soft, leather-like texture and subtle organic patterns result from natural growth processes, making each piece visually unique.

- Dynamic Aging: Unlike static industrial materials, this bio-composite evolves over time, enhancing its natural authenticity and emotional connection with users.

- Multi-Sensory Engagement: The material’s warm, breathable surface enhances comfort in furniture applications, improving haptic and visual interaction.

Cultural & Design Impact

- Reframing Material Value: The project challenges traditional perceptions of luxury, introducing living materials as a culturally significant, sustainable alternative to leather and synthetics.

- Narrative & Emotional Connection: The material’s biological origins tell a story of symbiosis and transformation, encouraging users to appreciate its ephemeral beauty.

- Integration in Contemporary Design: By combining craftsmanship with biotechnology, the project opens new possibilities for sustainable, high-quality design applications.

Aesthetics & Sensory Experience

- Material Expressiveness: The material’s soft, leather-like texture and subtle organic patterns result from natural growth processes, making each piece visually unique.

- Dynamic Aging: Unlike static industrial materials, this bio-composite evolves over time, enhancing its natural authenticity and emotional connection with users.

- Multi-Sensory Engagement: The material’s warm, breathable surface enhances comfort in furniture applications, improving haptic and visual interaction.

Cultural & Design Impact

- Reframing Material Value: The project challenges traditional perceptions of luxury, introducing living materials as a culturally significant, sustainable alternative to leather and synthetics.

- Narrative & Emotional Connection: The material’s biological origins tell a story of symbiosis and transformation, encouraging users to appreciate its ephemeral beauty.

- Integration in Contemporary Design: By combining craftsmanship with biotechnology, the project opens new possibilities for sustainable, high-quality design applications.

By leveraging regenerative resources like bacterial cellulose and mycelium, the material offers a sustainable, scalable alternative that can be produced with minimal cost, making it accessible for various sectors and communities.

Inclusivity through Accessibility and Affordability

- Affordable and Scalable Production: The bio-composite material can be produced locally, using accessible resources and low-cost methods. This reduces the reliance on expensive synthetic or animal-derived materials, ensuring that the product remains affordable for diverse markets.

- Low Environmental Impact for All: By using regenerative and biodegradable materials, the project addresses environmental challenges that affect all communities, particularly those most vulnerable to the consequences of climate change and pollution

Inclusive Societal Models

- Open and Collaborative Processes: The project incorporates open-source methodologies that invite a broader range of participants to engage in the design and production process. This creates opportunities for local communities and smaller producers to contribute to and benefit from the material’s development.

- Ethical, Regenerative Production: The project proposes a new societal model where materials are cultivated, not exploited, promoting ethical practices that support socioeconomic inclusivity by creating jobs in sustainable and regenerative industries.

Inclusivity through Accessibility and Affordability

- Affordable and Scalable Production: The bio-composite material can be produced locally, using accessible resources and low-cost methods. This reduces the reliance on expensive synthetic or animal-derived materials, ensuring that the product remains affordable for diverse markets.

- Low Environmental Impact for All: By using regenerative and biodegradable materials, the project addresses environmental challenges that affect all communities, particularly those most vulnerable to the consequences of climate change and pollution

Inclusive Societal Models

- Open and Collaborative Processes: The project incorporates open-source methodologies that invite a broader range of participants to engage in the design and production process. This creates opportunities for local communities and smaller producers to contribute to and benefit from the material’s development.

- Ethical, Regenerative Production: The project proposes a new societal model where materials are cultivated, not exploited, promoting ethical practices that support socioeconomic inclusivity by creating jobs in sustainable and regenerative industries.

The project has not directly involved citizens or civil society through formal engagement activities, but it has been designed with the potential to impact local communities in a meaningful way. The focus on sustainable and regenerative materials such as bacterial cellulose and mycelium speaks to the growing need for eco-friendly and accessible solutions. The project’s design aims to provide a new alternative to traditional materials, which could benefit small businesses and local artisans by introducing innovative, low-cost, and sustainable production methods.

Although there was no formal citizen engagement, the project’s development within Polifactory, a fab lab, ensured an environment of interaction and collaboration with a community of makers, researchers, and designers. This setting facilitated the exchange of knowledge and ideas, which indirectly impacted the final design. The community of Polifactory, with its interdisciplinary approach, helped refine the materials and prototypes, ensuring their practicality and sustainability.

The impact of this involvement lies in how the project can act as a catalyst for further collaboration and the adoption of sustainable design practices. By testing and developing bio-based materials, the project offers a model for how local stakeholders, such as small businesses and producers, can incorporate these materials into their processes, ultimately benefiting both the local economy and the environment.

Although there was no formal citizen engagement, the project’s development within Polifactory, a fab lab, ensured an environment of interaction and collaboration with a community of makers, researchers, and designers. This setting facilitated the exchange of knowledge and ideas, which indirectly impacted the final design. The community of Polifactory, with its interdisciplinary approach, helped refine the materials and prototypes, ensuring their practicality and sustainability.

The impact of this involvement lies in how the project can act as a catalyst for further collaboration and the adoption of sustainable design practices. By testing and developing bio-based materials, the project offers a model for how local stakeholders, such as small businesses and producers, can incorporate these materials into their processes, ultimately benefiting both the local economy and the environment.

The project was developed and tested within Polifactory, a fablab that fosters interaction between various types of knowledge and expertise, facilitating connections with the community and access to innovative resources. The main focus was on using natural and regenerative materials such as bacterial cellulose and mycelium, which are locally sourced and have a low environmental impact, addressing the needs for sustainability and accessibility. The design of the bench, created following the principles of Design for Sustainability, such as Design for Disassembly and Design for Material Efficiency, ensures the product’s durability and reusability. The project has the potential to be adopted by small local businesses, supporting a production model that values natural and regenerative materials, making sustainability accessible at the local level.

The project was developed based on a background in product design, with theoretical study of scientific papers providing the necessary knowledge for proceeding with DIY biofabrication of the material. It reflected disciplines such as material science, sustainable design, and product design. Material science and biotechnology were essential for selecting bacterial cellulose and mycelium, focusing on their regenerative properties. Sustainable design principles, such as Design for Sustainability and Design for Disassembly, guided the design process to ensure durability and reusability. The interaction of these fields led to the creation of a practical and sustainable bench, exploring new material applications in design. Interdisciplinarity will be crucial for further developing the material, with the designer playing a key role as a catalyst for new opportunities in the field.

The innovative character of the project lies in its use of regenerative materials like bacterial cellulose and mycelium, which are not yet widely used in mainstream design practices. This approach stands out by integrating biofabrication methods, such as DIY techniques, to produce materials that are sustainable, locally sourced, and have a low environmental impact. Unlike traditional, synthetic materials, these natural resources offer a new pathway for sustainable design, emphasizing the potential of nature-based solutions in product development.

Additionally, the project incorporates Design for Sustainability principles, such as Design for Disassembly and Design for Material Efficiency, which are not always prioritized in mainstream design.

The innovation also extends to the new material itself, which combines mycelium with bacterial cellulose, improving its stability over time and enhancing its resistance to water. This not only boosts the material’s performance but also expands its applicability in product design.

This approach is not only innovative in terms of the materials used but also in terms of the overall design process, which combines product design with interdisciplinary knowledge from material science and biotechnology. The result is a product that is not just sustainable but also capable of inspiring a broader shift toward bio-based, circular design practices.

Additionally, the project incorporates Design for Sustainability principles, such as Design for Disassembly and Design for Material Efficiency, which are not always prioritized in mainstream design.

The innovation also extends to the new material itself, which combines mycelium with bacterial cellulose, improving its stability over time and enhancing its resistance to water. This not only boosts the material’s performance but also expands its applicability in product design.

This approach is not only innovative in terms of the materials used but also in terms of the overall design process, which combines product design with interdisciplinary knowledge from material science and biotechnology. The result is a product that is not just sustainable but also capable of inspiring a broader shift toward bio-based, circular design practices.

The methodology used in the project was based on thw Material Driven Design method (MDD), where the material itself guided the design process. The approach began with theoretical research, studying scientific papers to understand the properties of bacterial cellulose and mycelium. This research provided the foundation for the DIY biofabrication process, allowing the creation of these regenerative materials.

The focus then shifted to prototyping the materials within the context of the design, specifically for the bench. The design process adhered to principles of sustainability, incorporating aspects of Design for Disassembly and Design for Material Efficiency, ensuring that the final product could be disassembled and its materials reused or recycled.

The project was carried out independently, without official testing or involvement from other professionals, but the approach remains grounded in a thorough understanding of materials and their potential for sustainable design. This allowed for the development of a product that is both innovative and practical, demonstrating the potential of bio-based materials in design.

The focus then shifted to prototyping the materials within the context of the design, specifically for the bench. The design process adhered to principles of sustainability, incorporating aspects of Design for Disassembly and Design for Material Efficiency, ensuring that the final product could be disassembled and its materials reused or recycled.

The project was carried out independently, without official testing or involvement from other professionals, but the approach remains grounded in a thorough understanding of materials and their potential for sustainable design. This allowed for the development of a product that is both innovative and practical, demonstrating the potential of bio-based materials in design.

The project’s use of bacterial cellulose and mycelium, along with DIY biofabrication methods, can be replicated in other contexts, communities, and makerspaces. The approach to sustainable material production and circular design principles like Design for Disassembly and Design for Material Efficiency can be easily transferred to different locations. The knowledge gained from experimenting with regenerative materials and the biofabrication process offers valuable insights that can be adapted to other product designs or local sustainability efforts. Additionally, the thesis is based on available scientific knowledge, and it is publicly accessible, making it a resource that can further inspire and inform others in various fields.

The project addresses global challenges such as the environmental impact of synthetic materials, waste management, and the need for sustainable product design by providing local solutions. It uses bacterial cellulose and mycelium, regenerative and biodegradable materials, to reduce reliance on harmful synthetic resources and mitigate environmental damage. By incorporating Design for Disassembly and Design for Material Efficiency, it promotes a circular economy, ensuring products like the bench can be easily reused or recycled, reducing waste. Through biofabrication, the project creates sustainable materials locally, minimizing the environmental impact of transportation and industrial production. Additionally, DIY biofabrication methods make creating regenerative materials accessible to local communities and makerspaces, fostering grassroots innovation and democratizing sustainability. These local solutions contribute to a more sustainable, regenerative approach to design, with the potential to inspire broader systemic change toward eco-friendly practices and circularity.

1-Material Improvement: Continue developing bacterial cellulose and mycelium materials to enhance stability, water resistance, and adaptability. The aim is to refine biofabrication processes to improve scalability and consistency.

2-Community Engagement: Increase involvement with local communities, maker spaces, and fab labs to share knowledge, facilitate workshops, and enable experimentation with DIY biofabrication methods.

3-Dissemination and Education: Increase the project’s visibility through publications, conferences, and collaborations with academic and industry partners, contributing to sustainable design discussions.

4-Sustainable Production and Scaling: Explore small-scale production, focusing on circular systems for material reuse and recycling. Local partners will support scaling the project and its principles.

5-Professional Collaboration for Material Development: Work with professionals in biotechnology, engineering, and chemistry to address limitations in sample sizes and improve material production and growth. Official testing will confirm the material’s enhanced properties.

6-Large-Scale Development and Sustainability: Scale up material production using pure mycelium instead of composite, reducing substrate waste. This method limits reliance on lignocellulosic substrates, essential for growth. It offers a more efficient solution compared to startups that treat substrates extensively to ensure consistency.

2-Community Engagement: Increase involvement with local communities, maker spaces, and fab labs to share knowledge, facilitate workshops, and enable experimentation with DIY biofabrication methods.

3-Dissemination and Education: Increase the project’s visibility through publications, conferences, and collaborations with academic and industry partners, contributing to sustainable design discussions.

4-Sustainable Production and Scaling: Explore small-scale production, focusing on circular systems for material reuse and recycling. Local partners will support scaling the project and its principles.

5-Professional Collaboration for Material Development: Work with professionals in biotechnology, engineering, and chemistry to address limitations in sample sizes and improve material production and growth. Official testing will confirm the material’s enhanced properties.

6-Large-Scale Development and Sustainability: Scale up material production using pure mycelium instead of composite, reducing substrate waste. This method limits reliance on lignocellulosic substrates, essential for growth. It offers a more efficient solution compared to startups that treat substrates extensively to ensure consistency.